Preparation method of fast ion conductor and conducting polymer dual-modified ternary cathode material for lithium-ion battery

A conductive polymer, lithium-ion battery technology, used in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as easy coating unevenness, difficult to determine components, etc., to reduce morphology damage, low cost, and operation. simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

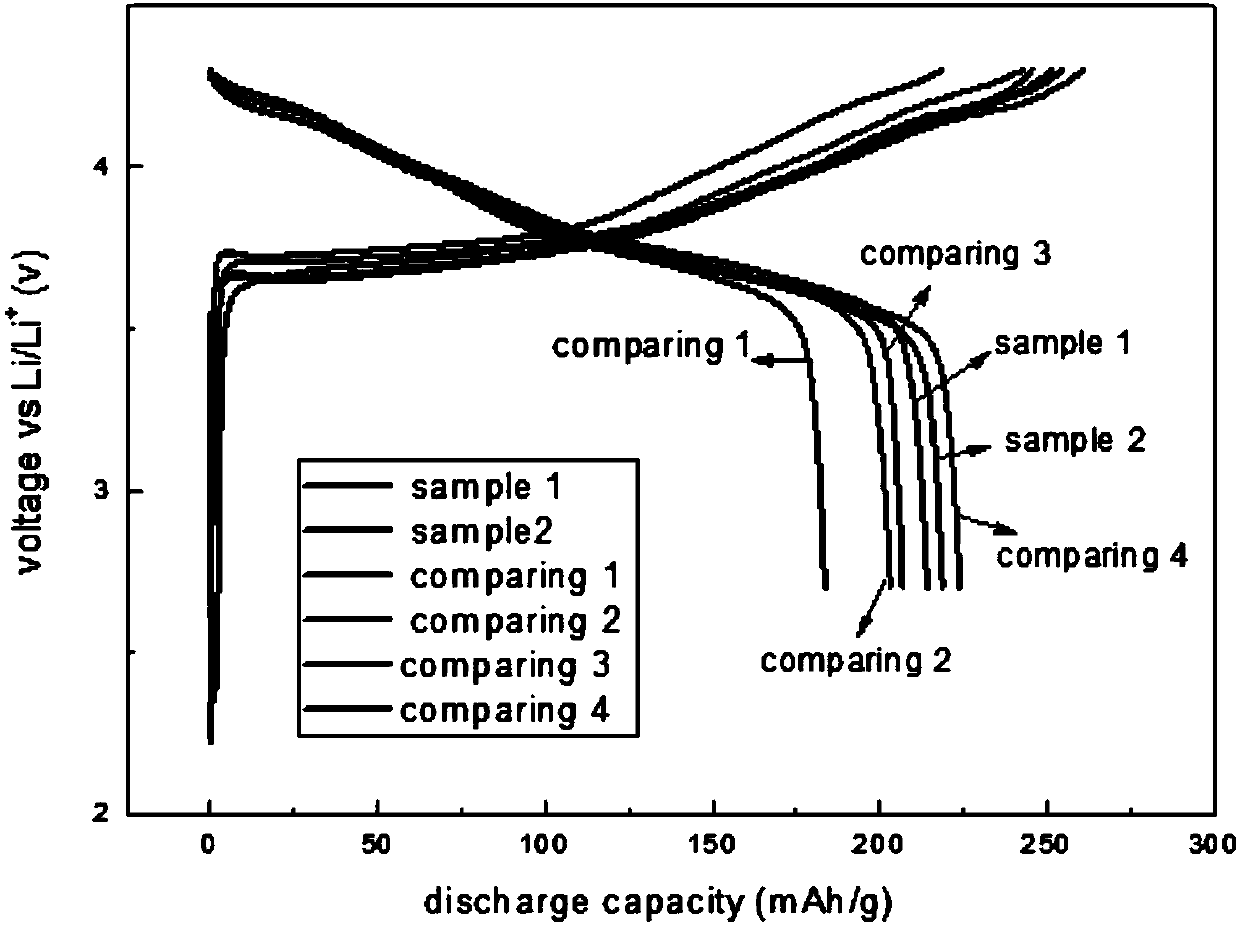

[0035] will Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor and LiOH·H 2 O is mixed at a molar ratio of 1:1.07 and then fully ground, heated at a rate of 5°C / min in an oxygen atmosphere, and calcined at a high temperature of 750°C for 15 hours to finally obtain a lithium-ion battery LiNi 0.8 co 0.1 mn 0.1 o 2 Cathode material. Then weigh V according to the coating amount of 3wt.% 2 o 5 , the LiOH·H 2 O and V 2 o 5 Mix and grind for 10 minutes at a molar ratio of 3:1 to make V 2 o 5 The reaction completely generates lithium vanadate, then add LiNi 0.8 co 0.1 mn 0.1 o 2 Continue to grind the positive electrode material for 30 minutes until the generated lithium vanadate has no obvious agglomeration phenomenon, so that it can fully react and evenly adhere to the surface of the positive electrode material. The fully ground material is calcined at 700°C for 8 hours by high-temperature calcination method to obtain the fast ion conductor vanadium Lithium acid modified lithium...

Embodiment 2

[0038] LiOH·H 2 O ball milled for 30min to 1-20 micron, then Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor and LiOH·H 2 O was mixed evenly at a molar ratio of 1:1.05, and calcined at 780°C for 15 hours at a heating rate of 5°C / min in an oxygen atmosphere to obtain a lithium-ion battery LiNi 0.8 co 0.1 mn 0.1 o 2 Cathode material. Then weigh V according to the coating amount of 1wt.%. 2 o 5 , the LiOH·H 2 O and V 2 o 5 Mix and grind for 10 minutes at a molar ratio of 3:1 to make V 2 o 5 The reaction completely generates lithium vanadate, add LiNi 0.8 co 0.1 mn 0.1 o 2 Continue to grind the positive electrode material for 30 minutes to mix the generated lithium vanadate with the positive electrode material evenly so that the reaction is sufficient and evenly attached to the surface of the positive electrode material. The fully ground material is calcined at 700°C for 8 hours by high-temperature calcination to obtain lithium vanadate Modified lithium ion battery LiNi ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com