Solid electrolyte and preparation method thereof

A technology of solid electrolyte and crystal, which is applied in the direction of chemical instruments and methods, circuits, electrical components, etc., can solve the problems of unsatisfactory solid electrolyte, high resistance of solid particle boundary, deviation of chemical stability, etc., and achieve high production efficiency, electric Good chemical stability and the effect of solving safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

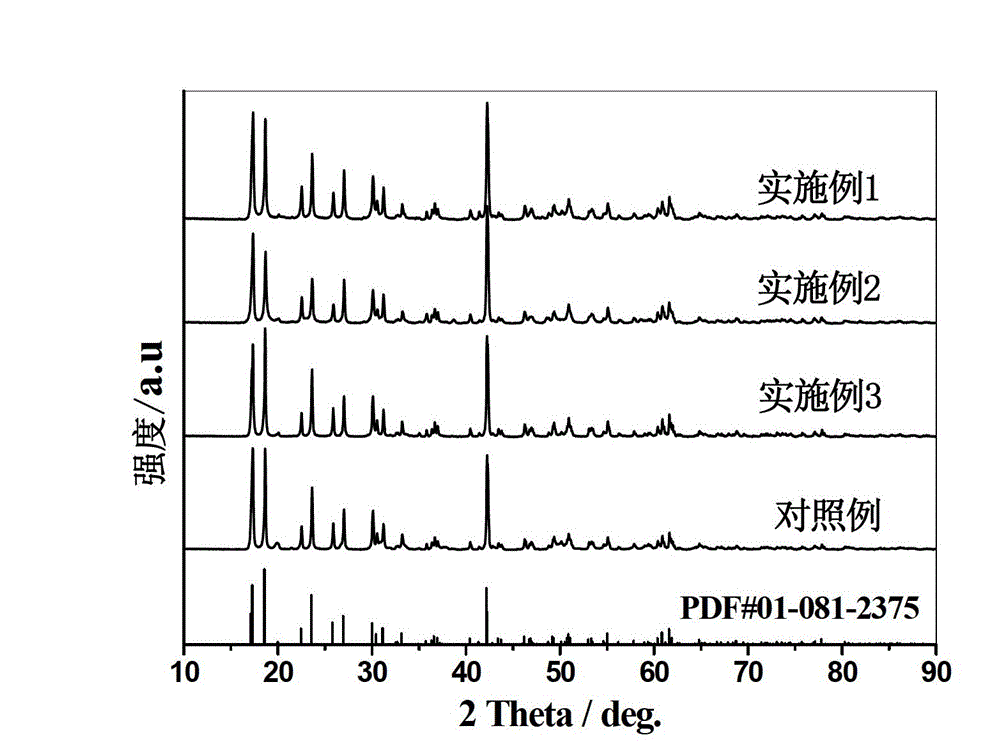

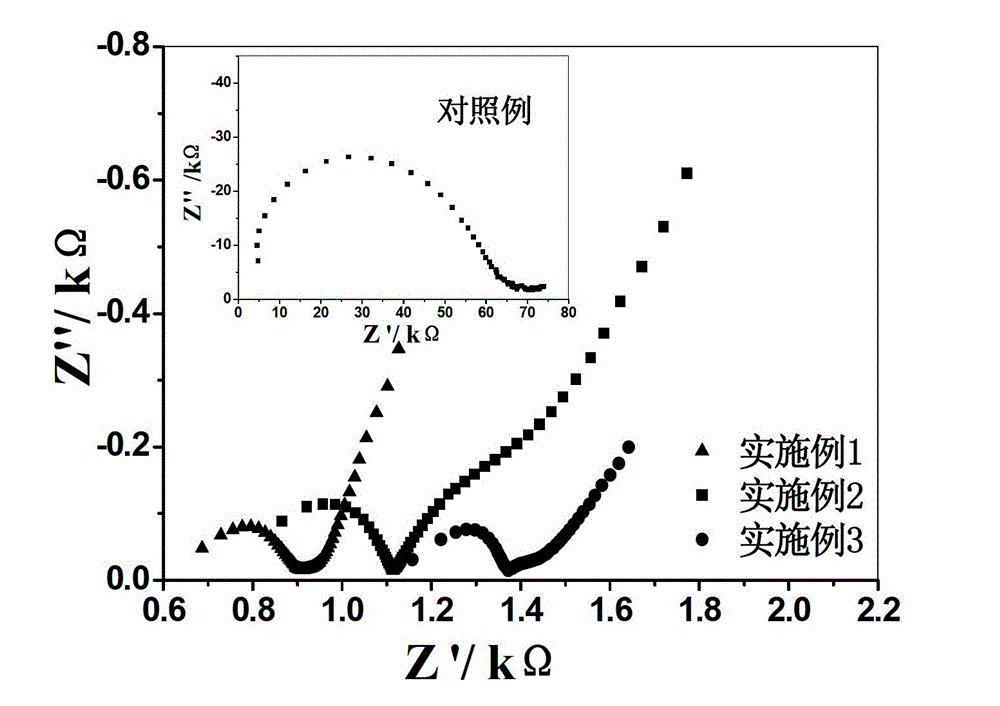

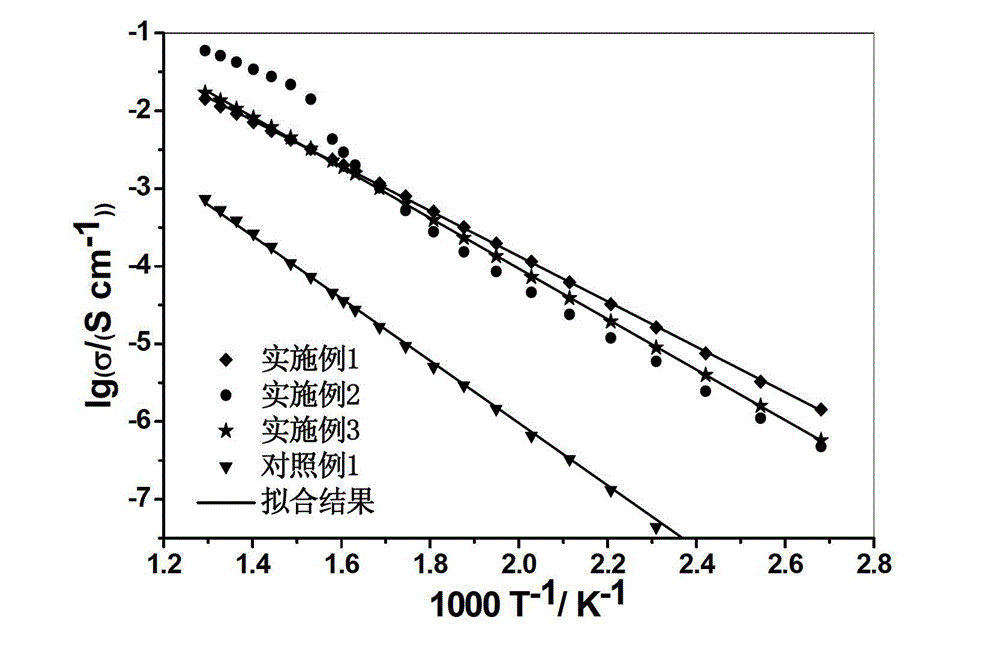

Embodiment 1

[0047] (1) The chemical formula is Li prepared by high-temperature solid-state method 6.15 Zr 1.85 Y 0.15 o 7 Solid electrolyte: LiOH·H 2 O powder, ZrO 2 Powder and Y 2 o 3 The powder was weighed according to the stoichiometric ratio, and it was ground and mixed with an agate mortar for 2 hours. In order to supplement the LiOH·H 2 Loss of lithium ions in O, adding an excess of 10wt% LiOH·H before powder grinding 2 Grinding together with O, in order to obtain a smaller grain boundary resistance between solid particles, adding a mole number of ZrO 2 , Y 2 o 3 and LiOH·H 2 2% of the total moles of O in B 2 o 3 as a sintering aid;

[0048] (2) Put the uniformly mixed powder in step (1) into an alumina crucible with a lid, put the crucible into a muffle furnace at a heating rate of 3°C / min to 800°C and keep it at this temperature for 20 hours, Then the sample is cooled to room temperature at a cooling rate of 10°C / min;

[0049] (3) Grind the white powder obtained in ...

Embodiment 2

[0051] (1) The chemical formula is Li prepared by high-temperature solid-state method 6.15 Zr 1.85 In 0.15 o 7 Solid electrolyte: LiOH·H 2 O powder, ZrO 2 Powder and In 2 o 3 The powder was weighed according to the stoichiometric ratio, and mixed with an agate mortar for 1.5 hours. In order to supplement the LiOH·H 2 Loss of lithium ions in O, adding an excess of 9wt% LiOH·H to the powder before grinding 2 Grinding together with O, in order to obtain a smaller grain boundary resistance between solid particles, adding a mole number of ZrO 2 , Y 2 o 3 and LiOH·H2 2% of the total moles of O in B 2 o 3 as a sintering aid;

[0052] (2) Other steps were processed according to steps (2) and (3) of Example 1 to obtain a solid electrolyte.

Embodiment 3

[0054] (1) The chemical formula is Li prepared by high-temperature solid-state method 6.3 Zr 1.85 Zn 0.15 o 7 Solid electrolyte: LiOH·H 2 O powder, ZrO 2 The powder and ZnO powder were weighed according to the stoichiometric ratio, and mixed with an agate mortar for 2 hours. In order to supplement the LiOH·H 2 Loss of lithium ions in O, adding an excess of 10wt% LiOH·H before powder grinding 2 Grinding together with O, in order to obtain a smaller grain boundary resistance between solid particles, adding a mole number of ZrO 2 , ZnO and LiOH·H 2 2% of the total moles of O in B 2 o 3 as a sintering aid;

[0055] (2) Other steps were processed according to steps (2) and (3) of Example 1 to obtain a solid electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com