All-solid lithium-ion battery and manufacturing method thereof

A lithium-ion battery, all-solid-state technology, applied in the field of electrochemistry, can solve problems such as explosion, leakage, and hindered development of commercial power lithium batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

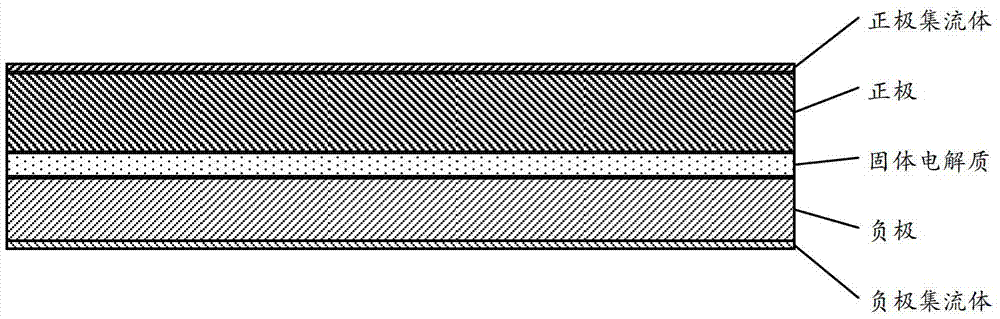

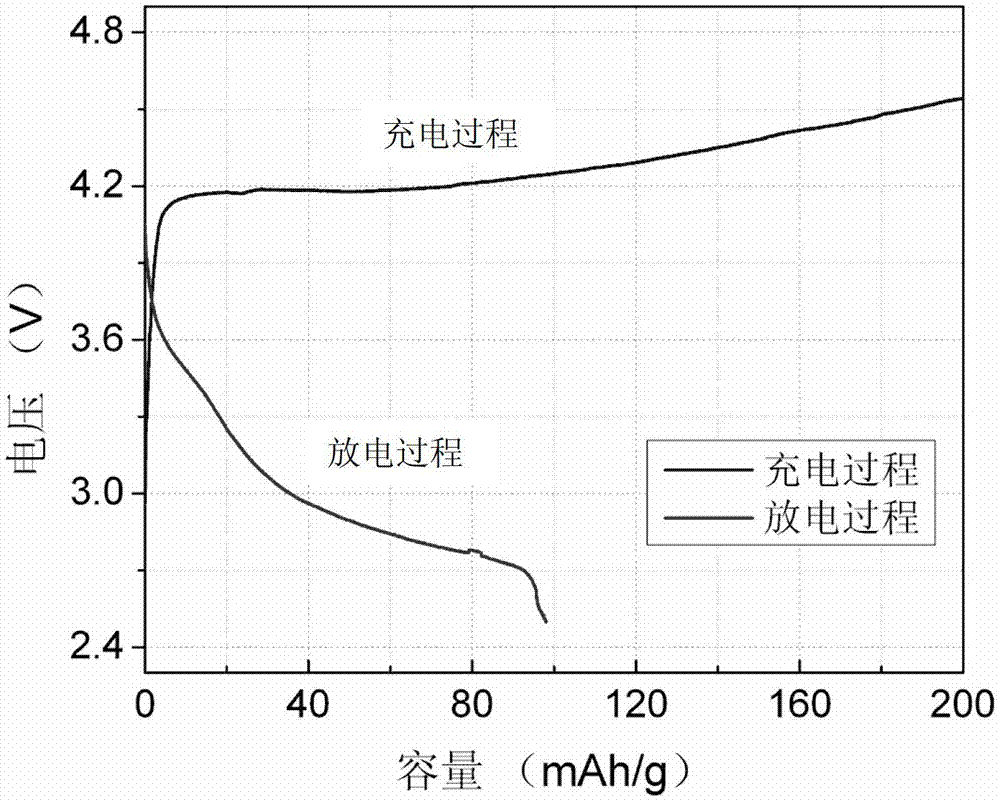

[0023] Embodiment 1, making lithium manganate positive electrode all-solid-state lithium-ion battery

[0024] Lithium manganate is used as the positive electrode material, germanium-doped lithium lanthanum zirconate is used as the solid electrolyte, and lithium metal is used as the negative electrode material to assemble a solid lithium ion battery. First, germanium-doped lithium lanthanum zirconate was polished to smooth on 300#, 800# and 1500# sandpaper in sequence, ultrasonically treated in ethanol for 10 minutes, and dried at 70°C to obtain a solid electrolyte with a clean surface. Lithium manganese oxide, PVDF and Super P were evenly mixed in a ratio of 80:5:15, and coated on the surface of the solid electrolyte. Paste the metal lithium sheet on the other surface of the solid electrolyte. Finally, aluminum foil and copper foil were added as current collectors on the positive side and the negative side, respectively. The above structure is packaged in a stainless steel c...

Embodiment 2

[0026] Embodiment 2, making lithium cobalt oxide positive electrode all-solid-state lithium-ion battery

[0027]Lithium cobaltate is used as the positive electrode material, aluminum-doped lithium lanthanum zirconate is used as the solid electrolyte, and graphite is used as the negative electrode material to assemble a solid lithium-ion battery. First, aluminum-doped lithium lanthanum zirconate was polished to smoothness on 500#, 1000# and 2000# sandpaper in sequence, ultrasonically treated in ethanol for 12 minutes, and dried at 90°C to obtain a solid electrolyte with a clean surface. Lithium cobaltate, PVA and acetylene black were mixed evenly in a ratio of 90:5:5, and coated on the surface of the solid electrolyte. Mix graphite and PVA evenly in a ratio of 95:5, and coat it on the other surface of the solid electrolyte. Finally, aluminum foil and copper foil were added as current collectors on the positive side and the negative side, respectively. The above structure is p...

Embodiment 3

[0029] Embodiment 3, making nickel-cobalt-manganese ternary positive electrode all-solid-state lithium-ion battery

[0030] A solid lithium-ion battery is assembled using nickel-cobalt-manganese ternary material as the positive electrode material, germanium-doped lithium lanthanum zirconate as the solid electrolyte, and graphite as the negative electrode material. First, germanium-doped lithium lanthanum zirconate was polished to smooth on 400#, 800# and 1500# sandpaper in sequence, ultrasonically treated in ethanol for 15 minutes, and dried at 80°C to obtain a solid electrolyte with a clean surface. The nickel-cobalt-manganese ternary material, PVDF and Super P are uniformly mixed in a ratio of 85:5:10, and coated on the surface of the solid electrolyte. Graphite, conductive carbon black and PVDF are mixed uniformly according to the ratio of 90:5:5, and coated on the other surface of the solid electrolyte. Finally, aluminum foil and copper foil were added as current collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com