Patents

Literature

135 results about "Lanthanum zirconate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

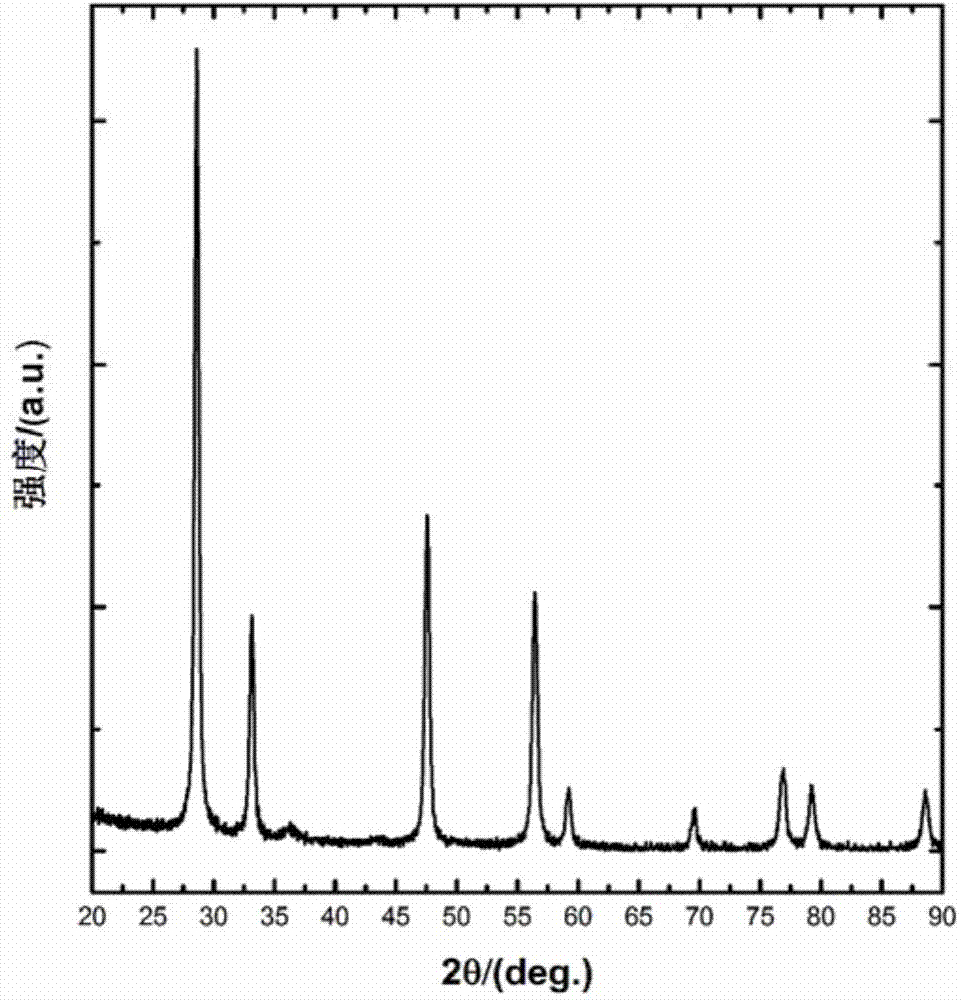

Method for preparing lanthanum zirconate powder

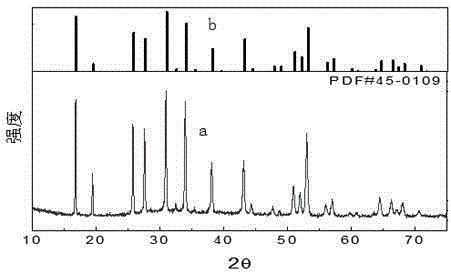

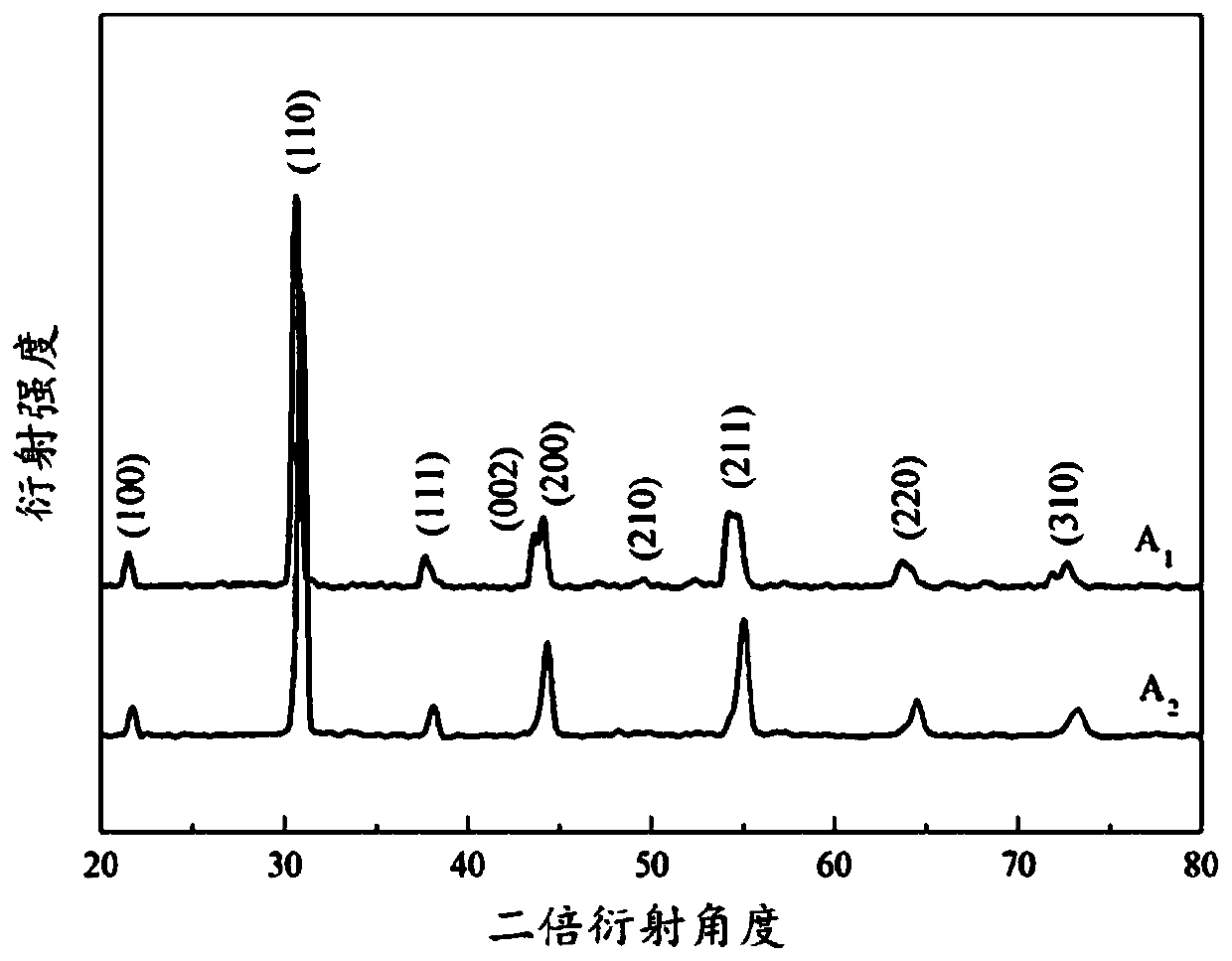

InactiveCN101407336ALow thermal conductivityGood heat insulationZirconium compoundsRare earth metal compoundsSolid reactionPyrochlore

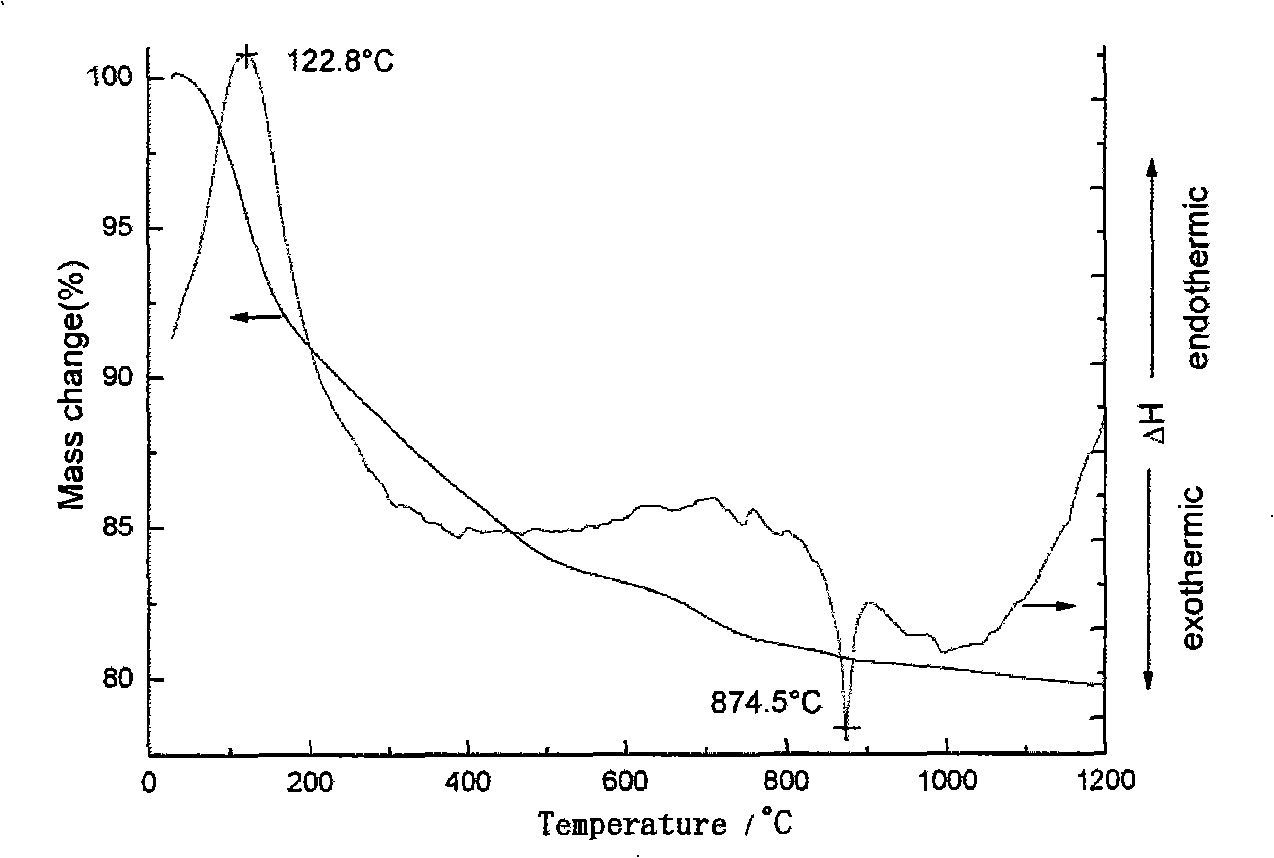

The invention relates to a method for preparing a lanthanum zirconic acid powder, which belongs to the preparation field of ceramic powder used for high temperature heat barrier. The method uses lanthanum oxide or lanthanum soluble salt and zircon salt for respectively preparing the solutions containing La<3+> and Zr<4+>; the two solutions are mixed and dropped into a precipitator (or the precipitator is dropped into the mixing solutions) under continual stirring to obtain precipitate; and the precipitate are washed with a plurality of times, then dried, ground and finally calcined at certain temperature to obtain La2Zr2O7 of defect fluorite structure or pyrochlore constitution. Compared with the existing universal solid reaction process, the method lowers the synthesis temperature by 500-700 DEG C. The heat-insulating property (heat diffusivity) of the obtained power is reduced by about 50 percent compared with YSZ, and reduced by about 40 percent compared with the lanthanum zirconic acid powder obtained by the solid reaction process. The method solves the problems of overhigh heat diffusivity, severe sinter and phase change inefficiency in the existing ceramic materials used for the coating of high temperature heat barrier.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Garnet-structured ceramic electrolyte material, preparation method and application therefor

The invention relates to a garnet-structured ceramic electrolyte material, a preparation method and an application therefor. The chemical composition of the garnet-structured ceramic electrolyte material is (1-z) Li (7-2x+2y) La3Zr (2-x) WxO (12+y)+ zA, wherein x is more than 0 and less than or equal to 1.00; y is more than 0 and less than or equal to 2.00; z is more than or equal to 0 and less than or equal to 10 wt.%; and A is any one of Li2O, MgO, CaO, SrO, BaO, Y2O3, B2O3, SiO2, WO3, CuO or Al2O3. According to the cubic garnet-structured lanthanum zirconate lithium crystal doped with W element provided by the invention, by doping W ion (+6 valence), which is higher than zirconium ions Zr4+ in valence, in the lanthanum zirconate lithium crystal to replace part of zirconium ions Zr4+ in crystal lattices, the number of lithium ions Li+ in the crystal is reduced, the vacancy of the lithium ions Li+ is increased, and the formation of an migration channel for the lithium ions Li+ is facilitated, so that the garnet-structured ceramic electrolyte material is higher in volume phase ionic conductivity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

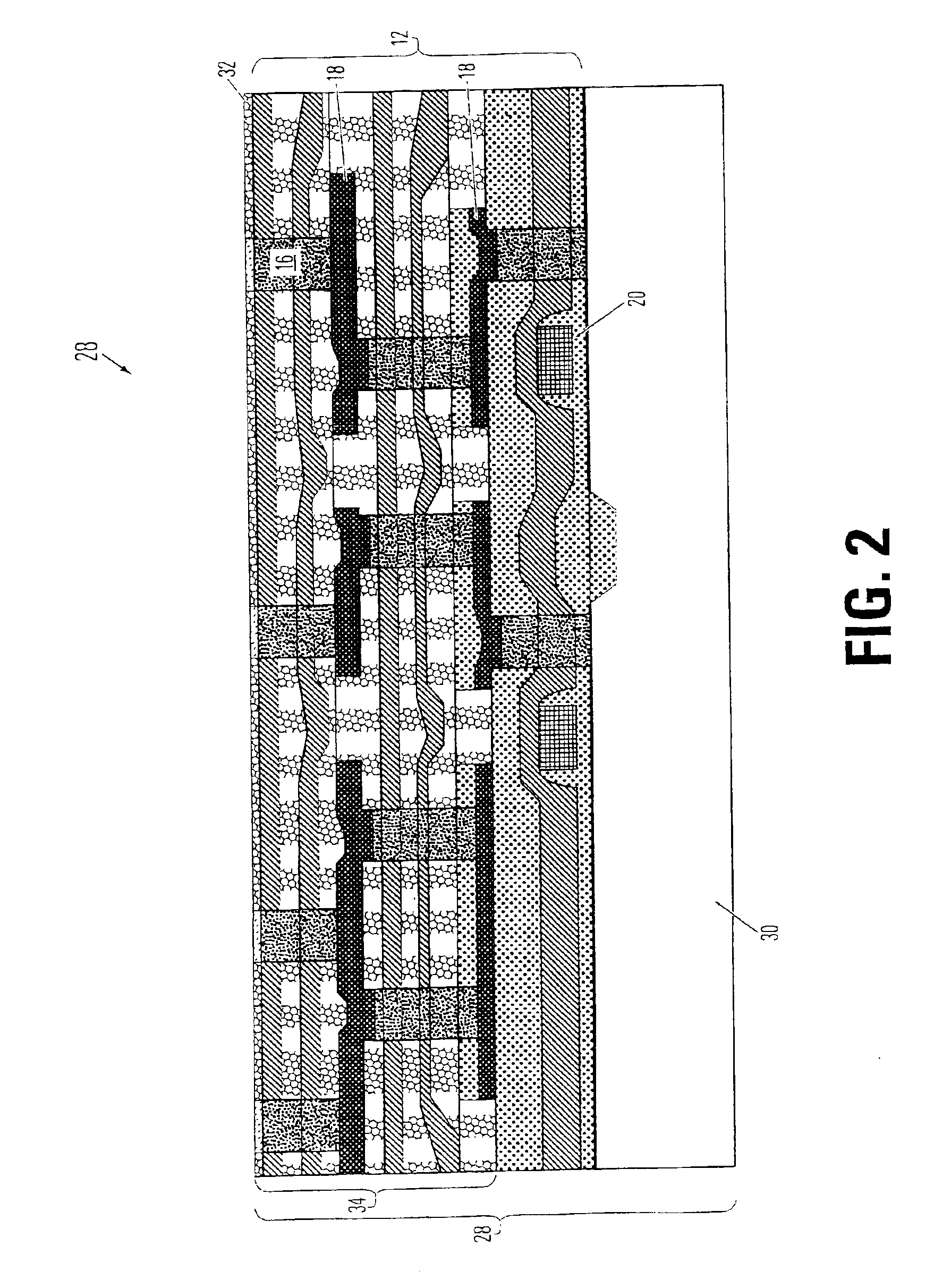

Plasma evaporation deposition lanthanide thermal barrier coating ceramic layer with long service lifer, high insulation performance and composite structure, and preparation method thereof

ActiveCN103966539AImprove deposition efficiencyPollution controlMolten spray coatingVacuum evaporation coatingLanthanideNanostructure

The invention discloses a plasma evaporation deposition lanthanide thermal barrier coating ceramic layer with a long service life, a high insulation performance and a composite structure, and a preparation method thereof, and belongs to the technical field of thermal barrier coating. The ceramic layer material comprises lanthanum zirconate or cerate; the thermal barrier coating comprises a bonding layer, a first ceramic layer and a second ceramic layer which are prepared on a base body, wherein the first ceramic layer adopts a YSZ coating; the second ceramic layer comprises the lanthanum zirconate or cerate; in the preparation method of the ceramic layer, the pressure of a vacuum chamber is lower than 1 mbar; through adjusting parameters of spraying electric power, current, gas flow rate, temperature of the basal body, powder feeding rate, spraying distance and the like, the YSZ coating layer and the lanthanide thermal barrier coating ceramic layer which are provided with microstructures of columnar crystal structures, layered structures, layered structures and columnar crystal structures, or nano- structured coating and the like can be obtained. The service life of the thermal barrier coating is long and the heat-insulating property is favorable.

Owner:BEIHANG UNIV

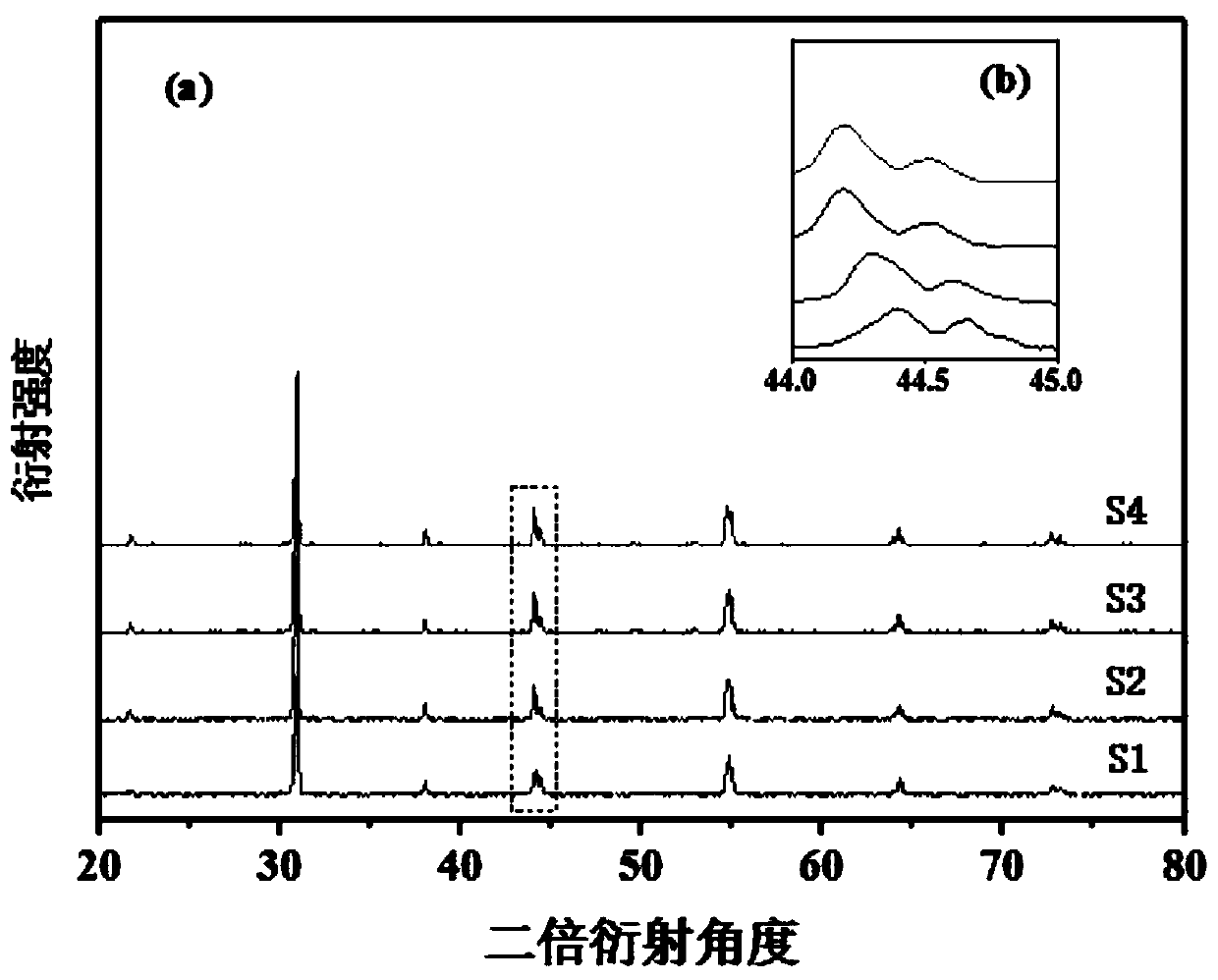

Tantalum-doped cubic garnet structured Li7La3Zr<2-x>TaxO12 material synthesized via intermediate phase, and synthesis method thereof

InactiveCN105336980ANo change in crystal formReduce high temperature lossFinal product manufactureElectrolyte accumulators manufactureLithiumPhysical chemistry

The invention discloses a tantalum-doped cubic garnet structured Li7La3Zr<2-x>TaxO12 material synthesized via an intermediate phase, and a synthesis method thereof. The synthesis method comprises following steps: step 1, lanthanum zirconate, a lanthanum source, a lithium source, and a tantalum source used for doping are weighed at a metal element molar ratio according with that of Li7La3Zr<2-x>TaxO12, and the above materials are fully mixed; step 2, an obtained mixture is dried at 80 DEG C for 4 to 6h, and is grinded for 30min so as to obtain a raw material precursor; and step 3, the raw material precursor is subjected to roasting at 900 DEG C for 3 to 5h, so as to obtain a one time roasted product of Li7La3Zr<2-x>TaxO12, wherein x ranges from 0.25 to 1. According to the synthesis method, lanthanum zirconate is taken as a raw material; the tantalum-doped cubic garnet structured Li7La3Zr<2-x>TaxO12 material is convenient to prepare; technical route is simple; roasting time can be shortened greatly; energy consumption is reduced; lithium high temperature loss is reduced; and the synthesis method is suitable for large scale production.

Owner:SHANGHAI POWER ENERGY STORAGE BATTERY SYST ENG TECH +1

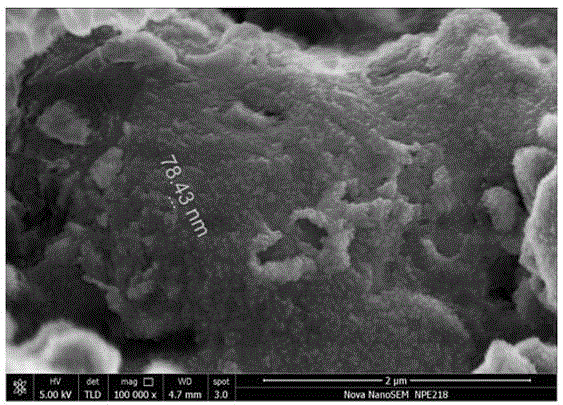

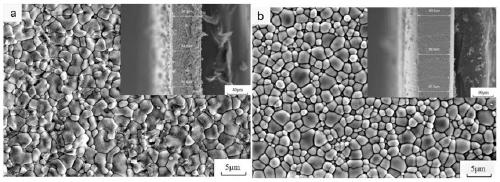

Preparation method of zirconic acid lanthanum ceramic fiber

ActiveCN103553596ASmall diameterEvenly distributedInorganic material artificial filamentsFiberFilamentation

The invention relates to a preparation method of a zirconic acid lanthanum ceramic fiber. The method comprises the following steps: preparing a gel fiber through a colloidal sol centrifugal fiber forming technology by using zirconium nitrate as a zirconium source, lanthanum nitrate as a lanthanum source, citric acid as a chelating agent, and water as a solvent, and calcining the gel fiber to form the zirconic acid lanthanum ceramic fiber. A precursor prepared by the invention has stable colloidal sol property and is good in filamentation property with no need of adding a polymer spinning additive. The prepared zirconic acid lanthanum ceramic fiber is good in flexibility, compact in microstructure, good in phase stability an low in heat conductivity coefficient and can be used for high-temperature thermal-insulation material, and the crystal form of the zirconic acid lanthanum ceramic fiber is pyrochlore form.

Owner:SHANDONG UNIV

Preparation method of thermal barrier coating of lanthanum zirconate fiber doped lanthanum zirconate

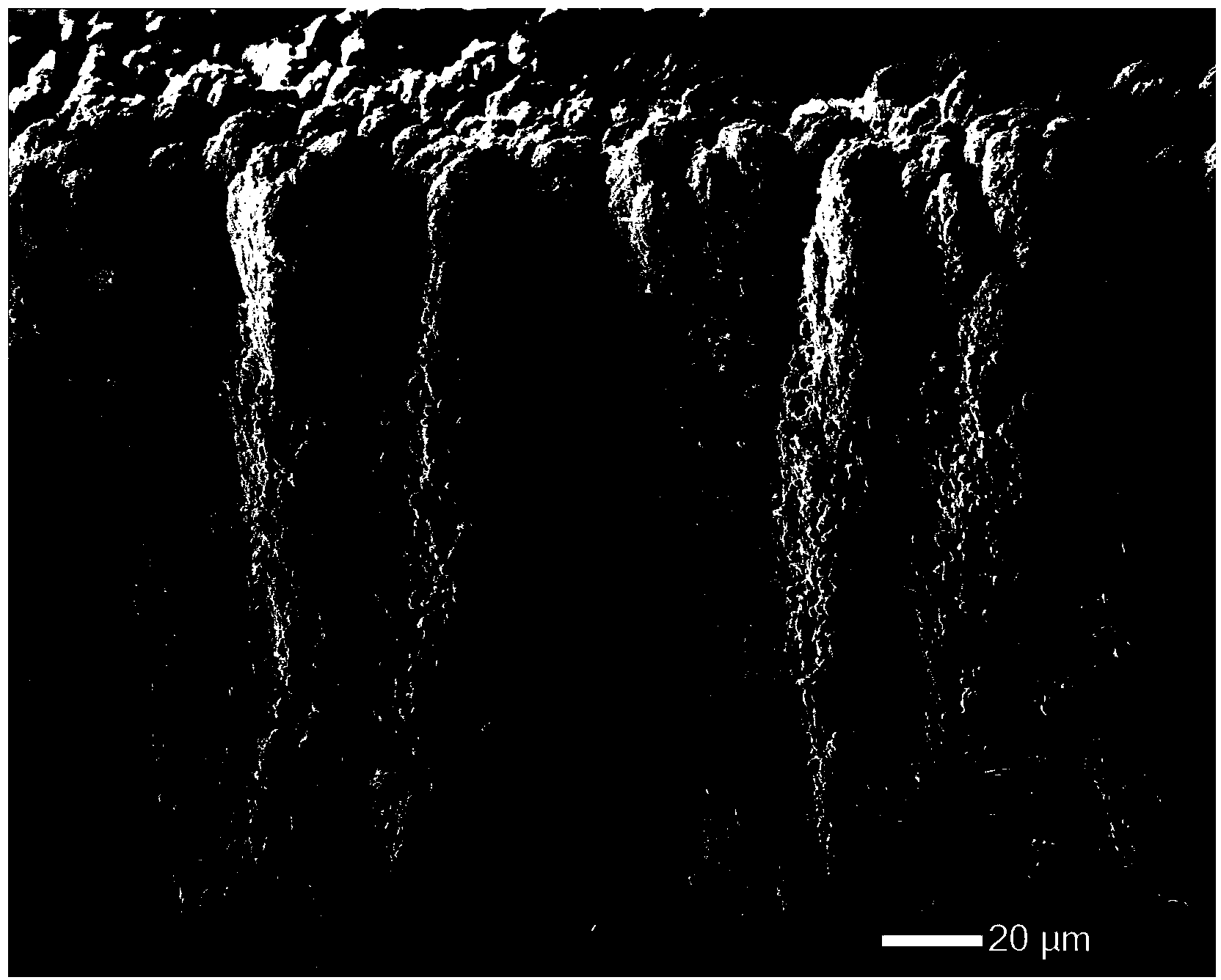

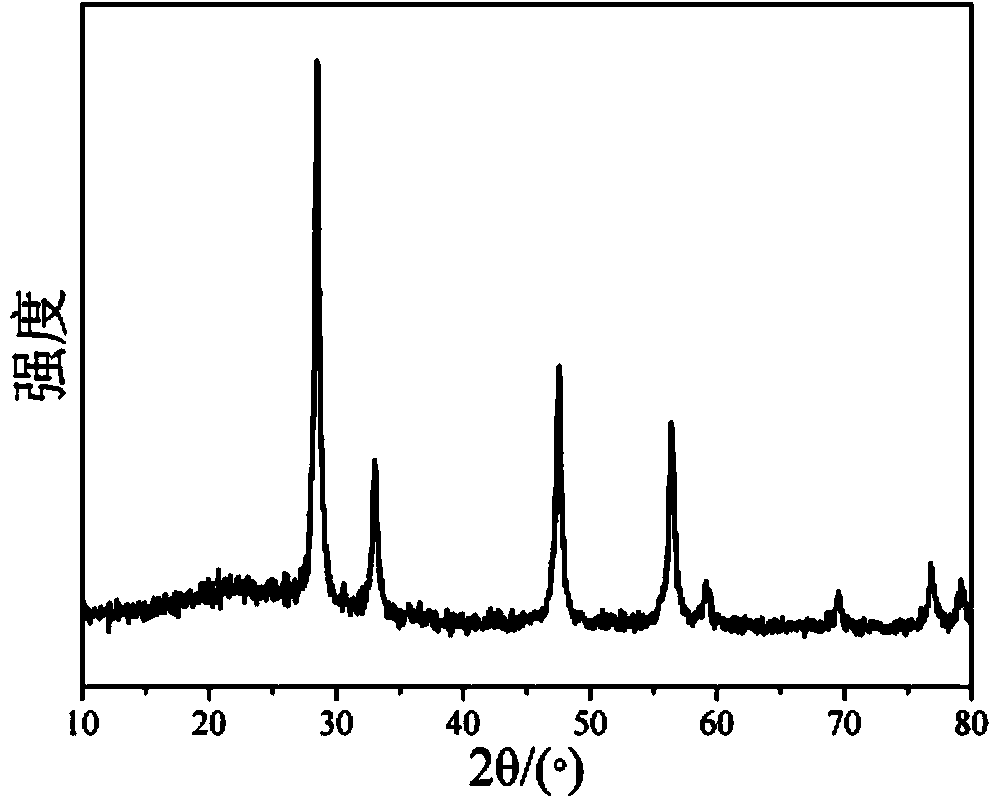

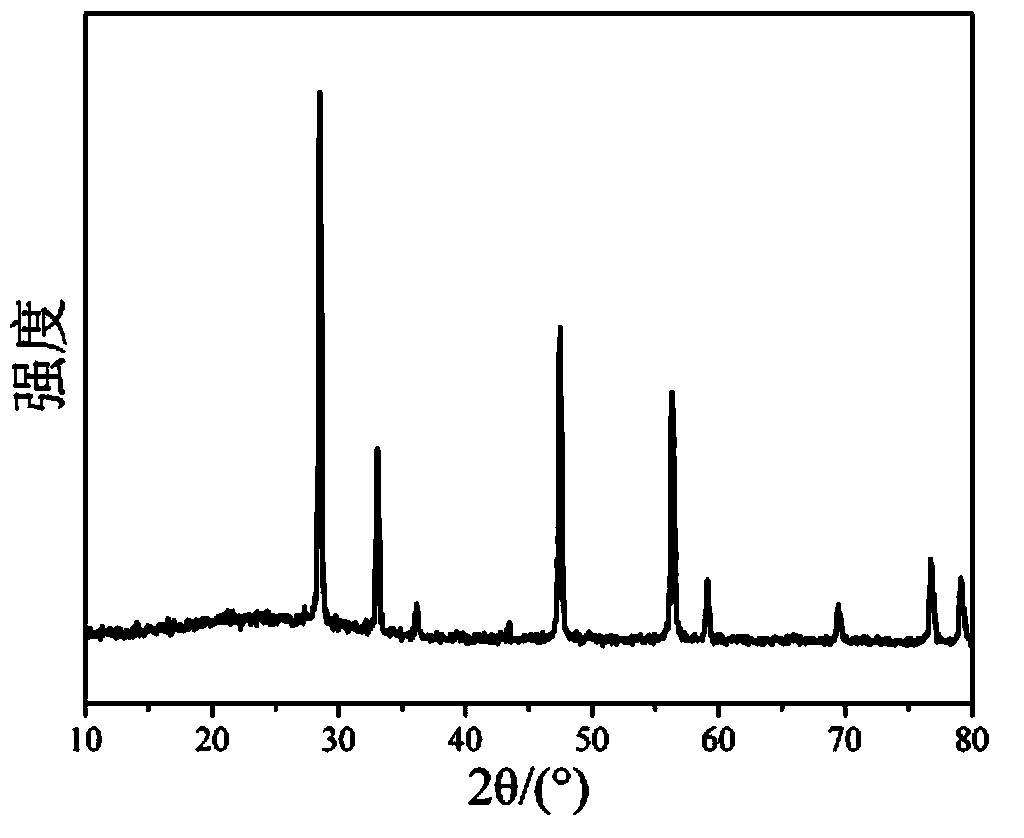

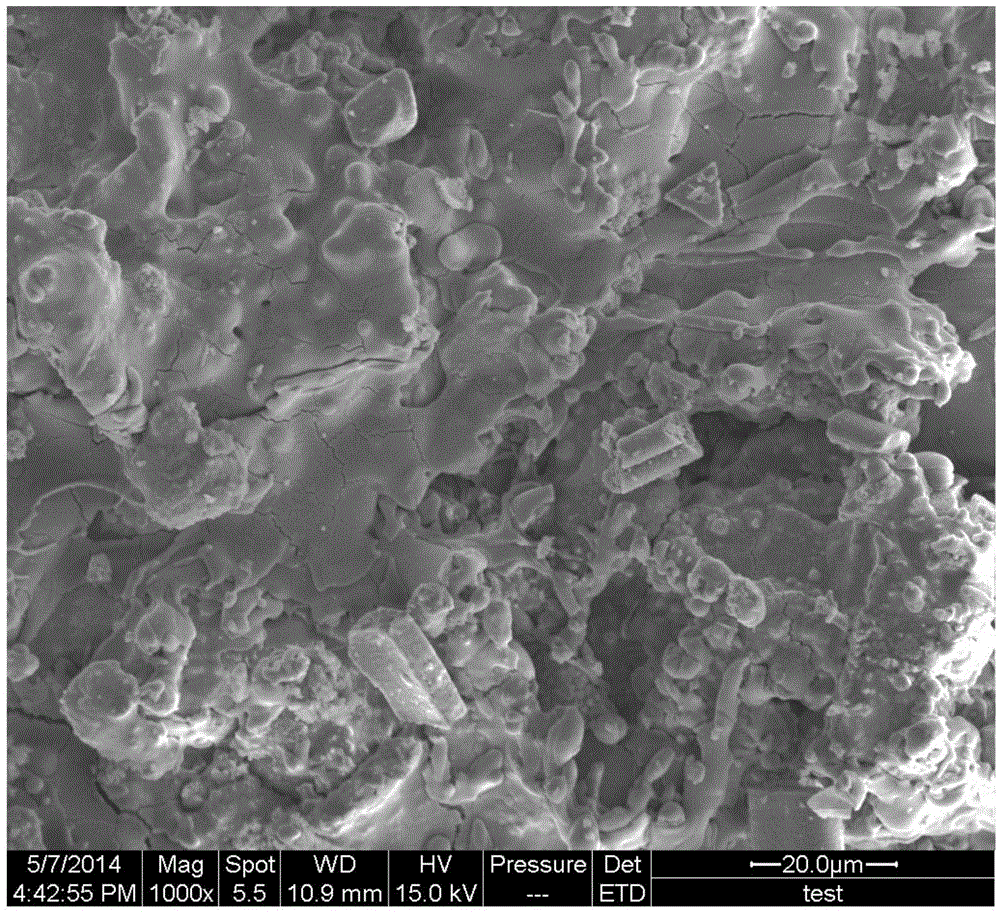

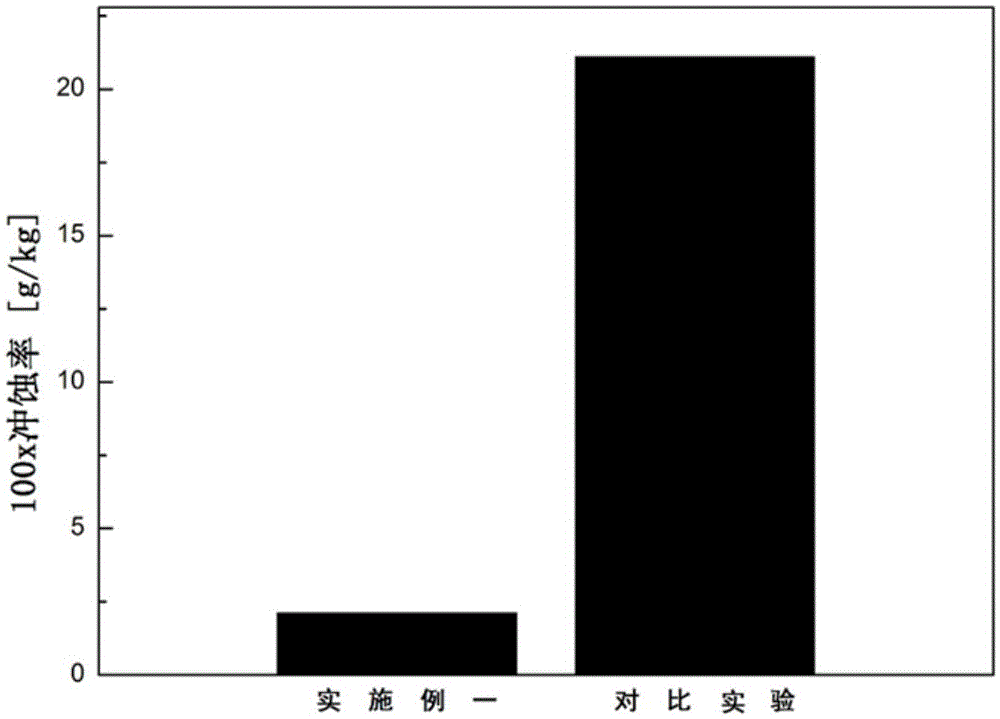

ActiveCN105483597AReduce erosion rateStrong erosion resistanceMolten spray coatingEfficient propulsion technologiesFiberWear resistance

The invention discloses a preparation method of a thermal barrier coating of lanthanum zirconate fiber doped lanthanum zirconate, and relates to a preparation method of a thermal barrier coating. The technical problems that a novel lanthanum zirconate thermal carrier coating is poor in erosive wear resistance and is likely to lose efficacy when impacted by external particles are solved. The preparation method comprises the steps that a composite lanthanum zirconate ceramic layer spraying powder material is prepared; a bonding layer spraying material is sprayed to the surface of preprocessed matrix metal; a layer of composite lanthanum zirconate ceramic layer spraying material is sprayed to a bonding layer. Compared with a traditional thermal barrier coating which is not reinforced by fiber, the erosive wear resistance of the thermal barrier coating system is higher. The preparation method is applied to the field of composite materials.

Owner:HARBIN ENG UNIV

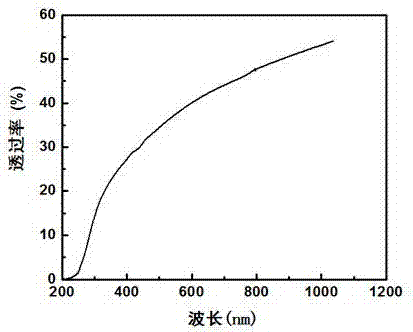

Ferroelectric photovoltaic device and preparation method of ferroelectric photovoltaic device

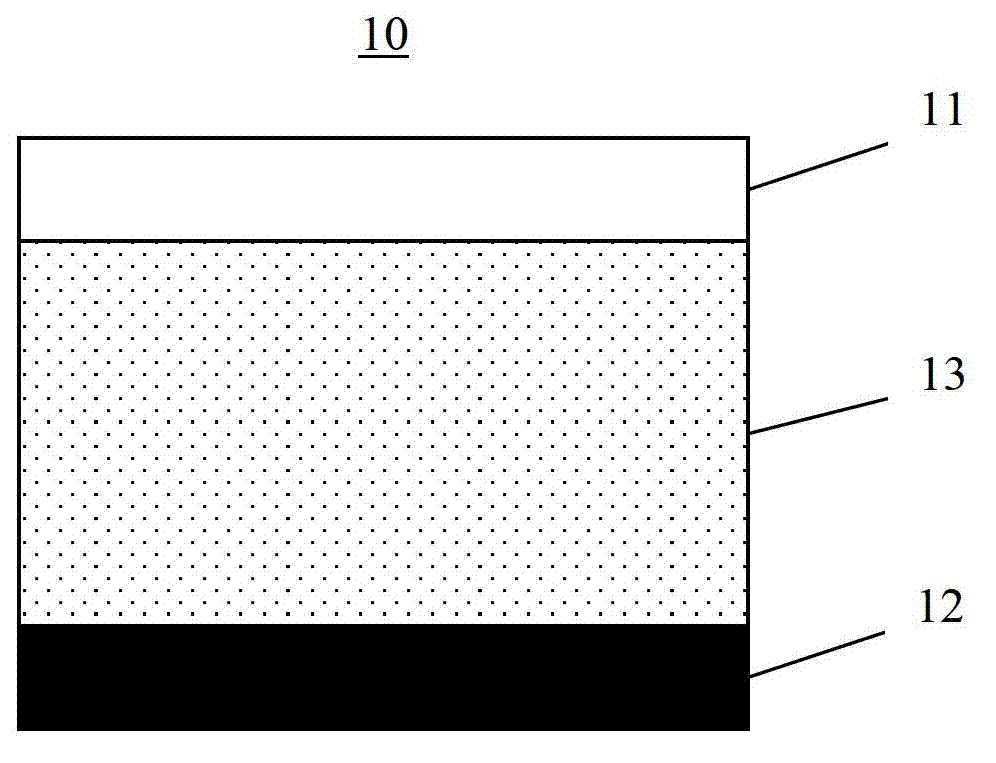

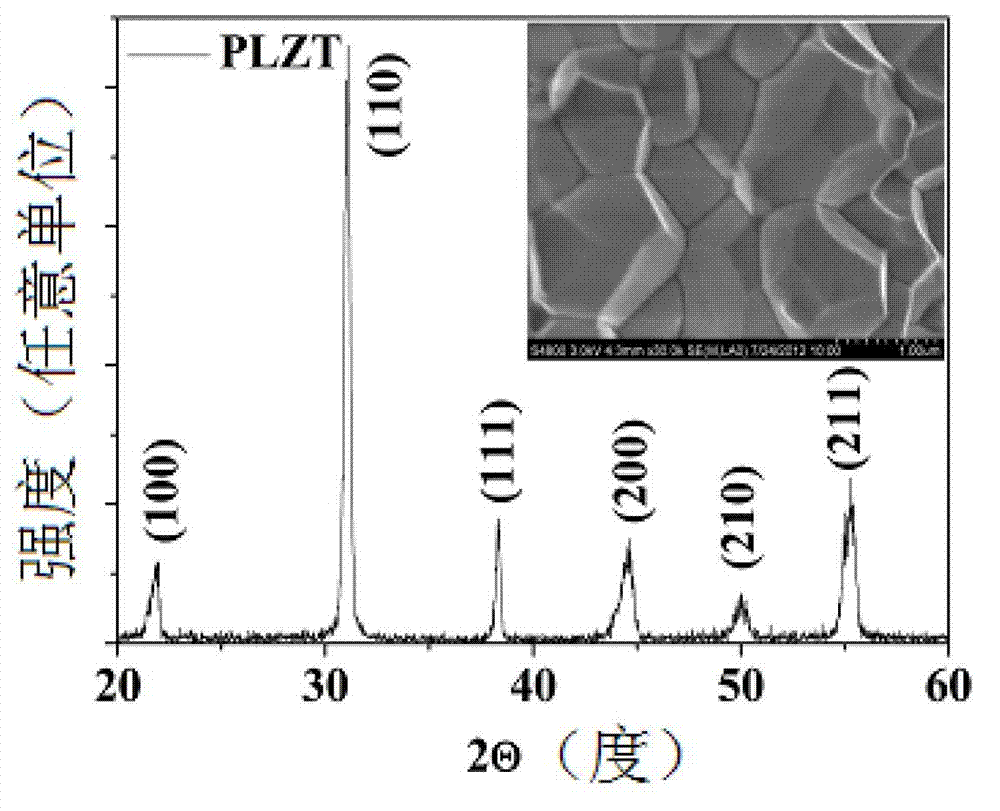

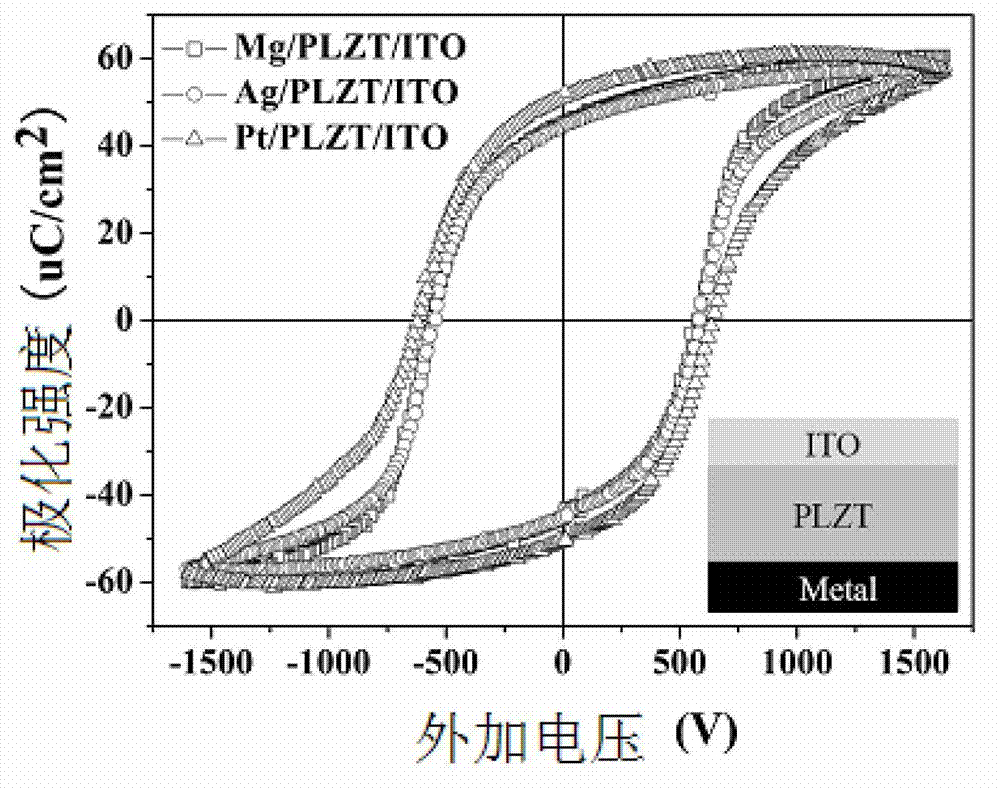

InactiveCN102832266AImprove performanceLower Schottky Barrier HeightFinal product manufacturePhotovoltaic energy generationLead zirconate titanateUltraviolet lights

The invention discloses a ferroelectric photovoltaic device which comprises an upper electrode, a lower metal electrode and a ferroelectric material between the two electrodes. The ferroelectric material is lead lanthanum zirconate titanate (PLZT), lead zirconate titanate (PZT), barium titanate (BTO) or bismuth ferrite oxide (BFO), etc., the upper electrode is made of a transparent electrode material such as indium tin oxide (ITO) or aluminum doped zinc oxide (AZO), and the lower metal electrode is made of the metal with a low work unction such as Ag, Al or Mg. The invention also discloses a preparation method of the ferroelectric photovoltaic device. According to the invention, the photovoltaic characteristic of this kind of ferroelectric photovoltaic device can be improved through material design and energy band engineering based on the photoelectric effect of the metal with the low work function and the photovoltaic effect of the ferroelectric material; the light response wavelength of the traditional broad-band gap ferroelectric photovoltaic device can be extended from the range of ultraviolet light to the range of visible light; and the application field of the ferroelectric photovoltaic device can be enlarged.

Owner:SUZHOU UNIV

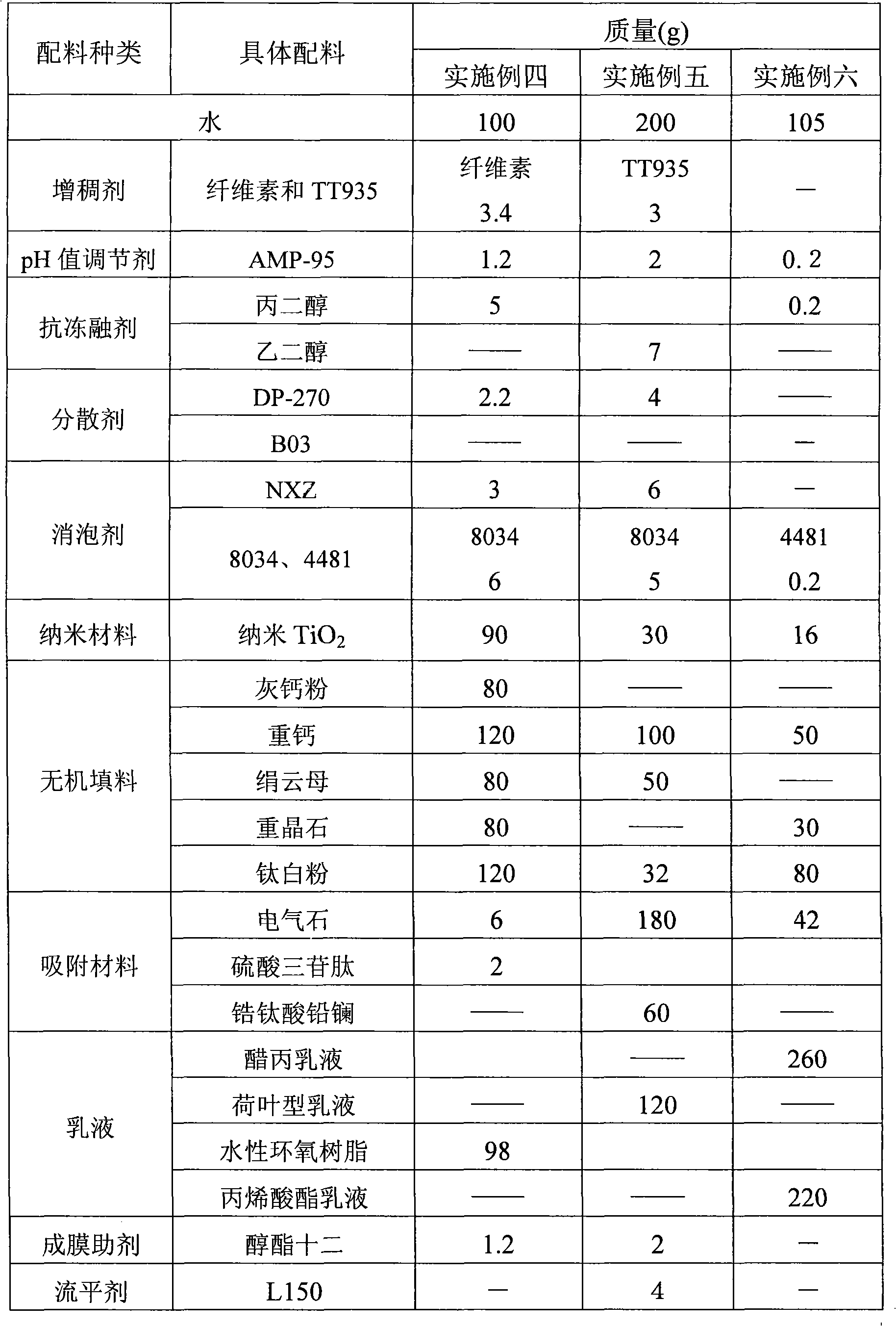

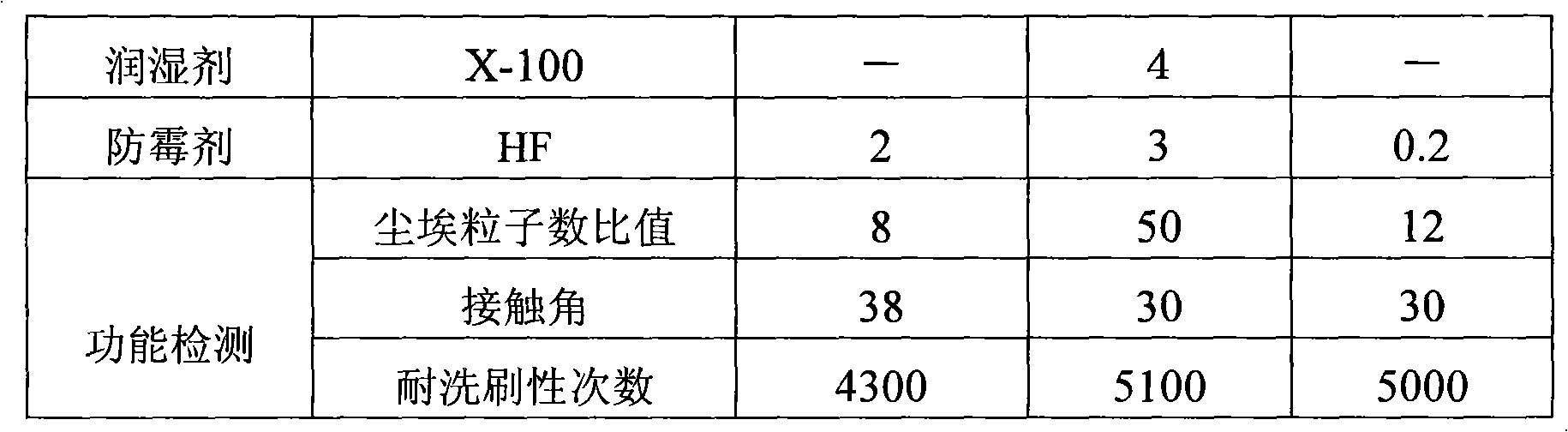

Dust absorbing, dust removing inner wall decorative coating and preparation thereof

ActiveCN101348627APlay a decorative effectImprove adsorption capacityDispersed particle separationEpoxy resin coatingsCrystalline materialsDust fall

The invention provides dust absorption and dust falling decorative paint for an internal wall and a preparation method thereof, belonging to the building material field. The paint in every 100 weight portion at least comprises 1 to 40 weight portions of a sorbing material, 2 to 15 weight portions of a nanometer material and 20 to 60 weight portions of an inorganic filling material. The paint which takes a crystalline material with the pyroelectric effect such as tourmaline, triglycine sulfate, and lead lanthanum zirconate titanate as an adsorption function material and the paint is obtained by adding nanometer materials such as nanometer titanium dioxide, etc., has the eight times dust collection and dust falling capacities of the prior paint, has the contact angle less than 45 degrees, and the scrubbing resistance more than 4,500 times, meets the requirement of the internal wall paint high-class products, is applied to the surface of the building, and has the functions of dust absorption, dust falling, and easy cleanness besides the function of the inside surface decorative material.

Owner:CHINA BUILDING MATERIALS ACAD

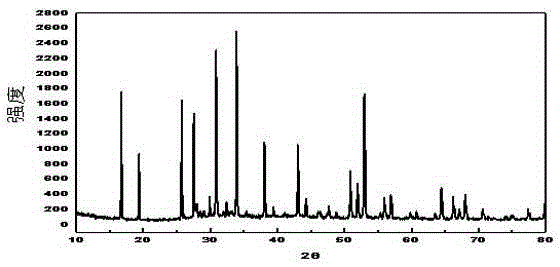

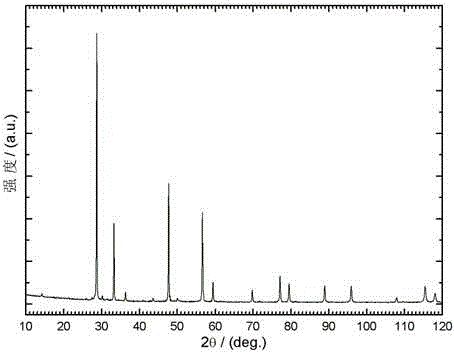

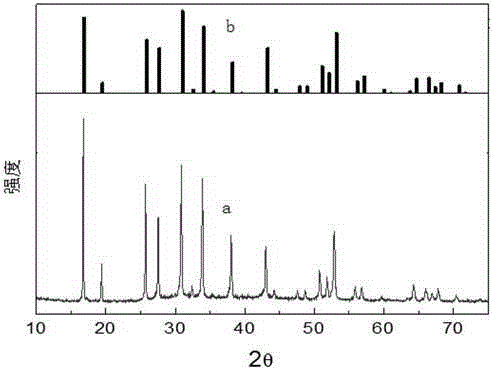

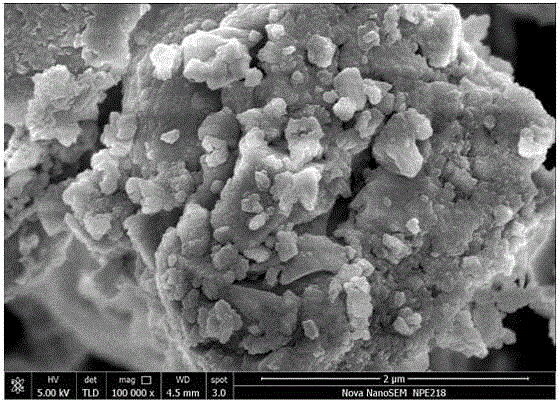

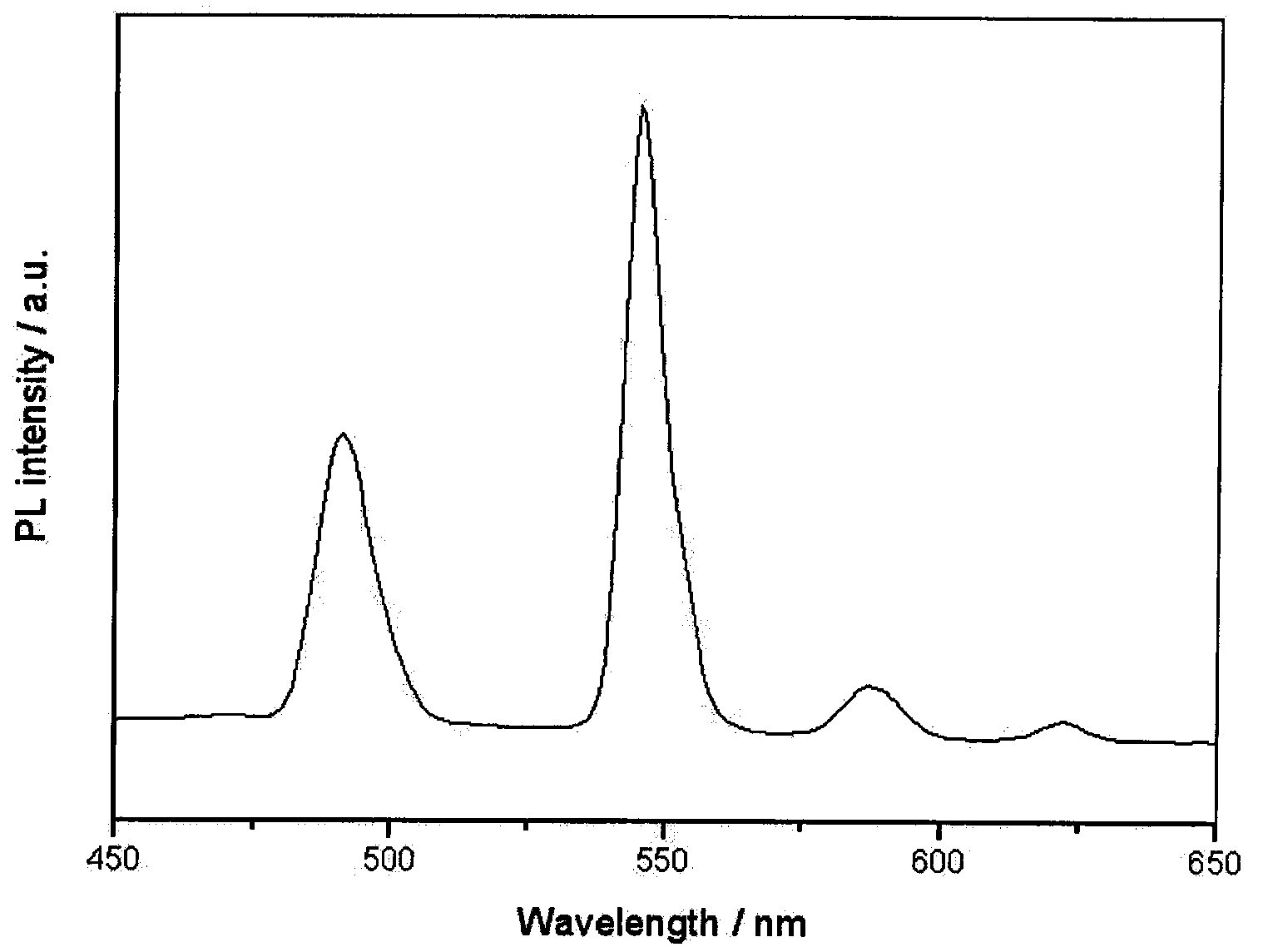

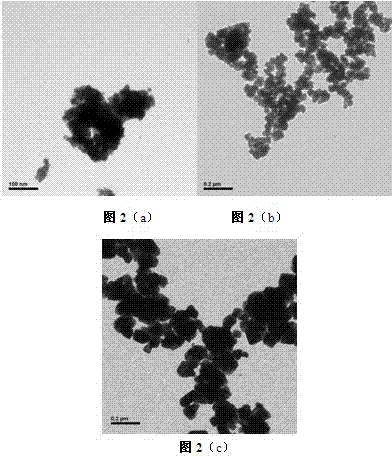

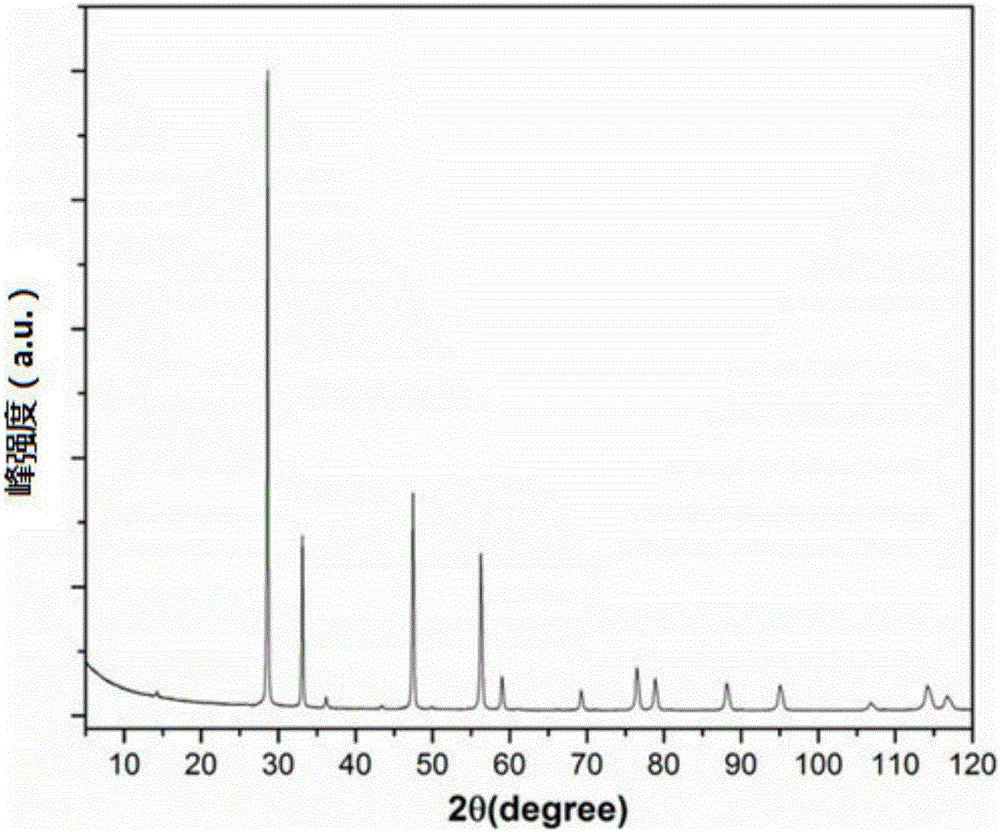

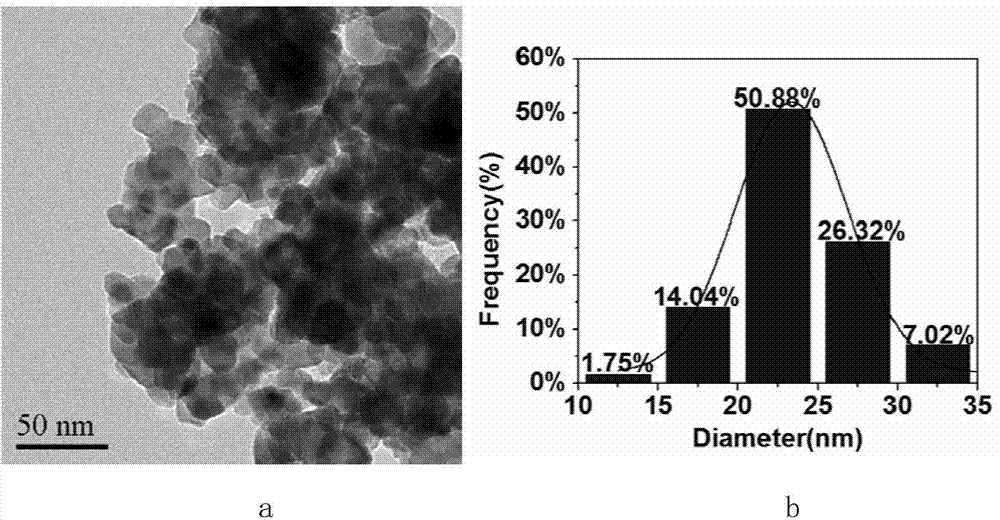

Cerium-doped lanthanum zirconate nano powder and preparation method thereof

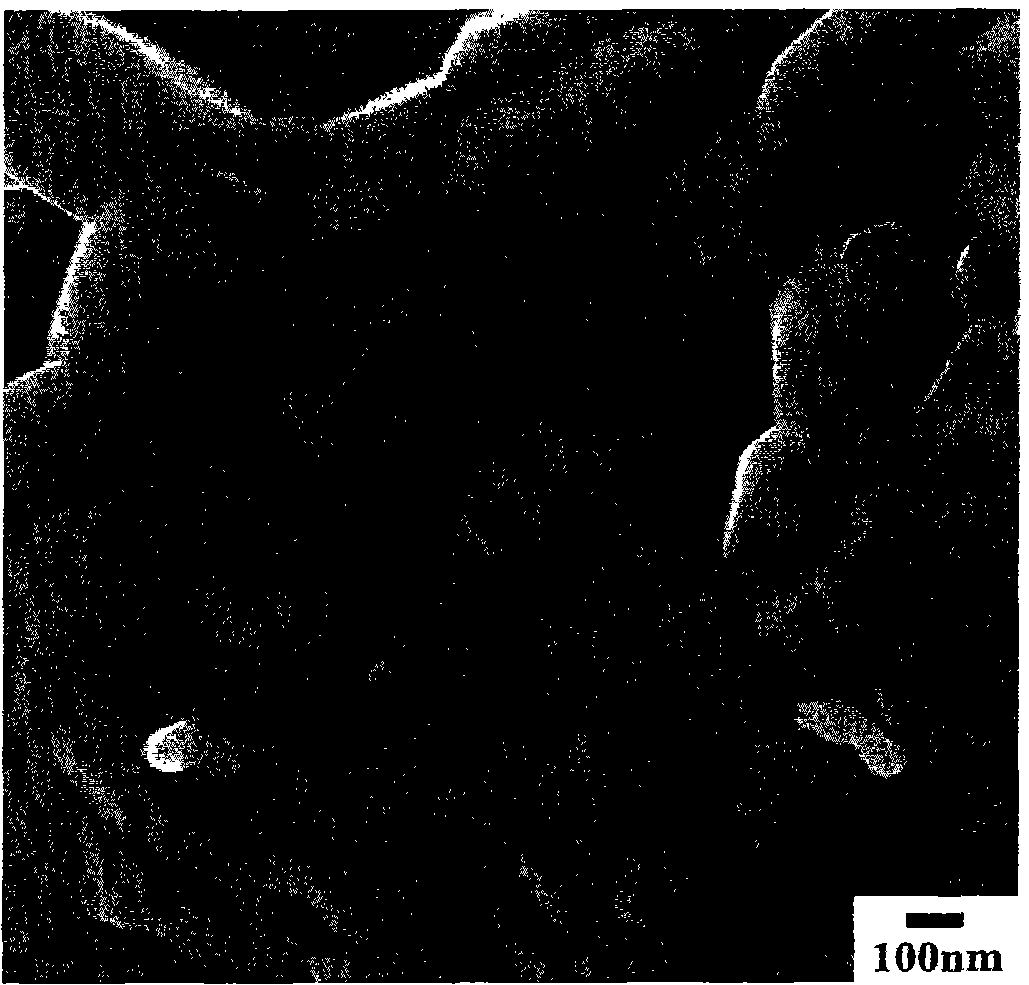

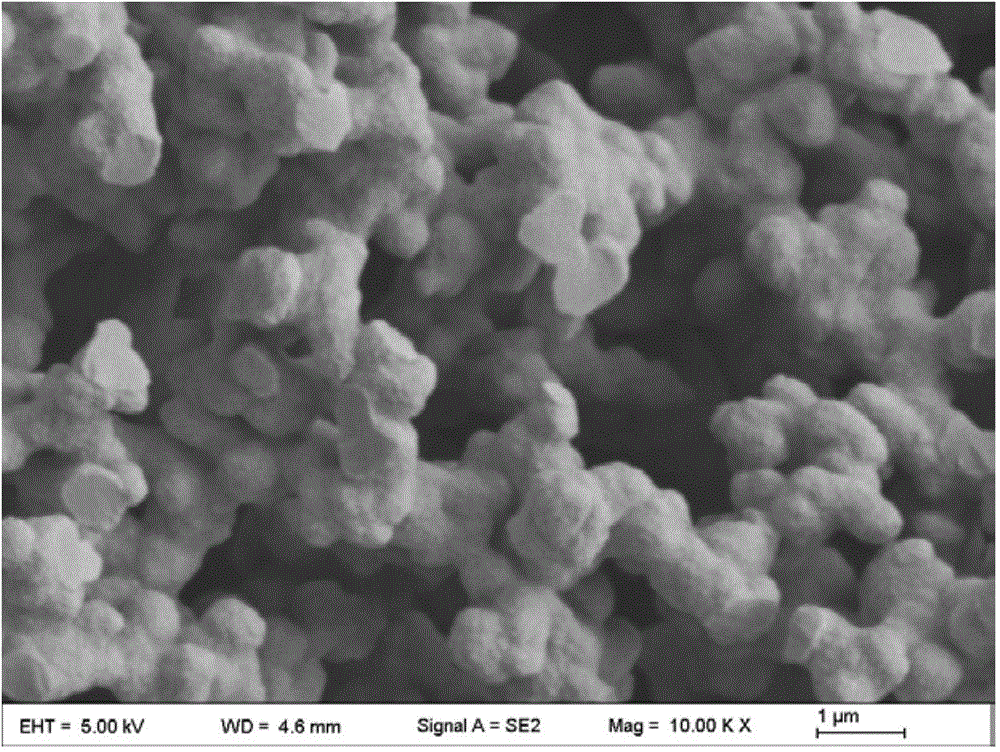

InactiveCN102718485AExcellent anti-sinteringSmall granularityNanotechnologyChemical industryPyrochlore

The invention relates to cerium-doped lanthanum zirconate nano powder and a preparation method thereof. The cerium-doped lanthanum zirconate nano powder is characterized in that the cerium-doped lanthanum zirconate nano powder is of a single-phase pyrochlore structure, has the particle size of 30 to 250nm, is uniformly distributed, is of a sphere shape, is prepared by carrying out doping on the Zr position by Ce and has the chemical formula of La2Zr2-xCexO7, wherein x is less than or equal to 0.5 and more than or equal to 0.1. The cerium-doped lanthanum zirconate nano powder is of the single-phase pyrochlore structure, has excellent anti-sintering performance, has small particle size, is uniformly distributed, has regular morphology and has stable structure at high temperature; the thermal expansion coefficient of the powder from the room temperature to the temperature of 1,400 DEG C can reach 12*10<-6<K<-1>; and the cerium-doped lanthanum zirconate nano powder has the thermal conductivity of lower than 1.5W.m<-1>.K<-1>, is particularly suitable for preparation of various high temperature resistance thermal barrier coating or high temperature resistance abrasion-resistant anticorrosion coating materials, and is applied to the industries of aerospace, gas turbines, ships, vehicles, machinery, chemical industry and the like.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Tantalum-doped cubic garnet structure Li7La3Zr2-xTaxO12 material and preparation method thereof

ActiveCN105244536AReduce high temperature lossLow content requirementSolid electrolytesSecondary cellsLithiumPhysical chemistry

The invention discloses a tantalum-doped cubic garnet structure Li7La3Zr2-xTaxO12 material and a preparation method thereof. The preparation method comprises the steps that 1, lanthanum zirconate, a lanthanum source, a lithium source and a doped element being a tantalum source are weighed; the materials are placed in a container successively, a complexing agent is added into the container, and then stirring is performed for 4-6 h; 2, the temperature is gradually increased to 80 DEG C and kept till excessive moisture is removed, and a precursor processed in a high-temperature solid-phase mode is obtained; 3, the precursor is preheated for 3-5 h at the temperature of 400 DEG C, and a product is taken out, sufficiently and evenly ground and roasted for 1.5-5 h at the temperature of 900 DEG C to obtain a primary roasted product, wherein the value of x is 0.25-0.6. The method is simple in process, the requirement for the content of the doped materials is lowered, energy consumption and lithium high-temperature losses are reduced in the preparation process due to the fact that the roasting time is shortened, energy is saved, the cost is greatly reduced, and the preparation method is quite suitable for large-scale production.

Owner:SHANGHAI POWER ENERGY STORAGE BATTERY SYST ENG TECH +1

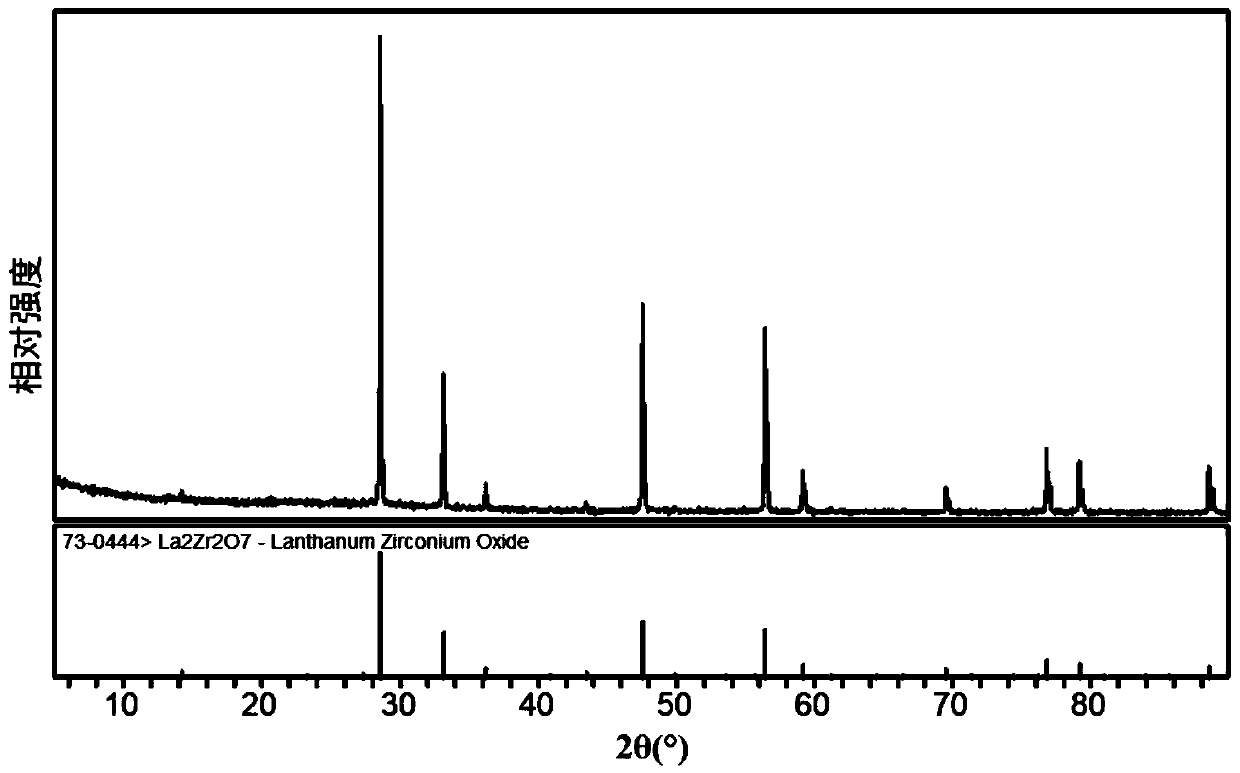

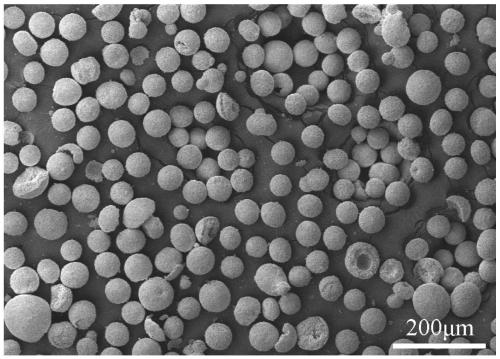

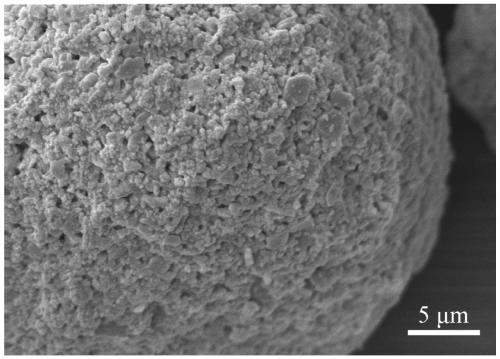

Preparation method of lanthanum zirconate spherical powder for thermal spraying

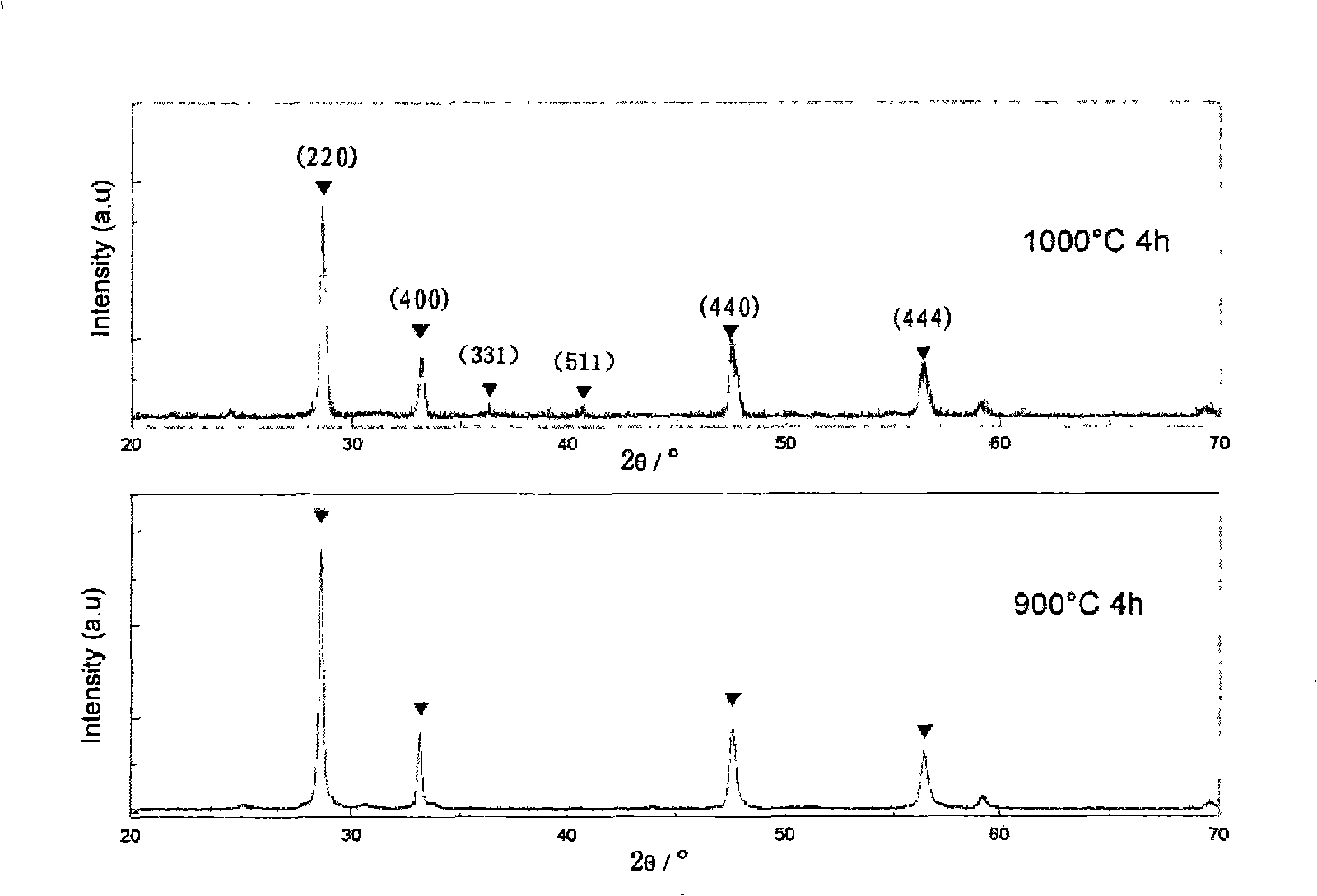

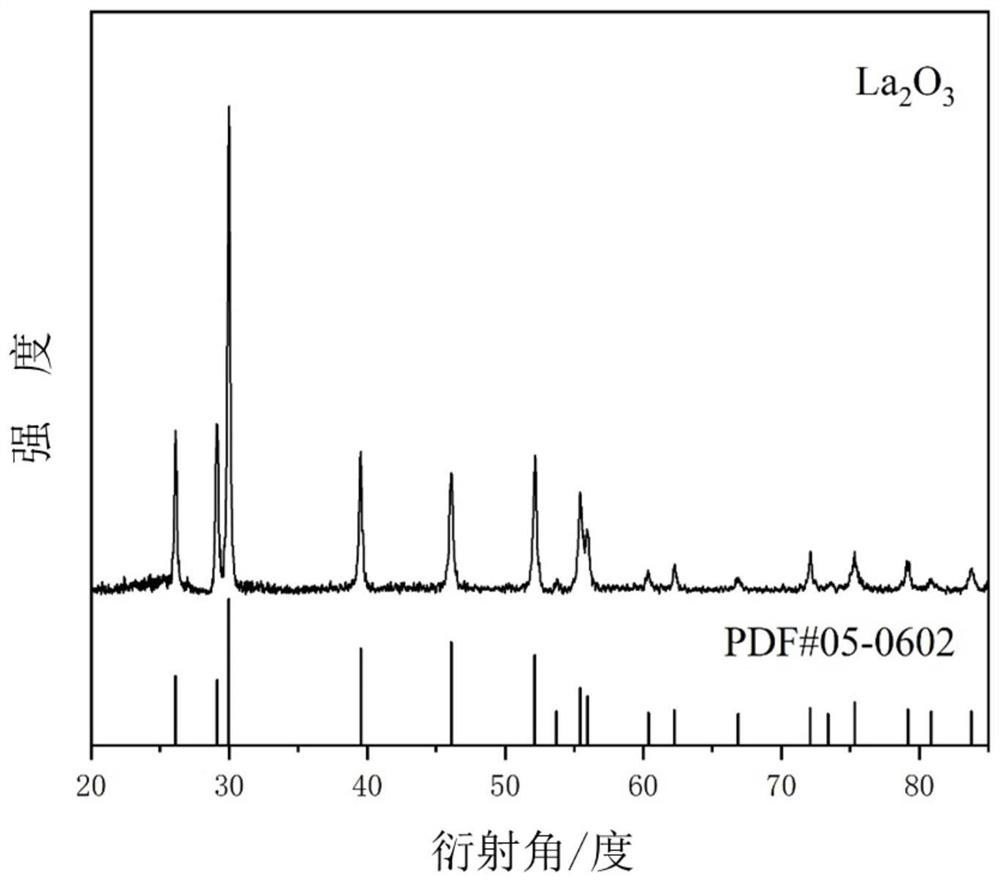

InactiveCN111153434AAvoid growing upLow reaction temperatureZirconium compoundsRare earth metal compounds preparation/treatmentMolten saltSpray dried

The invention discloses a preparation method of lanthanum zirconate spherical powder for thermal spraying, wherein the method comprises the following steps: carrying out wet ball milling on La2O3 andZrO2 in a molar ratio of 1:2 and a molten salt medium, uniformly mixing, drying the mixture, heating to 900-1200 DEG C, keeping the temperature for 4-10 h, and cooling to room temperature; washing thereaction product with water to remove the residual molten salt medium, adding a binder and deionized water to obtain slurry, and granulating the slurry by using spray drying equipment to obtain spherical powder; and calcining the prepared spherical powder at high temperature to remove the binder and densify the spherical powder to obtain the lanthanum zirconate spherical powder for thermal spraying. Molten salt is used as a reaction medium to provide a liquid-phase environment, so that the reaction temperature is reduced, and the growth of particles is avoided; oxides are adopted as raw materials, the conversion efficiency and the production efficiency are high, molten salt can be recycled, the synthesis cost is low, time is short, operation is easy, and the method is suitable for mass production.

Owner:SOUTH CHINA UNIV OF TECH

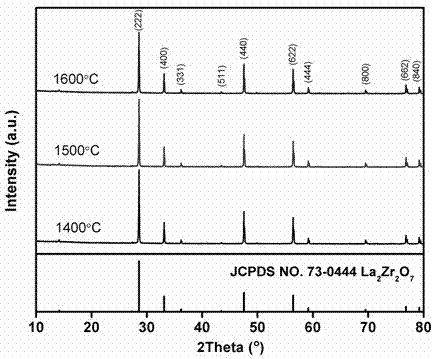

Compound lanthanum zirconate proton conductor mixed material and its preparing method

InactiveCN101009148AImprove conductivityNon-metal conductorsChemical/physical/physico-chemical processesElectrical conductorWater vapor

The invention relates to recombination doping zirconic acid lanthanum proton conductor material and its preparation method. Its chemical formula and matching is: La2-yNyZr2-xMxO7-delta;M is that Yb3+,Er3+,Gd3+,Sc3+ are doping in Zr bit, x is 0.01-1;N is Sr2+,Ca2+ are doping in La bit, y is 0.002-0.4;delta is oxygen vacant site, it depends on x and y. Dosage as proportion, water or alcohol is the medium, it is ball grinded and mixed for 4-10 hours and then dried, then synthesized in 1400DEG C, heat preserved for 2-20 hours. The synthesized material is then ball grinded, dried, screened, and loaded into die. The pressure is 50-120MPa, it is isostatic pressing, the pressure is 120-300MPa;it is adglutinated in 1400-1650DEG C, the warming-up rate is 2-10DEG C / minute, heat preserved for 2-50 hours, then cooled to room temperature, the doping zirconic acid lanthanum material is produced. The invention adopts the recombination doping which is not reported to produce proton conductor material which possesses perfect conductivity; it lays the foundation of developing hydrogen gas and steam sensor, hydrogen pump, accelerant and concentration cell electrolyte material.

Owner:TIANJIN UNIV

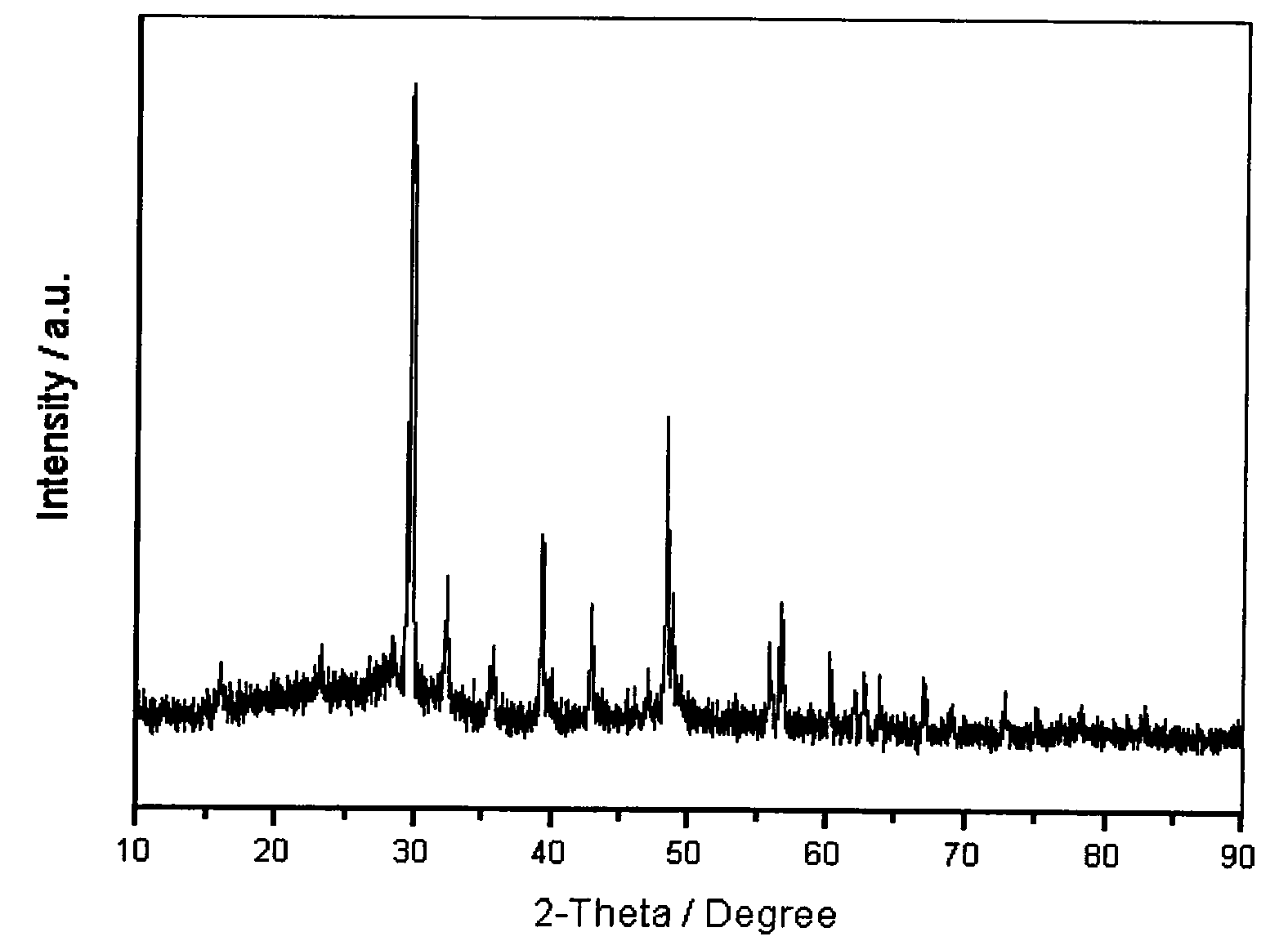

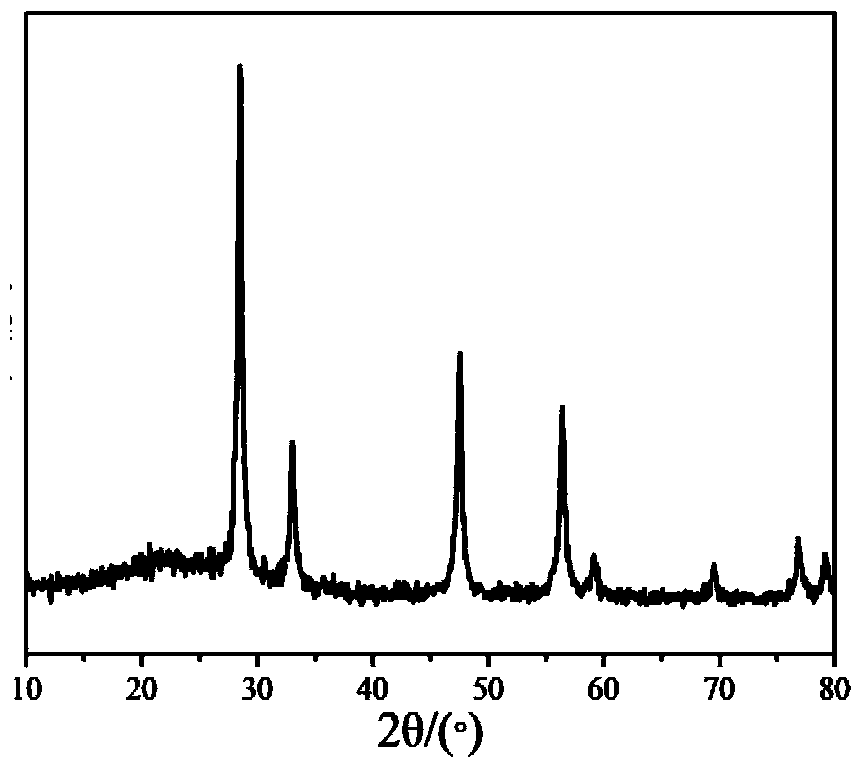

Method for preparing cubic shape green luminescent material of lanthanum zirconate doped with cerium and terbium

The invention discloses a method for preparing a cubic shape green luminescent material of lanthanum zirconate doped with cerium and terbium. The method comprises the following steps: dissolving lanthanum nitrate, cerium nitrate and terbium nitrate in deionized water according to the mole ratio and stirring; adding PVP into the solution, controlling the concentration of the mass percent of the PVP at 0.25-1% and stirring; adding zirconium acetate into the solution, controlling the mole number of the zirconium acetate and the mole number of the total rare earth cation to be equivalent, adding a sodium hydroxide solution drops by drops to obtain a white precipitate and controlling the pH value of the solution at 6-9; putting the solution into a high-pressure kettle, taking the filling degree at 80% and processing for 6-40 hours at 180-220 DEG C; and centrifugalizing and drying the processed solution to obtain the cubic shape green luminescent material of lanthanum zirconate doped with cerium and the terbium.

Owner:ZHEJIANG SCI-TECH UNIV

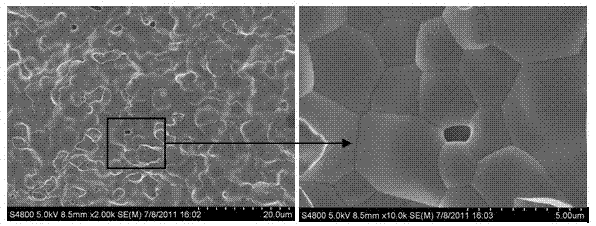

Compact pure-phase lanthanum zirconate ceramic with low thermal conductivity and high strength, and preparation method thereof

The invention discloses compact pure-phase lanthanum zirconate ceramic with low thermal conductivity and high strength, and a preparation method thereof. A chemical formula of the lanthanum zirconate ceramic is La2Zr2O7, the compactness is greater than 85%, the compression strength is 310-500MPa, the thermal conductivity and the thermal diffusion coefficient at normal temperature respectively are 1.55-1.79W / (m.K) and (0.90-0.76)*10<-6>m<2> / s; the thermal conductivity and the thermal diffusion coefficient at the temperature of 1200 DEG C respectively are 0.75-0.94W / (m.K) and (0.35-0.45)*10<-6>m<2> / s; the breaking tenacity is 1.45-1.70MPa. The lanthanum zirconate ceramic prepared according to the lanthanum zirconate ceramic preparation method provided by the invention has the advantages of low thermal conductivity, high melting point, good inoxidizability, excellent mechanical property, good high temperature-phase stability and the like, and the requirements of hypersonic velocity aerospace vehicles on the performances of high-strength thermal insulation ceramic materials can be met.

Owner:ZHEJIANG UNIV

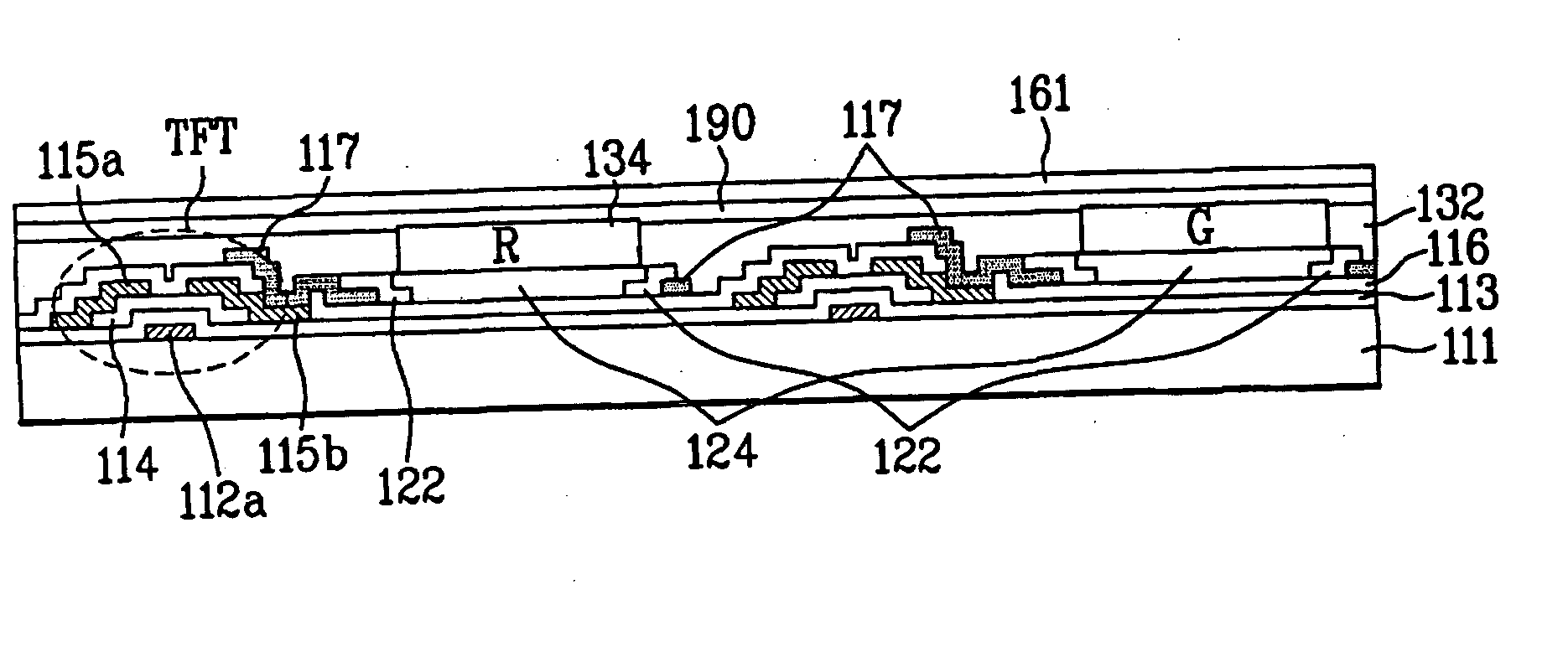

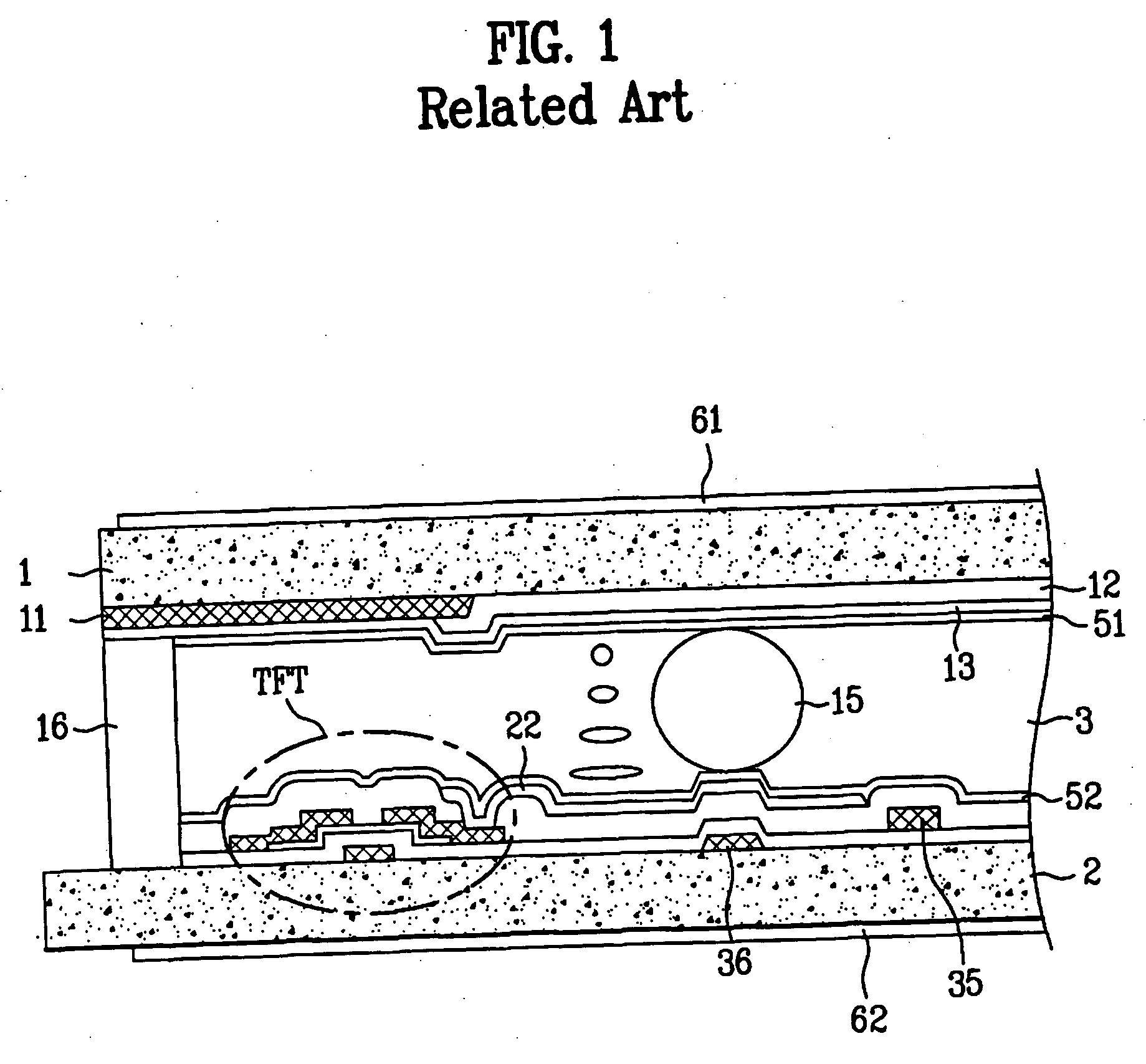

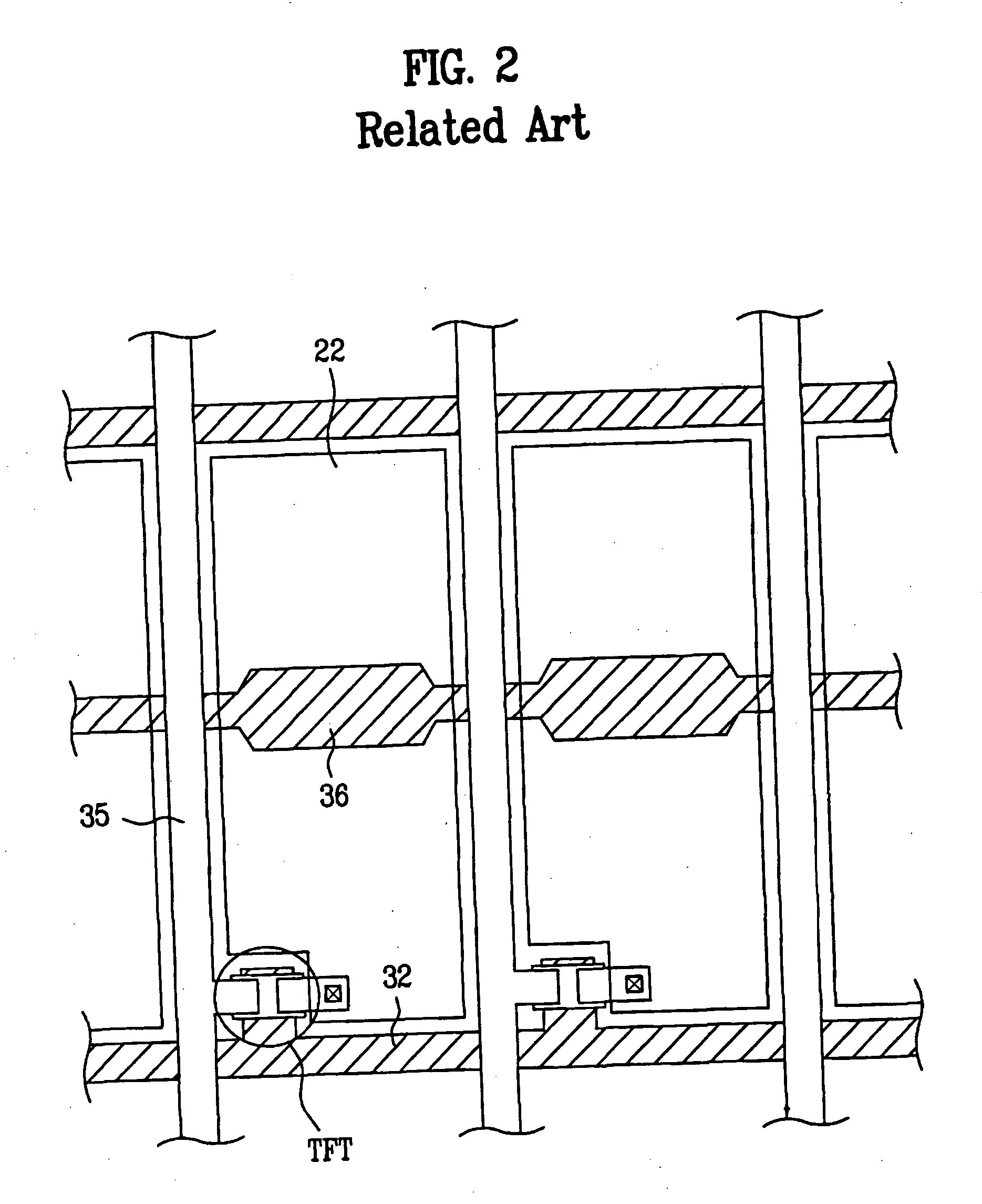

Display device with piezoelectric material and method for fabricating the same

ActiveUS20050243258A1Simplify the manufacturing processOvercome problemsOther printing matterSemiconductor/solid-state device detailsLead zirconate titanateDisplay device

The present invention discloses a display device having a gate line and a data line crossing each other on a substrate to define a pixel region, a thin film transistor at each crossing of the gate line and data line, a pixel electrode about a circumference of the pixel region and having an opening at a central portion of the pixel region, the pixel electrode electrically connected to the thin film transistor, a piezoelectric lead lanthanum zirconate titanates (PLZT) layer in the opening of the pixel region, and a piezoelectric lead zirconate titanates (PZT) layer between the pixel electrode and the PLZT layer.

Owner:LG DISPLAY CO LTD

Preparation method for lanthanum zirconate ceramic fiber blanket

ActiveCN103643402AFlat surfaceIncrease elasticityGlass making apparatusNon-woven fabricsFiberChloride

The invention relates to a preparation method for a lanthanum zirconate ceramic fiber blanket. The method uses lanthanum zirconate as the zirconium source, and lanthanum nitrate and lanthanum chloride and corresponding hydrate thereof as the lanthanum source, prepares precursor sol according to the molar ratio of La<3+>:Zr<4+> = 1:(0.87-1.15), and obtains gelatinous fiber through centrifugal fiber formation technology after aging; the gelatinous fiber is made into a gelatinous fiber blanket through cotton collecting and blanket forming; the La2Xr2O7 ceramic fiber blanket of pyrochlore type is obtained after calcination. The La2Xr2O7 ceramic fiber blanket of pyrochlore type, prepared by the invention, has a flat surface, is low in shot content, good in resilience, has a heat conductivity coefficient of 0.037-0.056W / (m*K), and has an excellent heat-insulating property; the method reduces the calcination temperature, and is simple in structure, controllable in technology, and suitable for large-scale production of the lanthanum zirconate ceramic fiber blanket.

Owner:SHANDONG UNIV

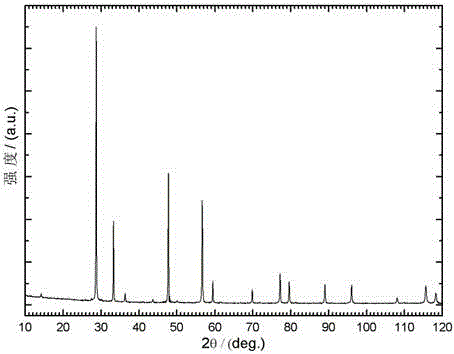

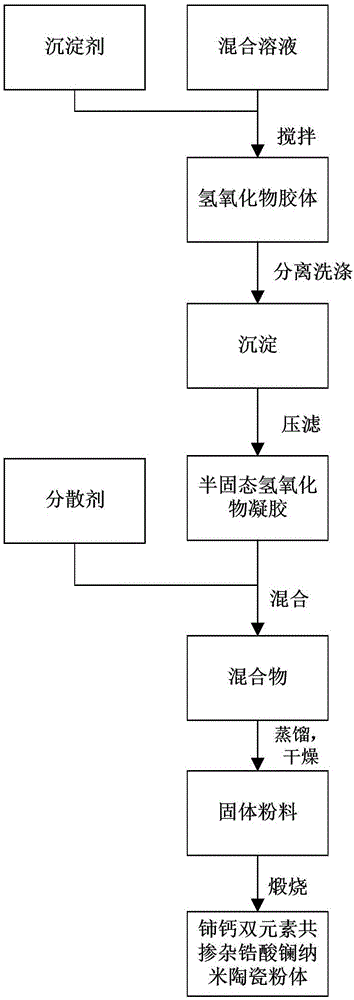

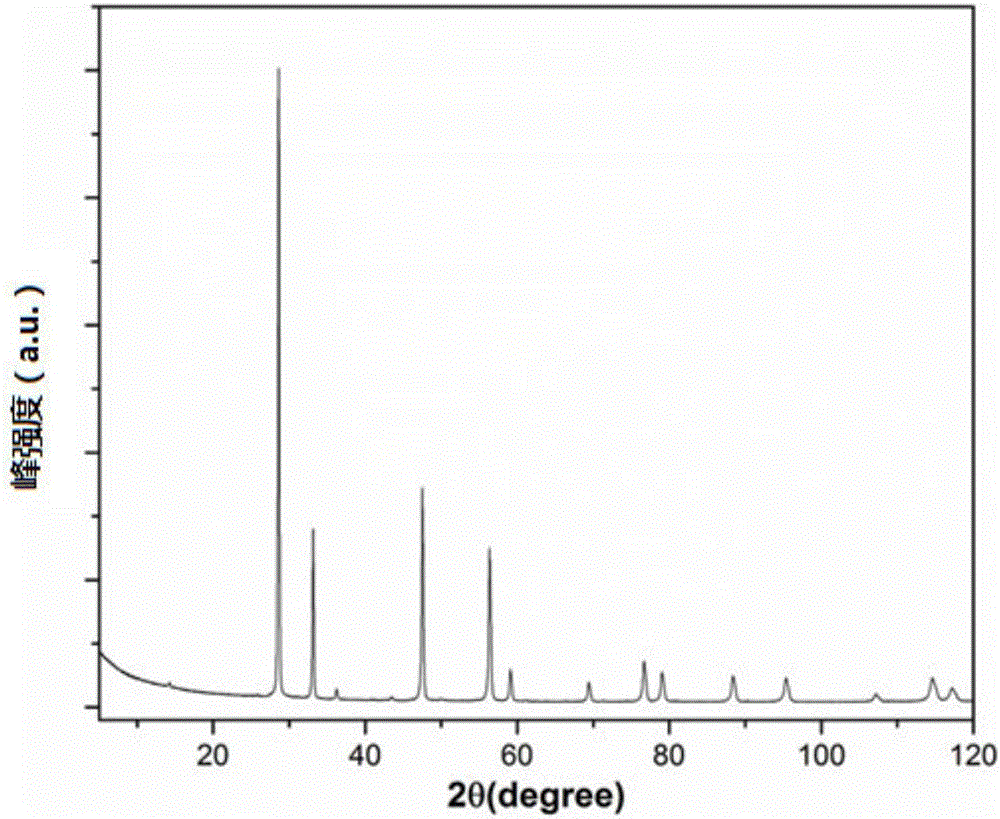

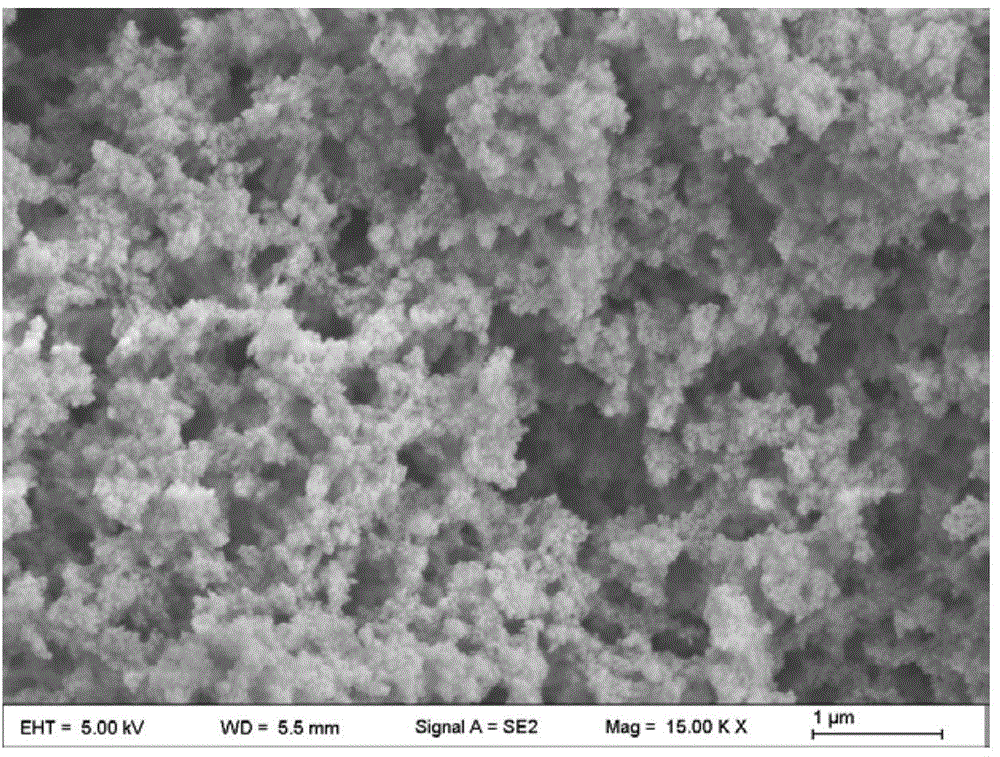

Cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder and preparation method thereof

The invention provides cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder and a preparation method thereof. The preparation method includes following steps: preparing a mixed solution, and mixing the same with a precipitant to obtain hydroxide colloid; separating and washing the hydroxide colloid to obtain precipitate; press-filtering the precipitate to obtain semi-solid-state hydroxide gel; well mixing the semi-solid-state hydroxide gel with a dispersant to obtain a mixture; distilling the mixture, and drying to obtain solid powder; calcining the solid powder to obtain the cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder. The structural formula of the cerium-calcium bi-element co-doped lanthanum zirconate nano ceramic powder is (La1-2xCexCax)2(Zr0.7Ce0.3)2O7, wherein x is greater than or equal to 0.05 and smaller than or equal to 0.2. The preparation method is few in process and easy to control.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing porous lanthanum zirconate block

The invention discloses a method for preparing a porous lanthanum zirconate block. The method comprises the following steps: at room temperature, dissolving inorganic salt of zirconium, inorganic salt of lanthanum and a phase separation inducer in a solvent and stirring until a transparent and clarified solution is obtained; adding a drying control chemical additive and stirring; adding a gel accelerator and stirring to obtain a homogeneous solution; placing the homogeneous solution into a sealed container and standing for 10-30 minutes at 30 DEG C-80 DEG C to obtain wet gel; aging the wet gel for 12-24 hours at 35-80 DEG C, firstly cleaning the wet gel with a solvent with a low surface tension and then soaking the wet gel with a surface modifier solution, and finally cleaning with the solvent with the low surface tension; drying the cleaned wet gel for 24-72 hours at 30-90 DEG C; and then carrying out heat treatment on the dried wet gel for 2-4 hours at 400-1300 DEG C to obtain the porous lanthanum zirconate block. The porous lanthanum zirconate block, which is prepared by the method, has the characteristics of co-continuous macroporous structure, high porosity, centralized distribution of pore sizes and the like.

Owner:ZHEJIANG UNIV

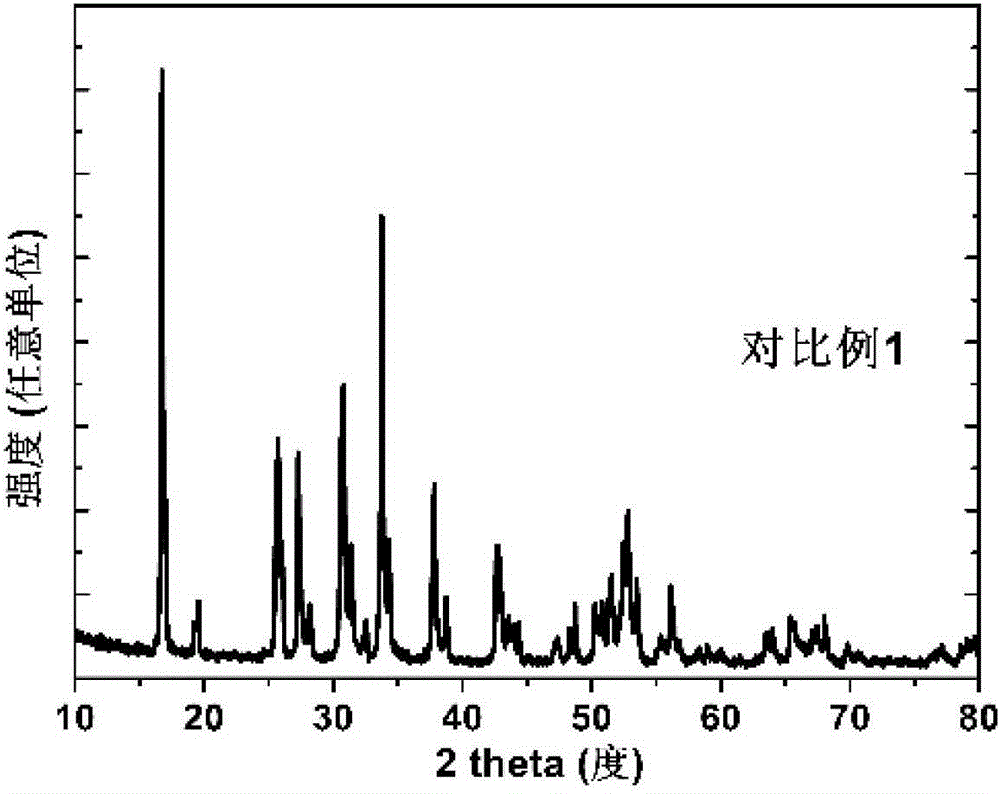

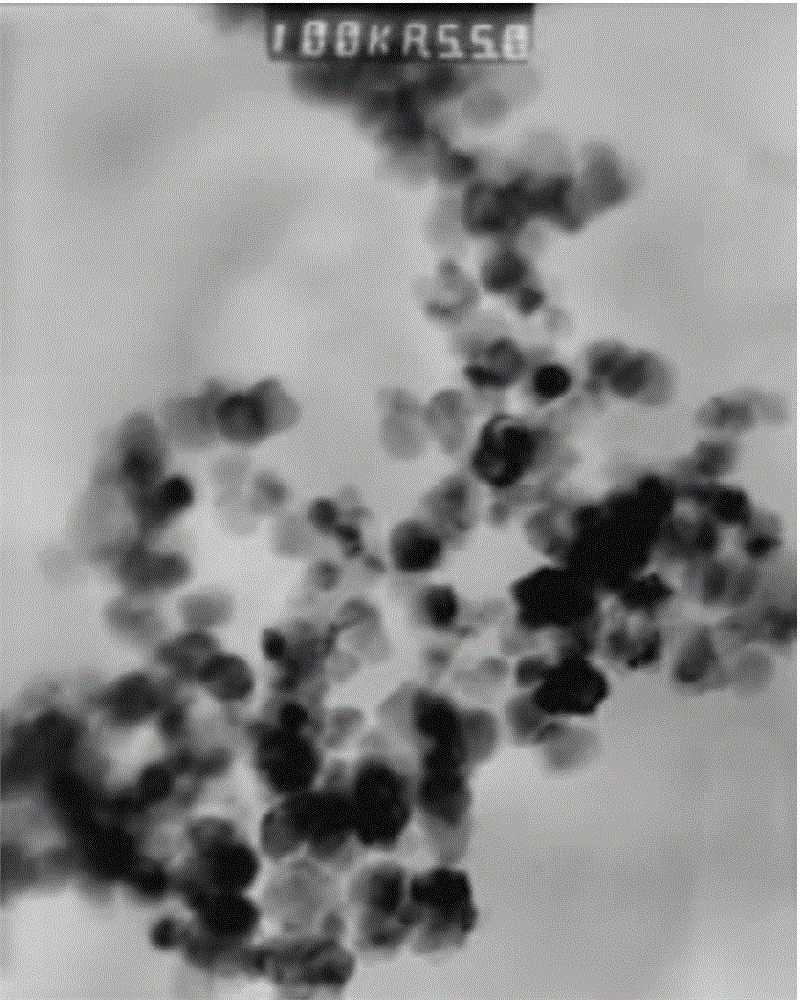

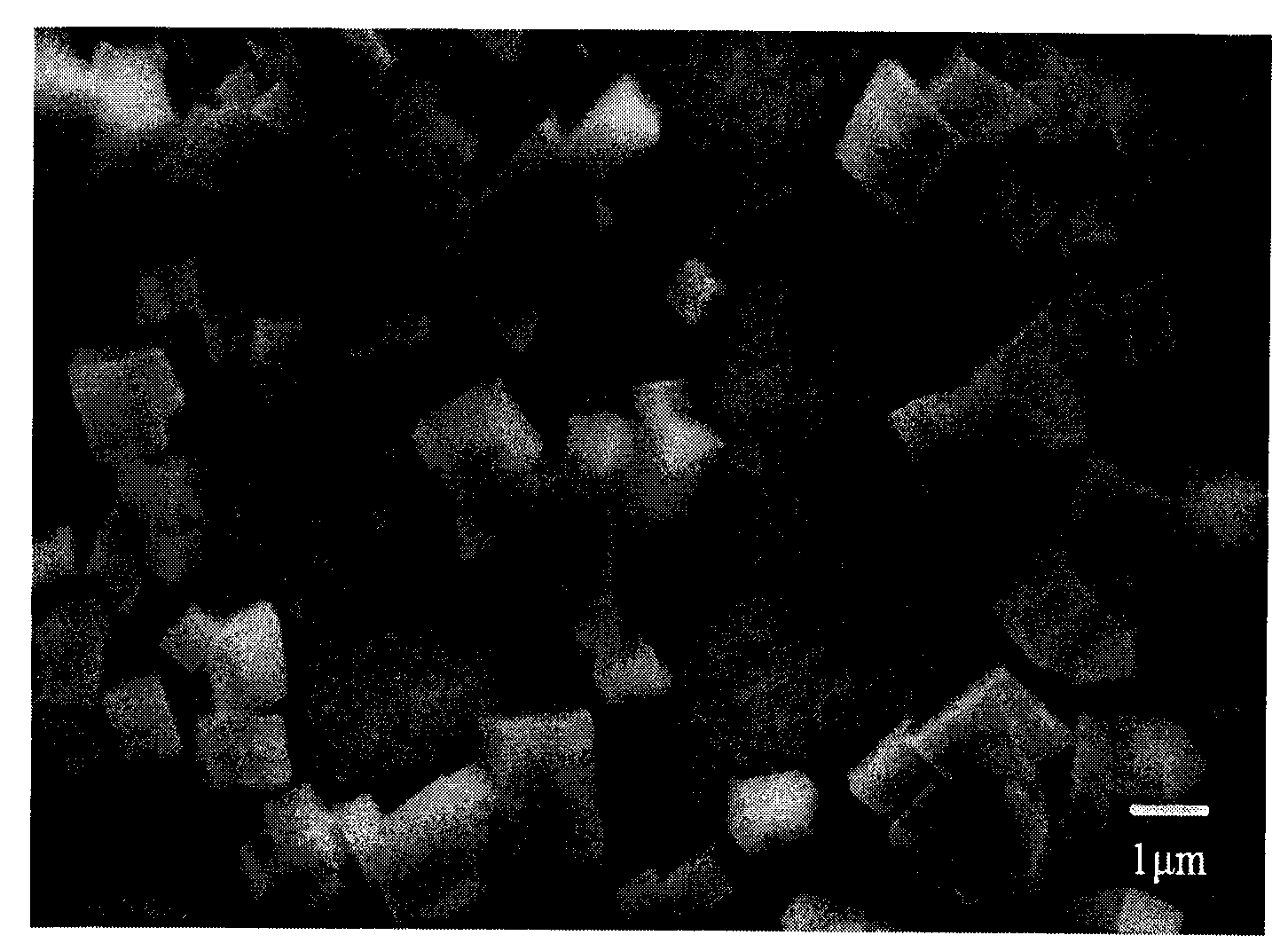

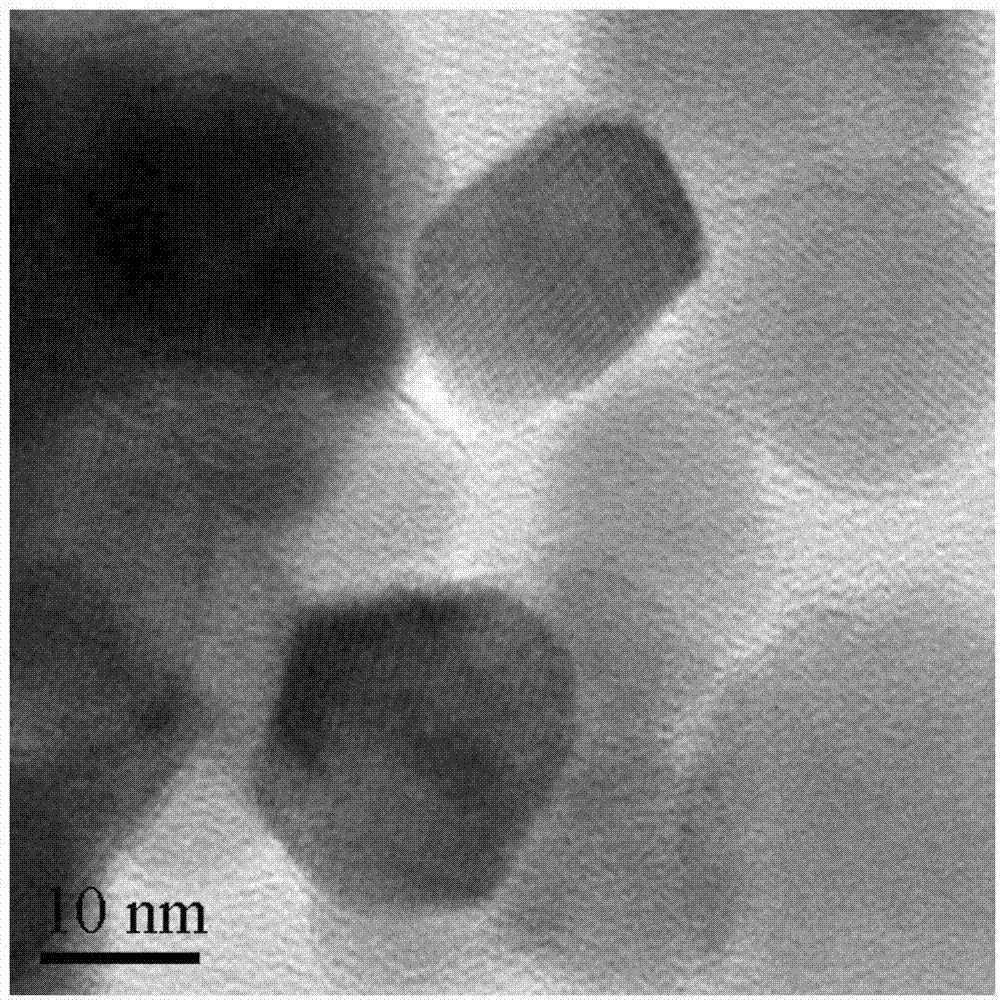

Preparation method of cubic lanthanum zirconate nanometer monocrystal

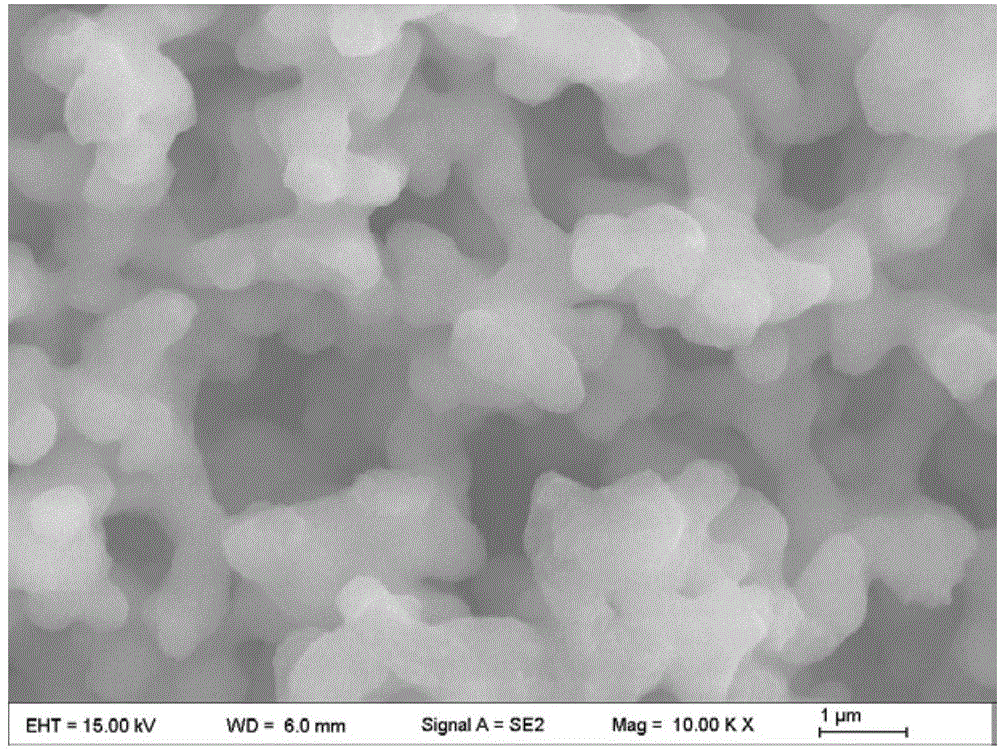

InactiveCN104843787AUniform and controllable grain distributionImprove mechanical propertiesMaterial nanotechnologyZirconium compoundsLanthanumAqueous solubility

The invention relates to a preparation method of a cubic lanthanum zirconate nanometer monocrystal. The method comprises the following steps: 1, preparing a hydroxide colloid: mixing an aqueous solution of a water-soluble zirconium salt with an aqueous solution of a water-soluble lanthanum salt, adding the obtained mixed solution into ammonia water, and stirring to obtain the hydroxide colloid; 2, carrying out solid-liquid separation, and washing; 3, drying; 4, carrying out salt melting: mixing the above obtained dried powder with a salt melting agent according to a mass ratio of 1:9, grinding, and carrying out salt melting at 450-700DEG C for 0.5-96h in order to obtain a salt melted product; and 5, carrying out centrifugal drying to obtain the cubic lanthanum zirconate nanometer monocrystal. The large-scale process production of the cubic nanometer monocrystal with the lanthanum zirconate of a pyrrhite structure and the crystal grain size of 10-40nm is easy; and the salt melting agent is added to effectively reduce the calcining temperature of lanthanum zirconate, and the calcining temperature is 500-750DEG C and is lower than that of traditional high temperature solid phase methods and coprecipitation methods, so the required energy is greatly reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

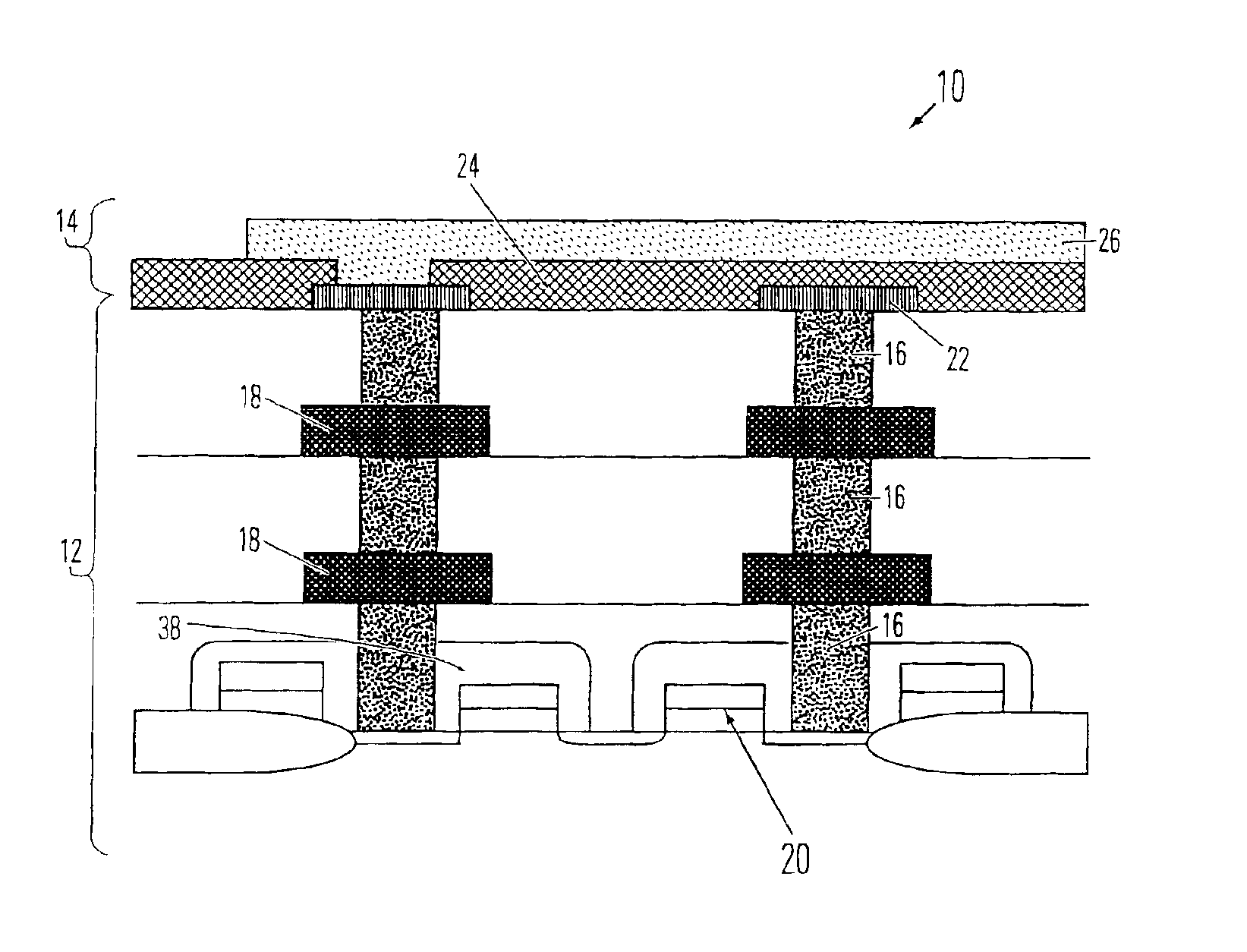

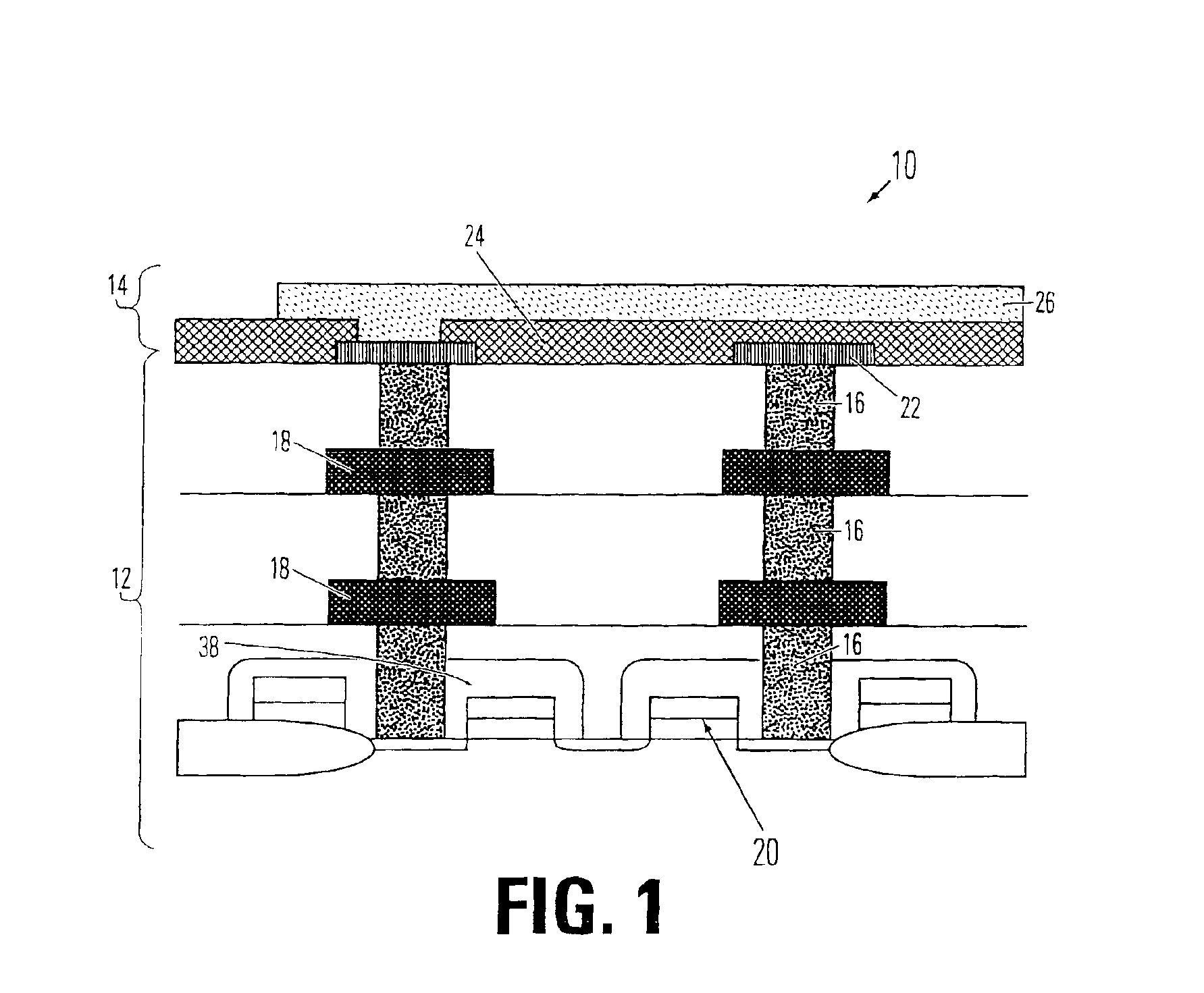

Ferroelectric device and method for making

InactiveUS6914282B2Reduce fatigueReduce thicknessTransistorFixed capacitor electrodesLead zirconate titanateLattice mismatch

A ferroelectric subassembly for an integrated circuit includes a second layer lying between and in contact with first and third layers. The second layer comprises a ferroelectric material while the first and third layers comprise capacitor electrodes in contact with the second layer. At least a portion of the first layer contacting the second layer has the same crystal structure as the second layer. The first layer acts as both a seed layer for the ferroelectric material and as a capacitor electrode. One or both of the first and third layers may comprise LaNiO3 (LNO). The second layer may, for example, comprise lead zirconate titanate (PZT), lead lanthanum zirconate titanate (PLZT) or SrBi2TaO9 (SBT) or an appropriate combination thereof. Any lattice mismatch between the first and second layers and / or between the second and third layers may be less than about 5 percent.

Owner:MACRONIX INT CO LTD

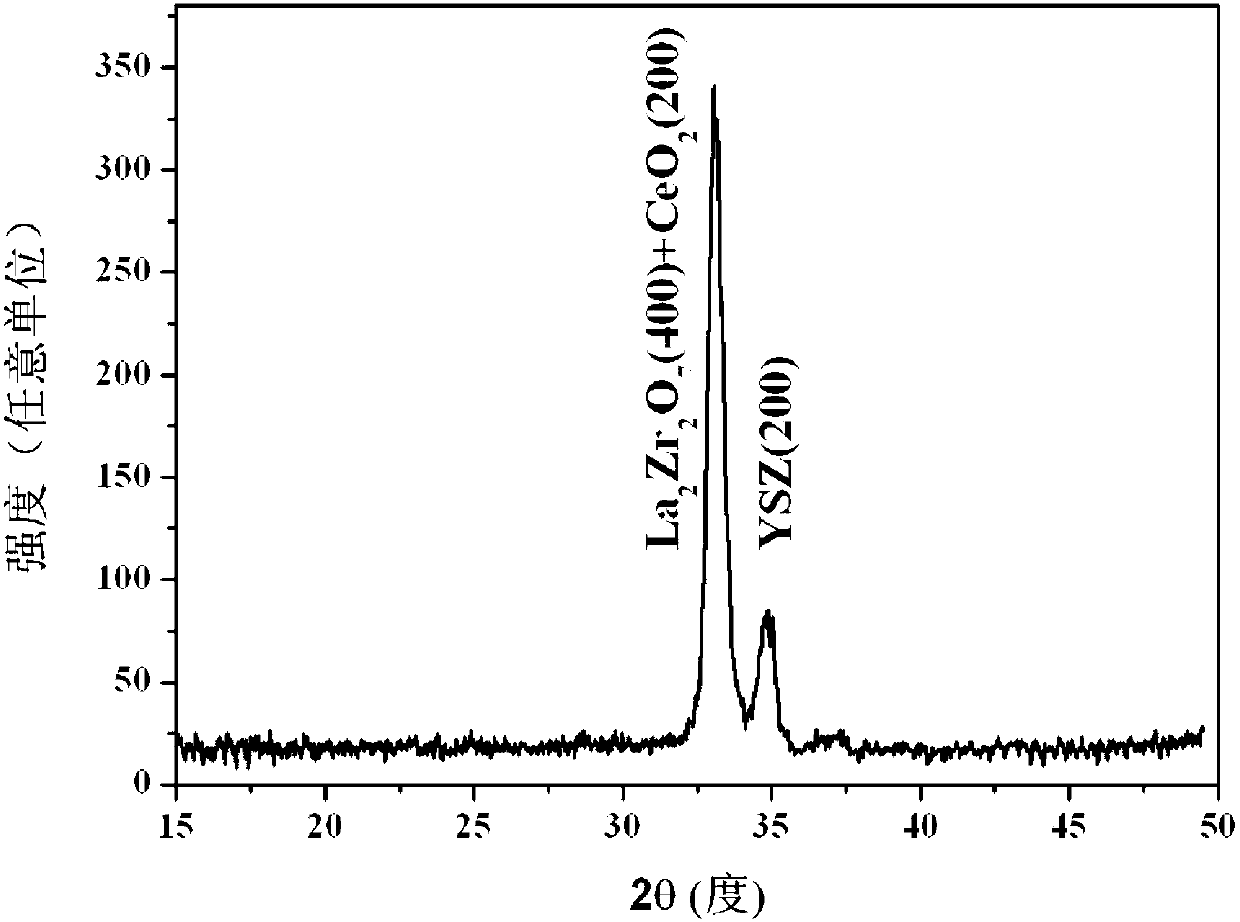

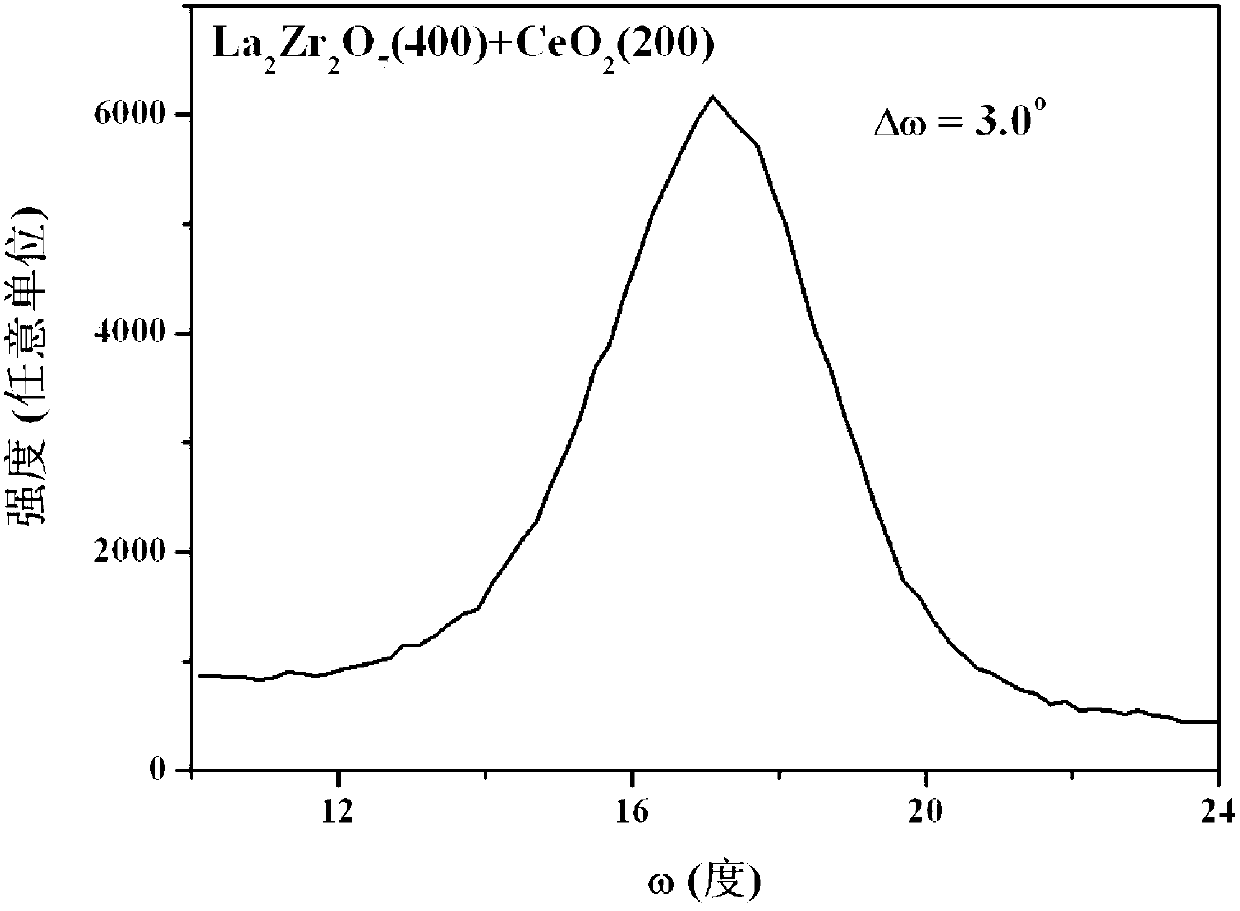

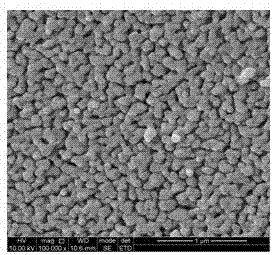

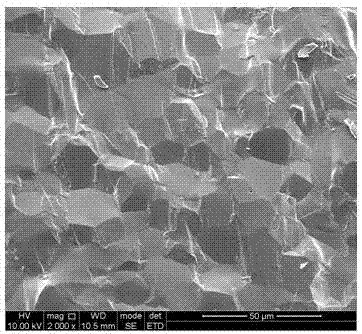

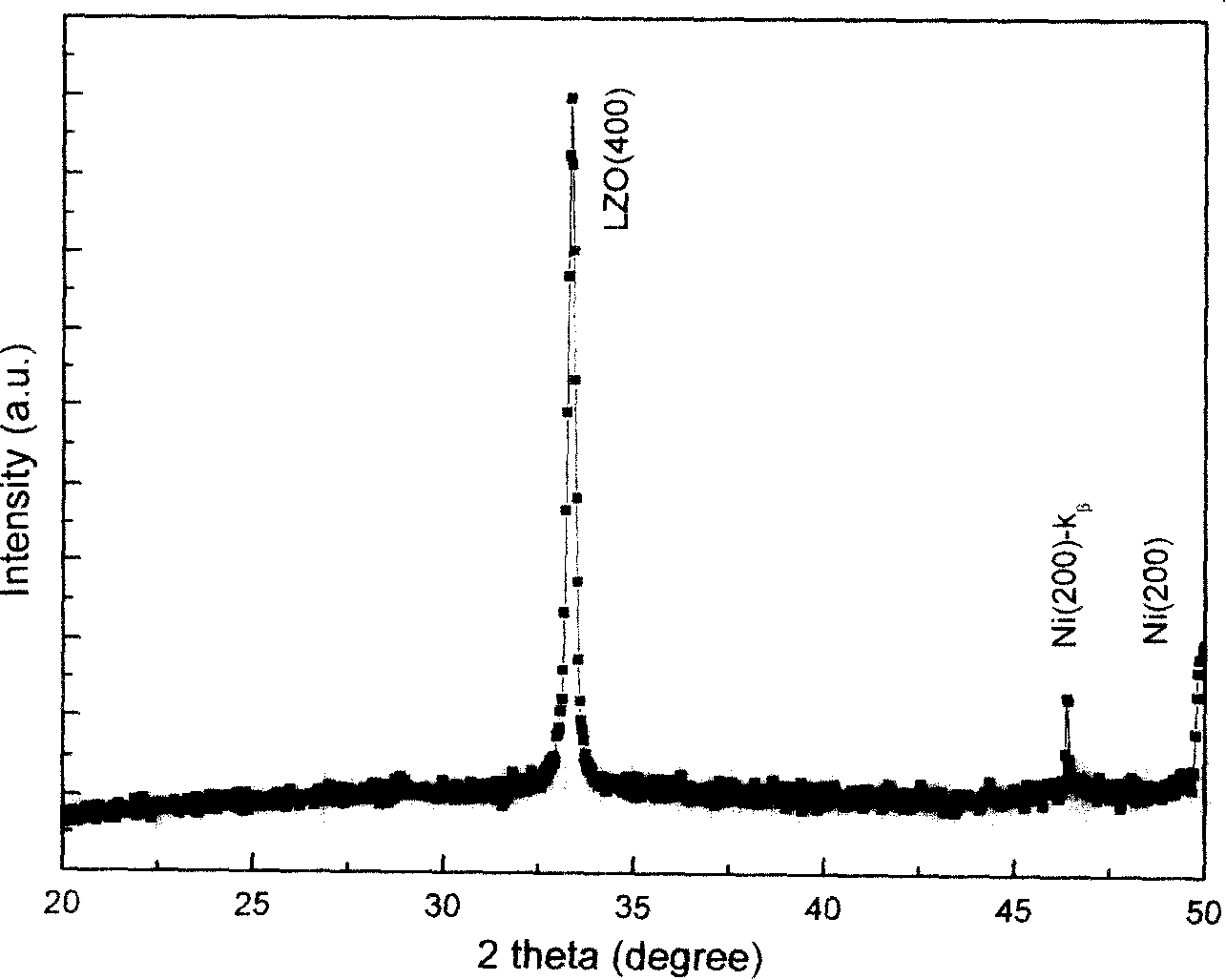

Novel composite isolating layer based on biaxial texture metal substrate and preparation method thereof

ActiveCN102774074AAvoid prone to breakage problemsImprove performanceVacuum evaporation coatingSputtering coatingIn planeRadio frequency magnetron sputtering

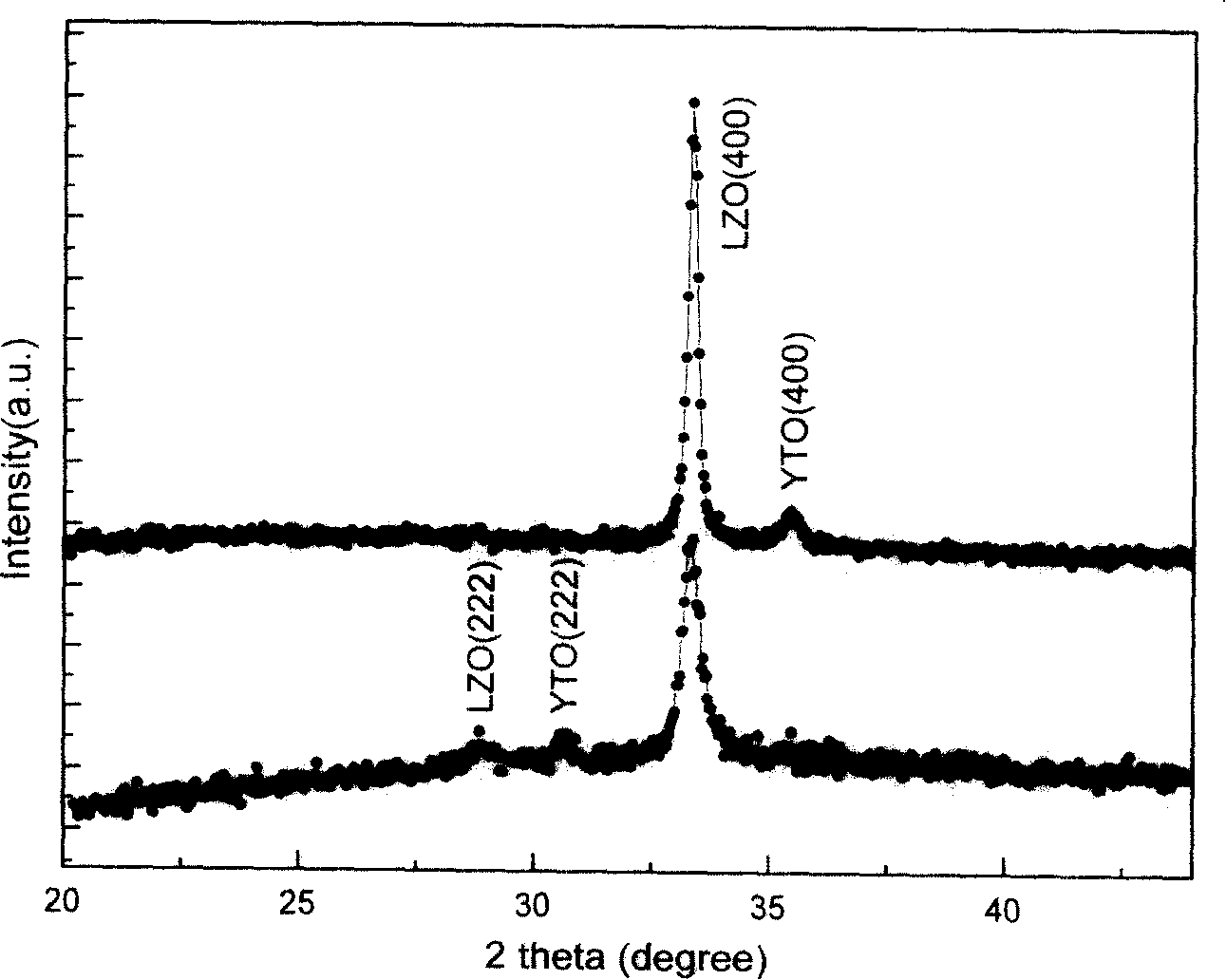

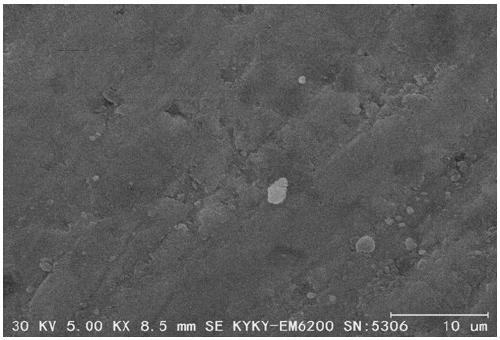

The invention discloses a novel composite isolating layer based on a biaxial texture metal substrate and a preparation method thereof. The novel composite isolating layer has a three-layer structure, wherein the upper layer is a lanthanum zirconate (La2Zr2O7) isolating layer, the intermediate layer is a yttria-stabilized zirconia (YSZ) isolating layer, and the lower layer is a cerium oxide (CeO2) isolating layer. A CeO2 cap layer in the traditional CeO2 / YSZ / CeO2 and CeO2 / YSZ / Y2O3 three-layer composite isolating layer structure is replaced by the lanthanum zirconate (La2Zr2O7), and the high-quality La2Zr2O7 isolating layer is prepared by employing a radio frequency magnetron sputtering coating technology. The method has high stability, high repeatability, high reliability and high deposition rate; and the prepared La2Zr2O7 isolating layer is dense and uniform and has high binding force with the YSZ isolating layer. The La2Zr2O7 / YSZ / CeO2 composite isolating layer based on the metal substrate has single (00 / ) orientation, high in-plane and out-of-plane textures and high surface smoothness and is suitable for epitaxial growth of a high-performance rare earth oxide superconducting layer on the isolating layer.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

High-purity and uniform-morphology lanthanum zirconate gadolinium powder and transparent ceramic preparation method

The invention discloses a high-purity and uniform-morphology lanthanum zirconate gadolinium ceramic powder preparation method which is characterized by including the steps: (1) dissolving Gd(NO3)3*6H2O, La(NO3)3*6H2O and ZrOCL2*8H2O in water, preparing mixed salt solution according to the mole ratio of Gd<3+>, La<3+> to Zr<4+> of 1:1:2, and titrating the mixed salt solution into ammonia water to obtain mixed solution; (2) performing suction filtration and cleaning after ageing of the mixed solution to obtain gelatinous precipitates, and dispersing the gelatinous precipitates into ethyl alcohol to obtain white slurry; (3) transferring the white slurry into a reaction kettle, performing suction filtration and cleaning after treatment of the white slurry to obtain white precipitates, drying the white precipitates to obtain precursor blocks, and grinding the precursor blocks to obtain precursor powder; (4) calcining the precursor powder, and grinding the calcined precursor powder to obtain GdLaZr2O7 ceramic powder; (a) performing sheeting on the ceramic powder, and performing cold isostatic pressing to obtain ceramic biscuits; (b) performing vacuum sintering on the ceramic biscuits to obtain ceramics; (c) performing annealing on the ceramics in the air, and polishing the surfaces of the ceramics to obtain transparent GdLaZr2O7 ceramic products with high purity, resistance and compactness.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Lanthanum zirconic acid/yttrium titanate film material and method for making same

InactiveCN101200127ACompact structureUniform structurePolycrystalline material growthSingle crystal growth detailsColloidTitanium

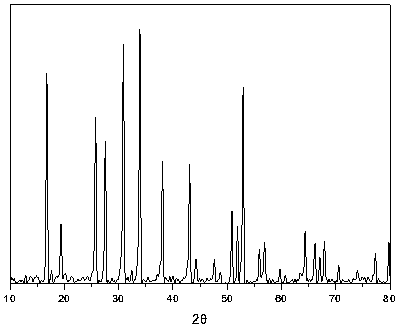

The invention discloses a Lanthanum zirconate / titanate Y film material and the preparation method of the Lanthanum zirconate / titanate Y film material. The material is the metal nickel of (100) axial orientation or the nickel alloy base covered in sequence with a Lanthanum zirconate seed layer of the (100) axial orientation, a Lanthanum zirconate layer of the (100) axis orientation, a titanate Y seed layer of (100) axial orientation and a titanate Y film of (100) axial orientation. In the preparation, according to the mol ratios of la: zieconim 1:1 and Y:Ti 1:1, the precursor colloid of the Lanthanum zirconate seed layer and the precursor colloid of the follow up layer of the Lanthanum zirconate seed layer are firstly respectively prepared. And then the metal nickel of (100) axial orientation or the nickel alloy base is coated in sequence with the above precursor colloid, which is also respectively and successively under the heat of 300 to 450 DEG C. for 15 to 30 minutes and in annealing under 850 to 1150 DEG C.for more than 15 minutes in a reduction atmosphere. Thus the Lanthanum zirconate / titanate Y film materal is produced. The material has high (100) axial orientation, which can be widely applied in catalysts, optical materials, superconducting materials and other fields.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Industrialized preparation method of tantalum-aluminum-codoped lithium-lanthanum zirconate solid-state electrolyte

InactiveCN109052473ASimple preparation processReduce instrument costTantalum compoundsSolid state electrolyteRepeatability

The invention discloses an industrialized preparation method of a tantalum-aluminum-codoped lithium-lanthanum zirconate solid-state electrolyte. The product has a structure expression of Li6.4-XLa3Zr2-XTaXAl0.2O12, wherein X is 0.2 to 0.5. According to the method, a normal-pressure solid-phase sintering method is adopted, the preparation process is simple, used instruments are low in cost and easyin operation, and industrial production is facilitated; although the sintering time is relatively long, the final obtained product is high in density, good in experimental repeatability and high in ionic conductivity. Tantalum of a proper amount and aluminum of a proper amount are codoped, Al plays a role in stabilizing cubical-phase lithium-lanthanum zirconate, and Ta is used for effectively improving the electric conductivity of the lithium-lanthanum zirconate.

Owner:淮安新能源材料技术研究院

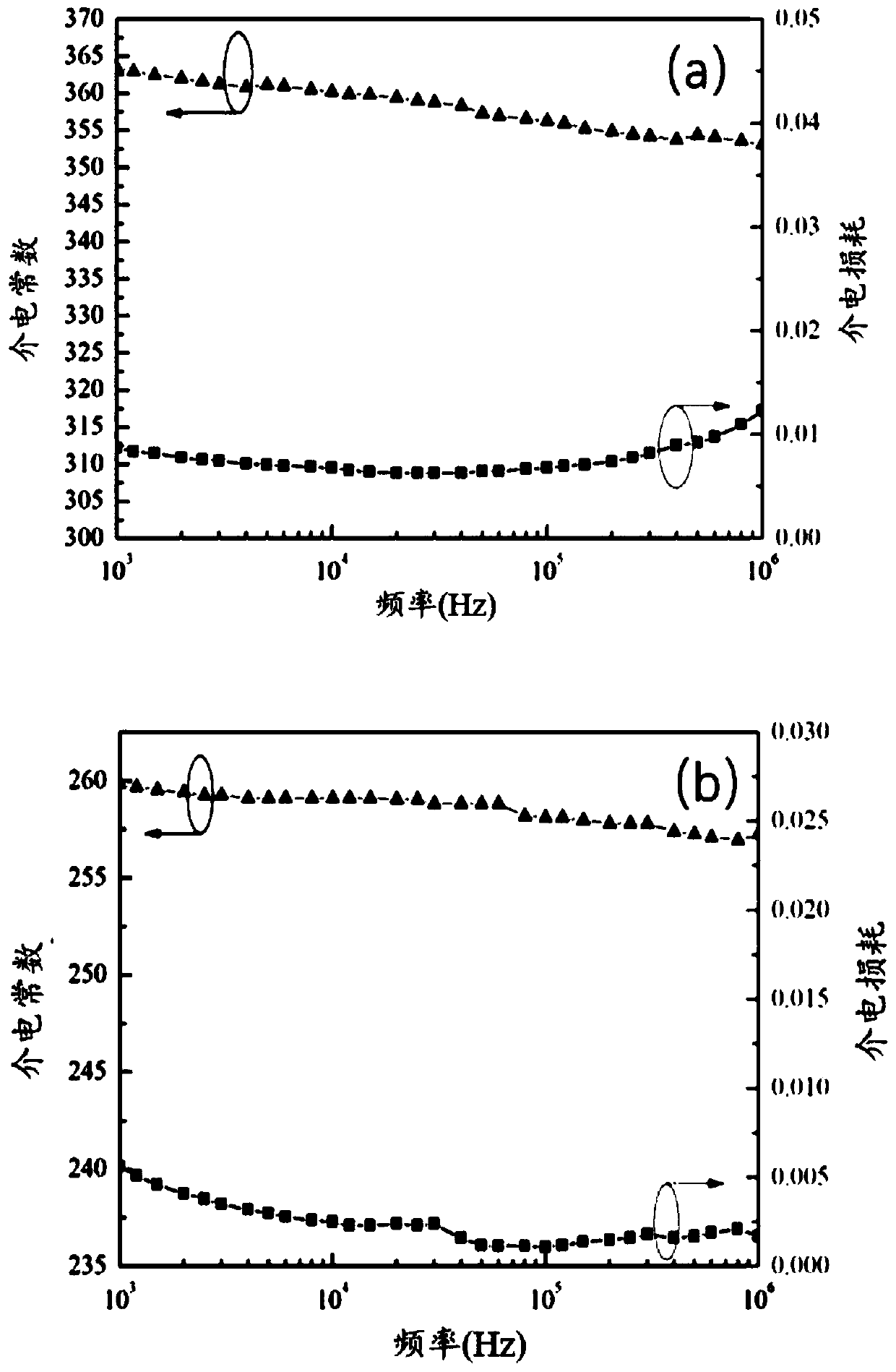

High-tin-content lead lanthanum zirconate titanate stannate thick film ceramic, and preparation method and application thereof

InactiveCN110526707AHigh energy storage densityImprove energy storage efficiencyFixed capacitor dielectricStacked capacitorsPolyvinyl butyralSlurry

The invention belongs to the field of dielectric materials, and discloses high-tin-content lead lanthanum zirconate titanate stannate thick film ceramic, and a preparation method and application thereof. The lead lanthanum zirconate titanate stannate thick film ceramic is Pb<0.97>La<0.02>(Zr<0.46-x>Sn<0.54>Ti<x>)O<3>, wherein x=0.04 to 0.18; and the preparation method includes the steps that PbO,La2O3, ZrO2, SnO2, and TiO2 are subjected to mixed ball milling to obtain powder A; the powder A is dried and sieved to obtain ceramic powder B; the ceramic powder B is pre-fired at 900 to 980 DEG C;then secondary ball milling and drying and sieving are conducted to obtain ceramic powder C; polyoxyethylene octylphenol ether and a solvent are added to the ceramic powder C to be subjected to roll milling to obtain premixed slurry; polyvinyl butyral is added, roll milling is conducted, then the solvent, a binder, and dioctyl phthalate are added and subjected to ball milling to obtain casting slurry; a lead lanthanum zirconate titanate stannate thick film ceramic embryo body is prepared from the casting slurry on a casting machine film belt; and the ceramic embryo body is tape-ranked at 400 to 600 DEG C, and the high-tin-content lead lanthanum zirconate titanate stannate thick film ceramic is prepared through calcination at 1250 to 1300 DEG C.

Owner:GUANGDONG UNIV OF TECH

Strontium-doped lead lanthanum zirconate stannate titanate relaxed anti-ferroelectric thick-film ceramic as well as preparation method and application thereof

InactiveCN111470863AHigh energy storage densityImprove energy storage efficiencyThin/thick film capacitorFixed capacitor dielectricStrontiumEnergy storage efficiency

The invention belongs to the technical field of dielectric materials, and discloses a strontium-doped lead lanthanum zirconate stannate titanate relaxed anti-ferroelectric thick-film ceramic as well as a preparation method and application thereof. The molecular formula of the thick-film ceramic is PbxSryLaz(ZrnSnmTiv)O3, and x is equal to 0.85 to 0.88, y is equal to 0.06 to 0.09, z is equal to 0.06, n is equal to 0.45 to 0.8, m is equal to 0.15 to 0.5, and v is equal to 0.05. The thickness of a strontium-doped lead lanthanum zirconate stannate titanate relaxed anti-ferroelectric thick film prepared by a tape casting process is controllable, the thickness of a single layer is 40-50 microns, and the number of overlapped layers reach 500-1000. The thick-film ceramic is good and uniform in compactness and has a good energy storage performance and energy storage efficiency, the energy storage density of the thick-film ceramic can reach 3.7-3.9 J / cm<3>, the energy storage efficiency of the thick-film ceramic is higher than 89.5%, and the thick-film ceramic has good application prospects in capacitors with zirconium energy storage density.

Owner:GUANGDONG UNIV OF TECH

Lead lanthanum zirconate stannate antiferroelectric ceramic as well as preparation method and application thereof

ActiveCN111393149AHigh energy storage densityImprove energy storage efficiencyChemical industryAdhesiveHigh energy

The invention belongs to the technical field of dielectric materials, and discloses lead lanthanum zirconate stannate antiferroelectric ceramic as well as a preparation method and an application thereof. The molecular formula of the ceramic is Pb0.97La0.02(ZrxSn1-x) O3, x is equal to 0.45-0.6, and the ceramic is prepared by the following steps: mixing PbO, La2O3, ZrO2 and SnO<2> according to a stoichiometric ratio, adding ethanol, and carrying out ball-milling mixing; drying and sieving the ball-milled powder to obtain ceramic powder; pre-sintering the ceramic powder at 880-980 DEG C, then adding the obtained powder into ethanol for secondary ball milling, and then drying and sieving the ball-milled powder to obtain ceramic powder; adding an adhesive into the obtained ceramic powder, uniformly grinding, and pressing into a ceramic green body under the pressure of 8-10MPa; and maintaining the pressure of the ceramic green body at 45-55MPa, discharging glue at 550-600 DEG C, and sintering at 1225-1230 DEG C to obtain the product. The ceramic has high energy storage density and high energy storage efficiency, and can obtain secondary ferroelectric phase change at room temperature.

Owner:GUANGDONG UNIV OF TECH

Lanthanum zirconate-based ceramic granulated powder for atmospheric plasma spraying and preparation method thereof

The invention provides lanthanum zirconate-based ceramic granulated powder for atmospheric plasma spraying and a preparation method thereof. The preparation method comprises the steps that mixed materials with the particle size of 60 nm or below are pressed into blocks, the material point distance among powder particles is reduced, the content of pores is reduced, and the densification is improved; mixed oxide blocks are obtained, and a solid phase reaction in the following sintering process is conducted smoothly and conveniently. In combination of the sintering process, the solid phase reaction of different oxides in the mixed materials is achieved, a lanthanum zirconate-based material is obtained and further crushed, low-speed sanding with low energy consumption is conducted at first, the loss of grinding bodies is reduced, the preliminary refinement of the larger sintered particles after sintering is achieved, and further refinement is facilitated; in combination with high-speed sanding at the second stage, nano-powder is obtained, the dispersion is good, the particle size is even, and the granulation requirements are met. Subsequently, in strict accordance with a defined granulation mode, the ceramic granulated powder meeting APS requirements is obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

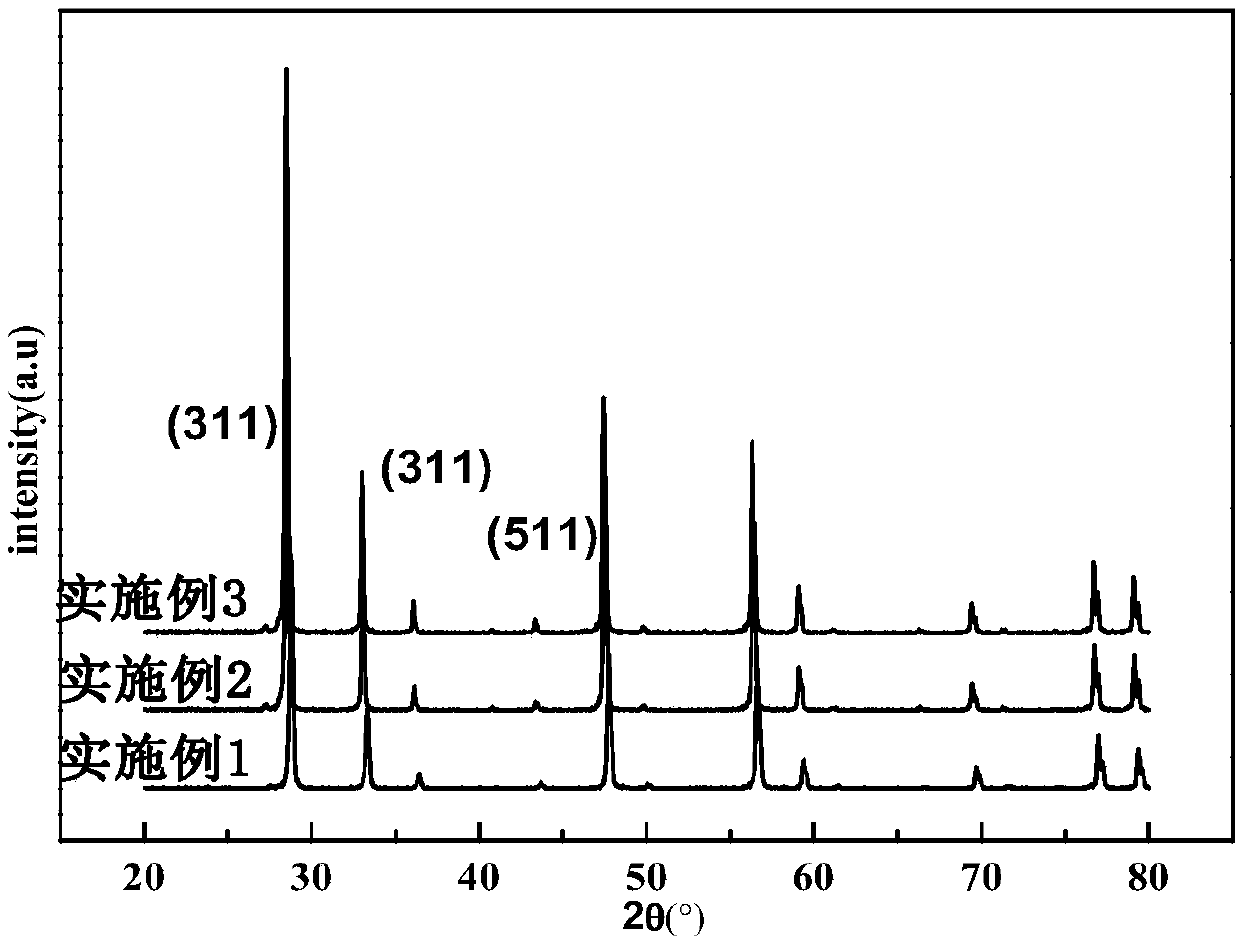

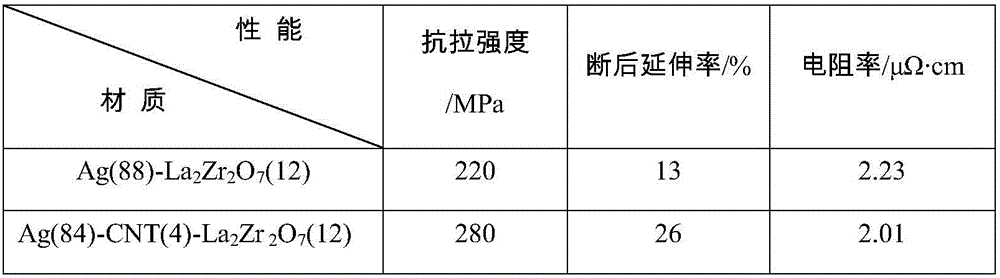

Method for preparing silver carbon nanotube and lanthanum zirconate composite electric contact material

ActiveCN105970015AImprove electrical performanceThe synthesis process is simpleContactsCarbon nanotubeElectron

The invention relates to the material preparation technology of electronic components, and aims to provide a method for preparing a silver carbon nanotube and lanthanum zirconate composite electric contact material. The method comprises the following steps: taking zirconium nitrate and lanthanum nitrate which have the equal molar ratio, and preparing a mixed solution with deionized water; adjusting the pH value with an ammonia water solution after adding citric acid, and settling and drying to obtain powder after stirring; grinding, sieving and sintering to obtain lanthanum zirconate nano-powder; matching and mixing lanthanum zirconate nano-powder, carbon nanotube powder and silver powder; drying and sieving after ball milling to obtain composite powder of a silver-based electric contact material; performing hot-press molding to obtain briquets; and performing hot extrusion treatment on the briquets to obtain the molded silver carbon nanotube and lanthanum zirconate composite electric contact material. The method is simple in synthetic process and stable in performance, can improve the plastic processibility and electric conductivity of the electric contact material, and guarantees the excellent overall performance of the electric contact material while reducing the consumption of Ag.

Owner:ZHEJIANG UNIV

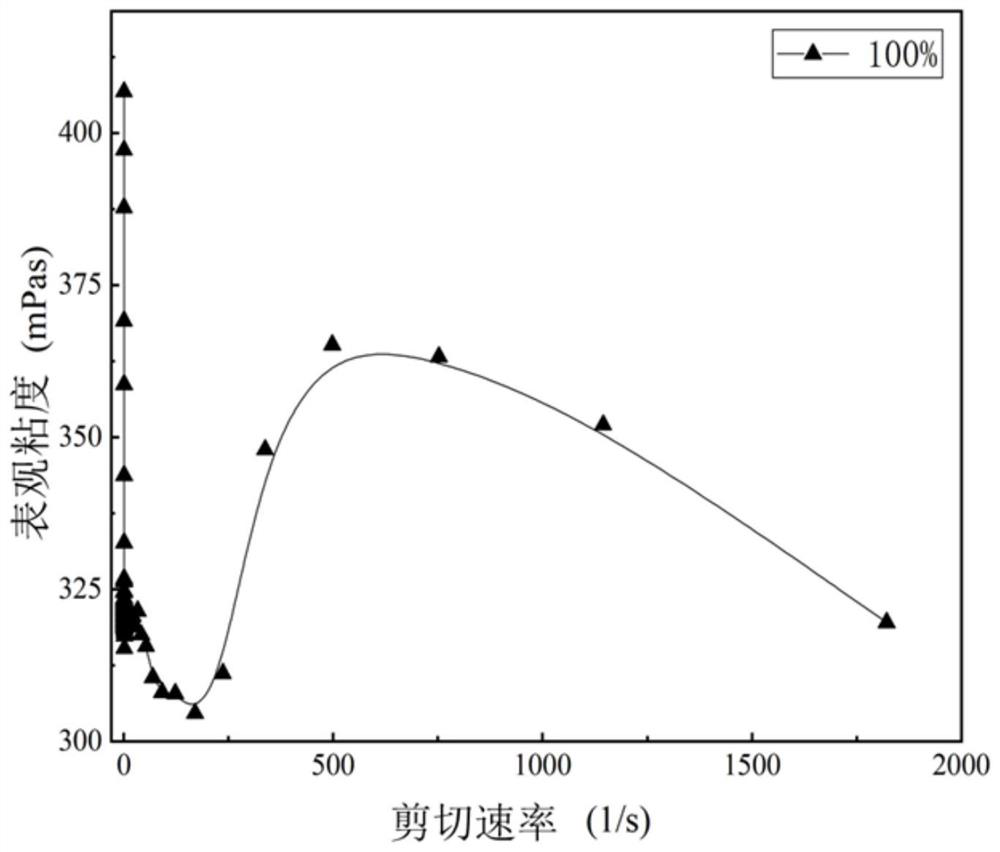

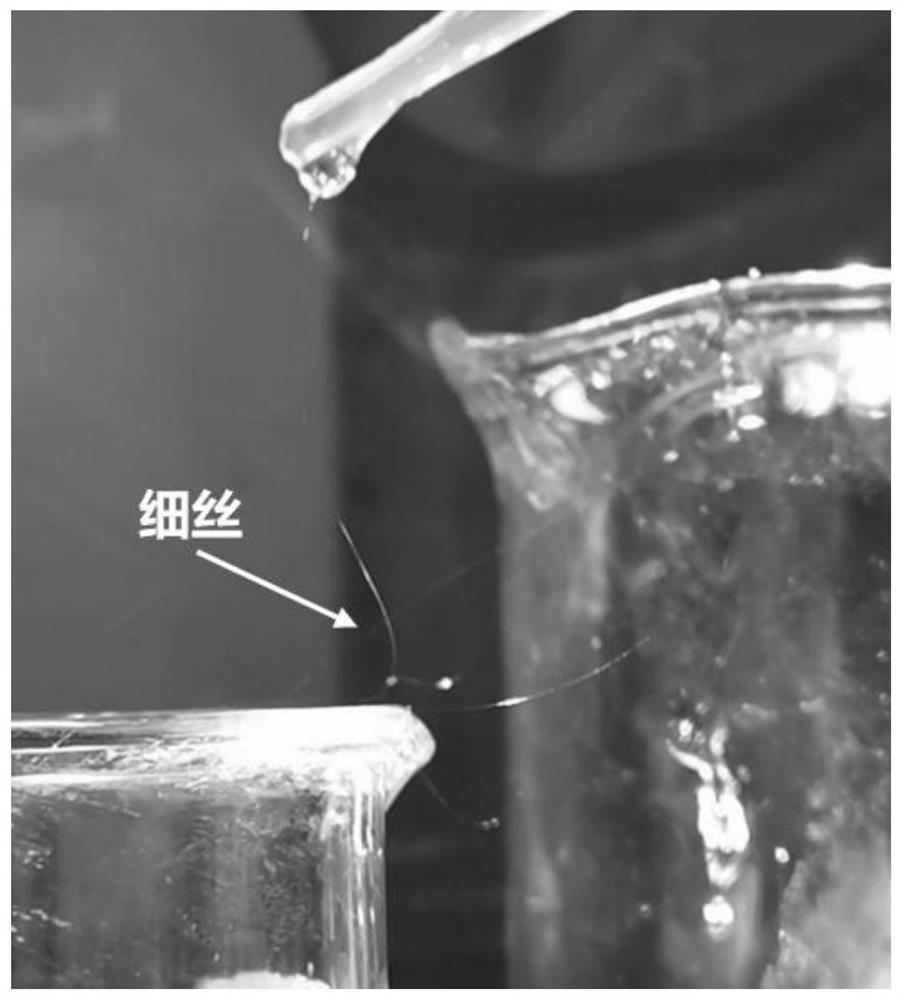

Preparation methods and application of lanthanum complex precursor, lanthanum oxide fiber and lanthanum zirconate fiber derived from lanthanum oxide fiber

ActiveCN113087729AReal-time drawingImprove spinnabilityOther chemical processesGroup 3/13 organic compounds without C-metal linkagesFiberSpinning

The invention relates to preparation methods and application of a lanthanum complex precursor, a lanthanum oxide fiber and a lanthanum zirconate fiber derived from the lanthanum oxide fiber. The precursors of the two fibers can be drawn in real time under the condition that no polymer spinning aid is added. For the lanthanum oxide fiber precursor, a precursor capable of being drawn in real time is obtained by taking a lanthanum source and a carboxylic acid ligand as raw materials; and the lanthanum zirconate fiber precursor is obtained by adding a certain proportion of a poly-zirconium precursor on the basis of the lanthanum oxide precursor. The lanthanum oxide and lanthanum zirconate fibers of 0.5-2 [mu]m can be prepared from spinning solutions prepared from the two precursors in an electrospinning mode respectively. The key point of the invention lies in the preparation of the lanthanum zirconate fiber precursor: while the high-spinnability lanthanum zirconate precursor is obtained, the simplicity of the preparation method is ensured, and the method has reference significance for synthesis of other rare earth oxides and zirconate spinnable precursors thereof and preparation of corresponding fibers, and is beneficial to promotion of wide application of the zirconate fiber.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com