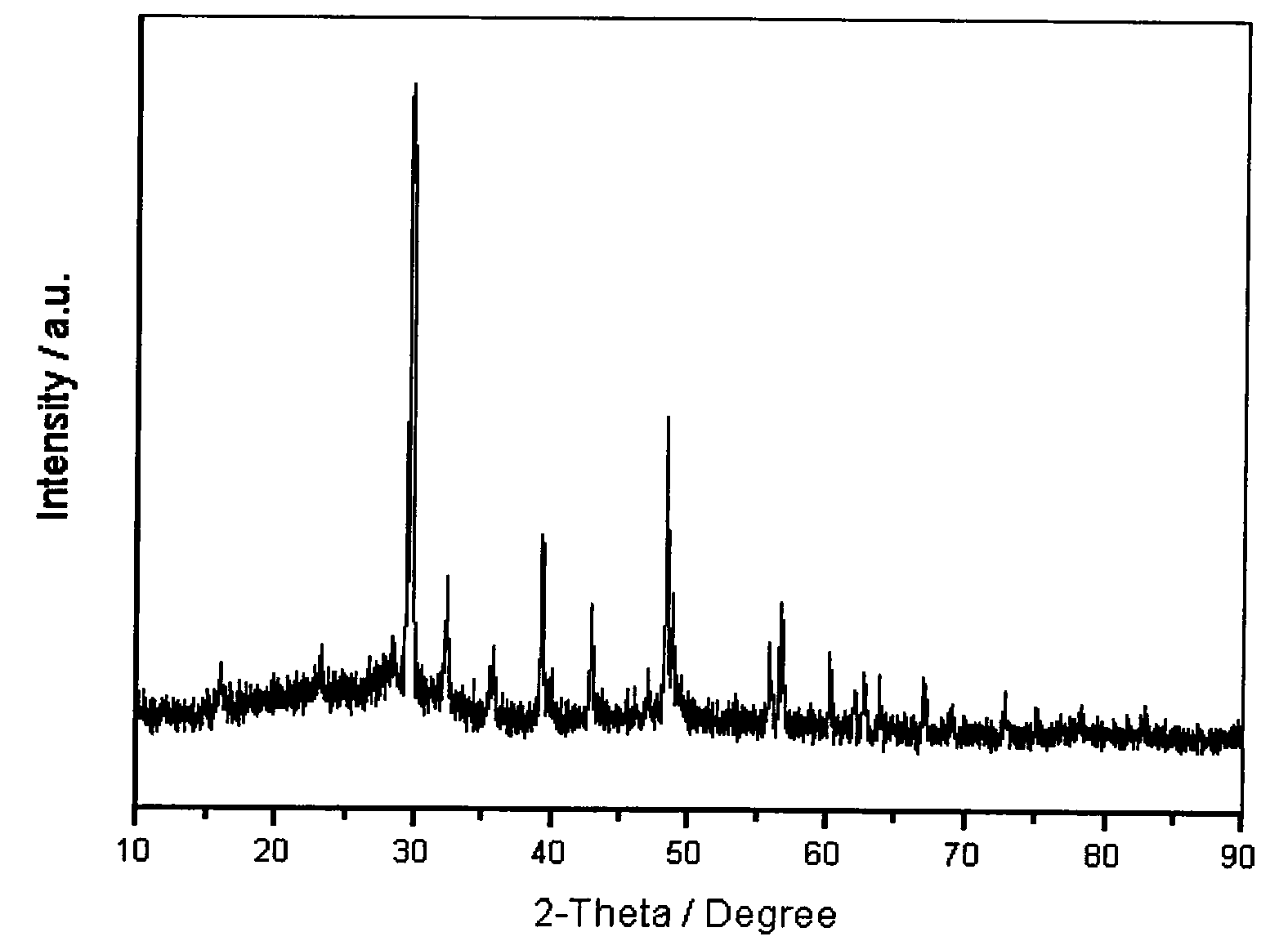

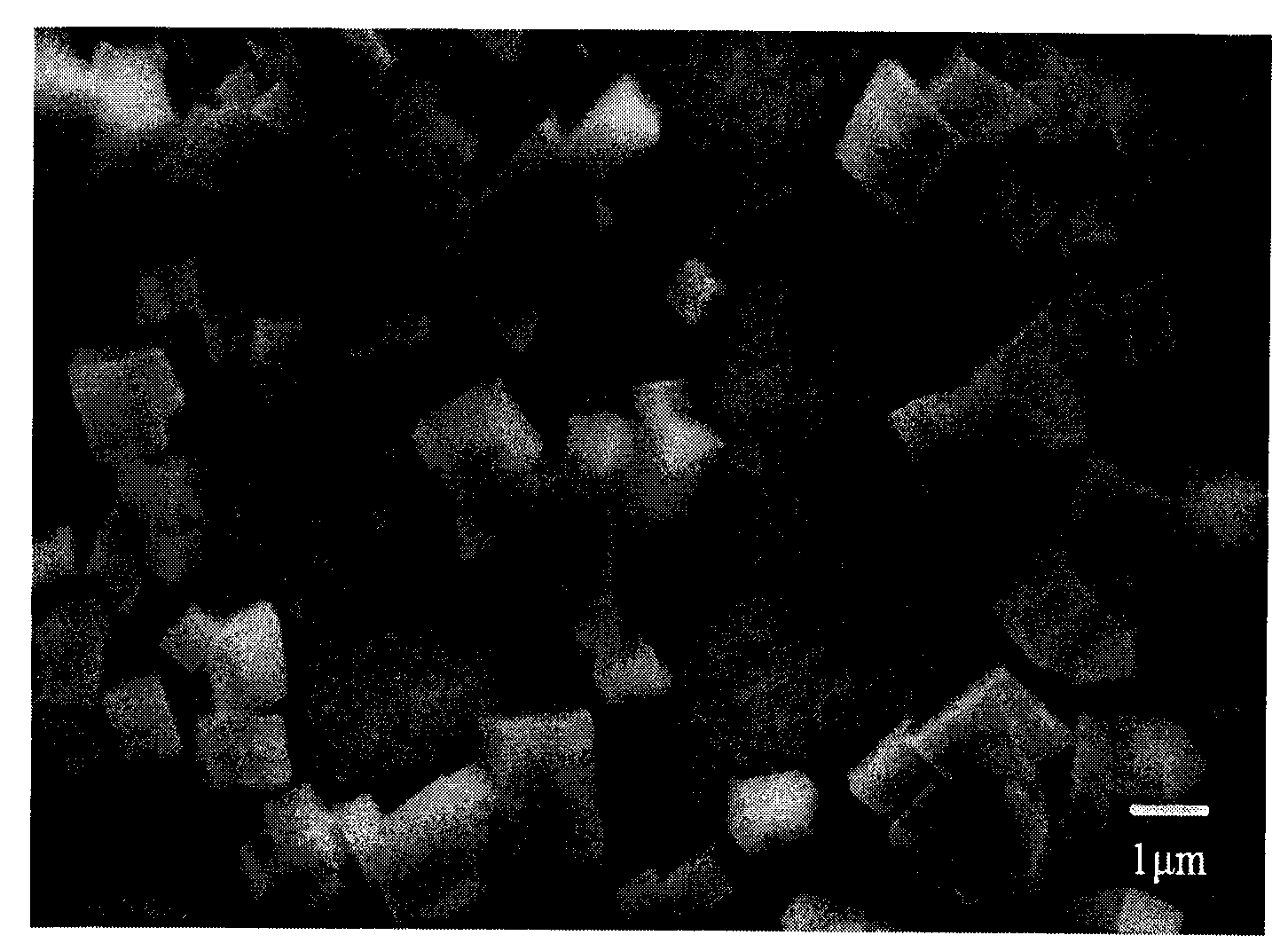

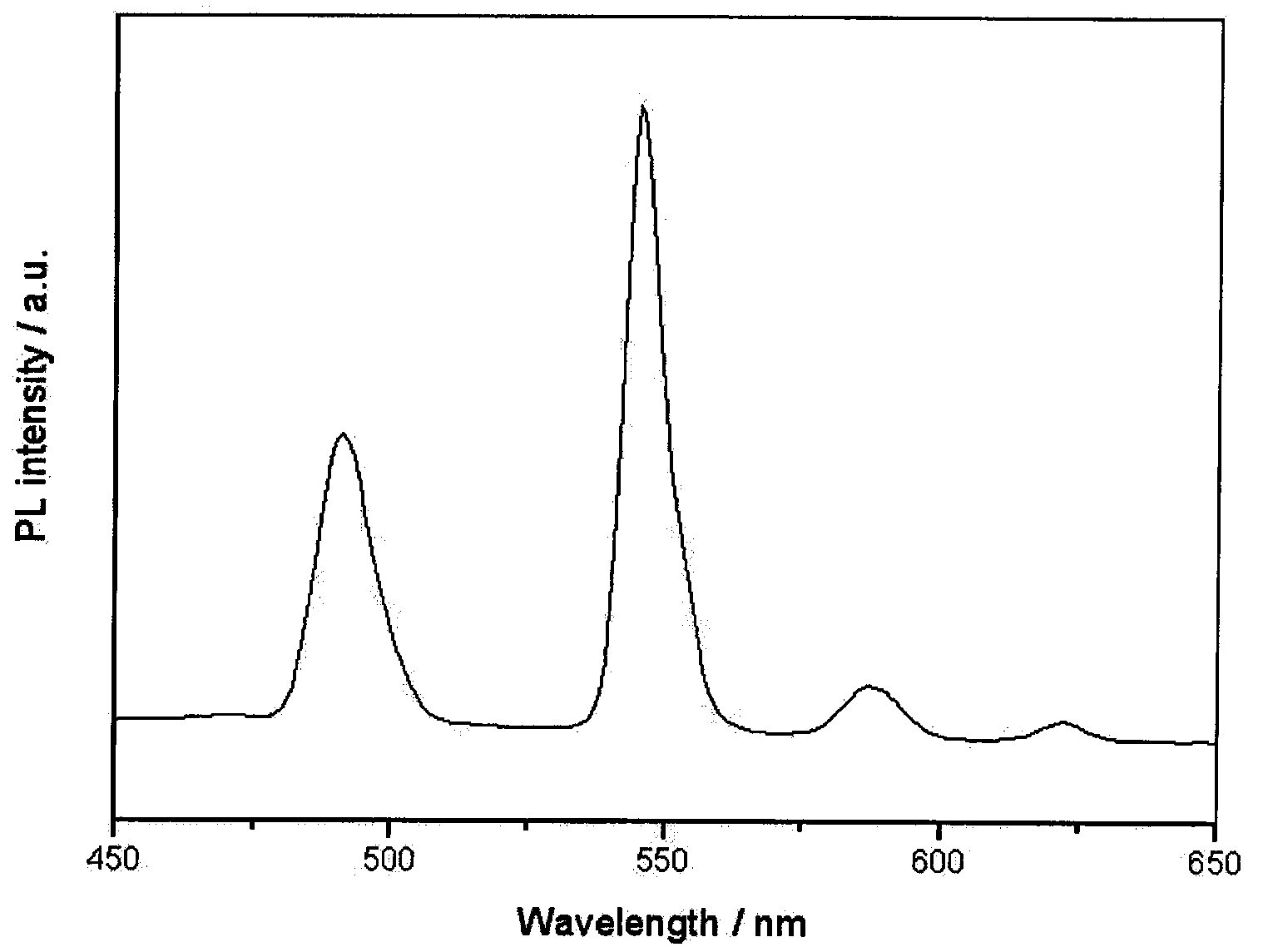

Method for preparing cubic shape green luminescent material of lanthanum zirconate doped with cerium and terbium

A luminescent material, lanthanum zirconate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of single research and less hydrothermal synthesis, and achieve the effect of lowering the synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Get 1.1691 grams of lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 0.0651 grams of cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), 0.068 grams of terbium nitrate (Tb(NO 3 ) 3 ·6H 2 O) be dissolved in 40 milliliters of deionized water, the molar concentration of lanthanum nitrate, cerium nitrate, terbium nitrate is respectively 0.0675 mole / liter, 0.0038 mole / liter, 0.0038 mole / liter; Add PVP (polyvinylpyrrolidone K30) in above-mentioned solution 0.1 g, the mass percent concentration of PVP is 0.25%, and stirred. Get 0.465 milliliters of zirconium acetate (Qingda Fine Chemical Industry, Yutai County) and dissolve in 40 milliliters of deionized water, the molar concentration of zirconium acetate is 0.079 mol / liter, add 40 milliliters of zirconium acetate solution dropwise to above-mentioned nitrate mixed solution, stir. Sodium hydroxide was added dropwise to the above mixed solution under stirring until no white precipitate was formed. The pH of the solution was adjusted to 6, an...

Embodiment 2

[0022] Get 1.5761 grams of lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 0.01736 grams of cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), 0.1450 grams of terbium nitrate (Tb(NO 3 ) 3 ·6H 2 O) be dissolved in 40 milliliters of deionized water, lanthanum nitrate, cerium nitrate, terbium nitrate molar concentration are respectively 0.1 mole / liter, 0.001 mole / liter, 0.008 mole / liter; Add PVP (polyvinylpyrrolidone K30) 0.2 in the above-mentioned solution gram, the mass percent concentration of PVP is 0.5%, and stirred. Get 0.66 milliliters of zirconium acetate (Qingda Fine Chemical Industry Co., Ltd., Yutai County) and dissolve it in 40 milliliters of deionized water. The molar concentration of zirconium acetate is 0.113 mol / liter. Add 40 milliliters of zirconium acetate solution to the above-mentioned nitrate mixed solution dropwise, and stir. Sodium hydroxide was added dropwise to the above mixed solution under stirring until no white precipitate was formed. The pH of the solution was ...

Embodiment 3

[0024] Get 3.464 grams of lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 0.0771 grams of cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O), 0.3221 grams of terbium nitrate (Tb(NO 3 ) 3 ·6H 2 O) be dissolved in 40 milliliters of deionized water, the molar concentrations of lanthanum nitrate, cerium nitrate, and terbium nitrate are respectively 0.2 mol / liter, 0.004 mol / liter, 0.017 mol / liter; in the above-mentioned solution, add PVP (polyvinylpyrrolidone K30) 0.4 gram, the mass percent concentration of PVP is 1%, and stirred. Get 1.32 milliliters of zirconium acetate (Yutai Qingda Fine Chemicals) and dissolve it in 40 milliliters of deionized water, the molar concentration of zirconium acetate is 0.225 mol / liter, add 40 milliliters of zirconium acetate solution to the above-mentioned nitrate mixed solution dropwise, and stir. Sodium hydroxide was added dropwise to the above mixed solution under stirring until no white precipitate was formed. The pH of the solution was adjusted to 9, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com