Patents

Literature

48results about How to "Low content requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

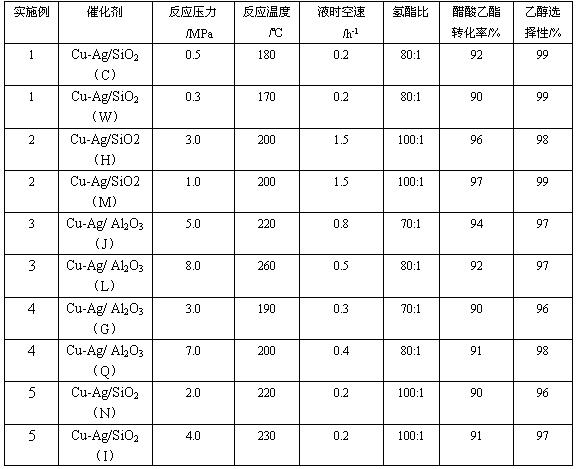

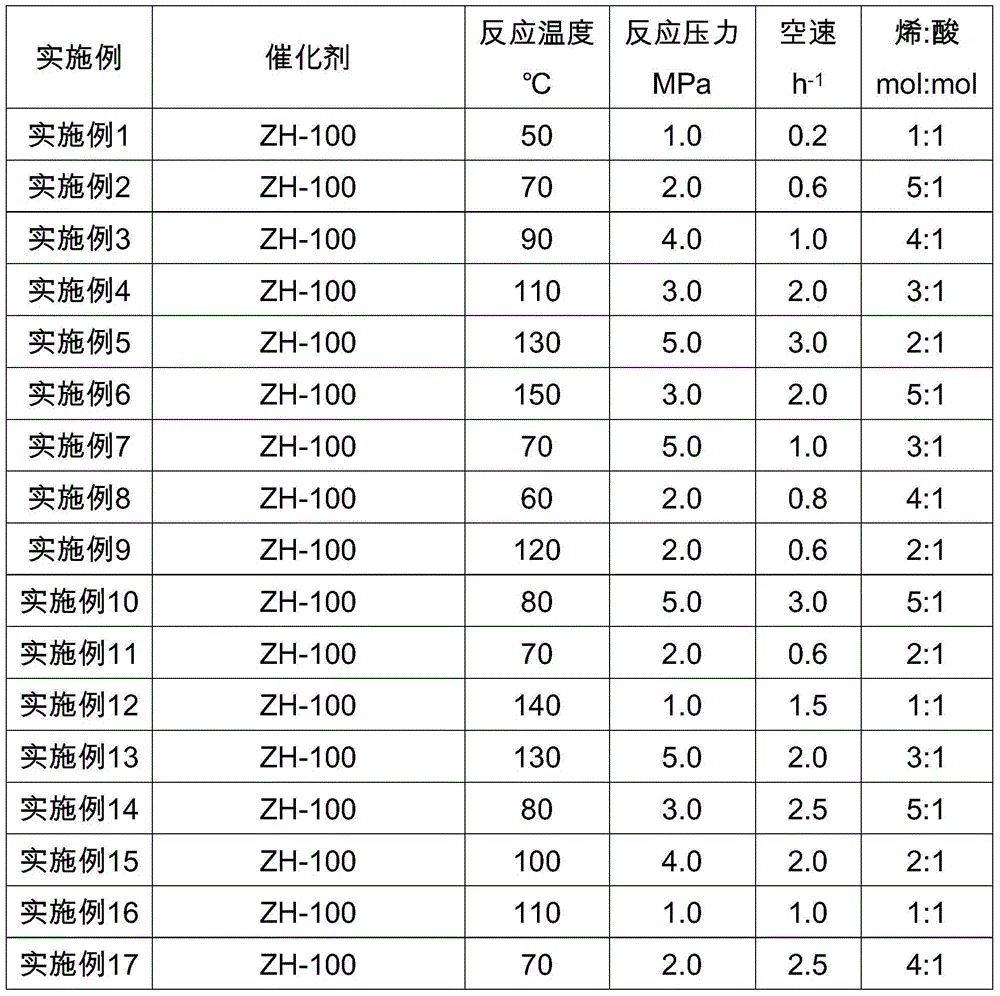

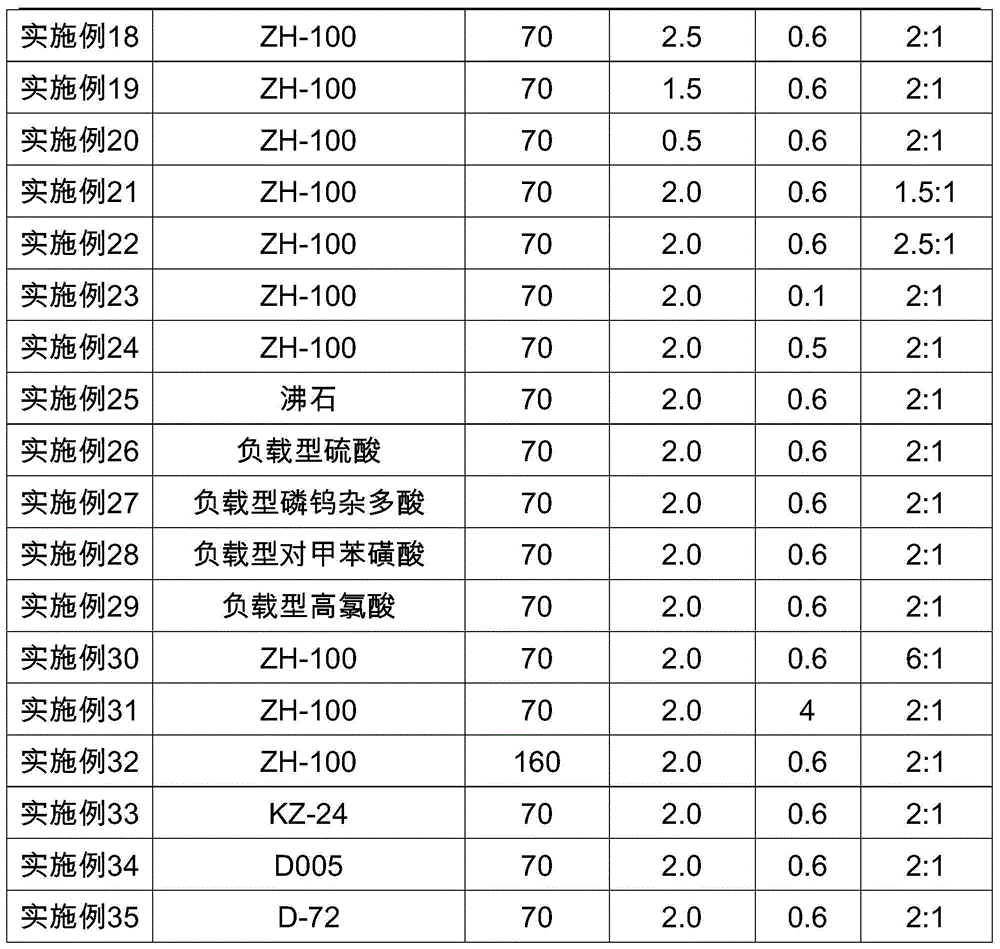

Method for preparing ethanol by hydrogenation of acetic ester

ActiveCN102093162AHigh activityImprove stabilityOrganic compound preparationHydroxy compound preparationReaction temperatureBULK ACTIVE INGREDIENT

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

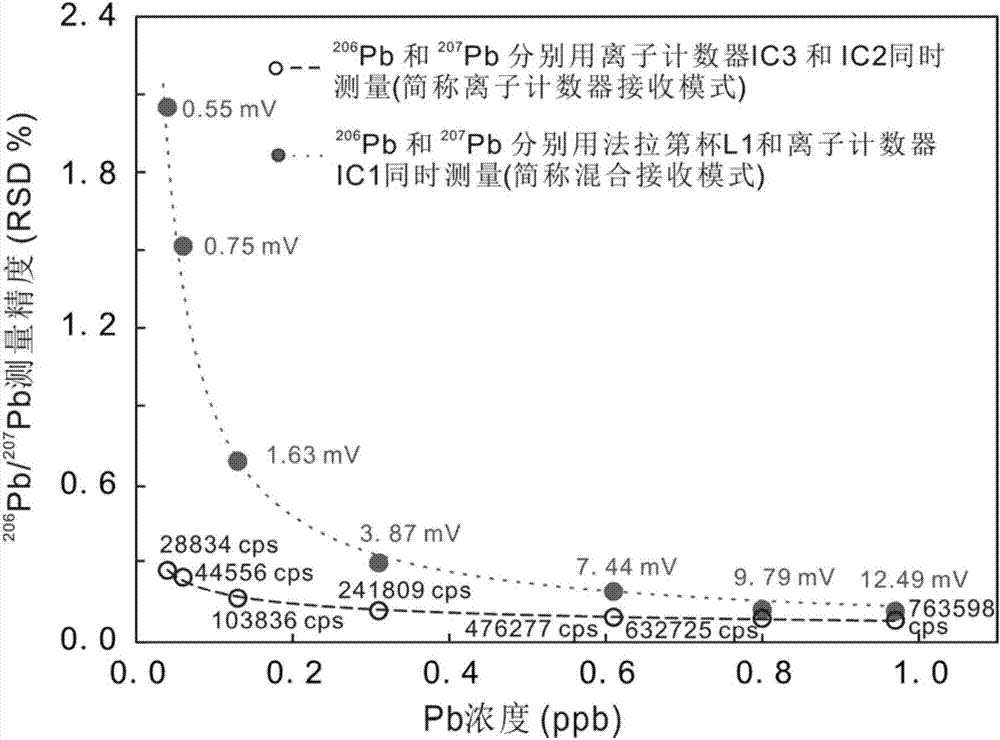

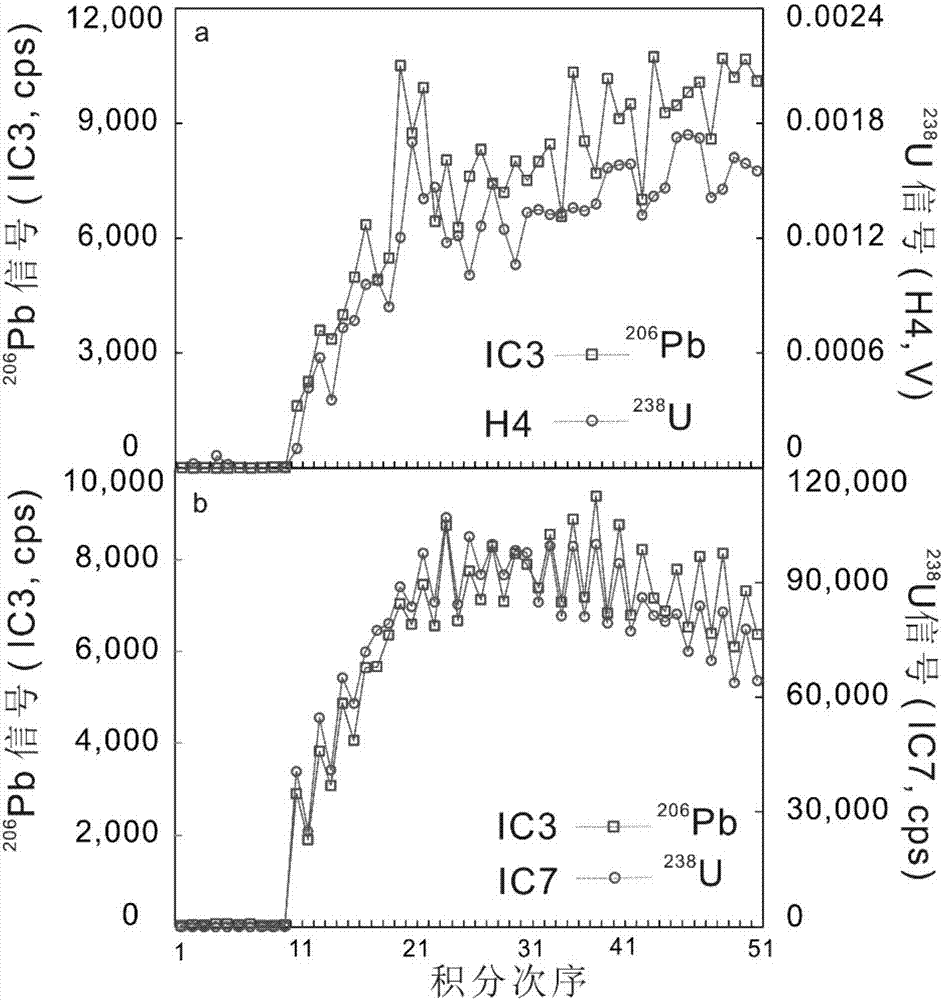

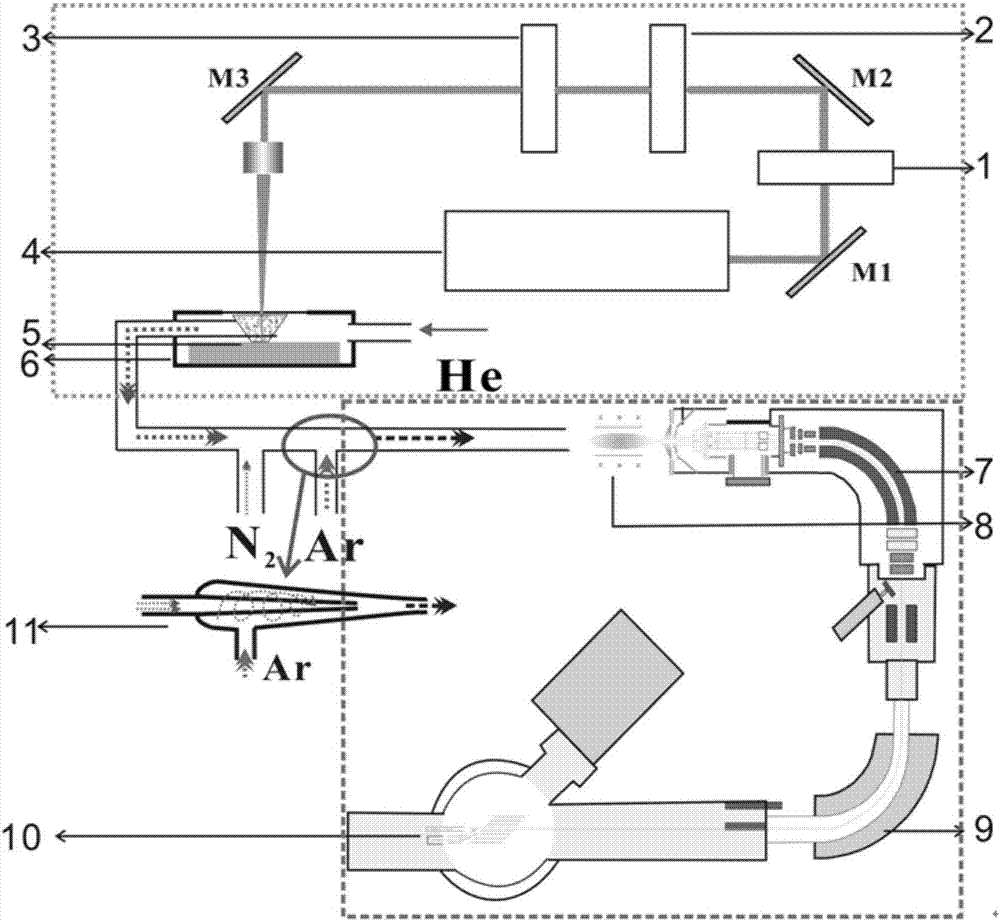

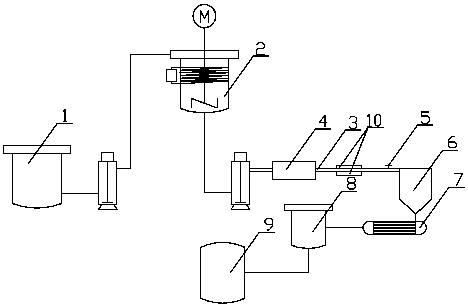

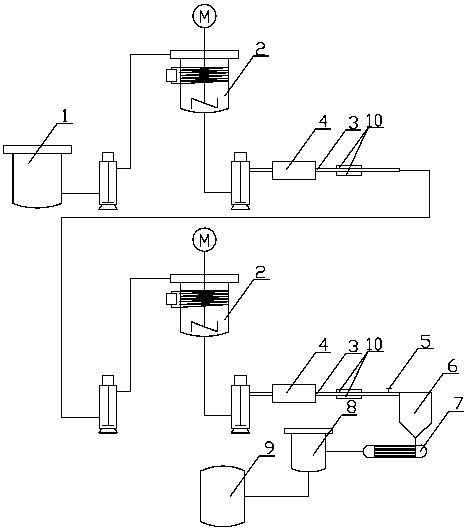

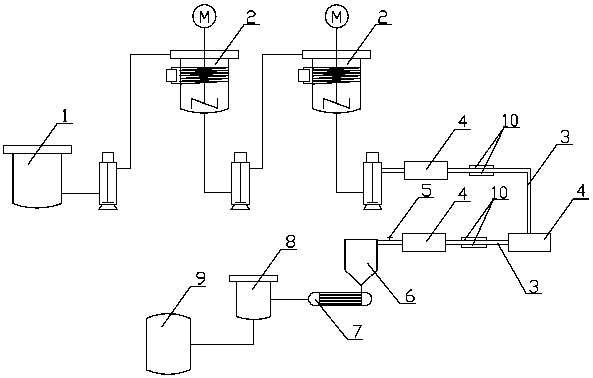

Method for determining U-Pb age of zircon sample

InactiveCN106908510AAdvantages of measurement accuracyImprove spatial resolutionMaterial analysis by electric/magnetic meansSpectrographMass analyzer

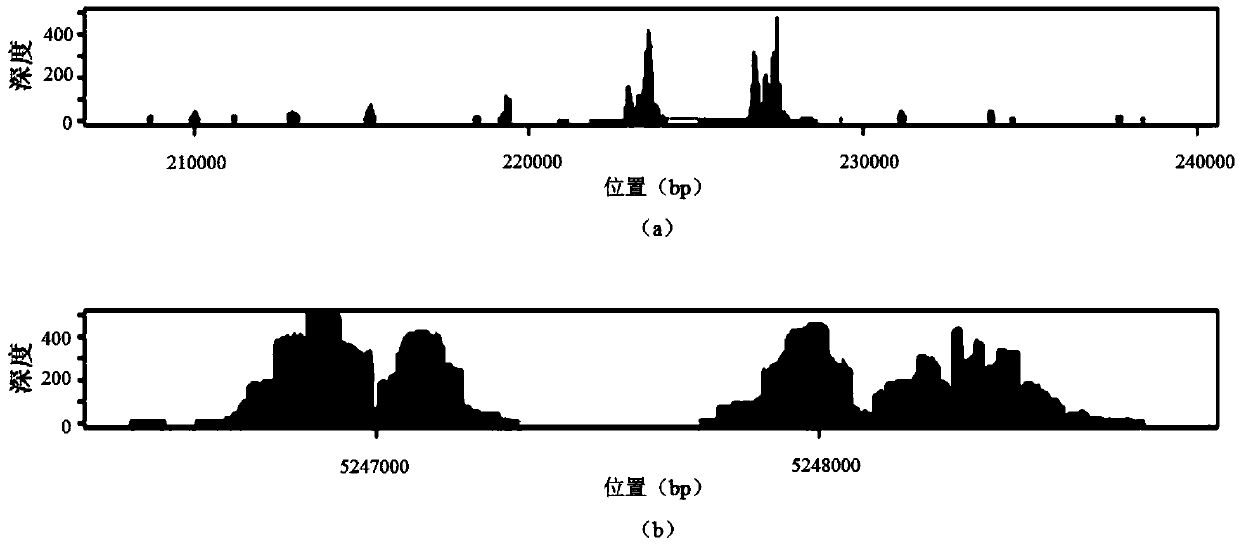

The invention discloses a method for determining the U-Pb age of a zircon sample. The method comprises the steps as follows: the zircon sample and a standard substance are made into a sample target; solid sol is obtained through laser ablation; the solid sol is loaded in a multi-receiving inductive coupled plasma mass spectrograph ion source (plasma) for ionization, and primary ions are obtained; the primary ions pass through an electric field and a magnetic field of a mass spectrograph to realize dual-focusing of energy and direction and arrive at an ion detection system; the original U-Pb ratio of the primary ions of the zircon sample and the zircon standard substance is detected and calculated; the original U-Pb ratio of the zircon sample is corrected by using the standard U-Pb ratio of zircon, and the corrected U-Pb ratio of the zircon sample is obtained; the U-Pb age of the zircon sample is calculated by using the corrected U-Pb ratio. The method has high precision and high sensitivity, has the low sample content requirement, has small ablation depth, and can be used for spatial high-resolution U-Pb age determination of zircon with the ablation diameter smaller than 10 mum.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

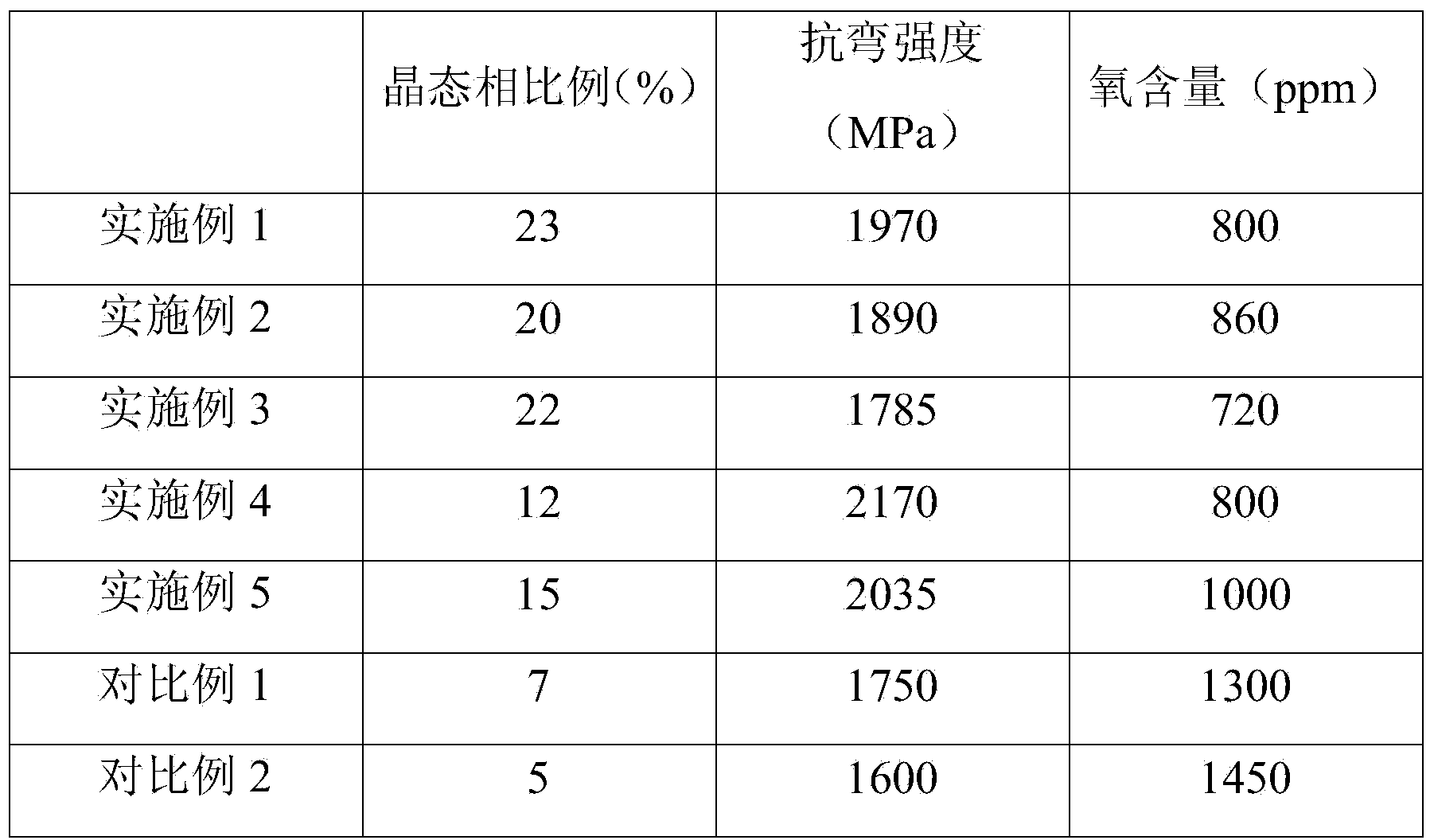

Zirconium-based amorphous alloy and preparation method thereof

ActiveCN103484800ALow preparation requirementsOverall performance will not be affectedMetallic materialsCritical dimension

Owner:METASTABLE TECH INVESTMENT CO LTD

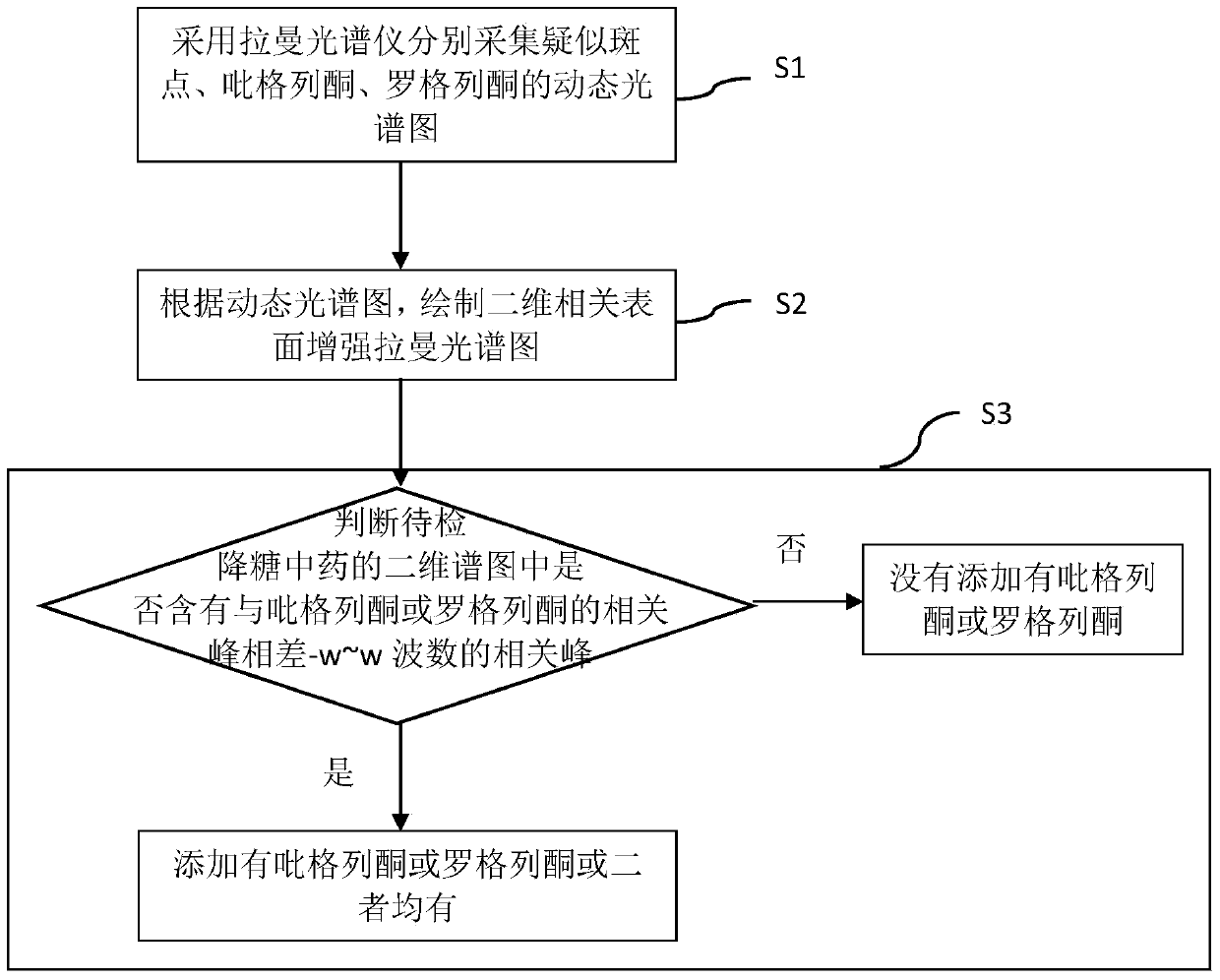

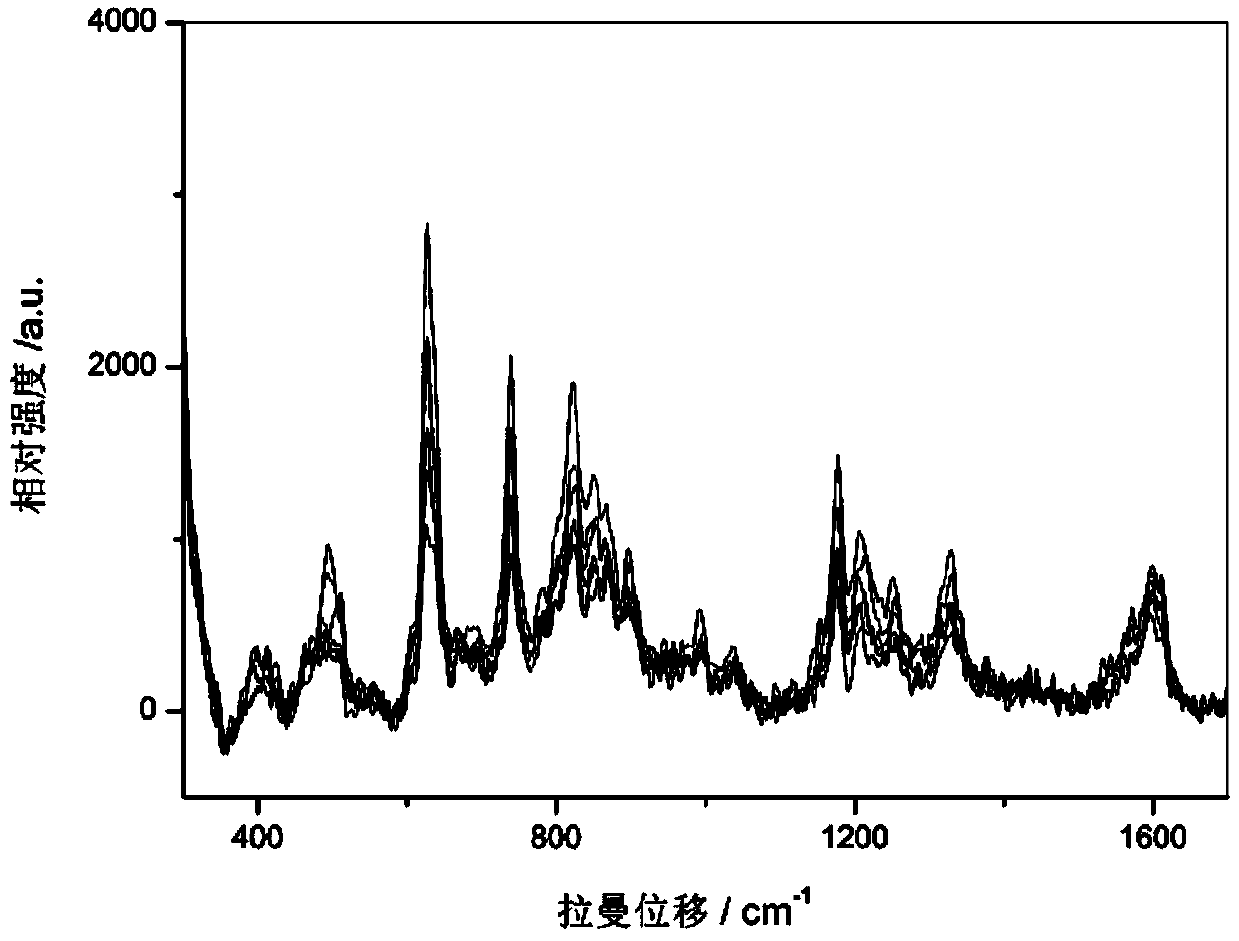

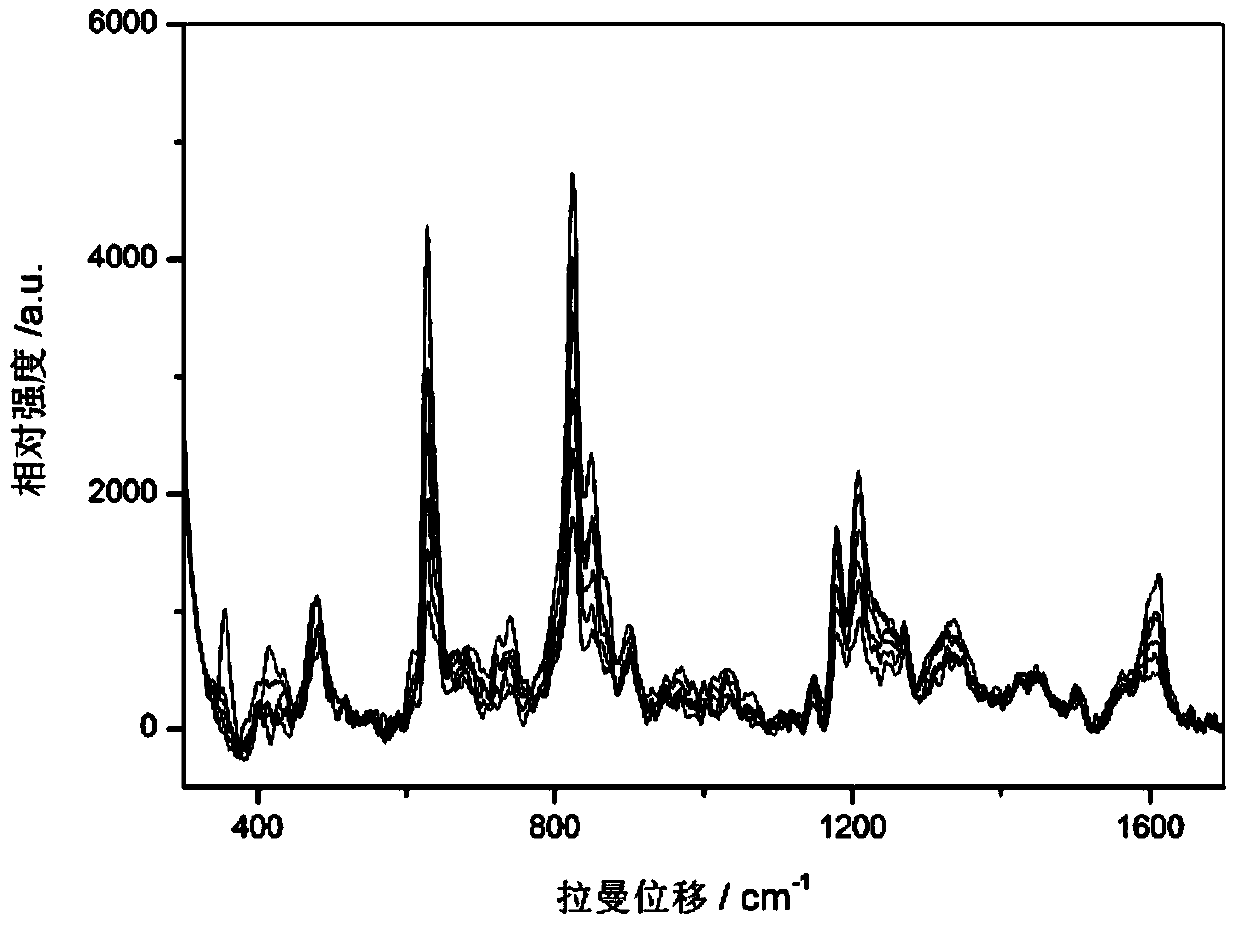

Method for identifying whether blood-glucose-lowering traditional Chinese medicine contains pioglitazone or rosiglitazone or not

ActiveCN103954608ARapid identificationQuick judgmentRaman scatteringSurface-enhanced Raman spectroscopyGlucose lowering

The invention provides a method for identifying whether a blood-glucose-lowering traditional Chinese medicine contains pioglitazone or rosiglitazone or not. The method comprises the following steps: carrying out thin layer chromatography on a blood-glucose-lowering traditional Chinese medicine to be detected; finding a suspected spot at a corresponding Rf value part of the pioglitazone and the rosiglitazone. The method is characterized by further comprising the following three steps: 1, collecting a series of one-dimensional surface enhanced Raman spectrums of the suspected spot to obtain a dynamic spectrum pattern of the blood-glucose-lowering traditional Chinese medicine to be detected; 2, pre-treating the dynamic spectrum pattern and drawing to obtain a two-dimensional correlation surface enhanced Raman spectrum of the blood-glucose-lowering traditional Chinese medicine to be detected; 3, judging whether the blood-glucose-lowering traditional Chinese medicine contains the pioglitazone or the rosiglitazone or not according to the two-dimensional correlation surface enhanced Raman spectrum of the blood-glucose-lowering traditional Chinese medicine to be detected. According to the technical scheme provided by the invention, whether the blood-glucose-lowering traditional Chinese medicine contains the pioglitazone or the rosiglitazone or not can be identified rapidly; the detection result is accurate and reliable, the cost is low and the operation is convenient.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

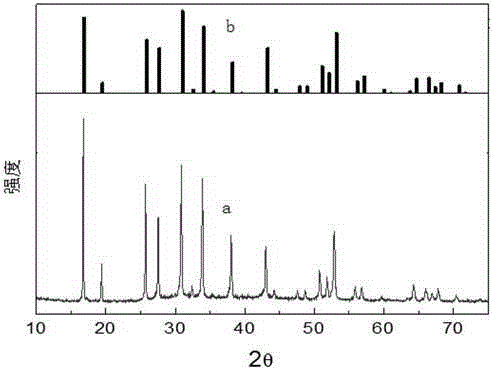

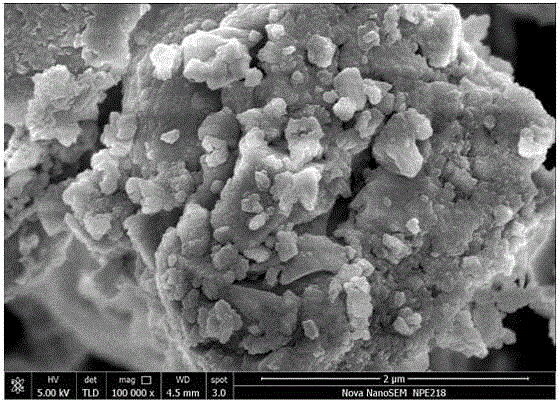

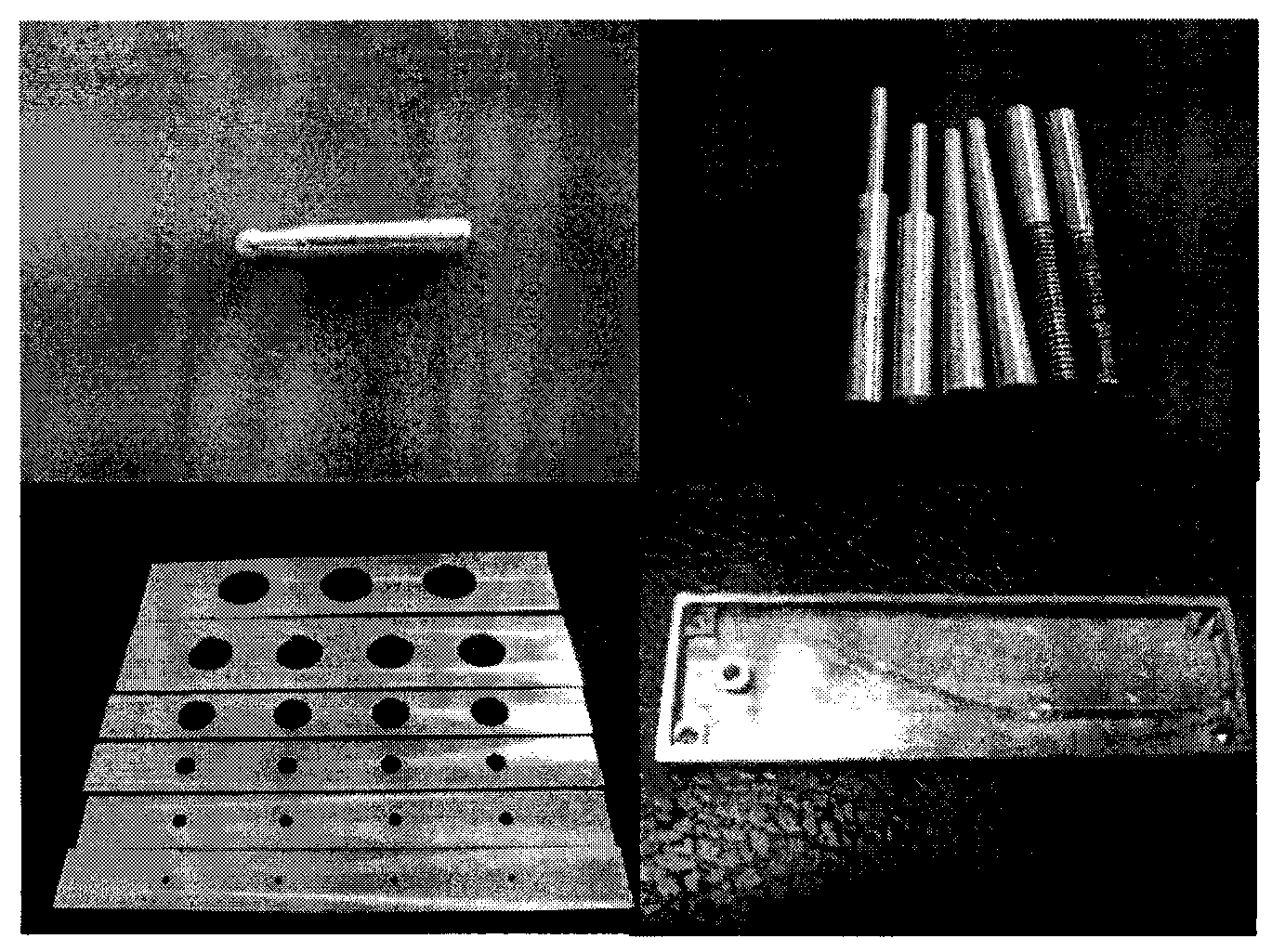

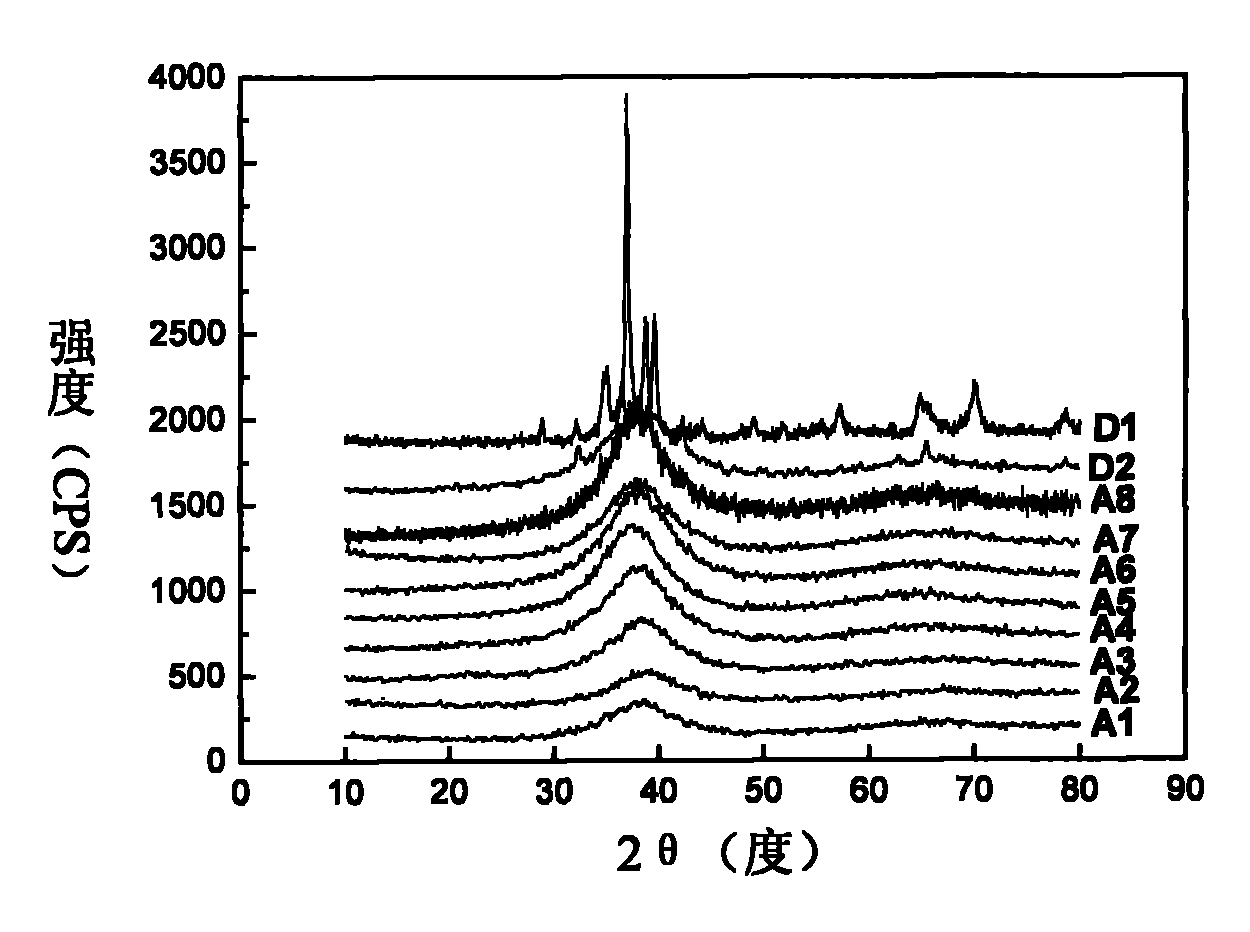

Tantalum-doped cubic garnet structure Li7La3Zr2-xTaxO12 material and preparation method thereof

ActiveCN105244536AReduce high temperature lossLow content requirementSolid electrolytesSecondary cellsLithiumPhysical chemistry

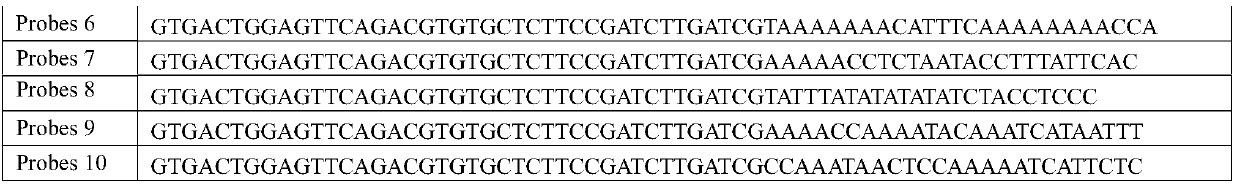

The invention discloses a tantalum-doped cubic garnet structure Li7La3Zr2-xTaxO12 material and a preparation method thereof. The preparation method comprises the steps that 1, lanthanum zirconate, a lanthanum source, a lithium source and a doped element being a tantalum source are weighed; the materials are placed in a container successively, a complexing agent is added into the container, and then stirring is performed for 4-6 h; 2, the temperature is gradually increased to 80 DEG C and kept till excessive moisture is removed, and a precursor processed in a high-temperature solid-phase mode is obtained; 3, the precursor is preheated for 3-5 h at the temperature of 400 DEG C, and a product is taken out, sufficiently and evenly ground and roasted for 1.5-5 h at the temperature of 900 DEG C to obtain a primary roasted product, wherein the value of x is 0.25-0.6. The method is simple in process, the requirement for the content of the doped materials is lowered, energy consumption and lithium high-temperature losses are reduced in the preparation process due to the fact that the roasting time is shortened, energy is saved, the cost is greatly reduced, and the preparation method is quite suitable for large-scale production.

Owner:SHANGHAI POWER ENERGY STORAGE BATTERY SYST ENG TECH +1

Curing agent for treatment of electroplating sludge, and preparation method and application method thereof

The invention relates to a curing agent for treatment of electroplating sludge. The curing agent comprises the following raw materials in percentage by weight: 75%-79% of cement, 10%-15% of sands, 5%-8% of sodium silicate and 6%-10% of activated aluminium oxide; the invention further discloses a preparation method and an application method of the curing agent. The curing agent has a wide application range, and overcomes potential hazards due to secondary environmental pollution of electroplating heavy metal sludge.

Owner:湖南中车环境工程有限公司

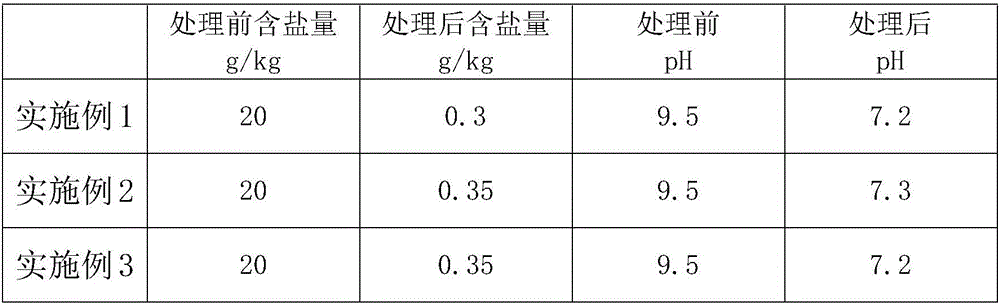

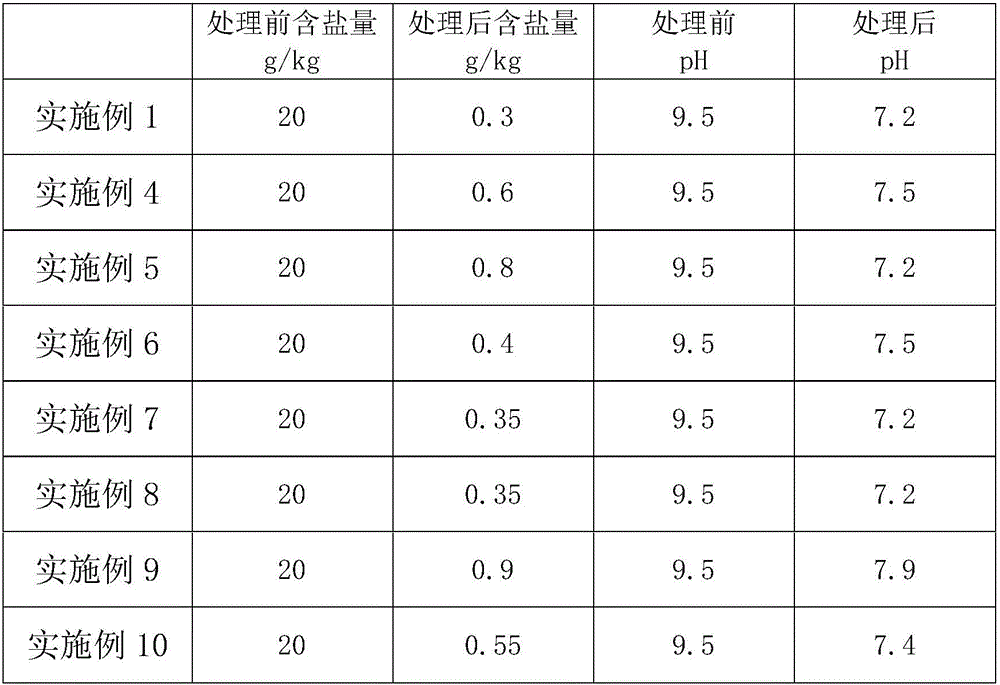

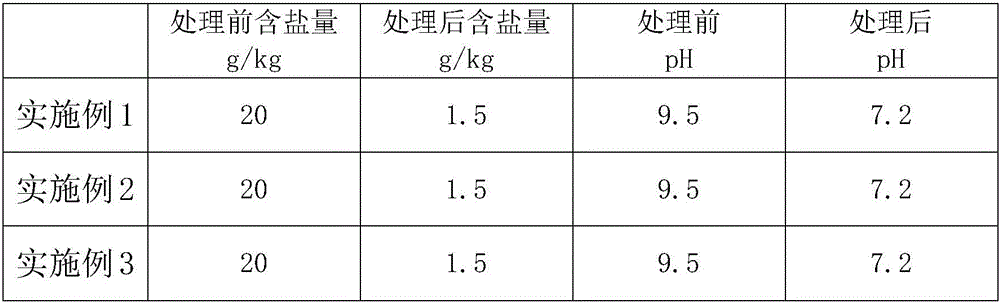

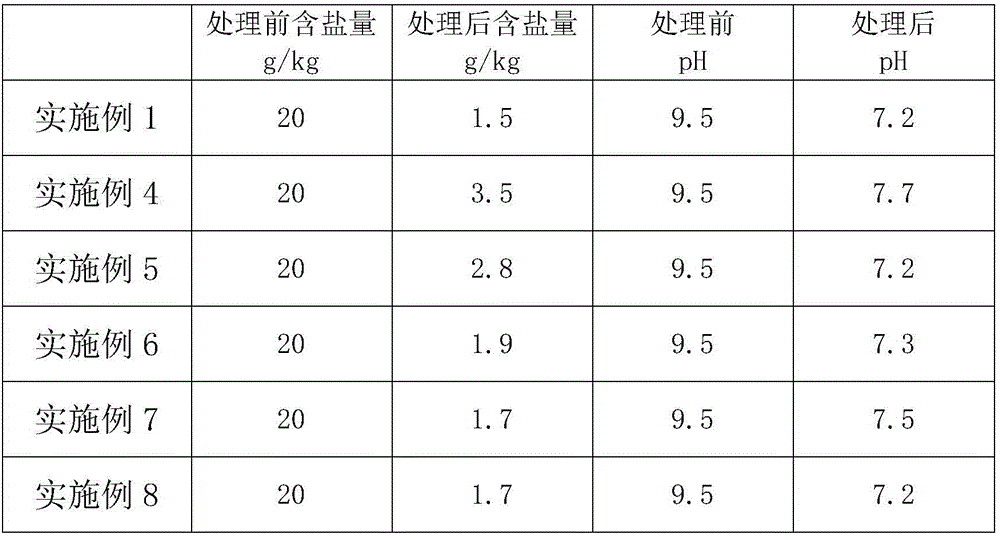

Microorganism improvement method for heavily salinized soil

InactiveCN106187585AImprove the growing environmentImprove survival rateExcrement fertilisersBioloigcal waste fertilisersAlkalinityEconomic benefits

The invention provides a microorganism improvement method for heavily salinized soil. The microorganism improvement method has the advantages that microorganism improvement and concealed-conduit salt elimination are combined according to the characteristics of the heavily salinized soil, namely high salinity, high alkalinity and non-suitability for crop growth, seedlings resistant to salt and alkali are planted, rice is planted after the seedlings are mature, and the salt is eliminated gradually, so that soil is improved, cost is reduced greatly, economic benefit is improved, and generally, after 5-7 years, the heavily salinized soil can be improved into fertile land.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

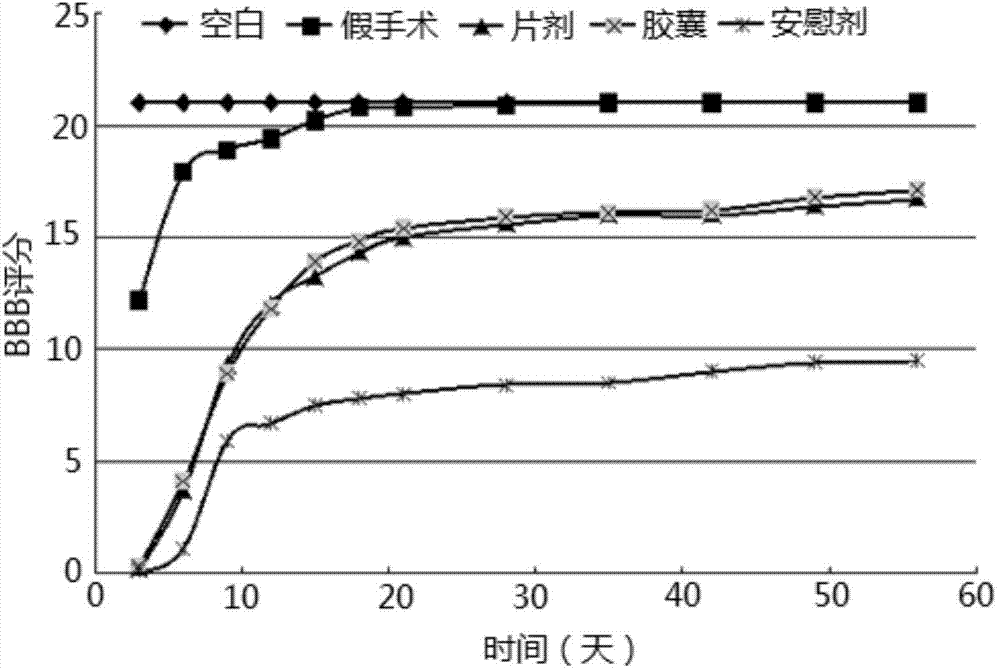

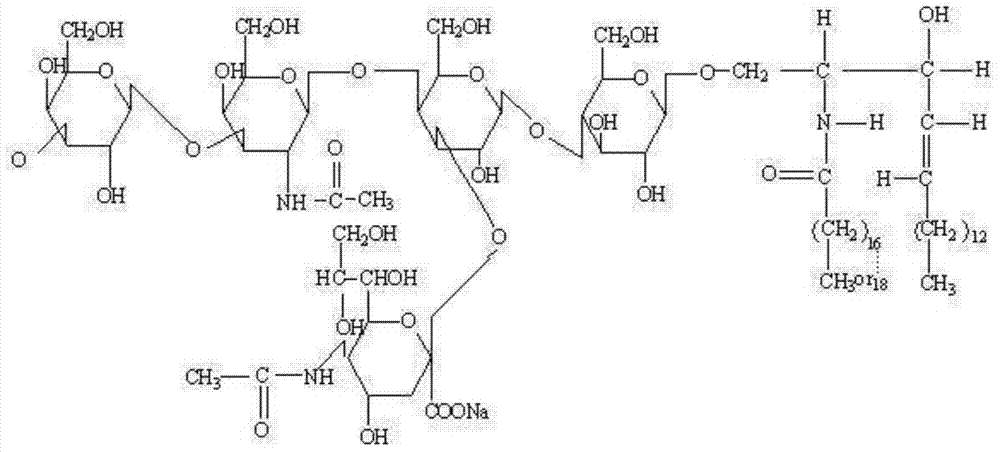

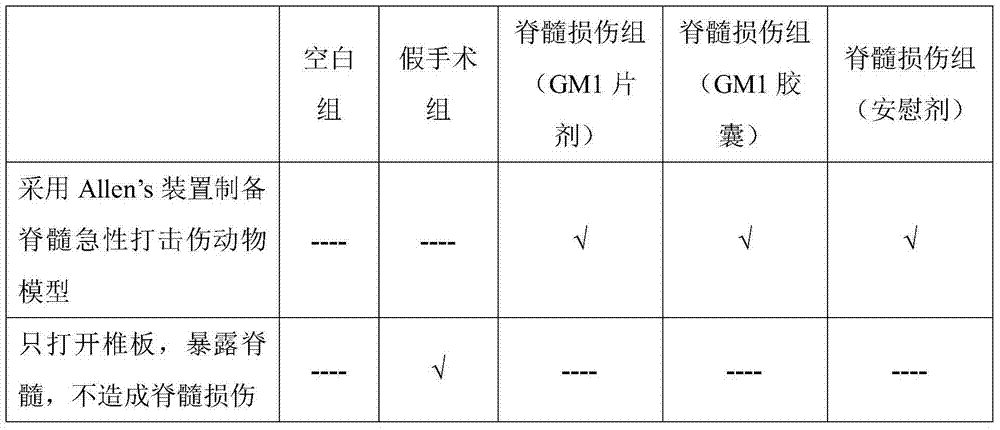

Oral preparation of monosialotetrahexosyl ganglioside sodium

InactiveCN104490837AEffectively exert biological activityImprove efficacyOrganic active ingredientsNervous disorderHard CapsuleAdhesive

The invention discloses an oral preparation of monosialotetrahexosyl ganglioside sodium, belongs to the field of medicines, and aims at solving the problems that a monosialotetrahexosyl ganglioside sodium injection hurts a human body and is high in cost. A monosialotetrahexosyl ganglioside sodium tablet is prepared from monosialotetrahexosyl ganglioside sodium, a filler, a drying adhesive, a disintegrating agent and a lubricant; and a hard capsule of monosialotetrahexosyl ganglioside sodium is prepared from monosialotetrahexosyl ganglioside sodium, a diluent, a lubricant, a glidant, a disintegrating agent and a wetting agent. The oral preparation has the advantages of relatively low cost, small medication pain and high medicine effect.

Owner:哈尔滨医科大学科技开发总公司

Preparation method of high-purity zinc oxide

InactiveCN106853982AHigh purityLow content requirementZinc oxides/hydroxidesPregnant leach solutionIron removal

The invention provides a preparation method of high-purity zinc oxide. The preparation method comprises the following steps: firstly, providing slurry of zinc-containing raw materials, wherein the raw materials comprise zinc and iron; the content of the zinc is limited to be not lower than 5 weight percent, and particle sizes of the raw materials are 100 to 150 meshes; neutrally leaching the slurry by adopting an acid solution, and carrying out solid-liquid separation to obtain a neutral leaching liquid; carrying out iron removal on the neutral leaching liquid and solid-liquid separation in sequence to obtain a treatment liquid, then carrying out zinc depositing reaction and calcining to obtain zinc-contained precipitation and obtaining the high-purity zinc oxide. According to the preparation method provided by the invention, the raw materials of which particle sizes are 100 to 150 meshes are provided; separation of the leaching liquid and filter residues is realized by mixing the acid solution; in the raw materials, the mass percentage of the zinc is not lower than 5 percent; by combining an iron removal step, sufficient removal of impurities in obtained precipitation is guaranteed, and the influence of iron on zinc precipitation in the zinc depositing process is further avoided; sufficient removal of the iron is realized by the steps, and the precipitation subjected to precalcined treatment is directly calcined to obtain the high-purity zinc oxide without crushing or ball milling.

Owner:河北长力环保科技有限公司

Catalyst for producing ethanol by hydrogenation of acetic ester, and preparation method thereof

ActiveCN103157490AAddressing the use of toxic and hazardous compoundsLow reaction pressureOrganic compound preparationHydroxy compound preparationActive componentCopper oxide

An object of the invention is to provide a catalyst for producing ethanol by hydrogenation of acetic ester by using copper metal or copper oxide or a mixture of the above two as a main active component, silver as a co-catalyst and alumina or silica sol as a carrier, and a preparation method and an application thereof. The catalyst is environment-friendly, is more suitable for industrialized production, has high reactivity and high selectivity at a relatively low temperature and pressure, and is beneficial for reducing raw material consumption in the industrialized production and increasing technical economy. Besides, the catalyst has good stability and long catalytic life.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Catalyst used in preparation of ethanol through hydrogenation of acetate and preparation method thereof

ActiveCN102423710BHigh activityImprove stabilityOrganic compound preparationHydroxy compound preparationActive componentCopper

The invention discloses a catalyst used in the preparation of ethanol through hydrogenation of acetate and a preparation method thereof. The catalyst uses Cu as an active component, SiO2 as a carrier and at least one selected from the group consisting of transition metal and alkali metal as an auxiliary agent. The copper-based catalyst provided in the invention has good stability and high activity, and has a low requirement for the content of the active component Cu, which only needs to be more than 15%. The preparation method provided in the invention has the advantages of simple operation, low cost and environment-friendliness and is benefit for industrial production.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

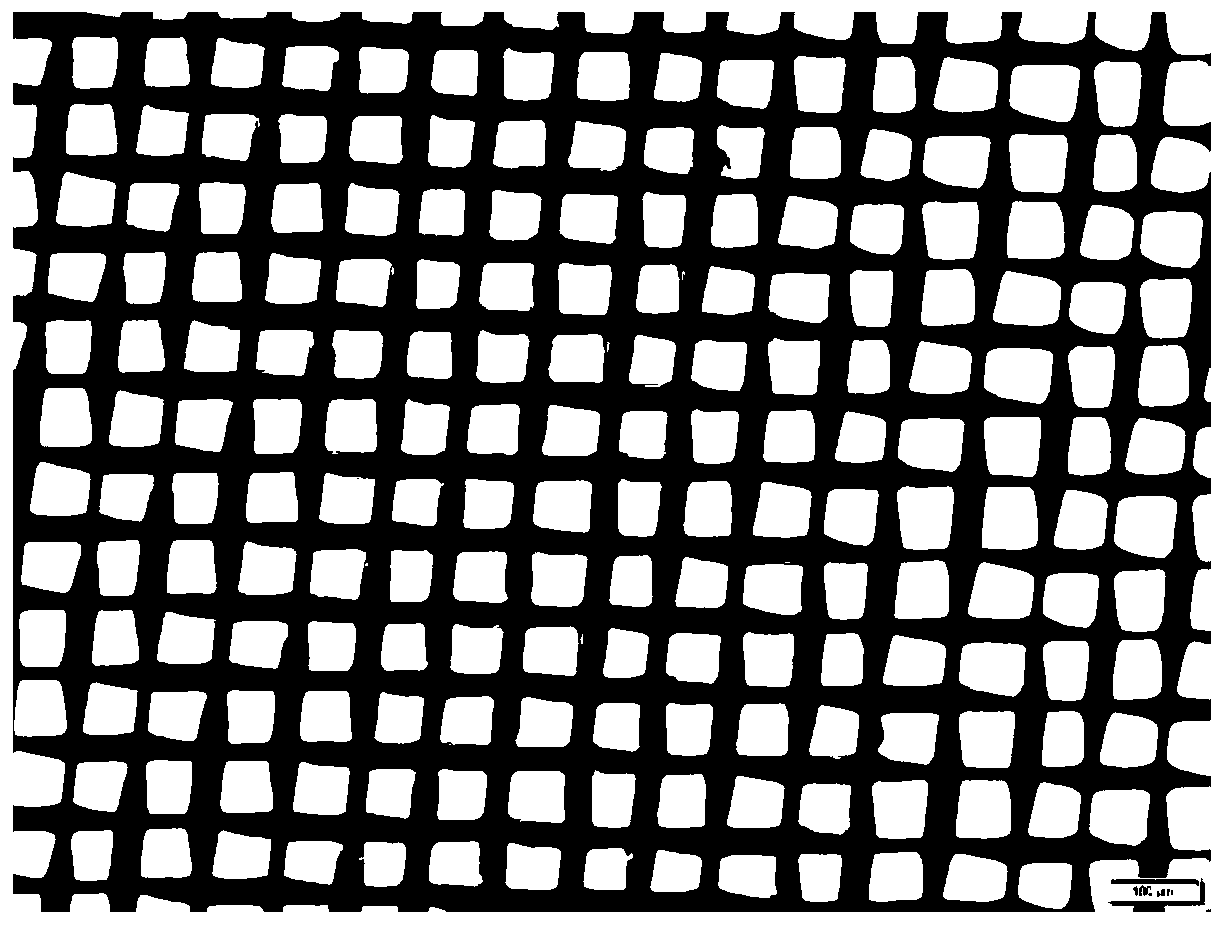

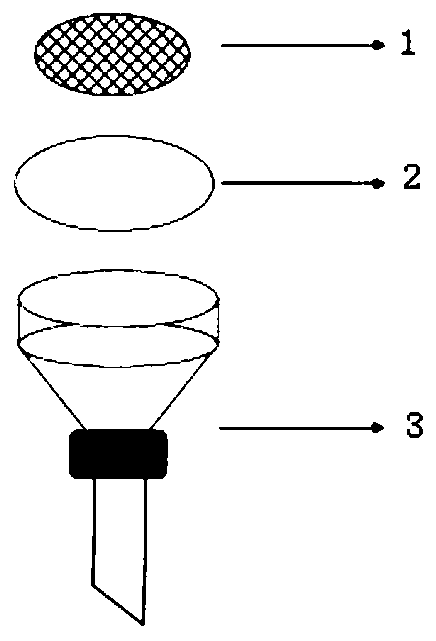

Rapid analysis method of small-size microplastic in water sample

ActiveCN110646334ALow content requirementReduce lossesPreparing sample for investigationMaterial analysis by optical meansWater qualityHydrogen peroxide

The invention belongs to the field of environmental pollutant detection, and discloses a rapid analysis method of small-size microplastic in a water sample. The method comprises the steps of: a. firstly, performing primary screening on a collected water sample in a glass bottle; b. diluting filtrate obtained by the primary screening with high-purity water; c. digesting the remaining mixed solution(a portion of about 50ml is taken for the determination of conventional water quality parameters) with a hydrogen peroxide solution for more than 48h; d. performing vacuum filtering on the digested water sample by using a dual filter membrane system comprising glass fiber filter paper and a metal mesh filter membrane; e. drying the filtered metal mesh filter membrane for more than 24h; f. performing primary observation on the dried metal mesh filter membrane under an optical microscope; and g. performing observation, scanning, sample measurement, statistics and analysis on the metal mesh filter membrane by using a microscopic infrared system. The entire analysis method is easy to operate and short in time and provides a simple and effective new idea for the analysis of the small-size microplastic in the water sample.

Owner:EAST CHINA UNIV OF SCI & TECH

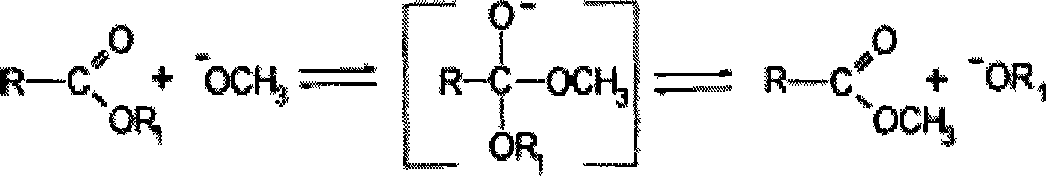

Process of preparing biological diesel oil

InactiveCN101058743AHigh catalytic activityEasy to makeFatty acid esterificationBiofuelsBiodieselPhysical chemistry

The invention discloses a making method of biological diesel coproducted glycerine and magnesium oxide through catalyzing plant oil by magnesium carbinol, which is characterized by the following: adopting non-refined plant oil as raw material; using magnesium carbinol as non-even phase catalyst; reacting through ester exchange to obtain the product and glycerine and magnesium oxide as by-product without neutralizing and processing; improving the receiving rate of magnesium oxide without discharging waste liquid.

Owner:EAST CHINA UNIV OF SCI & TECH

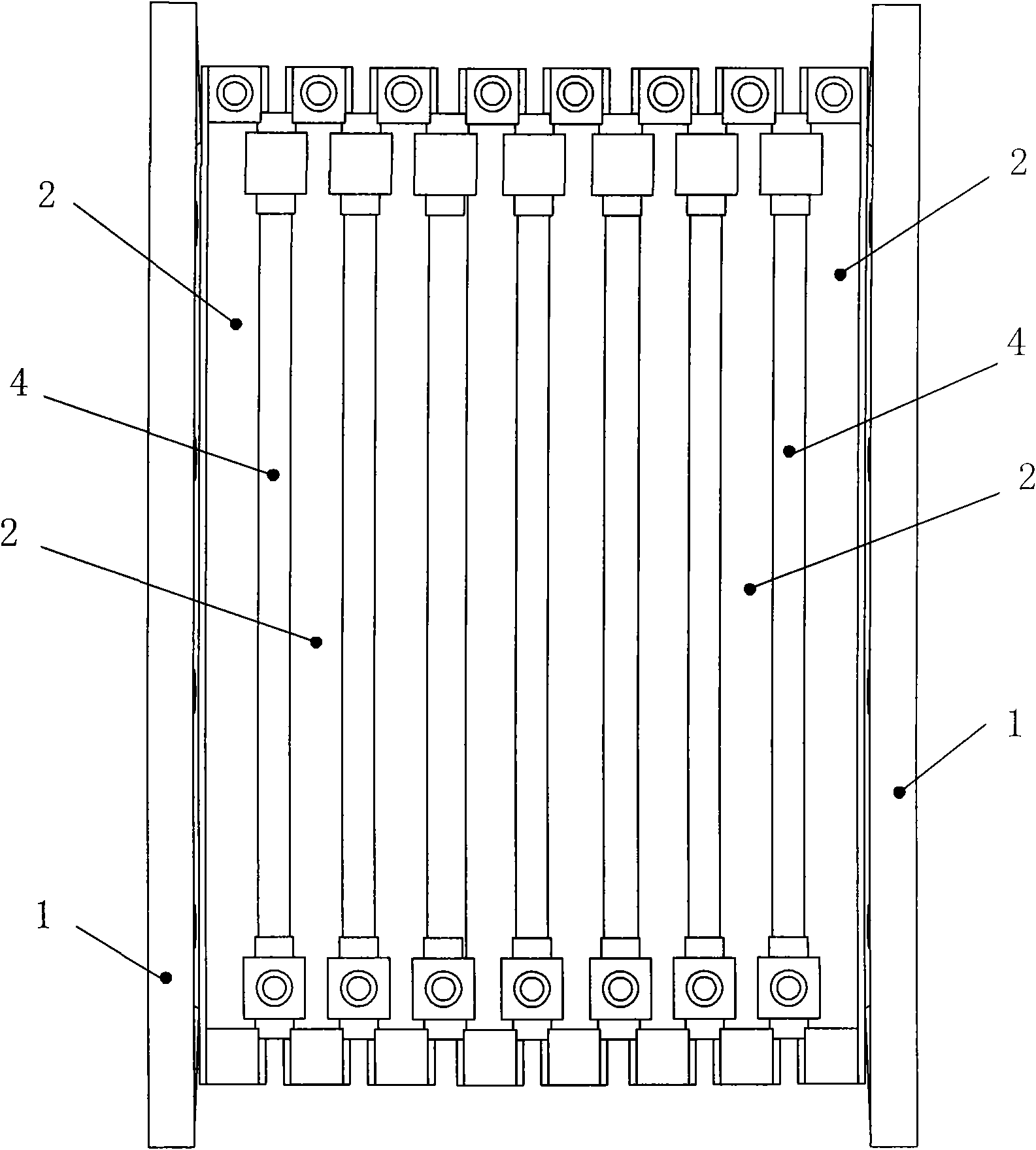

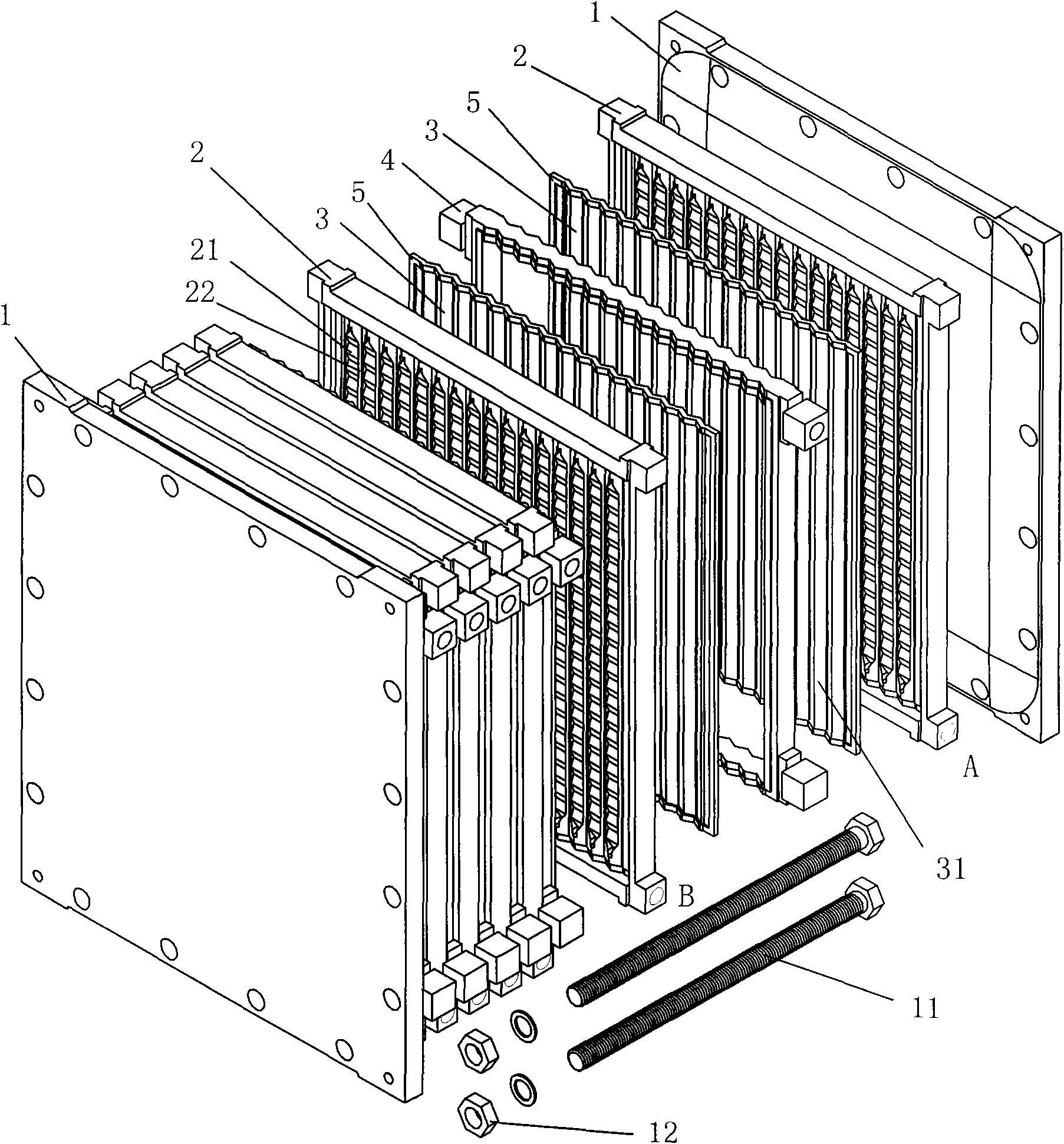

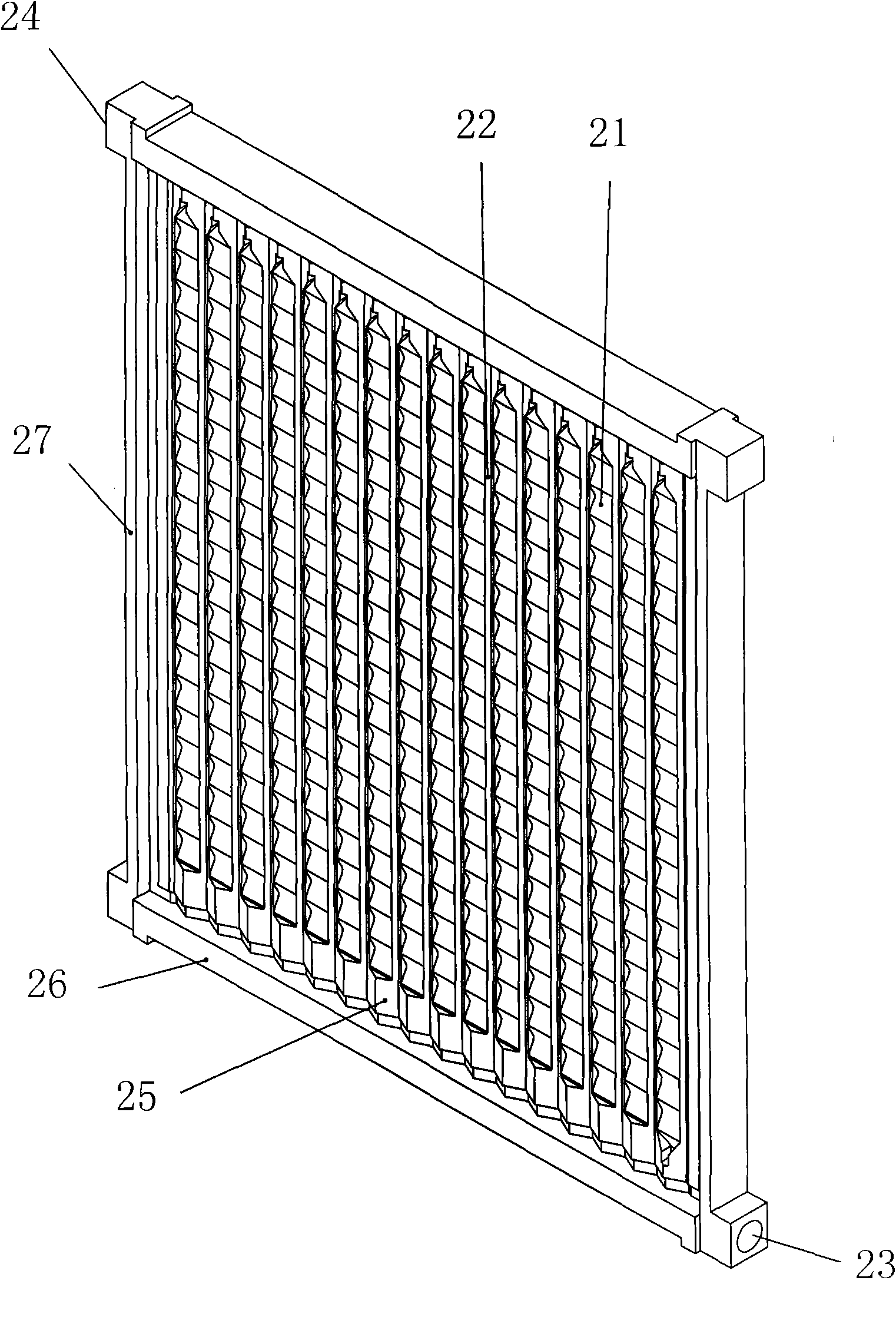

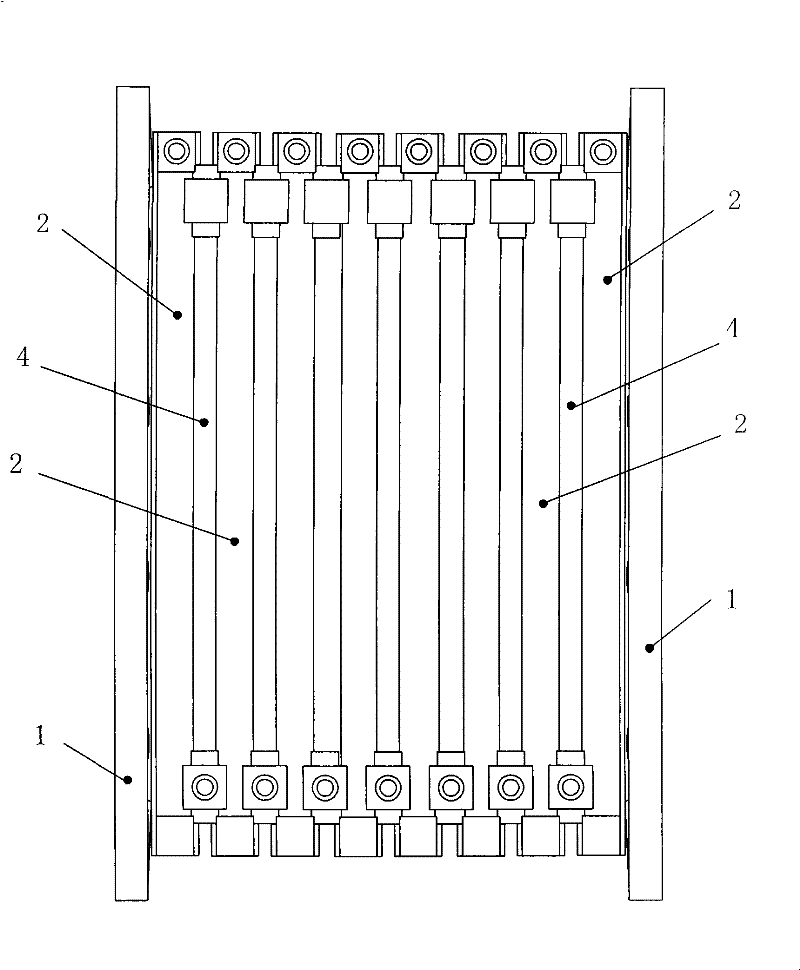

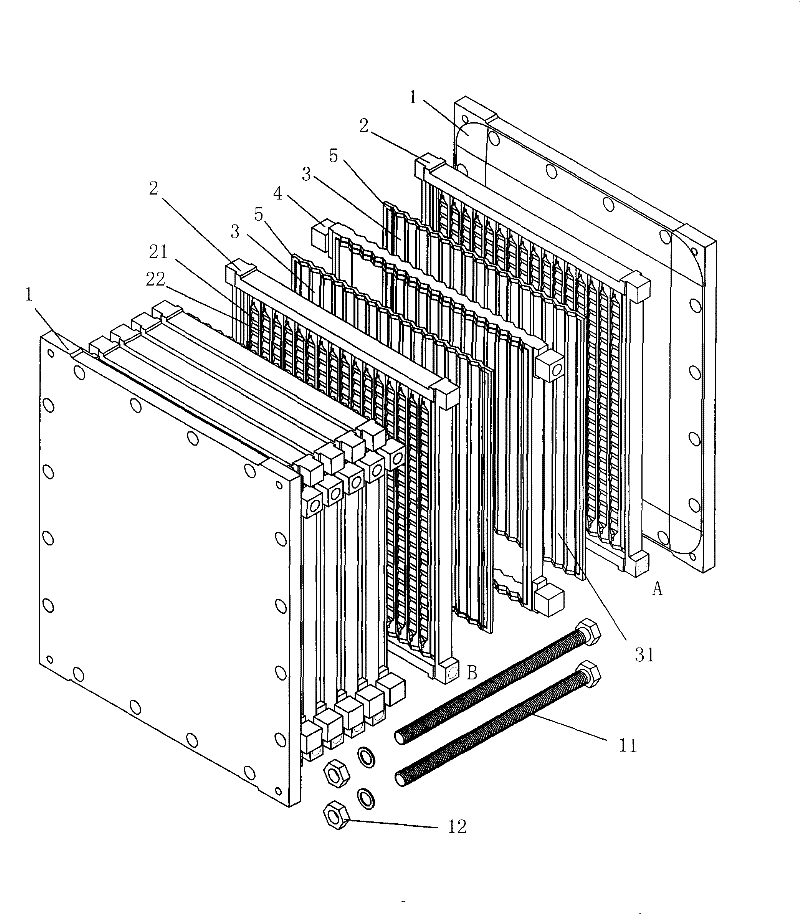

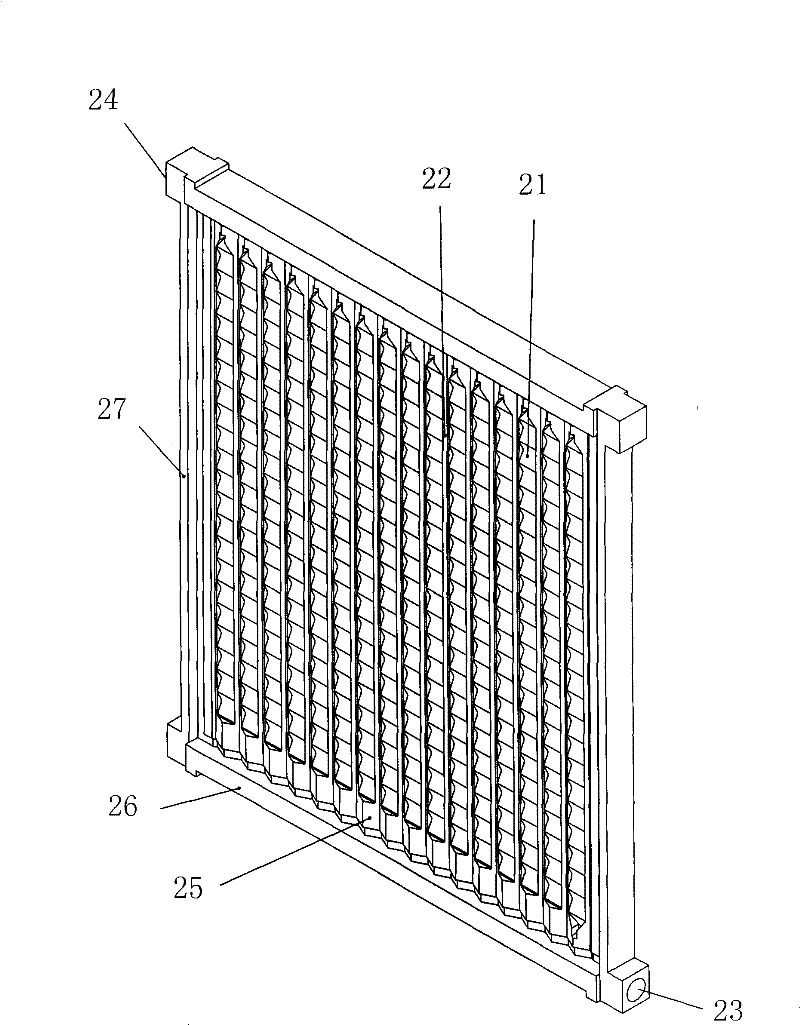

Plate cavity-type heat exchanger

InactiveCN101839657AImprove pressure bearing capacityReduce pressure requirementsHeat exchanger casingsCoatingsEngineeringOn demand

The invention relates to a plate cavity-type heat exchanger which is provided with a plurality of heat exchange units clamped between two pressure plates (1); each heat exchange unit is respectively provided with two opposite wave plates (3) with wavy cross section; bifarius surfaces of the two wave plates are respectively opposite to water plates (2) on the corresponding sides; the water plates are provided with a plurality of horizontal water plate wave troughs (21) which are vertical to longitudinal wave plate wave troughs (31) on plane surfaces opposite to the wave plates, and a plurality of longitudinal pressure bearing strips (22); all the pressure bearing strips respectively correspond to the trough parts of the wave plate wave troughs; a cavity frame (4) is arranged between the two water plates; the front side and the rear side of the side frame of the cavity frame are respectively inlaid in the water plates (2, 6) on the corresponding sides, and respectively seal and press the periphery of the wave plate (3) on the corresponding side to the corresponding water plate through the side frame; and the invention can improve the pressure bearing capability of the heat exchanger and reduce the pressure bearing requirement on the heat exchange wave plates, the size of the working substance cavity can be designed on demand, and the problems that impurities block a runner and the like can be overcome by enlarging the cross section of the heat carrying runner.

Owner:湖北拓博热力科技有限责任公司

Severe saline-alkaline land microorganism improvement and elaeagnus angustifolia planting method

InactiveCN106171734AImprove survival rateImprove the growing environmentExcrement fertilisersBioloigcal waste fertilisersAlkalinityMicroorganism

The invention provides a severe saline-alkaline land microorganism improvement and elaeagnus angustifolia planting method. Aiming at the characteristics that severe saline-alkaline land is high in salinity and alkalinity and not suitable for crop survival, microorganism improvement and concealed conduit salt elimination are combined, saplings resistant to salt and alkali are planted firstly, salt elimination is carried out step by step, soil is improved, cost is greatly reduced, economic benefits are increased, the severe saline-alkaline land can be improved into fertile farmland usually within 4-7 years, and then other trees can be planted in a mixed mode.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

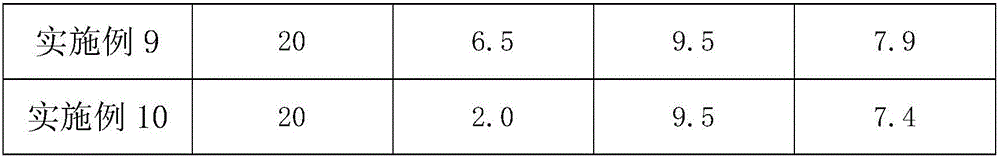

Method for synthesizing sec-butyl alcohol

InactiveCN104311390ALow content requirementEasy to separate and purifyOrganic compound preparationCarboxylic acid esters preparationOrganic synthesisAddition reaction

The invention relates to the technical field of organic synthesis, and in particular relates to a method for synthesizing sec-butyl alcohol. The method comprises the following steps: firstly, performing addition reaction to synthesize sec-butyl propionate from an n-butene raw material and propionic acid, and secondly, performing hydrolysis reaction on sec-butyl propionate, thereby obtaining a target product sec-butyl alcohol. According to the method, under specific reaction conditions, with the combination of addition reaction and hydrolysis reaction, n-butyl alcohol is synthesized in a roundabout mode, the reaction condition is gentle, the reaction selectivity is high, the conversion rate is high, products are easy to separate and purify, the requirement on the content of n-butene in the n-butene raw material is low, and when the content of n-butene is 20wt%, the conversion rate of propionic acid can be up to 70.5%, and the selectivity is as high as 98.7%. By adopting the method, the yield of sec-butyl alcohol can be increased to be 47.1% from 10% of a catalytic hydration method, the yield is greatly increased, and thus the method can be used in industrialization production.

Owner:ZHUHAI FEIYANG NOVEL MATERIALS +1

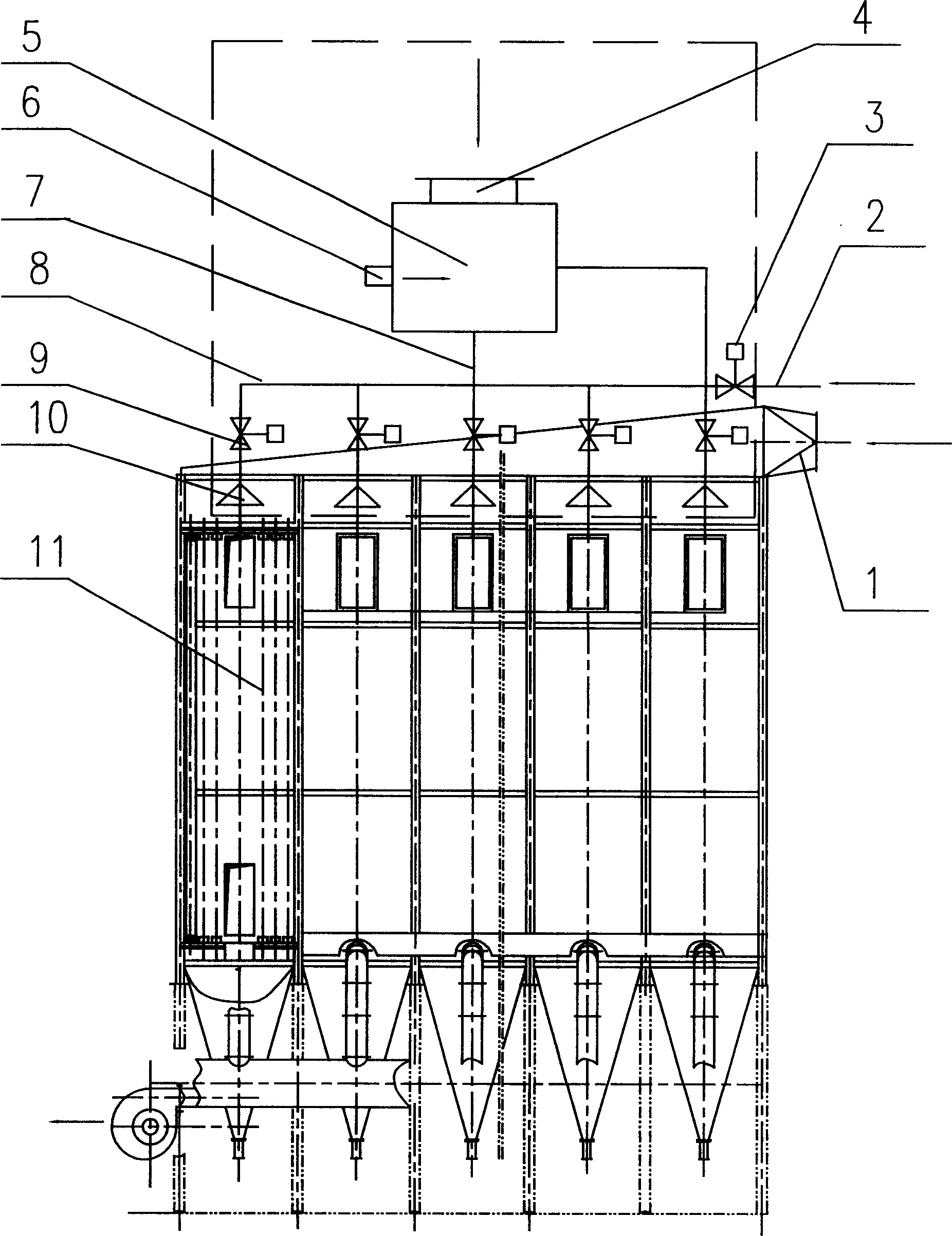

Dust cleaning method and equipment by using cloth bag of desulfurization and fluorine removal

InactiveCN1660478AHigh desulfurization, fluoride and dust removal efficiencyExtended service lifeDispersed particle filtrationAmount of substanceEnvironmental chemistry

A cloth-bag duster for removing sulfur and fluorine compounds fume is composed of a dusting chamber, chemical powder container, compressed air source, and nozzle in said dusting chamber. Its dusting method includes spraying the chemical powder onto the surface of cloth bag, reaction between said chemical powder and water vapor in fume to obtain resultant, reaction between said resultant and the sulfur oxide and fluoride to become non-toxic chemicals, and discharging them along with the dust. It is suitable for cement production.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

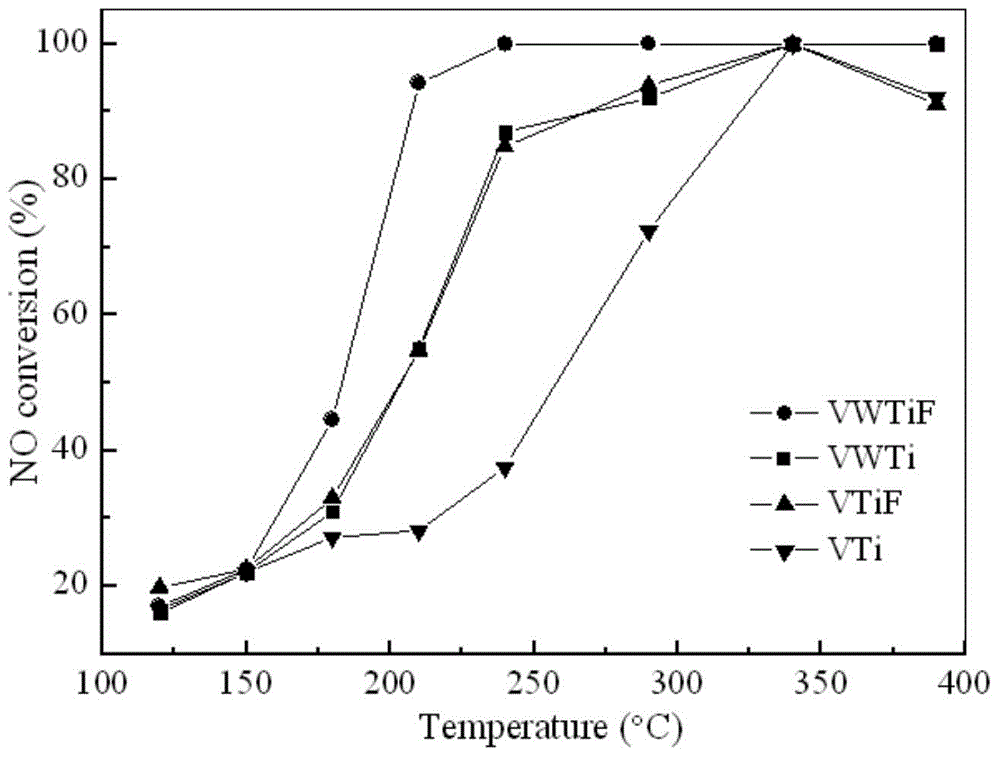

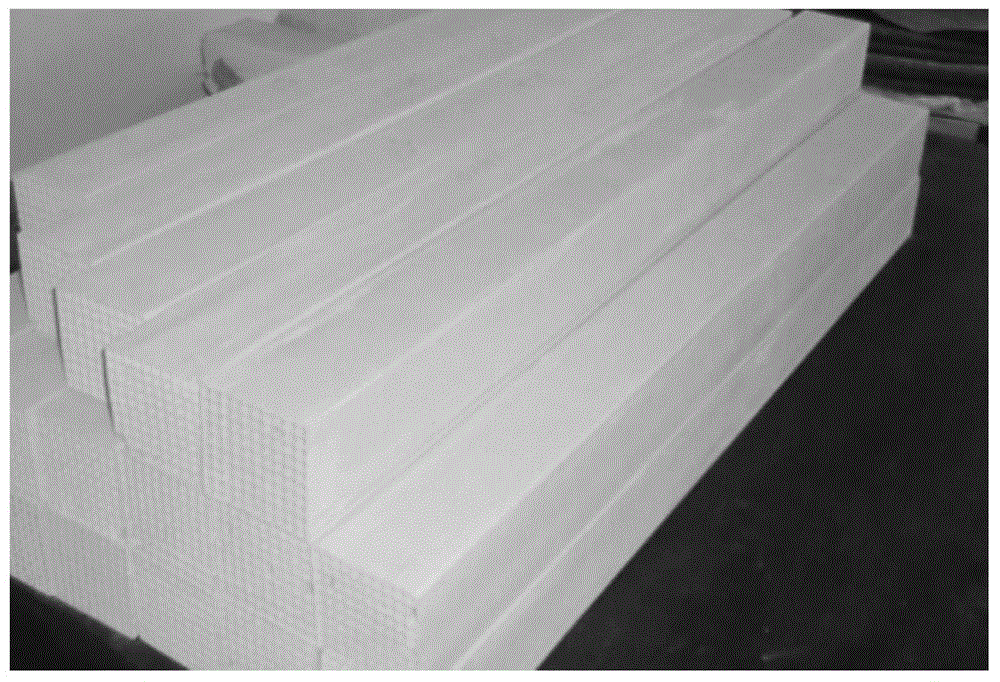

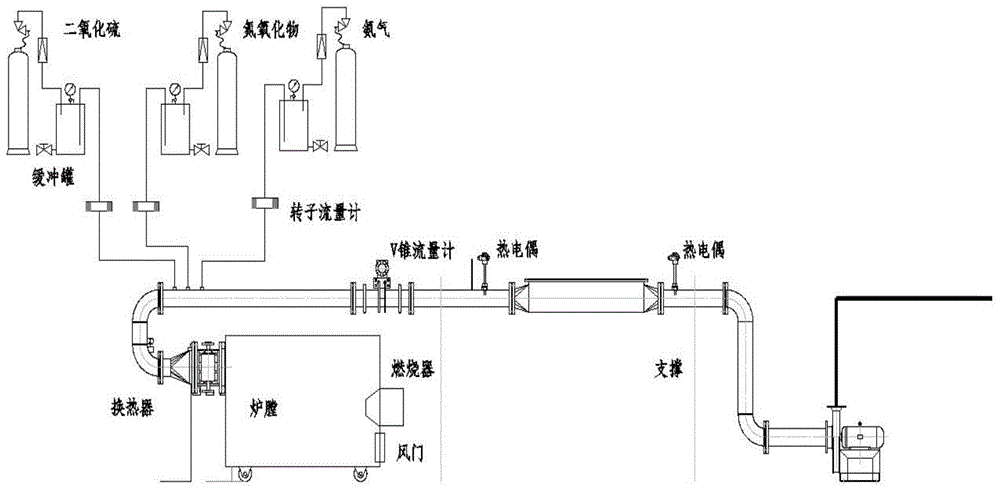

F-doped SCR catalyst, preparation method and application thereof to catalytic denitration

InactiveCN106552652APromote oxidationLow content requirementPhysical/chemical process catalystsDispersed particle separationHalogenFlue gas

The invention discloses an F-doped V2O5-WO3 / TiO2 catalyst for selective catalytic denitration. According to the catalyst, a halogen element F is doped to a widely-used commercial catalyst V2O5-WO3 / TiO2, and load amount of elements V and W in the catalyst and a load way for an element V in the catalyst are optimized, so that an activity temperature window of the V2O5-WO3 / TiO2 is widened. The F-doped V2O5-WO3 / TiO2 catalyst solves the technical problems that the V2O5-WO3 / TiO2 catalyst cannot realize the denitration purpose and the like when the temperature of coal-fired flue gas is too low and airspeed changes greatly, and is suitable for carrying out selective catalytic denitration on flue gas generated by industrial firing coals.

Owner:NANJING UNIV OF SCI & TECH

Integrated method for preparing potassium fertilizer from Bayan Obo potassium-rich slate

InactiveCN103539489ALow content requirementDoes not affect development and utilizationPotassium fertilisersFertilizer mixturesFertilizerCircular economy

The invention discloses an integrated method for preparing a potassium fertilizer from Bayan Obo potassium-rich slate. According to the method, potassium is extracted from potassium slate by using X-ray selection, microwave pretreatment and microbial leaching, and then, the potassium fertilizer is subjected to integrated preparation, so that compared with traditional fertilizer production, the investment is small, the cost is low, the economic benefit is good, and no pollution is caused. Compared with untreated microbial leaching potassium fertilizer preparation, due to the combination of microwave pretreatment and microbial leaching, the potassium fertilizer preparation efficiency is higher, and the potassium fertilizer preparation cycle is shorter. According to the method, a steeling tailing pond and the potassium-rich slate of Bayan Obo regions can be reasonably utilized, and the waste is changed into the valuable, so that the method is beneficial to the development of cyclic economy of China.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for deeply extracting calcium sulfate from phosphorus ore acid hydrolysis liquid

PendingCN112624174ALow content requirementModerate crystal sizeCalcium/strontium/barium sulfatesHydration reactionDihydrate Calcium Sulfate

The invention relates to a method for deeply extracting calcium sulfate from phosphorus ore acid hydrolysis liquid, and belongs to the technical field of chemical production. The method comprises the following steps: (1) acid hydrolysis; (2) acid hydrolysis liquid purification; and (3) calcium removal and crystal transformation. The calcium removal purification comprises two crystallization processes, calcium sulfate hemi-hydrate is generated by primary crystallization, and secondary crystallization is to add a seed crystal into a primary crystallization reaction solution to prepare calcium sulfate dihydrate. According to the method, the optimal conditions in each process are controlled by adopting a mode of flocculating and then crystallizing twice, so that the production process is effectively shortened, the requirement on the content of the used raw material (phosphorus ores) is relatively low, the application range is wide, and the method is not limited by the quality of the phosphorus ores. The produced calcium sulfate dihydrate product is moderate in crystal form particle size, the phosphorus content can be as low as 0.2%, and further utilization of phosphogypsum is better facilitated.

Owner:KINGENTA ECOLOGICAL ENG GRP +2

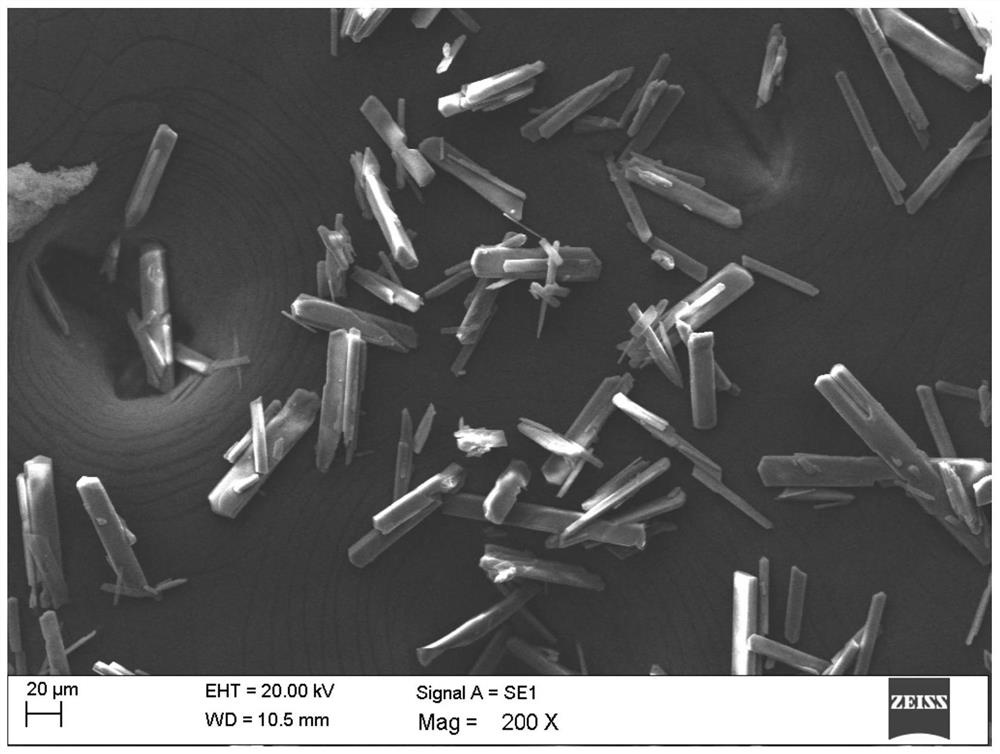

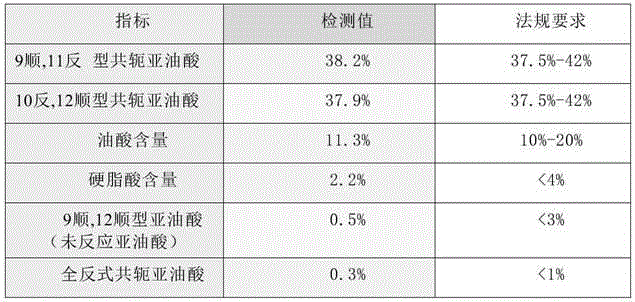

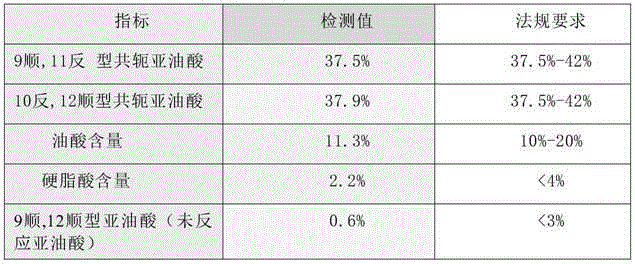

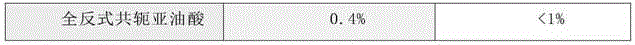

Method for preparing conjugated linoleic acid

InactiveCN104673499ALow content requirementIncrease contentFatty acid esterificationFatty acids production/refiningGlycerolConjugated linoleic acid

The invention provides a method for preparing conjugated linoleic acid. The method comprises the following steps: reacting linoleate under catalysis of organic base of which the pKa is more than 11, thereby obtaining the conjugated linoleic acid ester. Furthermore, an ester exchange reaction can be carried out between the conjugated linoleic acid ester and glycerin or derivatives thereof, and conjugated linoleic acid glyceride is prepared. By utilizing the conjugated linoleic acid prepared by the invention, the reaction conversion rate is high, and the content of fatty acids in the conjugated linoleic acid product meets the related statutory and regulatory requirements.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Method for preparing ethanol by hydrogenation of acetic ester

ActiveCN102093162BHigh activityImprove stabilityOrganic compound preparationHydroxy compound preparationReaction temperatureBULK ACTIVE INGREDIENT

The invention discloses a method for preparing ethanol by hydrogenation of acetic ester. The method comprises the following step of: hydrogenating the acetic ester at the reaction temperature of between 180 and 300 DEG C under the reaction pressure of between 1.0 and 5.0 MPa in the presence of a reducing and activating copper-based catalyst to generate the ethanol, wherein the copper-based catalyst takes Cu as an active ingredient, SiO2 as a carrier and at least one of transition metal or / and alkali metal as an aid. The method has high space-time yield, high ethanol selectivity, a simple process and low cost, is environmentally-friendly, and contributes to industrial production.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Preparation method of neohesperidin without heavy metals

ActiveCN111675742AEquilibrium yieldBalance puritySugar derivativesSugar derivatives preparationIon exchangeEthylic acid

The invention provides a preparation method of neohesperidin without heavy metals. The preparation method comprises the following steps: (1) impurity removal: crushing raw materials, removing impurities by using a cold aqueous solution containing basic salt and alcohol, filtering and collecting impurity-removed residues; (2) extraction; (3) flocculation: adding a flocculating agent into permeate,flocculating under an acidic condition, then performing solid-liquid separation, and collecting the permeate overnight; (4) chromatography: enabling the obtained permeate to pass through a cation exchange column, and collecting effluent; (5) coarse crystallization; (6) recrystallization: dissolving the obtained coarse crystals, and then recrystallizing; (7) nanofiltration; and (8) drying and crushing. According to the method provided by the invention, extraction separation, purification and heavy metal removal are performed by adopting the processes of removing impurities by using a low-temperature basic salt alcohol solution, flocculating by using acidic chitosan, removing impurities such as heavy metals by using ion exchange resin, performing coarse crystallization by using a low-temperature alkoxide solution, recrystallizing by using acetic acid and the like, so that a pure natural neohesperidin product with high purity and no heavy metals is obtained, the purity of the neohesperidin is 98 percent or above, and the yield is 90 percent or above.

Owner:JIANGXI HAIFU BIOENG

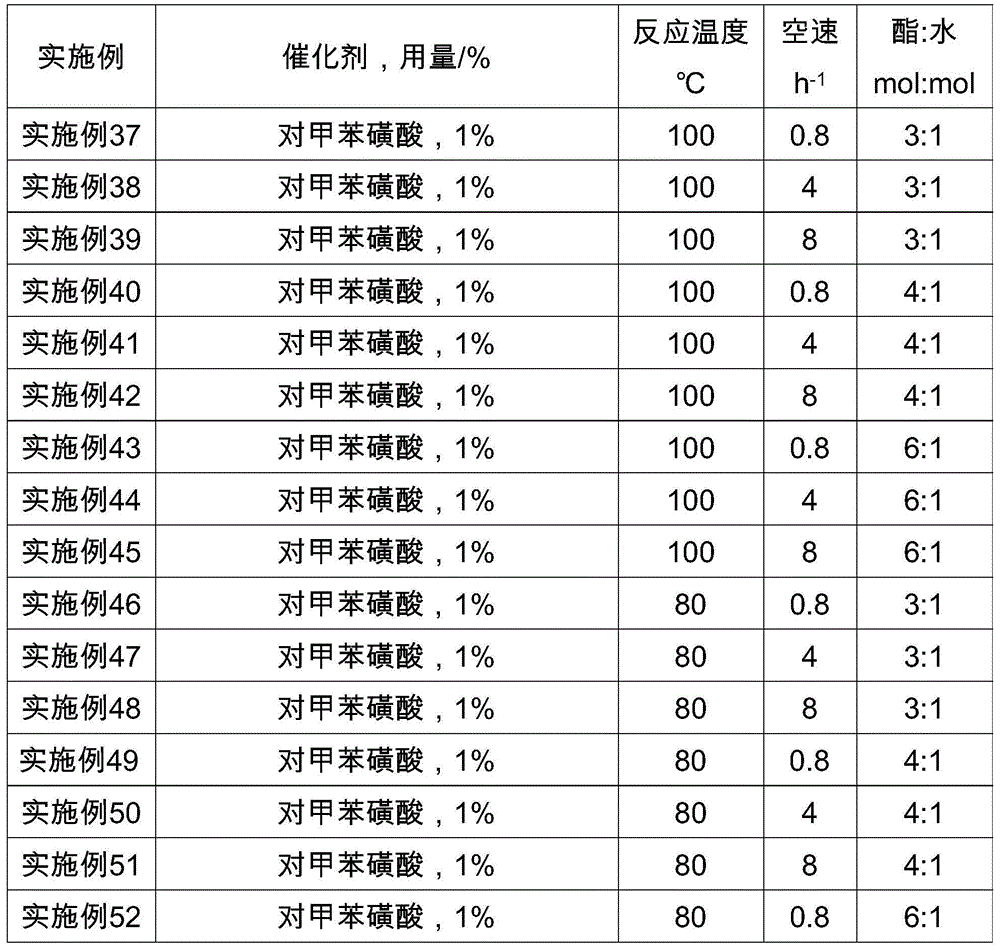

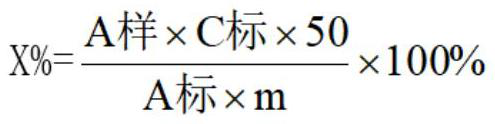

Preparation method and system of sec-butyl alcohol

ActiveCN111377802AIncrease productionEasy to operateOrganic compound preparationPreparation by hydrolysisOil phaseSec-Butyl acetate

The invention provides a preparation method of sec-butyl alcohol. The method includes the steps of: feeding a mixture obtained after the hydrolysis reaction into a sec-butyl alcohol azeotropic distillation tower for separation; withdrawing a mixed material containing sec-butyl alcohol, sec-butyl acetate and water from the side line of the upper part of the sec-butyl alcohol azeotropic distillationtower, feeding the mixed material into a multi-stage extraction tower, adding an extracting agent chilled water to obtain a sec-butyl alcohol-containing water phase at the bottom of the tower, and withdrawing the water phase at the bottom of the tower; feeding the mixture into a liquid separation tank to obtain a sec-butyl alcohol oil phase at the upper layer of the liquid separation tank; and feeding the sec-butyl alcohol oil phase obtained at the upper layer of the liquid separation tank into a sec-butyl alcohol refining tower for refining, and adding entrainer water to obtain the high-purity product sec-butyl alcohol at the bottom of the tower. According to the method, sec-butyl acetate and sec-butyl alcohol are effectively separated, the yield of the sec-butyl alcohol obtained after separation reaches 99.5% or above, and the one-way yield of the sec-butyl alcohol is greatly increased and is increased to 85% or above from 50%.

Owner:HUNAN ZHONGCHUANG CHEM

Detecting probe, method and kit for multi-target-point gene mutation, methylation modification and/or hydroxymethylation modification

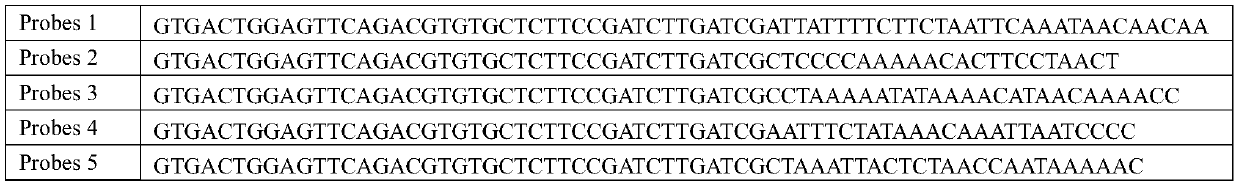

PendingCN109517819ALower synthesis costEasy to detectMicrobiological testing/measurementDNA/RNA fragmentationMulti targetingGene mutation

The invention provides a detecting probe. The detecting probe comprises at least one capturing probe; sequences from the 5' end to the 3' end of the capturing probe sequentially include a preamble sequence, a probe random label sequence and a target complementary sequence; the preamble sequence is shown as SEQ ID NO:1; the probe random label sequence is composed of 0-12 random basic groups; and the target complementary sequence comprises at least 10 continuous basic groups complementary with a to-be-detected gene. The detecting probe is used for detecting multi-target-point gene mutation, methylation modification and / or hydroxymethylation modification, low in content requirement for the to-be-detected gene, capable of effectively avoiding disturbance of length and content of the to-be-detected gene to detection, beneficial to detection of genes with high degradability and serious fragmentation, low in detection cost, high in efficiency and wide in application range.

Owner:SHENZHEN E GENE TECH

Titanium-based amorphous alloy and preparation method thereof

The invention discloses a titanium-based amorphous alloy which has the components shown as the following general formula: TiaCubSncTLdTDe, wherein a expresses the atomic percentage of Ti, and 40<=a<=55; b expresses the atomic percentage of Cu, and 30<=b<=45; c expresses the atomic percentage of Sn, and 0<=c<=4; d expresses the atomic percentage of TL, 1<=d<=7, and TL is selected from one or more of VIIB group elements, VIIIB group metal except for Ni, Ag and Au in the periodic system of elements; e expresses the atomic percentage of TD, 0<e<=5, and TD is Y and / or Sc; and the sum of a, b, c, d and e is 100. The titanium-based massive amorphous alloy provided by the invention has wide preparation conditions and favorable combination property, is suitable for the machining requirements, and has important realistic significance in industrialized production.

Owner:BYD CO LTD

Plate cavity-type heat exchanger

InactiveCN101839657BImprove heat exchange efficiencyReduce pressure requirementsHeat exchanger casingsCoatingsPlate heat exchangerLongitudinal wave

The invention relates to a plate cavity-type heat exchanger which is provided with a plurality of heat exchange units clamped between two pressure plates (1); each heat exchange unit is respectively provided with two opposite wave plates (3) with wavy cross section; bifarius surfaces of the two wave plates are respectively opposite to water plates (2) on the corresponding sides; the water plates are provided with a plurality of horizontal water plate wave troughs (21) which are vertical to longitudinal wave plate wave troughs (31) on plane surfaces opposite to the wave plates, and a pluralityof longitudinal pressure bearing strips (22); all the pressure bearing strips respectively correspond to the trough parts of the wave plate wave troughs; a cavity frame (4) is arranged between the two water plates; the front side and the rear side of the side frame of the cavity frame are respectively inlaid in the water plates (2, 6) on the corresponding sides, and respectively seal and press the periphery of the wave plate (3) on the corresponding side to the corresponding water plate through the side frame; and the invention can improve the pressure bearing capability of the heat exchangerand reduce the pressure bearing requirement on the heat exchange wave plates, the size of the working substance cavity can be designed on demand, and the problems that impurities block a runner and the like can be overcome by enlarging the cross section of the heat carrying runner.

Owner:湖北拓博热力科技有限责任公司

A kind of continuous production process of 3,6-dichlorosalicylic acid

ActiveCN105801397BReduced moisture requirementsImprove one-way yieldOrganic compound preparationCarboxylic compound preparationReaction systemOrganic chemistry

The invention relates to a continuous production process of 3,6-dichlorosalicylic acid, and belongs to the technical field of the synthesis of a herbicide dicamba intermediate. A specific continuous production process and a specific continuous production system are adopted, harsh requirements on the water content of a reaction system can be lowered, coking is reduced, equipment investment cost is lowered, efficiency is high, and continuous production is realized. The process disclosed by the invention lowers the harsh requirements on the water content of the reaction system, can meet reaction requirements if the water content is below 2000ppm, and has the advantages of high once through yield, high selectivity and little coking. When the process disclosed by the invention is adopted, the yield is above 55%, and the selectivity is above 96%.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

A kind of carbon black production method with electromagnetic shielding performance

ActiveCN112940542BLow costEasy to operatePigmenting treatmentMagnetic/electric field screeningPolymer scienceFerrocene

The present invention relates to a kind of production method of the carbon black with electromagnetic shielding property, described production method comprises the following steps: (1) configure raw material oil: add peroxide and ferrocene or derivatives thereof in raw material oil, configure Reaction raw materials; (2) Spray the configured raw material oil into a high-temperature reaction furnace for carbonization treatment, and the carbonization temperature is 1700-1850°C; (3) After the carbonization is completed, pass through quenching water for quenching treatment to generate carbon black and collect carbon Black, the final product is obtained after drying. The electromagnetic shielding effect of the carbon black product prepared by the invention is good. At the same time, cheap and easy-to-obtain raw materials and simple production operations enable the product to be industrially produced in large quantities.

Owner:山东联科新材料有限公司

Biodiesel for coal flotation and preparation method of biodiesel

InactiveCN102847612BReduce flotation costsLow content requirementFatty acid esterificationBiofuelsMonoglycerideTriglyceride

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com