Dust cleaning method and equipment by using cloth bag of desulfurization and fluorine removal

A bag filter and bag filter technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as air pollution, achieve long service life, reduce content requirements, and achieve high desulfurization, defluorination, and dust removal efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

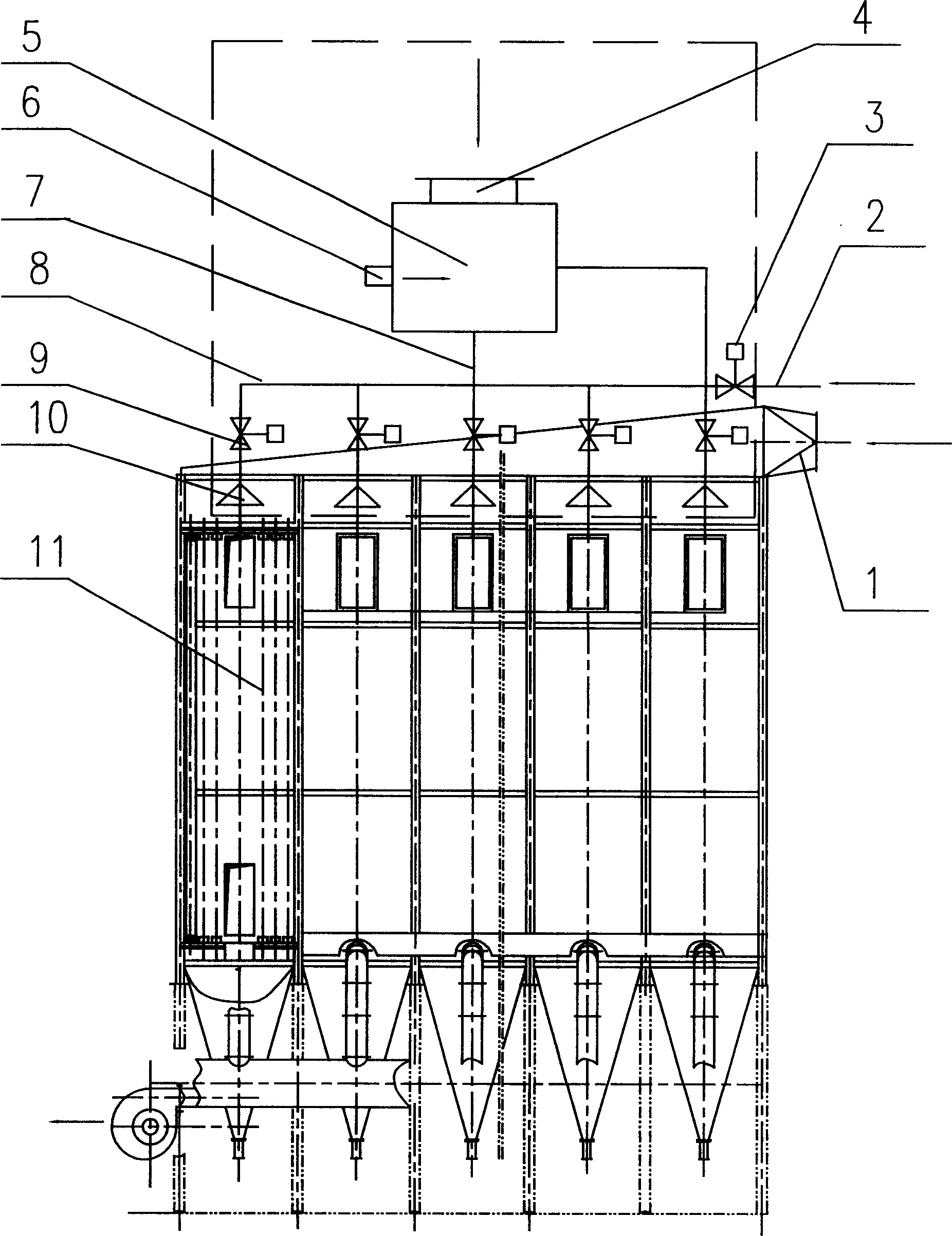

[0016] Example 1: A bag dust removal device for removing toxic substances sulfur and fluorine in dust.

[0017] Contains a container 5 for storing chemical powder. The container 5 is set on the top of the bag filter. The upper part of the container 5 is provided with an openable feeding port 4. A γ-ray level gauge 6 is installed in the container 5. The container 5 passes through the controllable valve 3. It communicates with the compressed air inlet 2 and is controlled by the control system to adjust the required pressure. There are also multiple connecting pipes 7 leading to the inner chamber of the working chamber 10 of the bag filter at the bottom of the container 5. The connecting pipes 7 are equipped with adjustable The control valve 8, the outlet end of the connecting pipe 7 is equipped with a nozzle 9, and the nozzle 9 is placed in the inner chamber of the working chamber 10 of the bag filter.

Embodiment 2

[0018] Example 2: The method of bag dust removal for simultaneously removing the toxic substances sulfur and fluorine in the dust.

[0019] First, clean the inner cavity of the working room 10 of the bag filter, and then remove the SO2 in the flue gas 2 , SO 3 The chemical powder CaO, which reacts with HF to generate non-toxic chemical substances, is added into the container 5 from the feeding port 4, and the compressed air enters the container 5 from the compressed air inlet 2 through the controllable valve 3 and through the connecting pipe 7. Under the control of the control system, The CaO powder is sent through the controllable valve 8 into the working room 10 of a certain bag filter after the dust has been cleaned and settled, sprayed out through the nozzle 9, and sprayed on the bag 11 in the working room 10 of the bag filter. On the surface, due to the homogenization and dispersion of the nozzle and the gravity of the CaO powder, the CaO powder will evenly adhere to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com