F-doped SCR catalyst, preparation method and application thereof to catalytic denitration

A kind of SCR catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of high catalyst cost, achieve reduced production costs, high activation temperature, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

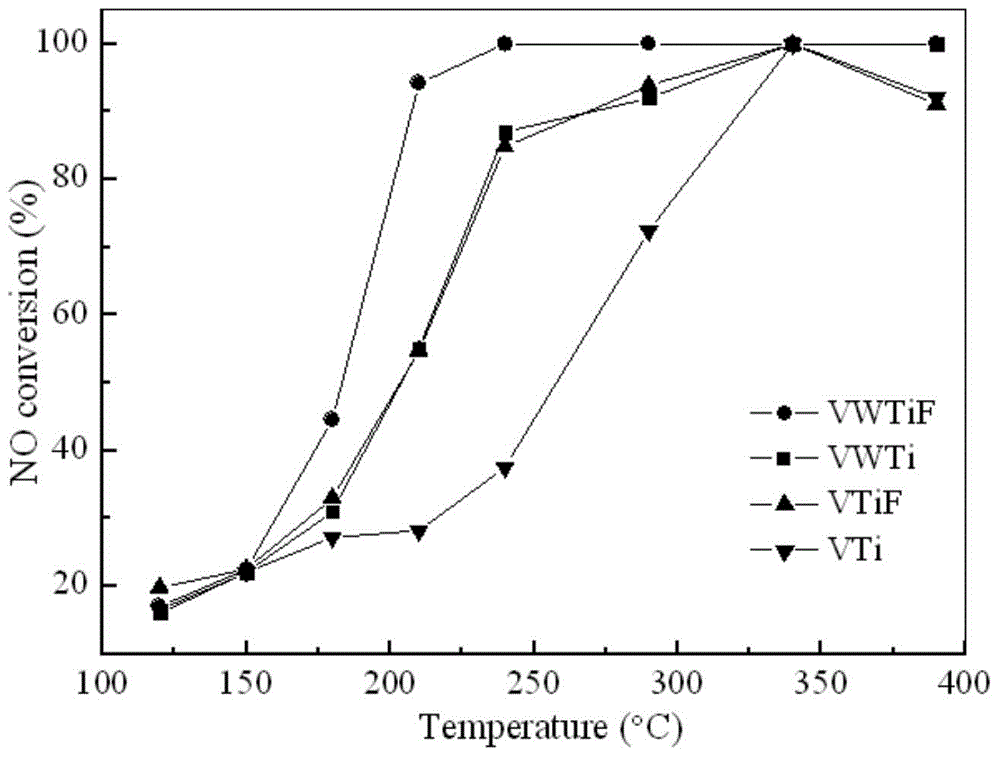

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] To 0.064mol butyl titanate (C 16 h 36 o 4 Add 0.128mol acetylacetone (acacH, C in Ti) 6 h 8 o 2 ), so that [acacH] / [Ti]=2; then add 50mL stoichiometric ammonium fluorotitanate ((NH 4 ) 2 TiF 6 ) of ethanol (C 2 h 6 O) solution, stirred for 2 hours to obtain a sol; after concentrating the sol in a water bath at 60° C., dried at 120° C. for 6 hours, and then calcined at 500° C. for 3 hours to obtain a fluorine-doped titanium oxide carrier, wherein the addition of ammonium fluorotitanate was Molar ratio [F] / [Ti]=0.5×10 -2 ~2×10 -2 , the catalyst sample is denoted as TiF y , where y represents 100×[F] / [Ti], such as TiF 1.35 Indicates that [F] / [Ti]=1.35×10 in the sample -2 . The prepared F-doped titania carrier was impregnated in 50 mL of ammonium paratungstate (H 8 N 2 o 4 W) in an aqueous solution, reflux in a water bath at 60°C for 4h, dry at 120°C for 6h, and then calcinate at 500°C for 2h to obtain F-doped WO 3 / TiO 2 , where WO 3 The loading amount ...

example 2

[0035] When the V loading was 0.8wt%, the catalyst formulation was:

[0036] Each substance is measured by mass: TiO 2 100 parts, 1.07 parts of ammonium metavanadate, 0.56 parts of ammonium fluotitanate, 4.01 parts of ammonium paratungstate, 3 parts of methyl cellulose (HPMC), 3 parts of polyvinyl alcohol (PVA), 3 parts of aluminum stearate, 3 parts of aluminum phosphate 2 parts, 7 parts of silica sol, 10 parts of glass fiber (4 parts of 0.5mm, 4 parts of 1.0mm, 2 parts of 2mm) and 3 parts of glycerin.

[0037] When the V loading was 1.0wt%, the catalyst formulation was:

[0038] Each substance is measured by mass: TiO 2 100 parts, 1.34 parts of ammonium metavanadate, 0.56 parts of ammonium fluotitanate, 4.67 parts of ammonium paratungstate, 2.7 parts of methyl cellulose (HPMC), 3 parts of polyvinyl alcohol (PVA), 3 parts of aluminum stearate, 3 parts of aluminum phosphate 5 parts of silica sol, 10 parts of glass fiber (4 parts of 0.5mm, 4 parts of 1.0mm, 2 parts of 2mm) an...

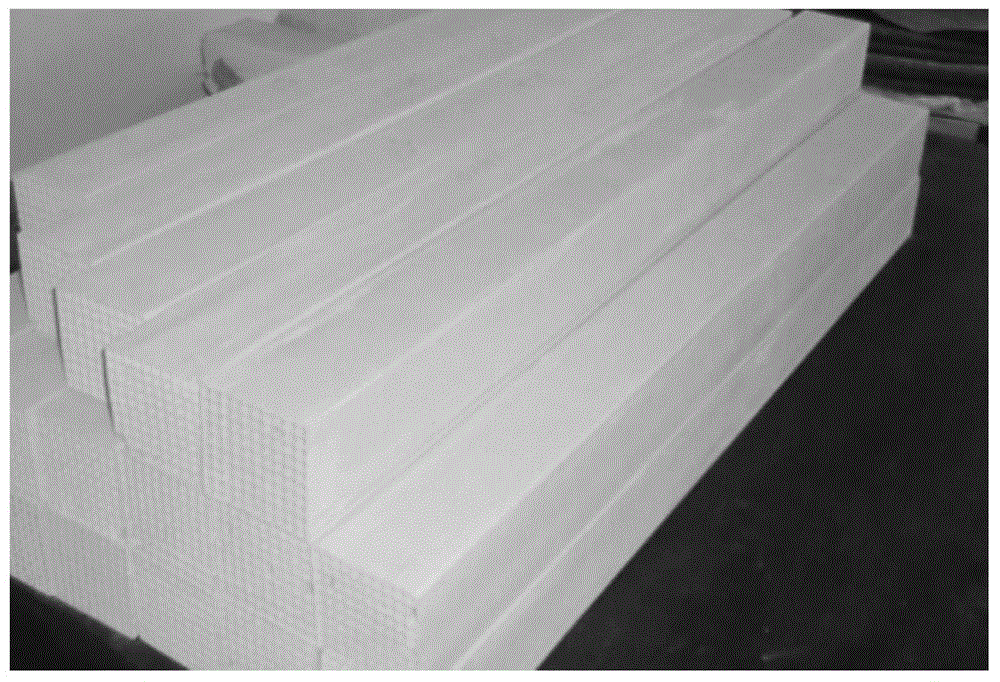

example 3

[0046] The modular catalyst was prepared by using the catalyst formula when the V loading in Example 2 was 1.2 wt% and using the method described in Example 2.

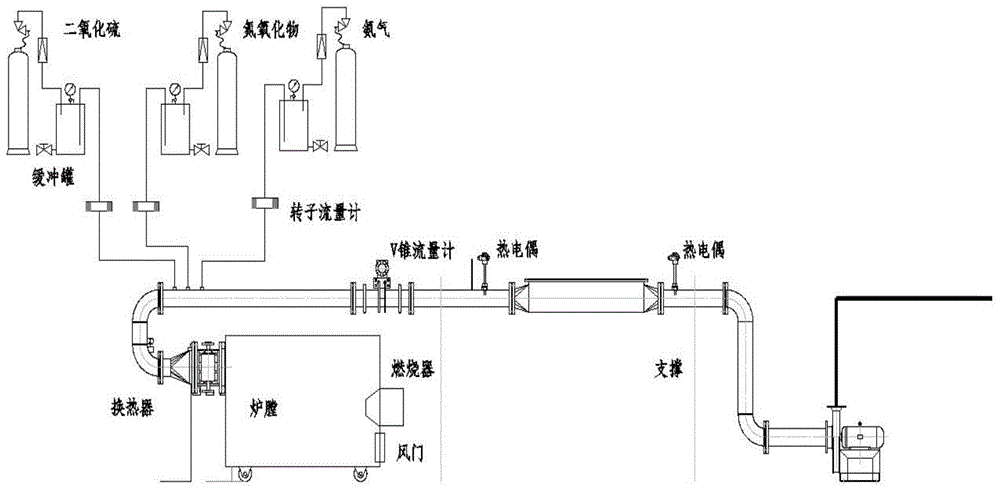

[0047] 1), using 70kW coal-fired simulated flue gas denitrification evaluation device NO x The influence of the concentration on the denitrification reaction of the catalyst, the results are as follows Figure 7 shown.

[0048] Depend on Figure 7 It can be seen that in NO x In the concentration range of about 300-800ppm, the SCR denitration rate of the V(1.2) catalyst is stable at about 91%, reflecting a wide range of NO x Concentration activity removal window.

[0049] 2) Using the 100kW real flue gas denitrification evaluation device to evaluate the changes in the concentration of nitrogen oxides at the inlet, the results are as follows Figure 8 shown.

[0050] Depend on Figure 8It can be seen that when the generator is under the condition of relatively high external load, thermal nitrogen oxides are gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com