Catalyst for producing ethanol by hydrogenation of acetic ester, and preparation method thereof

A technology for hydrogenation of acetate and catalyst, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high price, unfavorable industrial production, and high cost, and achieve Low price, reduced production energy consumption and investment in fixed equipment, less reaction by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

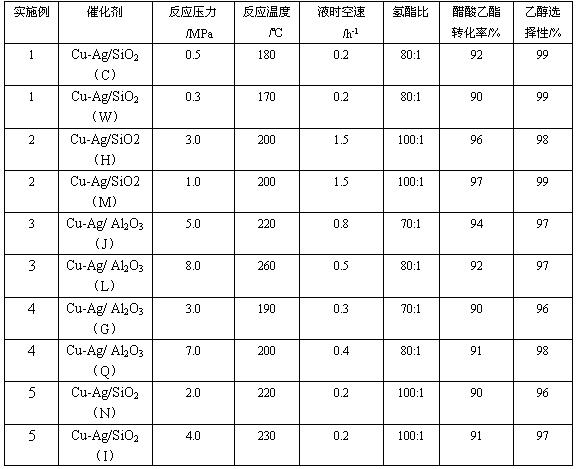

Examples

Embodiment 1

[0041] Weigh 2 parts of 100g silica sol carrier, one part is modified (recorded as SiO 2 (C)), one unmodified (denoted as SiO 2 (W)), configure the catalyst with 15wt% Cu and 5wt% Ag content based on the weight of the carrier, the steps are as follows: select copper nitrate, silver nitrate, and prepare an impregnating solution according to the Cu and Ag loading, in order to prevent the hydrolysis of metal ions to produce hydroxide Precipitation of substances or oxides, add a small amount of nitric acid to the impregnating solution to make the pH of the impregnating solution about 5~6, and then prepare the SiO 2 After the carrier was immersed in the solution for 24 hours, it was vacuum-dried for 6 hours, calcined at 650°C for 6 hours, and then reduced at 450°C for 6 hours with a flow rate of 400mL / min and a mixture of nitrogen and hydrogen containing 20% hydrogen. Cu-Ag / SiO 2 catalyst. Respectively denoted as Cu-Ag / SiO 2 (C) and Cu-Ag / SiO 2 (W).

Embodiment 2

[0043] Take by weighing 2 parts of 100g modified silica sol carrier, configure the catalyst with 20wt% Cu and 6wt% Ag content by carrier weight, the steps are as follows: select cupric chloride, silver nitrate, prepare impregnating solution according to Cu and Ag load capacity, for To prevent the hydrolysis of metal ions to produce hydroxide or oxide precipitation, a small amount of nitric acid is added to the impregnating solution to make the pH of the impregnating solution about 6.5, and then the prepared modified SiO 2 After the carrier is immersed in the solution for 10 hours, it is fully absorbed and dried into a solid in a water bath, and then the solid is dried at 120°C for 6 hours, and roasted at 500°C for 6 hours, and then the flow rate of 200mL / min contains hydrogen to 20 % nitrogen and hydrogen mixed gas, reduced at 600 ° C for 2 hours, then made into Cu-Ag / SiO 2 catalyst. Respectively denoted as Cu-Ag / SiO 2 (H) and Cu-Ag / SiO 2 (M).

Embodiment 3

[0045] Weigh 2 parts of alumina 100g carrier, one part is modified (denoted as Al 2 o 3 (J)), one unmodified (denoted as Al 2 o 3 (L)), configure the catalyst with 15wt% Cu and 5wt% Ag content based on the weight of the carrier, the steps are as follows: select copper nitrate, silver nitrate, and prepare an impregnating solution according to the Cu and Ag loads, in order to prevent the hydrolysis of metal ions to produce hydroxide Precipitation of substances or oxides, adding a small amount of nitric acid to the impregnating solution to make the pH of the impregnating solution about 5~6, and then the prepared modified Al 2 o 3 The carrier was soaked in the solution for 24 hours, dried in vacuum for 4 hours, calcined at 650°C for 4 hours, and then reduced at 450°C for 6 hours with a flow rate of 300mL / min and 20% hydrogen containing nitrogen and hydrogen gas to prepare into Cu-Ag / Al 2 o 3 catalyst. Respectively denoted as Cu-Ag / Al 2 o 3 (J) and Cu-Ag / Al 2 o 3 (L). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com