Quick and clean process for preparing biological diesel oil with esterification/ester exchange reaction

A technology of transesterification reaction and biodiesel, which is applied in the field of energy and chemical industry, can solve the problems of high production energy consumption and cost, difficult realization of heating engineering, discharge of washing wastewater, etc., and achieves low equipment corrosion, simplified post-treatment process, supercritical The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

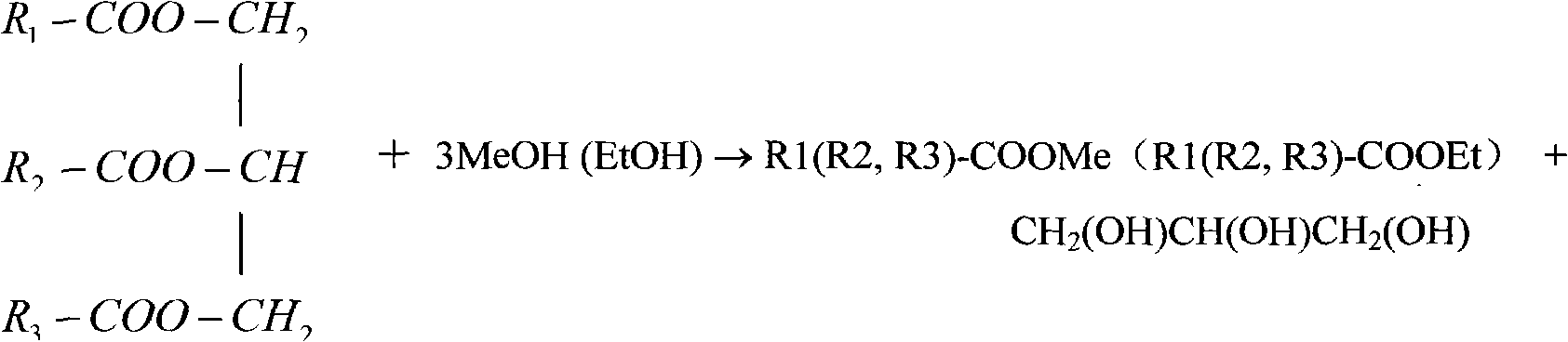

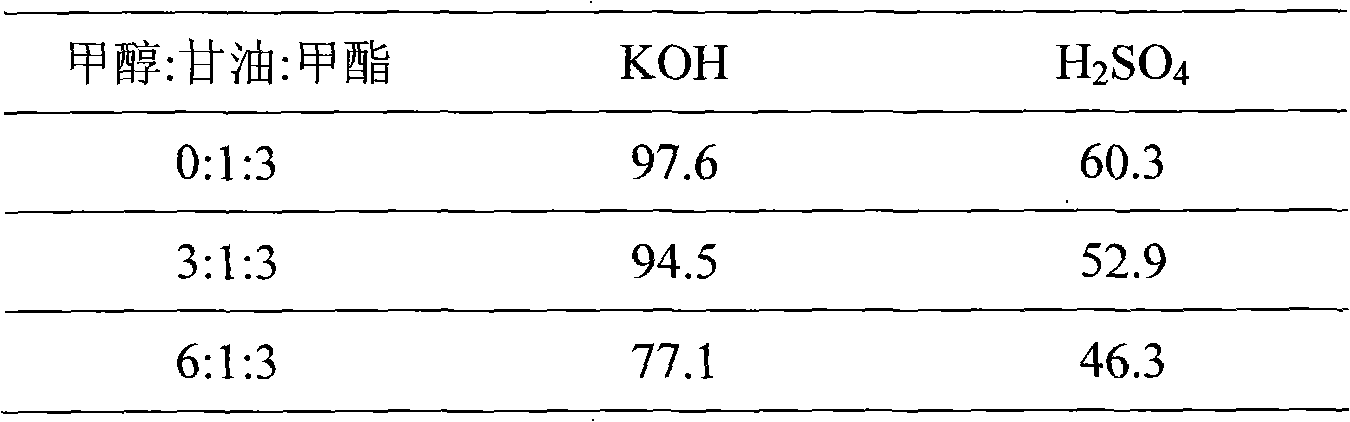

Method used

Image

Examples

Embodiment approach 1

[0033]Embodiment 1: Take 70.0g of acidified oil with an acid value of 50mgKOH / g, the amount of methanol is calculated according to the molar ratio of alkyd to 10:1, which is 1.0g, catalyst H 2 SO 4 The dosage is 1.5‰ of the oil weight, which is 0.10g, the reaction temperature is 120°C, the reaction time is 15 minutes, and the pre-esterification conversion rate can reach 98%. Mix the dehydrated refined oil with 100.0g methanol uniformly, and pre-add NaOH with 1‰ of the oil weight into the methanol. Rapeseed oil and methanol were added to a high temperature and high pressure airtight reactor with a volume of 300 ml. The reaction temperature is 200° C., and the reaction pressure is 2.5 MPa; after 15 minutes of reaction, the reactor is cooled to room temperature, the excess methanol is distilled under reduced pressure, and the product is allowed to stand and separate into layers. The upper layer is the methyl ester layer and the lower layer is the glycerin layer. The oil conversion ra...

Embodiment approach 2

[0034] Embodiment 2: The pre-esterification catalyst H in the above embodiment 1 2 SO 4 The addition amount was changed to 0.7‰ of the oil weight, and other conditions were unchanged. The experimentally measured pre-esterification conversion rate was 87%. After transesterification, the glycerin content in the methyl ester is less than 1%, the acid value is less than 0.5mgKOH / g, the sulfur content is less than 0.05%, and the alkali content is less than 10mg / kg.

Embodiment approach 3

[0035] Embodiment 3: Change the NaOH addition amount of the transesterification catalyst in the above embodiment 1 to 0.5‰ of the oil weight, other conditions remain unchanged, the fat conversion rate measured by the experiment is 88.5%, and the glycerin content in the methyl ester is less than 1%. The acid value is less than 0.5mgKOH / g, the sulfur content is less than 0.05%, and the alkali content is less than 10mg / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com