Preparation method of cyclohexane

The technology of cyclohexane and tower kettle is applied in the field of preparing cyclohexane, which can solve the problems such as the difficulty of catalyst replacement, and achieve the effects of stable operation and content reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

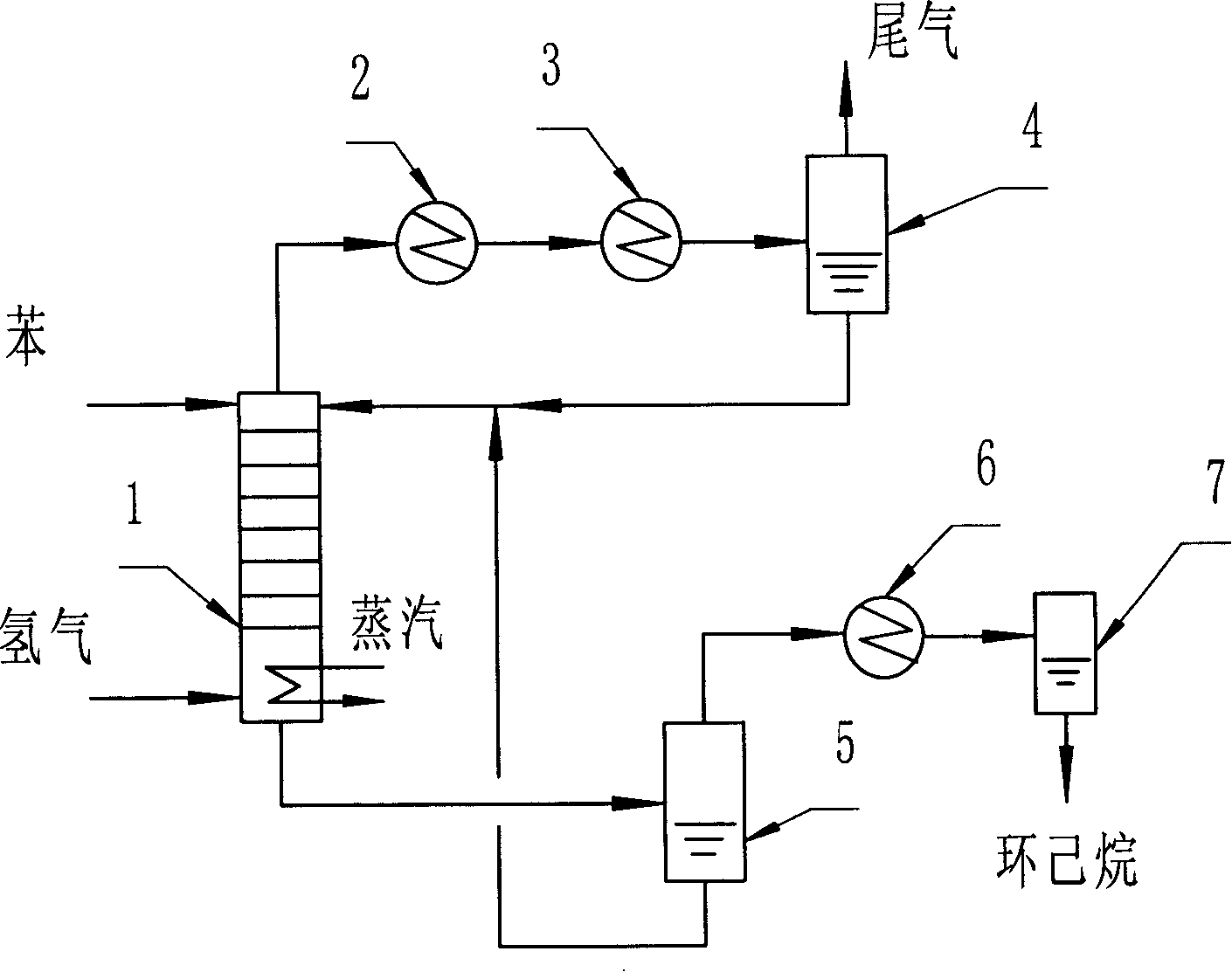

Image

Examples

Embodiment 1

[0024] Structural parameters of the reaction distillation tower: a sieve tray tower with a diameter of Φ100mm, the number of trays is 20, the aperture of the tray is Φ3mm, and the opening ratio is 3.0%, and a homogeneous complex nickel catalyst (produced by Sinopec Baling Branch, brand name HC-402-2).

[0025] Operating conditions: The pressure of the reaction distillation tower is 1800KPa, the temperature of the tower is controlled at 180°C, the amount of benzene fed to the top of the tower is 5 kg / hour, the ratio of hydrogen to benzene is 3.1, and the concentration of the main catalyst metal nickel in the feed tray is 700-1000 mg / kg, flash tank pressure 400KPa.

[0026] Experimental results: the residual benzene content is 700mg / kg, and the hydrogen utilization rate is 94.95%.

Embodiment 2

[0028] Operating conditions: The pressure of the reaction distillation tower is 1800KPa, the temperature of the tower is controlled at 180°C, the amount of benzene fed to the top of the tower is 5 kg / hour, the ratio of hydrogen to benzene is 3.1, and the concentration of the main catalyst metal nickel in the feed tray is 1700-1900 mg / kg. Other conditions are the same as example 1.

[0029] Experimental results: The residual benzene content is 200mg / kg, and the hydrogen utilization rate is 96.99%.

Embodiment 3

[0031] Operating conditions: The pressure of the reactive distillation tower is 1200KPa, the temperature of the tower tank is controlled at 170°C, the amount of benzene at the top of the tower is 5 kg / hour, the ratio of hydrogen to benzene is 4, and the pressure of the flash tank is 300KPa. Other conditions are the same as example 1.

[0032] Experimental results: the residual benzene content is 970mg / kg, and the hydrogen utilization rate is 73.99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com