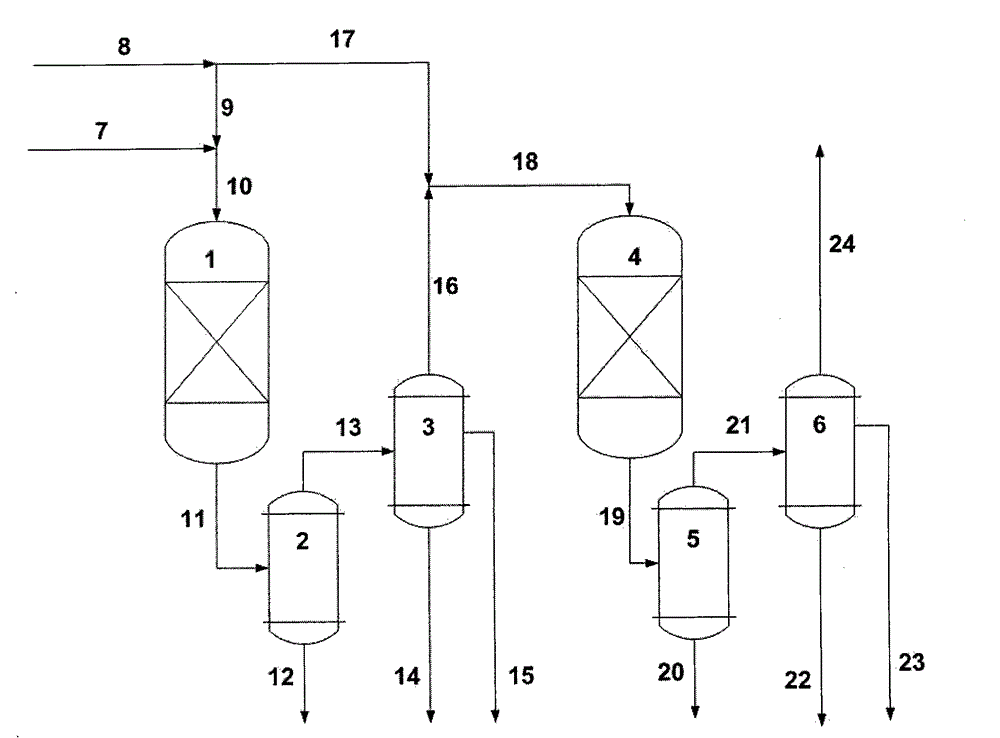

Fischer-Tropsch process device and technology

A Fischer-Tropsch synthesis and process technology, which is used in the production of hydrocarbons from carbon oxides, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as deactivation of catalysts due to reaction heat, and achieve the effect of reducing the deactivation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

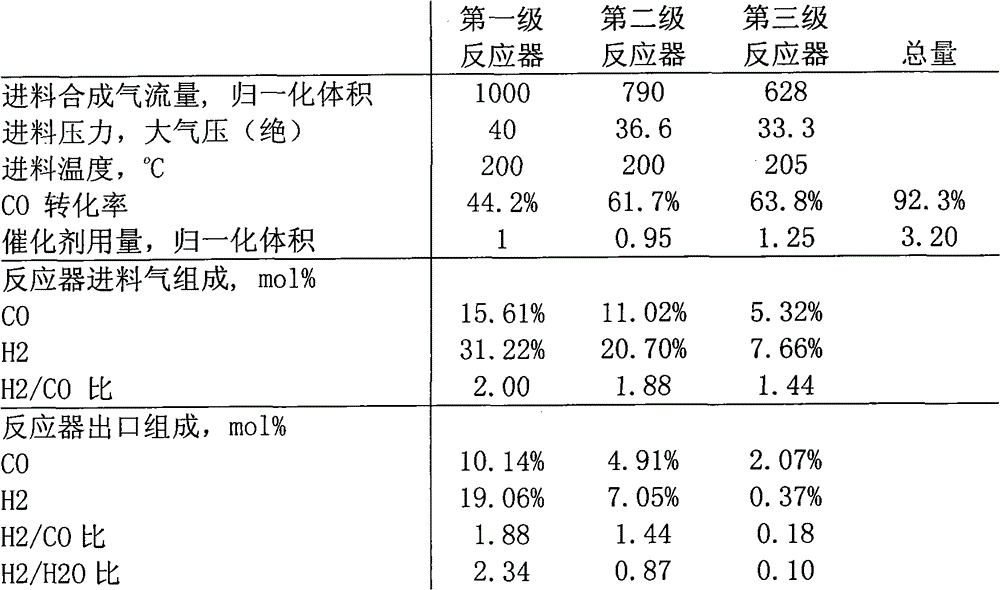

[0038] A three-stage fixed-bed reactor system in series, the three reactors all use the same cobalt-based catalyst, the products at the outlet of each reactor are cooled to separate hydrocarbon products and water, and the tail gas is sent to the next-stage reactor. Each reactor has no side hydrogen supply, and the operating conditions of the reactors are shown in Table 1. The ratio of hydrogen to water at the outlet of the second-stage reactor is 0.87. Under this working condition, the rapid deactivation of the catalyst will not be caused, but the ratio of hydrogen to carbon and the ratio of hydrogen to water at the outlet of the third-stage reactor are reduced to 0.18 and 0.1 respectively. , the deactivation rate of the catalyst is significantly accelerated, and normal operation becomes very difficult.

[0039] Table 1 Three-stage non-circulation series reactor without side line hydrogen supplement

[0040]

example 2

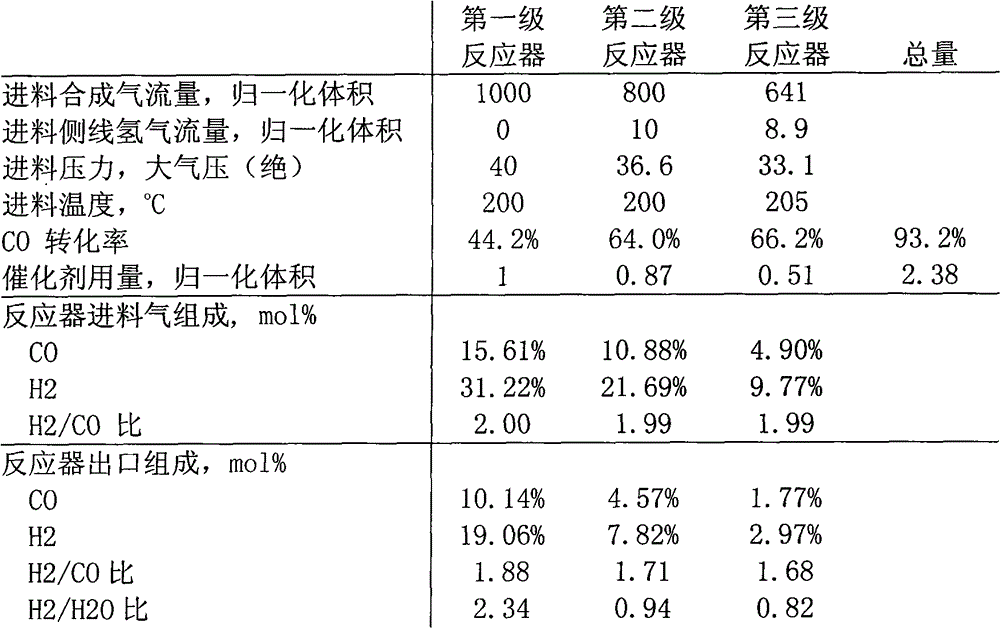

[0042] A three-stage fixed-bed reactor system in series, the three reactors all use the same cobalt-based catalyst, the products at the outlet of each reactor are cooled to separate hydrocarbon products and water, and the tail gas is sent to the next-stage reactor. The first-stage reactor has no side line hydrogen supplement, and the second and third-stage reactors have side line hydrogen supplement to increase the carbon-hydrogen ratio of the feed gas. The operating conditions of the reactors are shown in Table 2. Due to the use of side line to supplement hydrogen, the ratio of hydrogen to water at the outlet of the second-stage and third-stage reactors was 0.94 to 0.82 respectively, and the catalyst was not rapidly deactivated due to the protection of a sufficient amount of hydrogen. Compared with example 1, in the case of similar total conversion rate, due to the increase of hydrogen partial pressure, the kinetic efficiency of the catalyst is improved, and the amount of supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com