Airflow thermal insulation rubber hose assembly for high-temperature thermal radiation environment

A rubber hose, heat radiation technology, applied in the direction of protecting pipes, pipe elements, pipes/pipe joints/pipe fittings through thermal insulation, etc. Problems such as heat transfer from the heat-disconnecting source and performance degradation at the connection of the hose assembly can reduce the consumption of spare parts, make production faster, and reduce the investment of manpower and financial resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

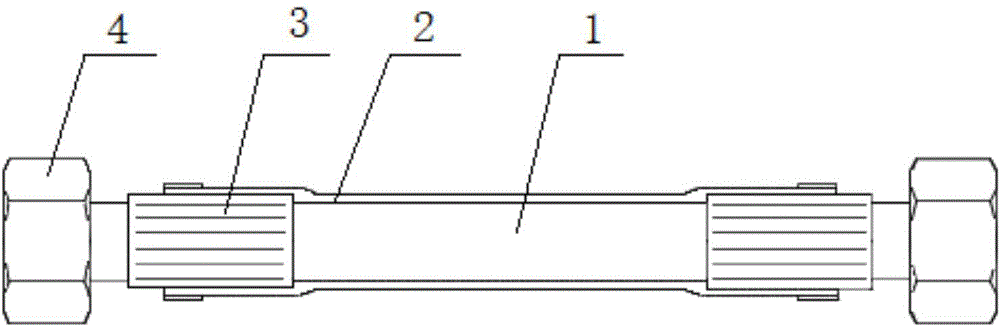

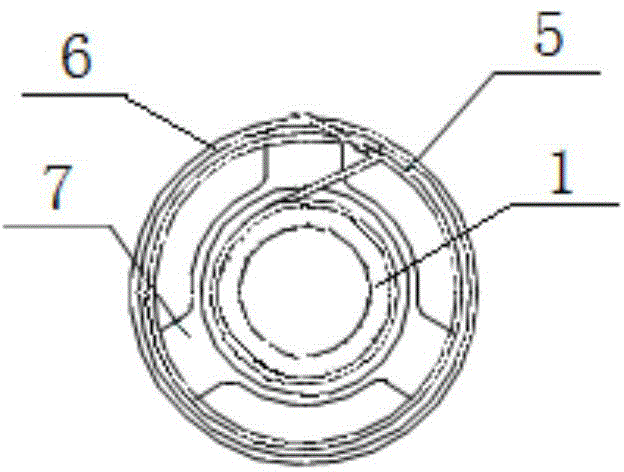

[0033] Embodiment 1: as attached figure 1 As shown, the two ends of the hose body 1 are respectively connected to the joints 4, the two joints (4) and the hose body (1) are connected through the sleeve (3), the protective layer 2 is covered between the two sleeves 3, and the protective layer 2 The elastic support frame 5 of the jacket wraps the outer sheath 6 outside the elastic support frame 5 .

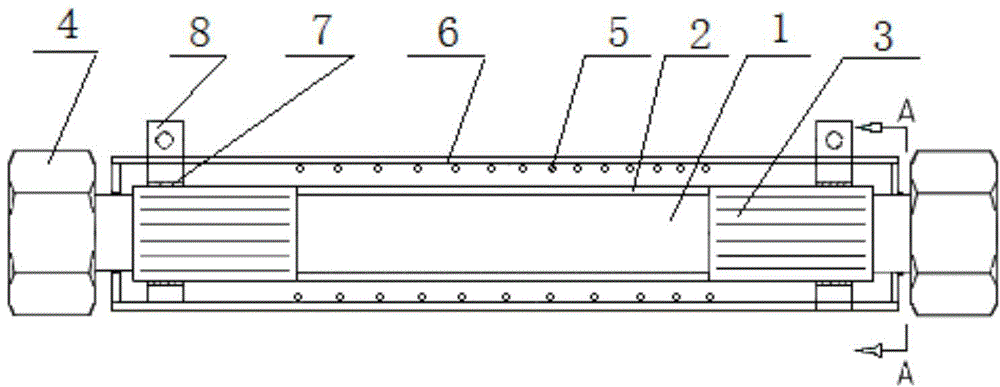

[0034] In the foregoing, the positioning sliding rings 7 are fitted outside the sleeve 3 respectively, and the outer edge of the positioning sliding ring 7 abuts against the inner wall of the outer sheath 6 .

[0035] In the foregoing, the elastic support frame 5 is a spring, which is made of existing general-purpose materials and techniques, with sufficiently long straight ends left at both ends, and corresponding heat treatment is carried out to facilitate winding on the neck of the hose joint; the elastic support frame 5 supports Outer sheath 6, and guarantee that flexible pipe ...

Embodiment 2

[0039] Embodiment 2: as attached Figure 6As shown in , when the radiant heat is very strong, in order to reduce the heat absorbed by the joint 4 and conduct it to the rubber hose body 1, the inner diameter of the outer sheath 6 and the elastic support frame 5 is increased, and the length of the outer sheath 6 is lengthened. Even exceeding the total length of the hose assembly, and making it extend the wrap around the joints 4 at both ends, the heat conduction distance can be extended. The length of the outer sheath 6 is greater than the distance between the outer faces of the joints 4 at both ends, and the inner diameter of the outer sheath 6 and the elastic support frame 5 is greater than the maximum outer diameter of the joint 4 and the joint connected thereto. When assembling and disassembling the hose assembly, the elastic support frame 5 can be axially compressed, and the joints 4 at both ends can be exposed.

Embodiment 3

[0040] Embodiment 3: as attached Figure 7 As shown; that is, as in Embodiment 2, the neck of the joint 4 and the length of the outer sheath 6 can also be lengthened at the same time.

[0041] The above three examples can choose the best solution according to the specific situation of radiant heat and installation conditions.

[0042] In the present invention, the hose body 1 is flexible, and both the direction of the pipeline and the movement of the equipment require the bending of the hose assembly. The elastic support frame 5 of the spring structure has small bending force and small radial deformation. The movable structure at both ends can Compensate for the inconsistent length change of the outer sheath 6 and the hose body 1 during bending; the neck winding structure of the joint 4 at both ends of the elastic support frame 5 can stretch the elastic support frame 5 when the length compensation is not enough to ensure that it is wrapped in the outer sheath 6 The inner slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com