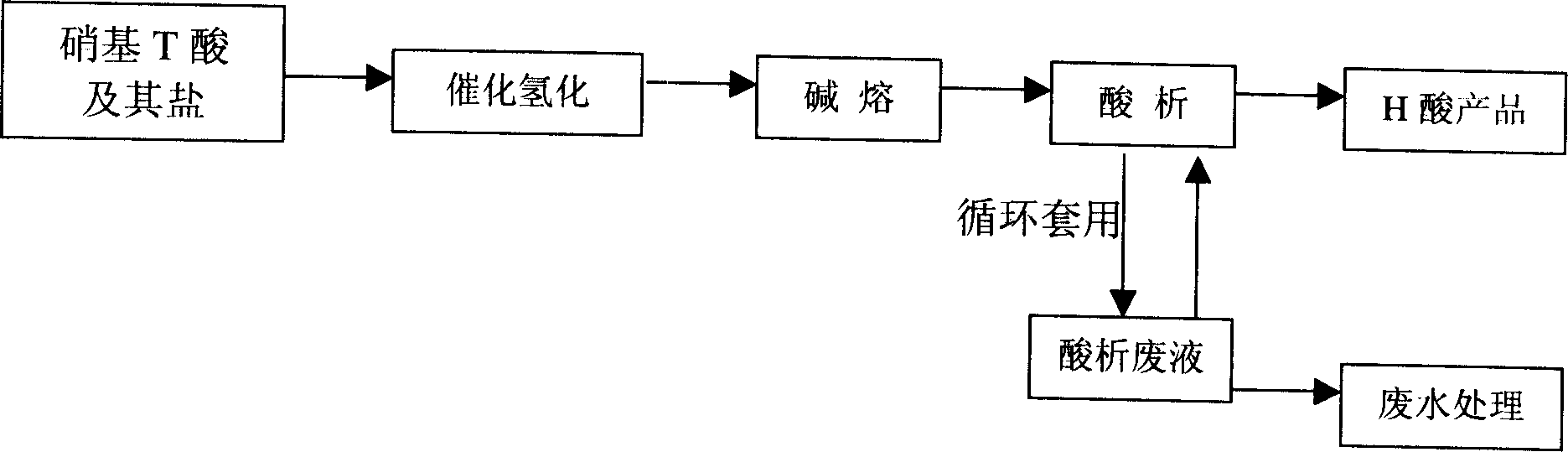

Catalytical hydrogenation process to produce II acid

A catalytic hydrogenation and process technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Amino value is 25g / L nitro-T acid and its salt solution adjustment pH is 7.5, changes in the autoclave, adds the catalyzer that is 0.5% by nitro-T acid weight measurement, and this catalyzer is the composite nickel containing 20% cobalt Cobalt catalyst, first react at 100-105°C for 2 hours under a hydrogen pressure of 1.0-2.0MPa under high-speed stirring, and then feed hydrogen to a pressure of 2.5MPa and further catalyze the reaction at 120°C for 2 hours, and then detect the amino acid by HPLC Conversion >95.

Embodiment 2~10

[0031] Examples 2-10 (catalytic hydrogenation reaction temperature, time, and reaction in the following examples refer to the second step reaction, and the first step hydrogenation reaction strips are all reacted at 100-105° C. for 2 hours under a hydrogen pressure of 1.0-2.0 MPa) :

[0032] Reality

Embodiment 11

[0034] Nitro-T acid HPLC content>98 nitrous acid concentration adjustment of solution is 35g / L, adds in autoclave, adds solid sodium hydroxide and is 50% of nitro-T acid weight measurement, adds methyl alcohol to be nitro-T acid weight measurement 45% of the metered amount, alkali fusion at 185°C for 2 hours, the alkali melt can be obtained. The alkali fusion conversion rate of amino T acid detected by HPLC is greater than 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com