Method for deeply extracting calcium sulfate from phosphorus ore acid hydrolysis liquid

A technology of deep extraction and acid hydrolysis, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of difficult recovery of phosphogypsum, high requirements for raw materials, long process flow, etc., and achieve moderate particle size and shortened The production process and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Investigate the effect of humic acid on the purification of acid hydrolysis solution

[0030] Take phosphate rock from Lufa Phosphate Mine in Guizhou, crush it to a particle size of figure 1 and figure 2 .

[0031] Further investigation on the addition of humic acid found that when the addition of humic acid was less than 5%, the flocculation time increased with the decrease of the addition; when the addition was ≥5%, the flocculation time did not change much. Therefore, the added amount of humic acid is selected to be 5-10% based on the weight of the added phosphate rock.

Embodiment 2

[0033] Investigate the influence of each parameter in the two crystallizations

[0034] Take the purified acid solution after humic acid flocculation in Example 1 as the test raw material for follow-up research. First, carry out component content analysis on the purified acid solution, the results are as follows in Table 1:

[0035] Table 1 - content test results

[0036] project P 2 o 5

[0037] (1) Influence of the two crystallization temperatures on the size of the product

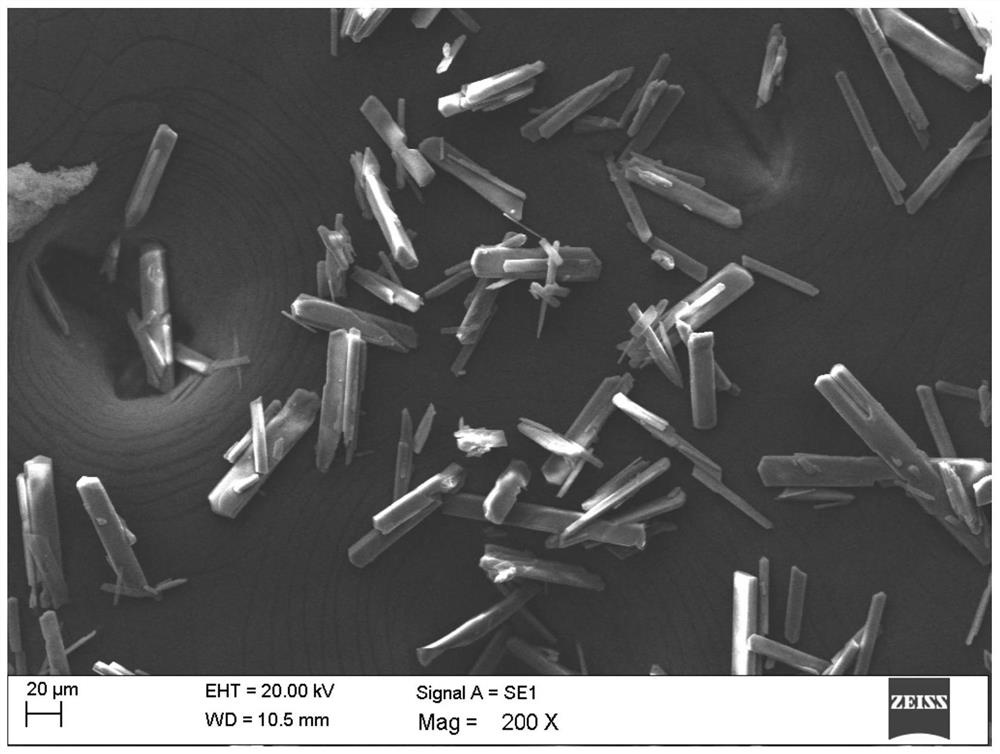

[0038] The present invention investigates the effect of the temperature of the two crystallization processes on the particle size of the prepared product. Add sulfuric acid or sulfate to the purified acid solution for one-time crystallization, control the reaction temperature (HH) at 30-70°C for 2 hours, and crystallize to obtain a calcium sulfate hemihydrate mixed solution; then control the temperature of the calcium sulfate hemihydrate mixed solution (DH) When the temperature is 30-...

Embodiment 3

[0066] Investigate the applicability of phosphate rock from different sources to this process

[0067] In order to avoid the defects of the freezing method widely used in foreign countries - the disadvantage of high requirements on raw materials, this method specially takes phosphate rocks from different sources of phosphate rocks to test the applicability range of raw materials for this process, and the content of iron, magnesium and aluminum is from high to low. wait. The content of each component in the selected phosphate rock is shown in the following table 8:

[0068] Table 8-Component content (%) in different phosphate rocks

[0069] source P 2 o 5

MgO al 2 o 3

K 2 o

Na 2 o

SO 4 2-

CaO Fe 2 o 3

SiO 2

F -

Linyi Sanqi 30.07 0.51 3.51 0.30 0.13 0 43.17 1.93 15.28 2.00 Guizhou Lufa 32.92 1.94 1.16 0.84 0.71 2.36 48.57 1.15 7.18 2.46 Jinan Railway 28.72 2.40 2.06 0.29 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com