Process of preparing biological diesel oil

A biodiesel and process technology, applied in the petroleum industry, biological raw materials, biofuels, etc., can solve the problems of demanding moisture content in raw oil, difficult separation of catalysts and products, and large amounts of waste water, so as to avoid saponification reaction and increase added value , the effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

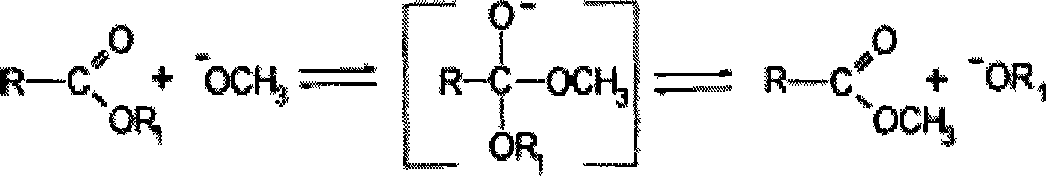

Method used

Image

Examples

Embodiment 1

[0038] Catalyst preparation:

[0039] Weigh 4g of magnesium metal and 98.4g of methanol and place them in a three-necked flask equipped with a stirrer, a thermometer, and a condenser tube, heat the reaction in a water bath, and control the reaction temperature from 40°C to 65°C until all the magnesium metal disappears, forming milky white Magnesium methoxide and methanol solution, timed for 1.5 hours.

[0040] Preparation of biodiesel:

[0041] Slowly add 160g soybean oil (about 0.7% of water content) in above-mentioned solution, continue stirring reaction 3 hours, control reaction temperature is 65 ℃, after reaction finishes, mixture is filtered, and filtrate and filter cake are collected, and filtrate normal pressure distillation, temperature At about 120°C, recover unreacted methanol. Then add 100ml of hot water at 80°C for washing, and dehydrate and refine the crude biodiesel under reduced pressure with a vacuum of 0.07-0.1MPa and a temperature of about 100°C to finally ...

Embodiment 2

[0046]Rapeseed oil was used as raw material to prepare biodiesel, the reaction time was 6 hours, the reaction temperature was 50°C, and the other process conditions were the same as in Example 1. 200g of rapeseed oil, 6g of magnesium, and 128g of methanol yielded 192g of biodiesel with a fatty acid methyl ester content of 97.9%. Catalyst post-treatment water 120ml, methanol 100ml, glycerol 19.2g, yield 96%, purity 96.4%. 9.93 g of magnesium oxide was obtained, and the recovery rate of magnesium was 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com