Method for synthesizing sec-butyl alcohol

A technology of sec-butanol and sec-butyl acid, which is applied in the field of synthesizing sec-butanol, can solve the problems of difficult product separation, serious equipment corrosion, high production cost, etc., and achieve the effects of easy separation and purification, high conversion rate and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

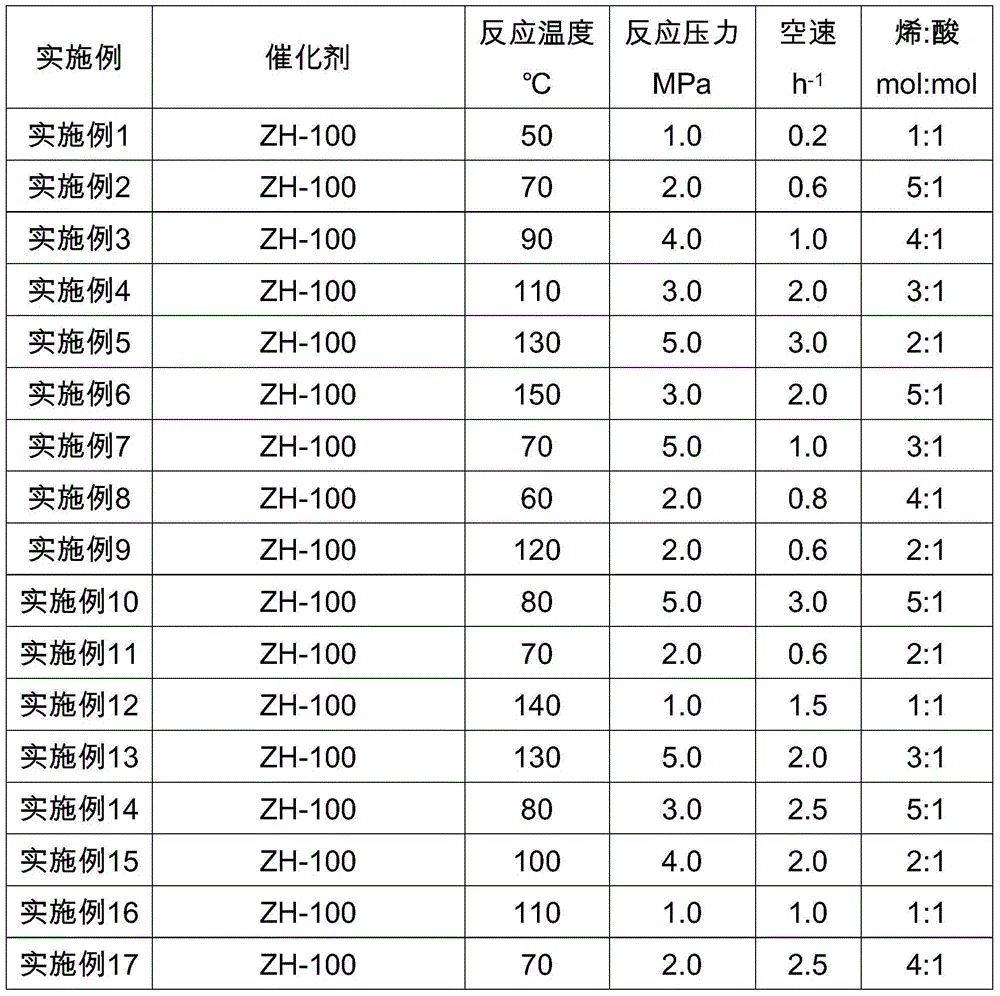

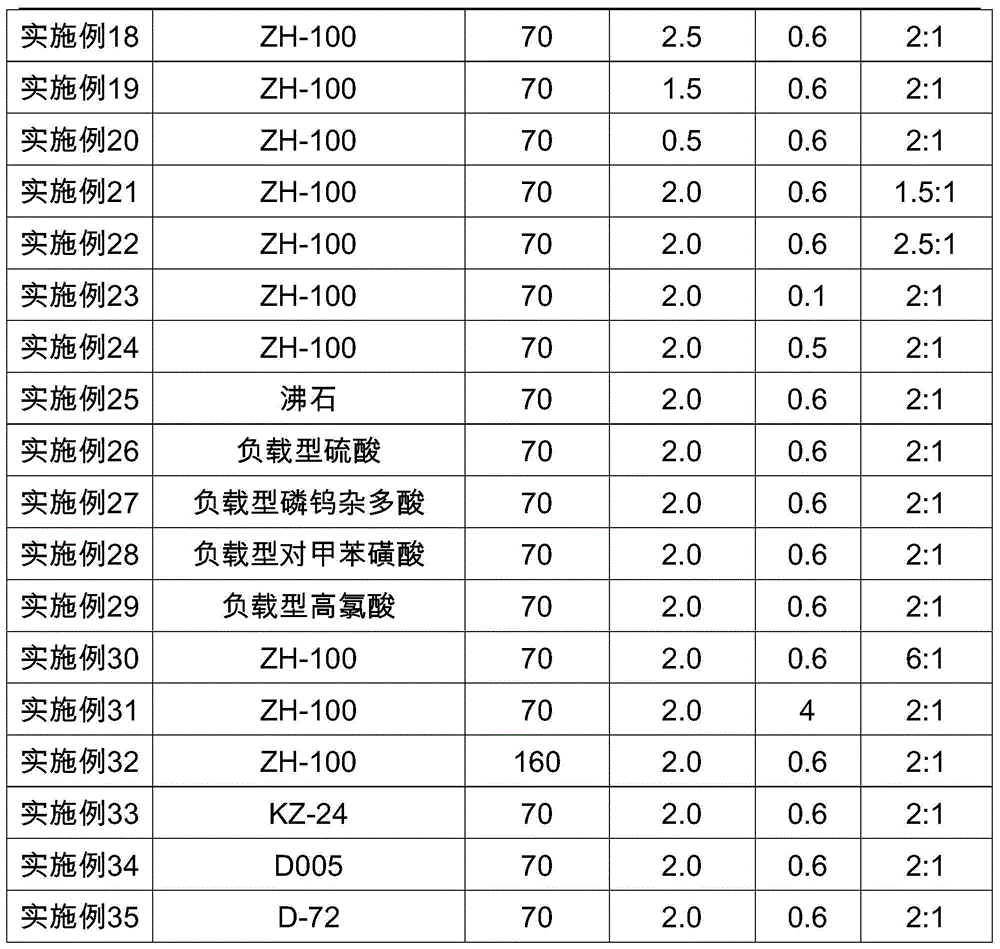

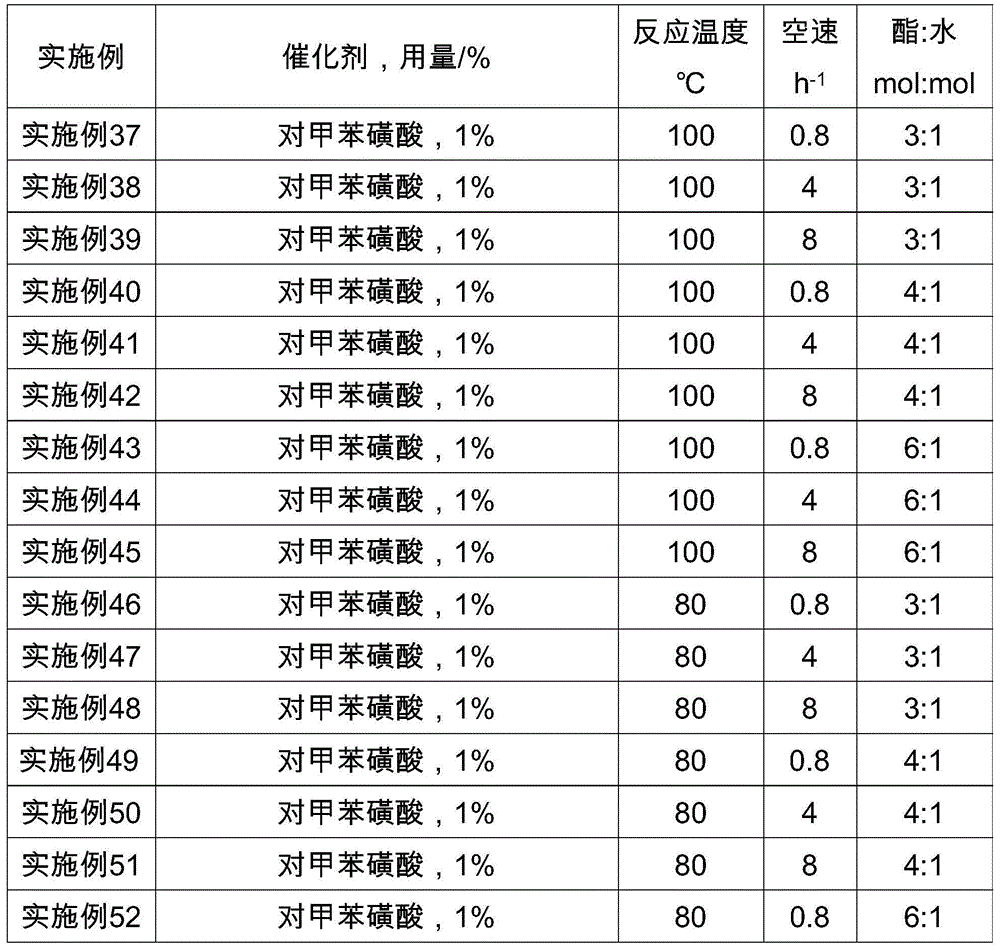

Examples

Embodiment 36

[0035] Synthesis of sec-butyl propionate: the synthesis method and reaction conditions of this embodiment and embodiment 11 are basically the same, the difference is: the synthesis reaction continues to run for 150h; Feed into the reaction raw materials, so that the synthesis reaction continued for 150h. Detect the reaction situation at the beginning of the reaction (the reaction is carried out for 2h) and the operation time of 150h.

[0036] Initial reaction conditions: the conversion of propionic acid was 70.2%, and the selectivity of sec-butyl propionate was 98.7%.

[0037] The reaction situation when running for 150 hours: the conversion rate of propionic acid is 67.6%, and the selectivity of sec-butyl propionate is 97.6%.

[0038] Hydrolyzed sec-butyl propionate:

[0039] The water in the water storage tank is first sent to the preheater to be heated to 100°C through the metering pump, and then sent to the lower part of the hydrolysis tower (hydrolysis reactor). At the...

Embodiment 74-80

[0052] Influence of the content of n-butene in the n-butene raw material on the reaction:

[0053] Among the embodiment 74-80, the addition reaction of propionic acid and n-butene is basically the same as that of Example 11 (the molar ratio of n-butene and propionic acid is 2:1), the difference is that: will contain 20wt% n-butene The n-butene raw materials of butenes were respectively replaced with n-butene raw materials containing 10wt%, 20wt%, 40wt%, 50wt%, 60wt%, 80wt%, and 99wt% of n-butenes.

[0054] The hydrolysis reaction of the sec-butyl acrylate obtained through the addition reaction is identical to that of Example 61.

[0055] The reactions of Examples 74-80 are shown in Table 5 below.

[0056] The reaction result of table 5 embodiment 74-80

[0057]

[0058] In other embodiments, the preheating temperature before the material enters the hydrolysis tower can also be 80-100°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com