Zirconium-based amorphous alloy and preparation method thereof

A zirconium-based amorphous alloy and alloy technology, which is applied in the field of metal materials and metallurgy, can solve the problems of limiting the wide application of amorphous alloys, increasing the production cost of amorphous alloy products, and being unable to mass-produce, achieving excellent mechanical properties, reducing high requirements, the effect of pressure to reduce raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

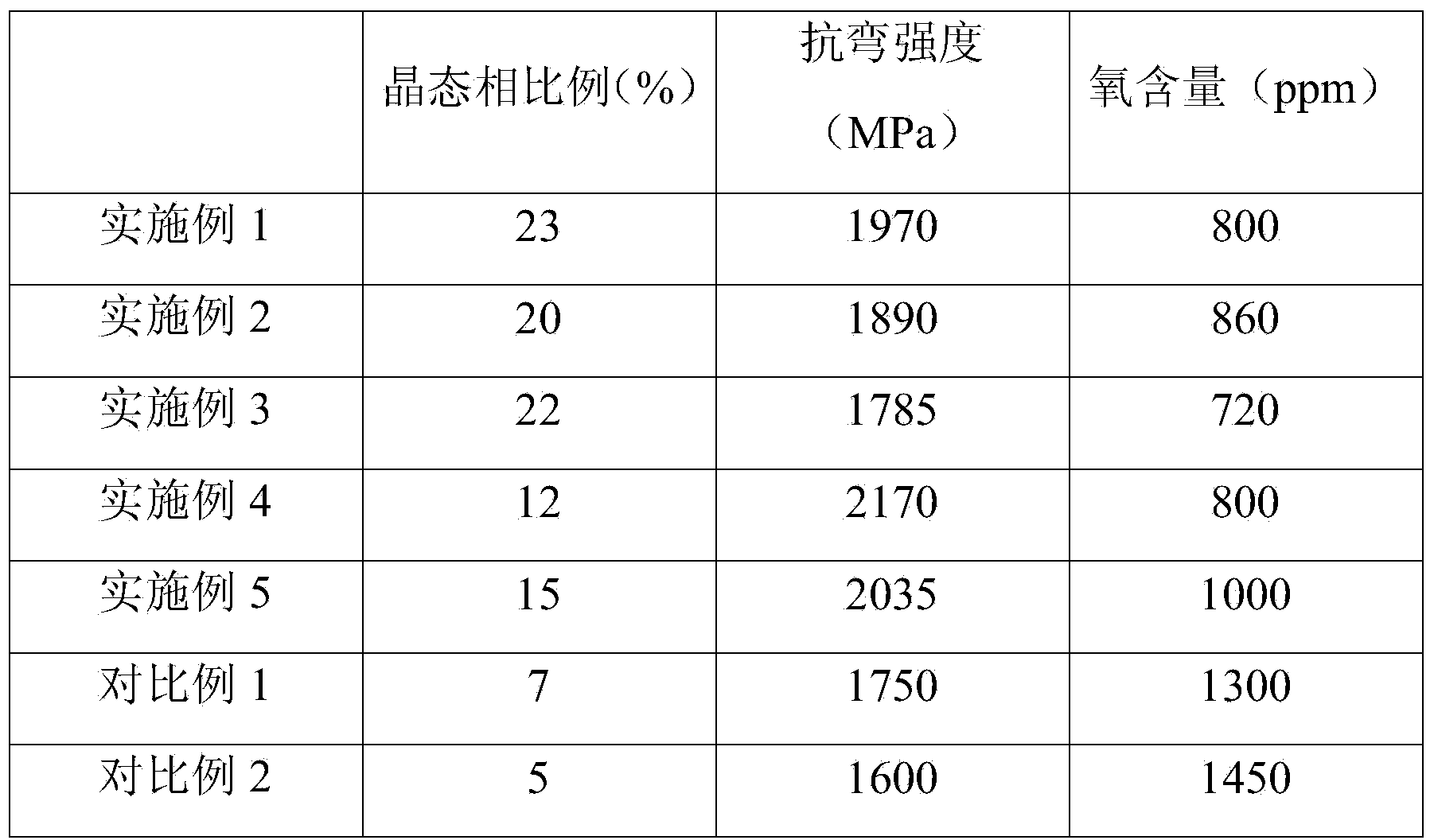

[0033] The preparation method of the zirconium-based amorphous alloy of the present invention can adjust the crystalline phase in the zirconium-based amorphous alloy by controlling the composition of the zirconium-based amorphous alloy and controlling the cooling and forming conditions according to conventional methods in the art and different proportions of the amorphous phase. The cooling forming conditions include cooling speed, pressure, mold material, mold thermal conductivity and the like. Among them, the cooling rate is one of the key factors controlling the ratio of crystalline phase and amorphous phase in zirconium-based amorphous alloys, and the selection range of conditions such as pressure, mold material, and mold thermal conductivity is wide, and the matching selector must ensure The cooling and forming conditions described above can be met only if an appropriate cooling rate can be obtained. In known casting methods, the volume fraction of the crystalline phase ...

Embodiment 1

[0043] Put various zirconium-based amorphous alloy raw materials with a purity of 99% by mass into the arc melting furnace, evacuate the arc melting furnace to 10Pa, and then pass in argon with a purity of 99.9% by volume as a protective gas. smelting for 3 minutes to fully melt the zirconium-based amorphous alloy raw material. The kind of the zirconium-based amorphous alloy raw material and the Zr that the atomic percentage is 50%, the Ti that the atomic percentage is 2%, the Cu that the atomic percentage is 15%, the Ni that the atomic percentage is 10%, 15 atomic percent of Al, 4 atomic percent of Y, 2 atomic percent of Sc, and 2 atomic percent of Si.

[0044] The molten sample is cast into a copper alloy mold by die-casting and cooled to obtain a zirconium-based amorphous alloy (Zr 100-x-y Ti x f y ) a (Cu m Ni n ) b al c m d N e .

Embodiment 2

[0046] Put various zirconium-based amorphous alloy raw materials with a purity of 99% by mass into the arc melting furnace, and vacuum the arc melting furnace to 10 -1 Pa, and then pass through argon with a purity of 99.9% by volume as a protective gas, and melt for 3 minutes at 1650 ° C to fully melt the zirconium-based amorphous alloy raw material. The type of the zirconium-based amorphous alloy raw material and Zr with an atomic percentage of 60%, Ti with an atomic percentage of 3%, Hf with an atomic percentage of 2%, and Cu with an atomic percentage of 12.5%, 7.5 atomic percent Ni, 5 atomic percent Al, 5 atomic percent Y, 3 atomic percent Sc, 1.5 atomic percent Si, The atomic percent content is 0.5% C.

[0047] The molten sample is cast into a copper alloy mold by die-casting and cooled to obtain a zirconium-based amorphous alloy (Zr 100-x-y Ti x f y ) a (Cu m Ni n ) b al c m d N e .

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com