Preparation method and application of an aluminum-based liquid-cooled heat dissipation structure

A liquid-cooled heat dissipation, aluminum-based technology, applied in cooling/ventilation/heating renovation, electrical equipment structural parts, electrical components, etc., can solve the problems of easy deformation and breakage, low strength, etc., achieve good heat dissipation capacity, and reduce preparation requirements , the effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

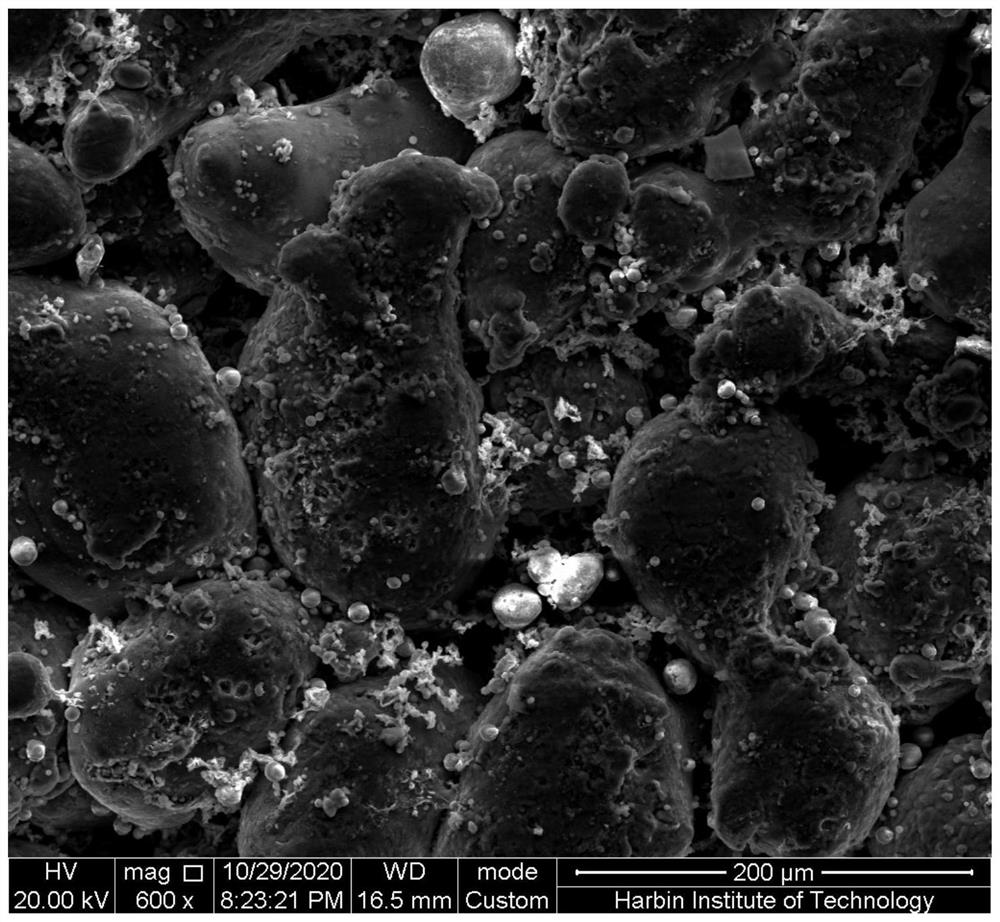

Image

Examples

specific Embodiment approach 1

[0025] Embodiment 1: This embodiment is a preparation method of an aluminum-based liquid-cooled heat dissipation structure, which is carried out according to the following steps:

[0026] 1. Preparation of foam aluminum structure:

[0027] 1. Add flux, particle reinforcing phase and gas-forming agent to the aluminum-based powder, and stir evenly to obtain a preform powder;

[0028] The mass ratio of the aluminum-based powder to the flux is 1:(0.01-1); the mass ratio of the aluminum-based powder to the particle reinforcing phase is 1:(0.01-1); the aluminum-based powder and the The mass ratio of the gas generating agent is 1:(0.01~1);

[0029] ②. Put the preform powder into the hot-pressing sintering mold, and pre-sinter for 5min-10h under the protective gas atmosphere, the temperature is 200℃~500℃ and the pressure is below 1GPa, to obtain the hot-pressing structure after pre-sintering ;

[0030] 3. Under the protective gas atmosphere, the temperature is 500 ℃~1500 ℃ and the ...

specific Embodiment approach 2

[0041] Embodiment 2: This embodiment is different from Embodiment 1 in that: the particle size of the aluminum-based powder described in step 1 ① is 10 mesh to 1000 mesh; the aluminum-based powder described in step 1 ① is Al powder or Al-Si alloy powder; the flux described in step 1① is KBr or QJ201; the particle reinforcing phase described in step 1① is SiC, TiO 2 Or AlN; the gas-forming agent described in step 1 ① is TiH 2 or CaCO 3 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the protective gas atmosphere described in step 1 ② and ③ is vacuum, air, high-purity Ar gas and Ar / H 2 mixed gas. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com