Metal-carbon nanotube foam composite material as well as preparation method and application thereof

A carbon nanotube and foam material technology, applied in the field of composite materials, can solve the problems of high density, high shielding performance, and inability to have both mechanical properties, etc., and achieve the effects of light weight, simple preparation process, and excellent shielding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation principle of the present invention is that the metal-carbon nanotube foam composite material of the present invention is synthesized by a chemical vapor deposition (CVD) process, and then reinforced by amorphous carbon (AC) and loaded with metal by a secondary CVD process. Without using any polymer matrix, the foam is flexible and compressively stable because the AC has welded the junctions between adjacent CNTs. At the same time, AC can bridge the electron transport path between CNTs, thereby enhancing the electrical conductivity and EMI shielding performance. The density of the metal-carbon nanotube foam composite is about 0.02-0.04g / cm 3 , about 60 times smaller than commonly used solid polymer composites. Overall, this invention can provide guidance for the manufacture of ultra-light and flexible EMI shielding materials, paving the way for the production of next-generation EMI shielding devices.

[0039] Among them, chemical vapor deposition (CVD) ...

Embodiment 1

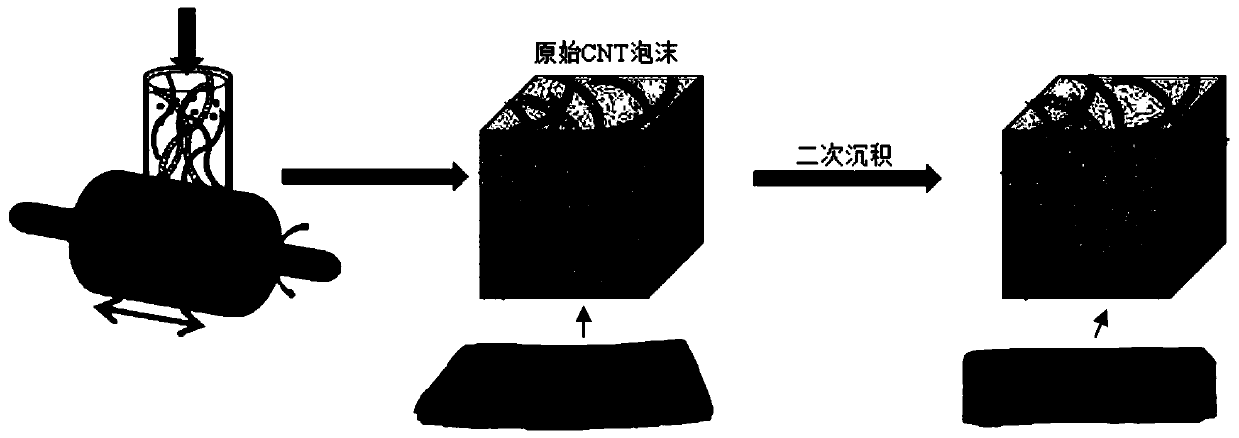

[0081] Example 1 as Figure 1-Figure 3 As shown, the specific technical steps of a preparation method of a carbon nanotube foam composite material loaded with metal nickel having elasticity and electromagnetic shielding properties are as follows:

[0082] 1) Raw carbon nanotube foam: the carbon nanotube fibers produced by floating CVD are collected and wound on a collecting shaft.

[0083] 2) Sample preparation: Cut the pristine carbon nanotube foam into regular rectangles with a laser.

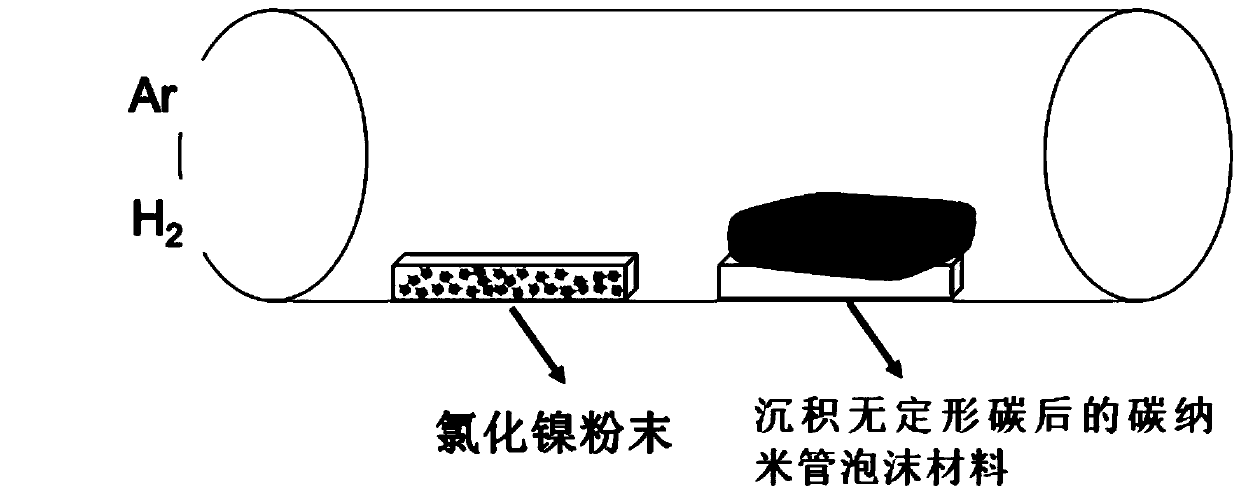

[0084] 3) Secondary deposition: see figure 1 As shown, put the original carbon nanotube foam in step 2) into the quartz boat, push the quartz boat into the middle of the quartz tube, fix the flanges at both ends of the quartz tube, and then pass argon gas to remove the air in the quartz tube. The flow rate of argon gas is 200-250 sccm, the temperature is raised to 1000-1100 °C at a rate of 10 °C / min, and the hydrogen and ethylene valves are opened, and the flow rates are 120-160 sccm and 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com