Coal-based polyaniline and anti-corrosive paint

A technology of coal-based polyaniline and anti-corrosion coatings, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor anti-corrosion effect and poor durability of coatings, and achieve adjustable coating thickness and durability Good, the effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Take Taixi anthracite, wash and deash, coarsely crush to a particle size of 97 ≤10μm, to obtain ultra-low ash ultra-fine coal powder. Aniline was purified by vacuum distillation to a purity higher than 95%. Premix ultra-low ash ultra-fine coal powder and aniline at a weight ratio of 3:7, mix with 1mol / L hydrochloric acid solution, stir ultrasonically and electrically for 0.5h in an ice-water bath at 4°C, then add ammonium persulfate solution dropwise, at 4°C Stirring was continued for 2.0 h under the ice-water bath, wherein the molar ratio of ammonium persulfate to aniline was 1:1, and the dropping time was controlled at 0.5 h. Remove the ice-water bath, perform electric stirring at room temperature, and control the total time of the above-mentioned electric stirring and magnetic stirring to 24 h. The obtained material was suction-filtered and washed, firstly dried at 60° C. under normal pressure for 4 hours, and then vacuum-dried at 60° C. for 24 hours to obtain coal-...

Embodiment 2

[0069] Take Taixi anthracite, wash and deash, coarsely crush to a particle size of 97 ≤10μm, to obtain ultra-low ash ultra-fine coal powder. Aniline was purified by vacuum distillation to a purity higher than 95%. Premix ultra-low ash Taixi anthracite and aniline at a weight ratio of 5:5, mix with 1mol / L hydrochloric acid solution, ultrasonically stir in an ice-water bath at 4°C and stir electrically for 0.5h, then add ammonium persulfate solution dropwise, at 4°C Continue electric stirring for 2.0 h under the ice-water bath, wherein the molar ratio of ammonium persulfate to aniline is 1:1, and the dropping time is controlled at 0.5 h, remove the ice-water bath, and carry out electric stirring at room temperature. The time is 30h. The obtained material was suction-filtered and washed, firstly dried at 60° C. under normal pressure for 8 hours, and then vacuum-dried at 60° C. for 24 hours to obtain coal-based polyaniline.

Embodiment 3

[0071] Take Jincheng anthracite, wash and deash, coarsely crush to a particle size of 97 ≤10μm, to obtain ultra-low ash ultra-fine coal powder. Aniline was purified by vacuum distillation to a purity higher than 95%. Premix ultra-low ash Taixi anthracite and aniline at a weight ratio of 6:4, mix with 1mol / L hydrochloric acid solution, ultrasonically stir in an ice-water bath at 4°C and stir electrically for 0.5h, then add ammonium persulfate solution dropwise, at 4°C Continue electric stirring for 2.0 h under the ice-water bath, wherein the molar ratio of ammonium persulfate to aniline is 1:1, and the dropping time is controlled at 0.5 h, remove the ice-water bath, and carry out electric stirring at room temperature. The time is 24h. The obtained material was suction-filtered and washed, firstly dried under normal pressure at 60° C. for 6 hours, and then vacuum-dried at 60° C. for 24 hours to obtain coal-based polyaniline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

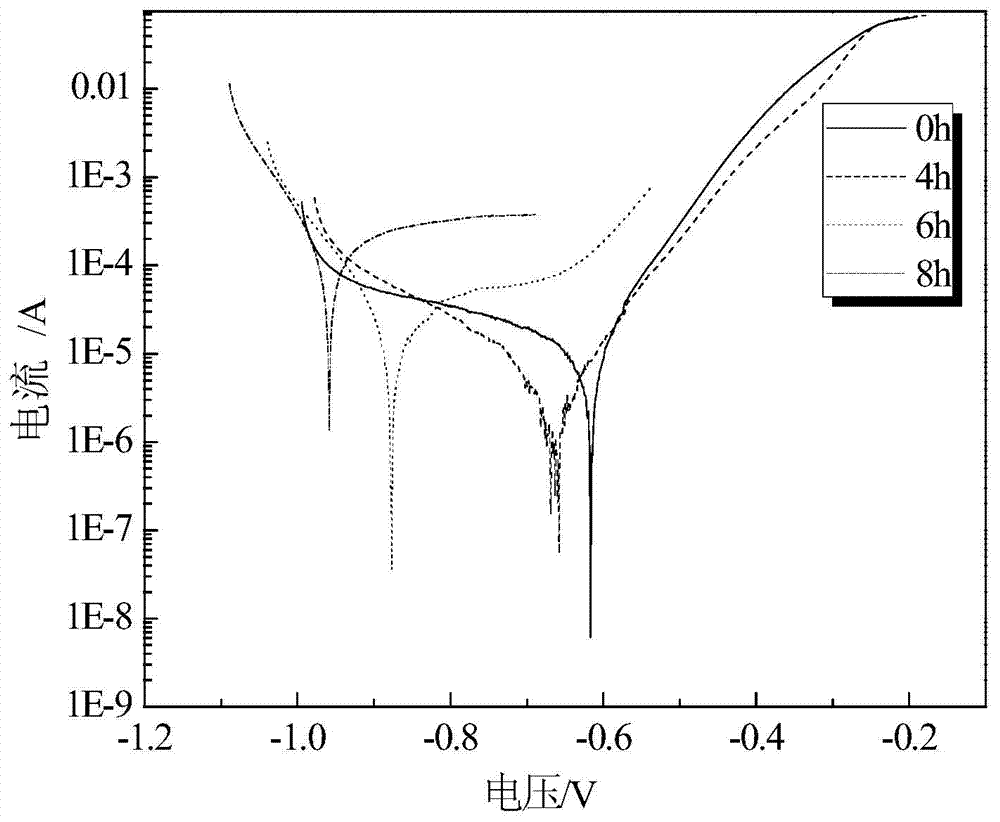

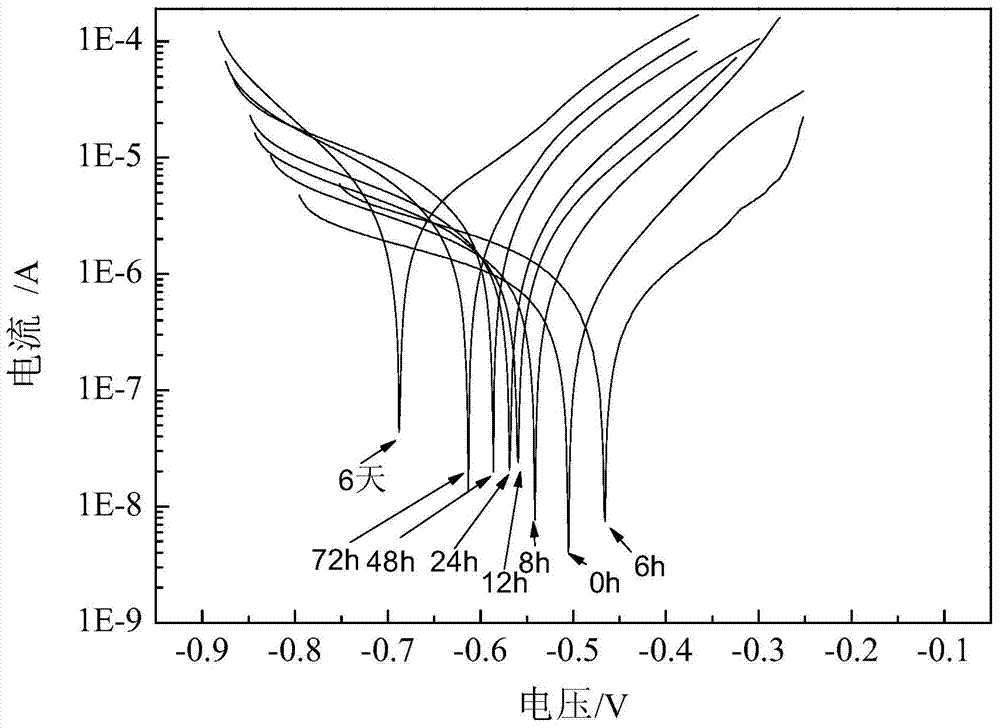

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com