Method of preparing carbon nanofiber reinforced polymethacrylimide foam through suspension polymerization

A polymethacrylimide and carbon nanofiber technology, applied in the field of materials, can solve the problems of not ensuring the maximization of the contact surface between graphene and the polymer matrix, affecting the mechanical properties of composite materials, etc., and achieving low density and number of defects. Less, the effect of shortened contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

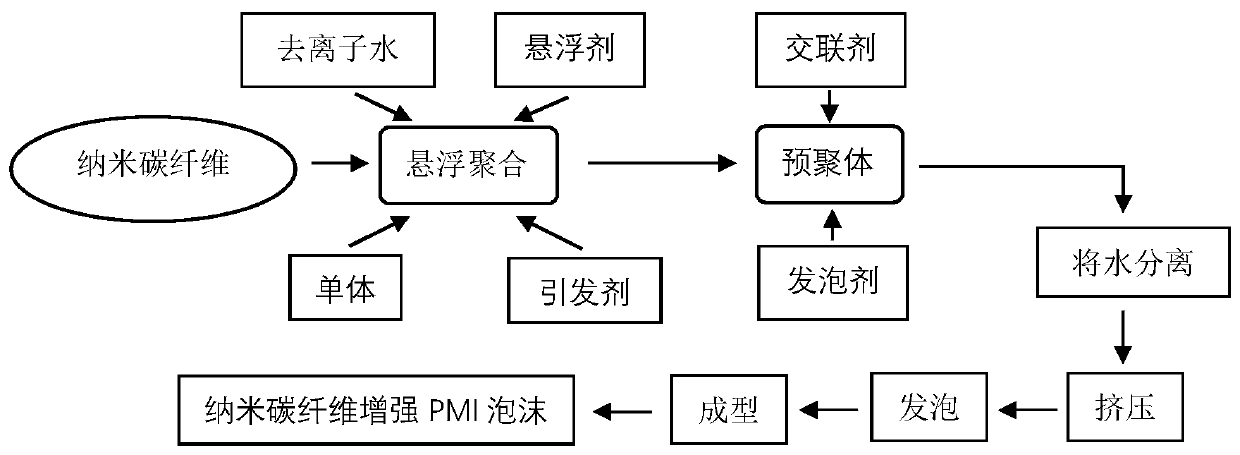

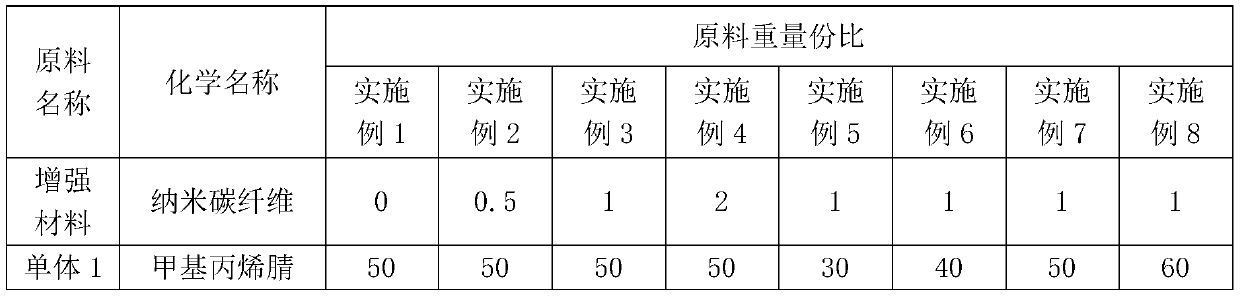

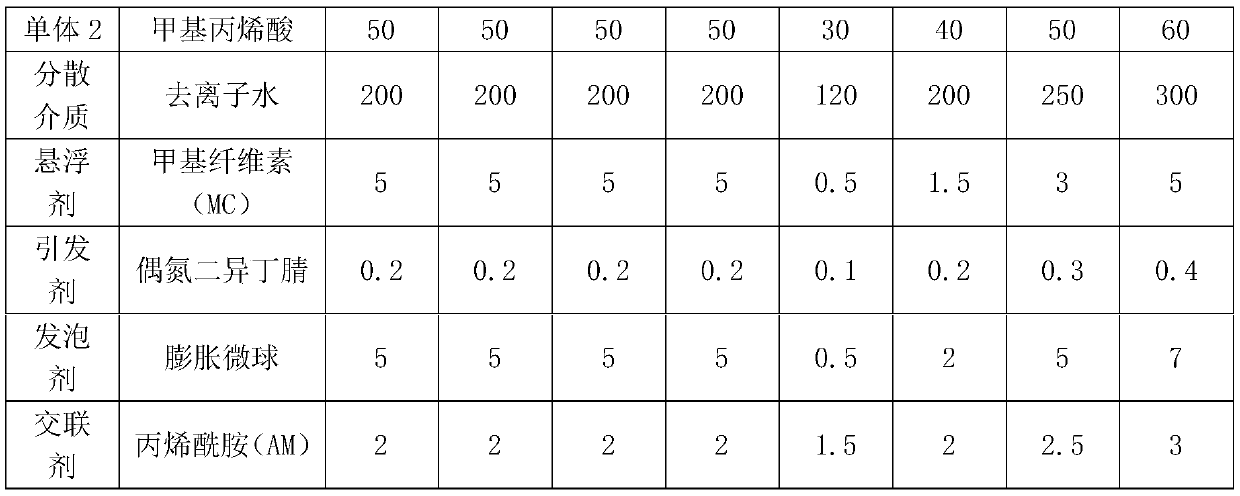

[0028] The invention provides a method for preparing nano-carbon fiber reinforced polymethacrylimide foam by suspension polymerization, the flow process is as follows figure 1 As shown, the component weight ratios of each embodiment are shown in Table 1 below.

[0029] The embodiment of table 1 nanometer carbon fiber reinforced polymethacrylimide foam material

[0030]

[0031]

[0032] Specific steps are as follows:

[0033] Step 1. Dissolve the suspending agent methylcellulose (MC) in the deionized water of the dispersion medium first, prepare the suspending agent solution, then add the suspending agent solution into the first reaction kettle, start the stirring device to stir, and the stirring speed is 100 -300r / min.

[0034]Step 2: adding monomer methacrylonitrile and methacrylic acid into the second reaction kettle, heating to a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com