Patents

Literature

94results about How to "With electromagnetic shielding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

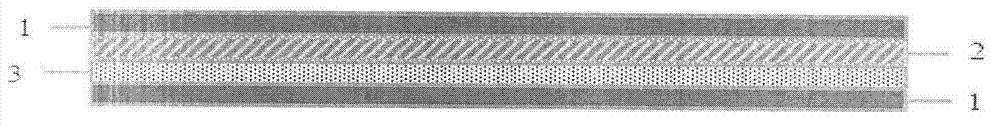

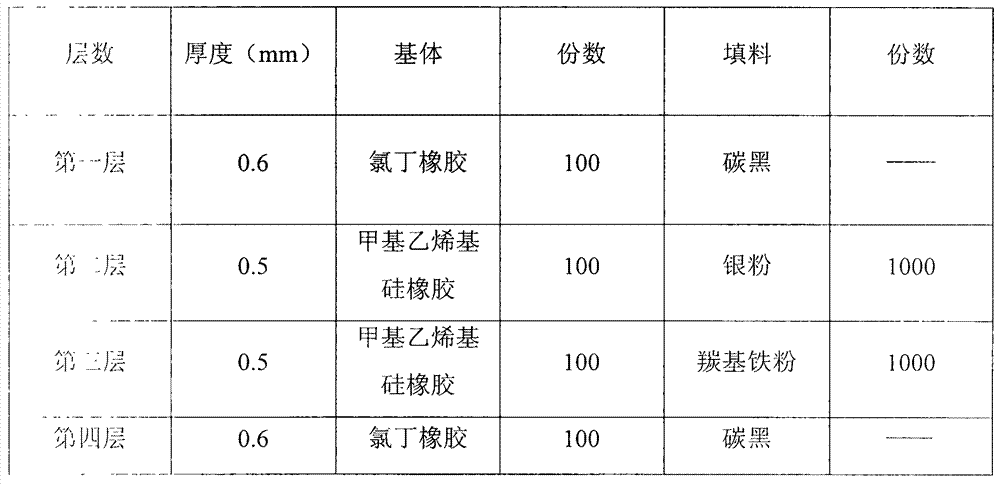

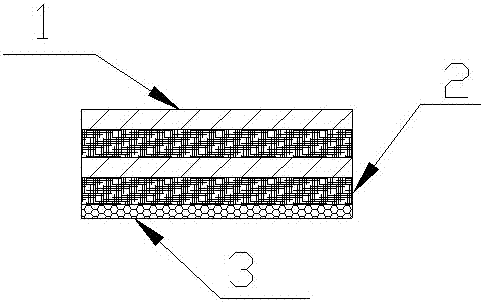

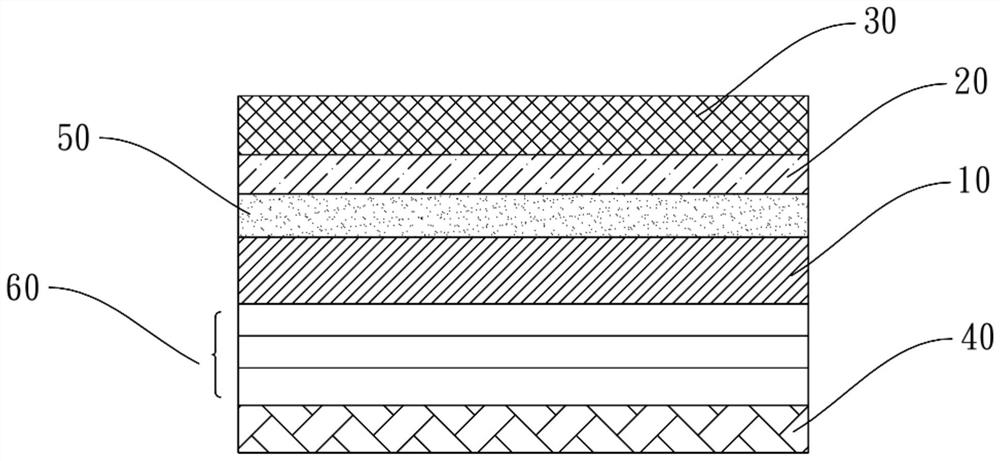

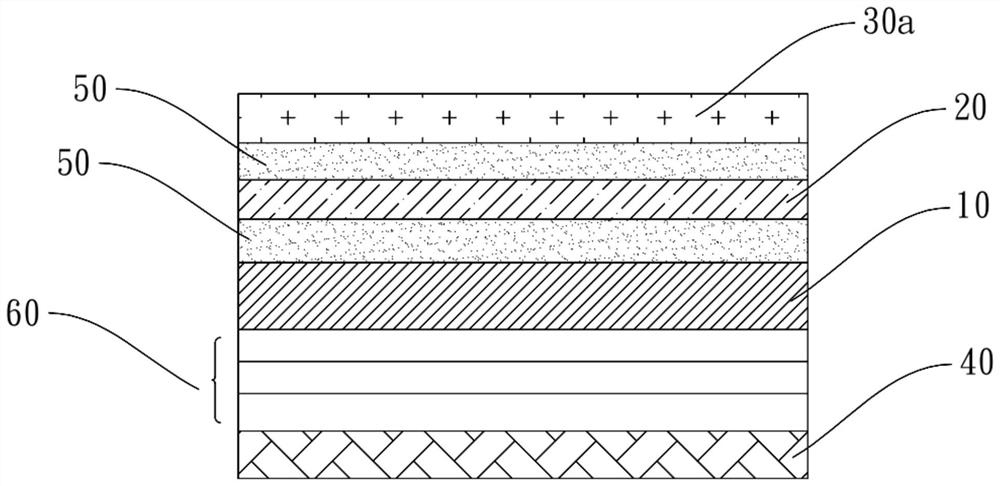

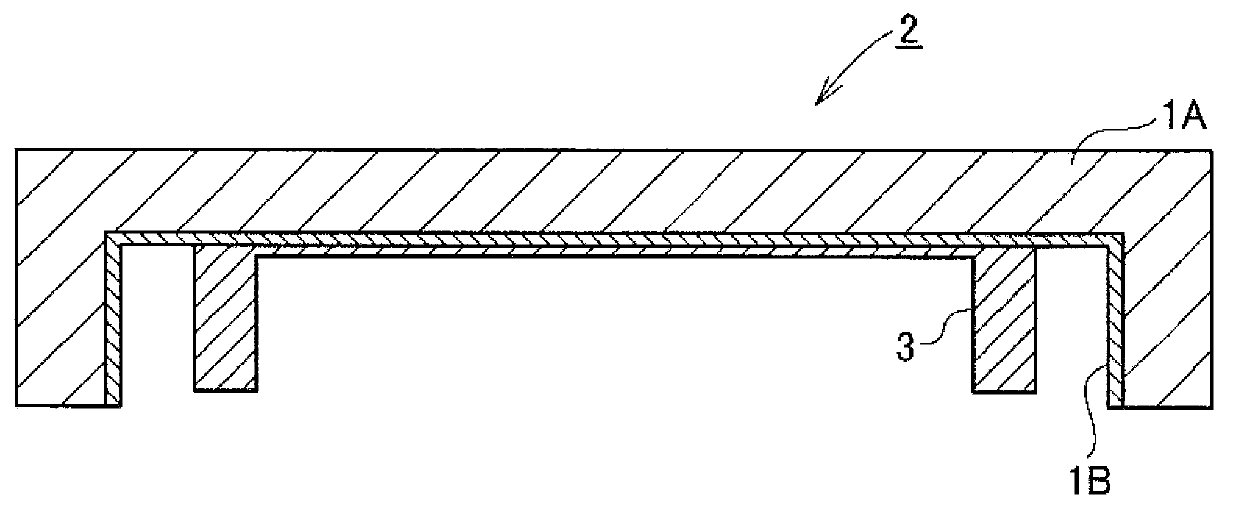

Electromagnetic shielding composite rubber material and preparation method thereof

ActiveCN104494241AAchieve electrical continuityImprove shielding effectLaminationLamination apparatusRubber materialBroadband

The invention provides an electromagnetic shielding composite rubber material, which is of a laminated structure, and comprises a shielding layer and a protective layer which are arranged from inside to outside, wherein the shielding layer comprises a conductive silicone rubber layer and a magnetic conductive silicone rubber layer, and the protective layer is a rubber layer. The shielding layer of the electromagnetic shielding composite rubber material comprises the conductive silicone rubber layer and the magnetic conductive silicone rubber layer, has an electromagnetic shielding performance in a broadband, wide shielding range and high shielding effectiveness, and can be widely used for electromagnetic shielding of electric power, electronics and other industries, and the protective layer selects rubber, and has excellent air tightness, and excellent watertight and mechanical properties, so that the overall strength of the composite material can be improved, the air is isolated, and the oxidation of the conductive filler is slowed, and thus the service life of the shielding material is prolonged, the service performances of the shielding material can be improved, and the shielding effectiveness of the material keeps stable as the service time increases.

Owner:STATE GRID CORP OF CHINA +2

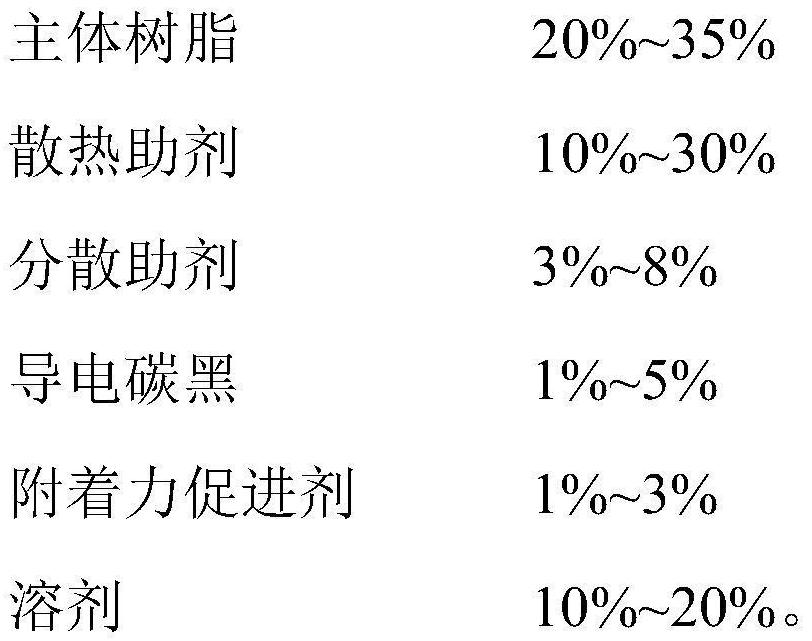

Expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding and preparation method thereof

PendingCN107513168AFix stability issuesThe overall thickness is thinSynthetic resin layered productsPolyurea/polyurethane coatingsElectromagnetic shieldingGraphite

The invention discloses an expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding and a preparation method thereof. The composite material comprises at least one expanded polytetrafluoroethylene film layer, a graphene electric-conductive and heat-transfer coating and a silica aerogel coating, wherein the surface of one side of the at least one expanded polytetrafluoroethylene film layer is compounded with the graphene electric-conductive and heat-transfer coating; and the surface of the other side of the at least one expanded polytetrafluoroethylene film layer is compounded with the silica aerogel coating. Thus, the problems of attachment compactness and fastness of the graphene electric-conductive and heat-transfer coating and the heat-insulating silica aerogel coating can be solved; the expanded polytetrafluoroethylene film coating composite material with functions like heat conduction, heat insulation, electric conduction and electromagnetic shielding has the advantages of good softness and bonding properties, strong coating tensile resistance, no cracking, small material thickness and environmental aging resistance; meanwhile, the coating-free surface of the expanded polytetrafluoroethylene has the functions of insulation and isolation.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

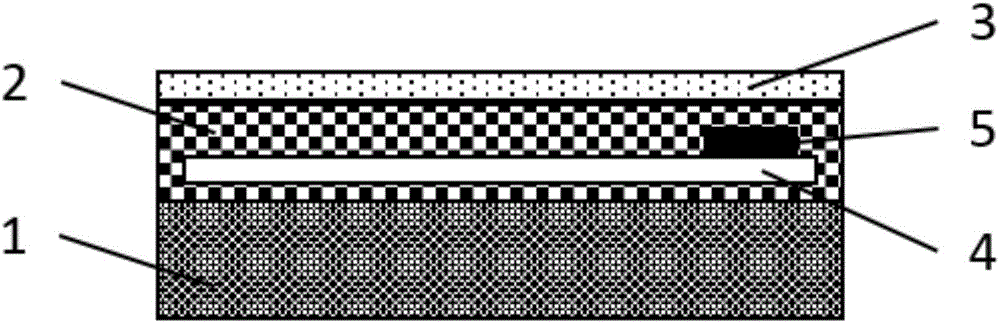

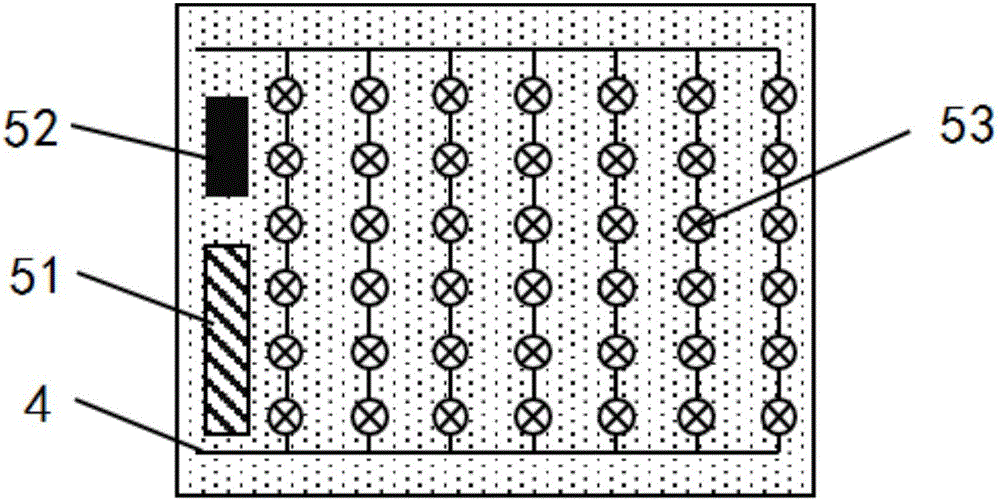

Intelligent wallpaper based on liquid metal

ActiveCN106677455ASolve the shortcomings of single functionWith room temperature measurementCovering/liningsSpecific functionLiquid state

The invention provides intelligent wallpaper based on liquid metal. The intelligent wallpaper comprises a wallpaper substrate, a packaging film and a decorative layer which are sequentially arranged from inside to outside. A liquid metal circuit is packaged in the packaging film. According to the intelligent wallpaper, by adoption of the conductivity and liquidity of the liquid metal, the defect that existing wallpapers are simplex in function is overcome, and by means of electronic devices with specific functions, the wallpaper can have various functions such as room temperature measurement, light adjustment, electromagnetic shielding, heat preservation, humidification, air freshening and the like; and in addition, the flexible liquid metal circuit can adapt to surfaces in any shape, and the intelligent wallpaper can be attached to the complex surfaces of the household equipment such a wall, a ceiling, furniture and an electric appliance and is wide in application range.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

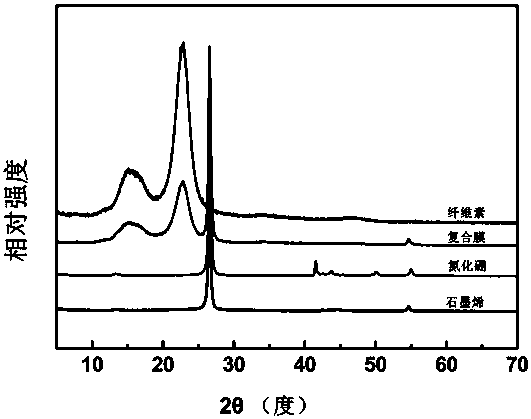

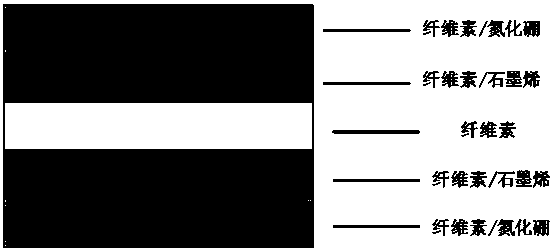

Multilayer composite thermal conductive film and preparation method thereof

The invention relates to a multilayer composite thermal conductive film and a preparation method thereof. The middle layer of the thermal conductive film is a nano-cellulose film. The upper and lowersurfaces of the nano-cellulose film are orderly coated with a nano-cellulose / graphene film layer and / or a nano-cellulose / boron nitride film layer. The layers are connected through hydrogen bonding between cellulose matrixes to form composite thermal conductive films with an ABA three-layer structure and an ACBCA five-layer structure. Each layer of the film has the mass of 15-30mg. The nano-cellulose / graphene film layer has graphene content of 6-10wt% and boron nitride content of 6-10wt%. The boron nitride and graphene have high thermal conductivity. The multilayer composite thermal conductivefilm has high thermal conductivity. Through the core toughening and the multilayer bionic structure of the middle cellulose layer, the excellent mechanical properties are obtained. The mixed layer ofboron nitride and cellulose is used as an outer layer so that the film has good electrical insulating properties. The multilayer composite thermal conductive film solves the heat dissipation problemsof the modern electronic device and can be used in a thermal conduction and heat dissipation device.

Owner:SHANGHAI UNIV

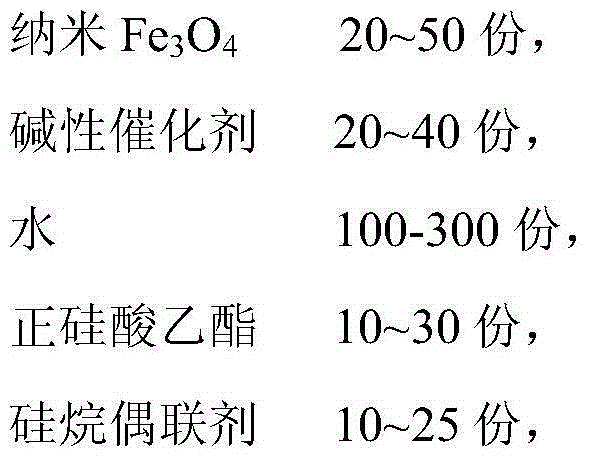

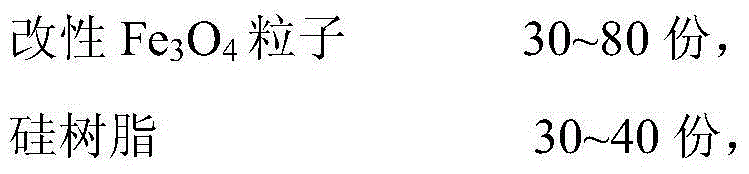

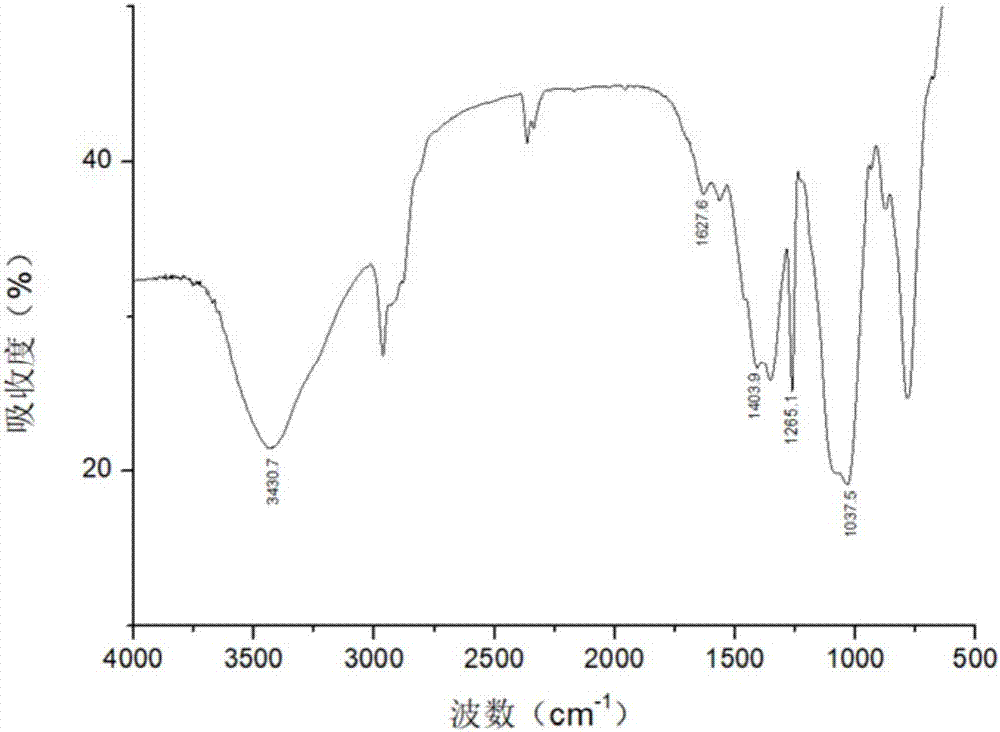

Preparation method of superhydrophobic superparamagnetic silicone resin composite coating

ActiveCN104694001AStrong interfacial adhesionSuperhydrophobicMagnetic paintsPolymer scienceElectromagnetic shielding

Owner:HANGZHOU NORMAL UNIVERSITY

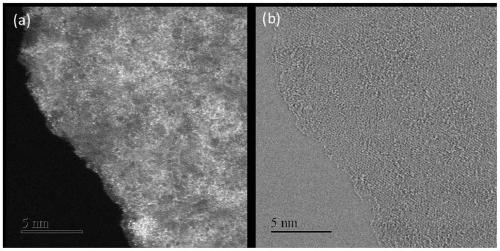

Polyiner/laminate inorganic nano composite material and its milling shearing preparation method

A nanometre-class polymer / laminated inorganic substance composite material features that it is prepared by use of the millstone-shaped force chemical reactor, which has a unique 3-D shear structure to provide strong squeeze-shear force field for grinding inserting, dispersing, and mixing to prepare the polymer / laminated inorganic substance composite powder, and then the said nanometre-class composite material is prepared by the universal processing method.

Owner:SICHUAN UNIV

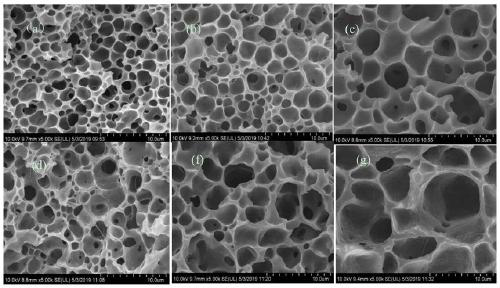

Silicone rubber composite material with gradient bubble structure, and preparation method of silicone rubber composite material

The invention belongs to the field of silicone rubber foam materials, and relates to a silicone rubber composite material with a gradient bubble structure, and a preparation method of the silicone rubber composite material. The invention provides the preparation method of the silicone rubber composite material with the gradient bubble structure. The preparation method comprises the following steps: (1) preparing a silicone rubber composite material; (2) preparing a silicone rubber composite material green body; (3) carrying out supercritical fluid foaming: covering part of the green body, obtained in the step (2), with a metal material, and then putting the green body into a high pressure reaction kettle, introducing gas for foaming, heating, and pressurizing until the gas is converted into supercritical fluid; after the supercritical fluid reaches a saturated state in the green body, using a rapid pressure relief method to enable composite material green body to be foamed so as to obtain a foamed material; (4) vulcanizing. The preparation method provided by the invention is not only simple and stable in process, low in requirement for equipment and simple to operate, but is also good in controllability, thus having a very good application prospect.

Owner:SICHUAN UNIV

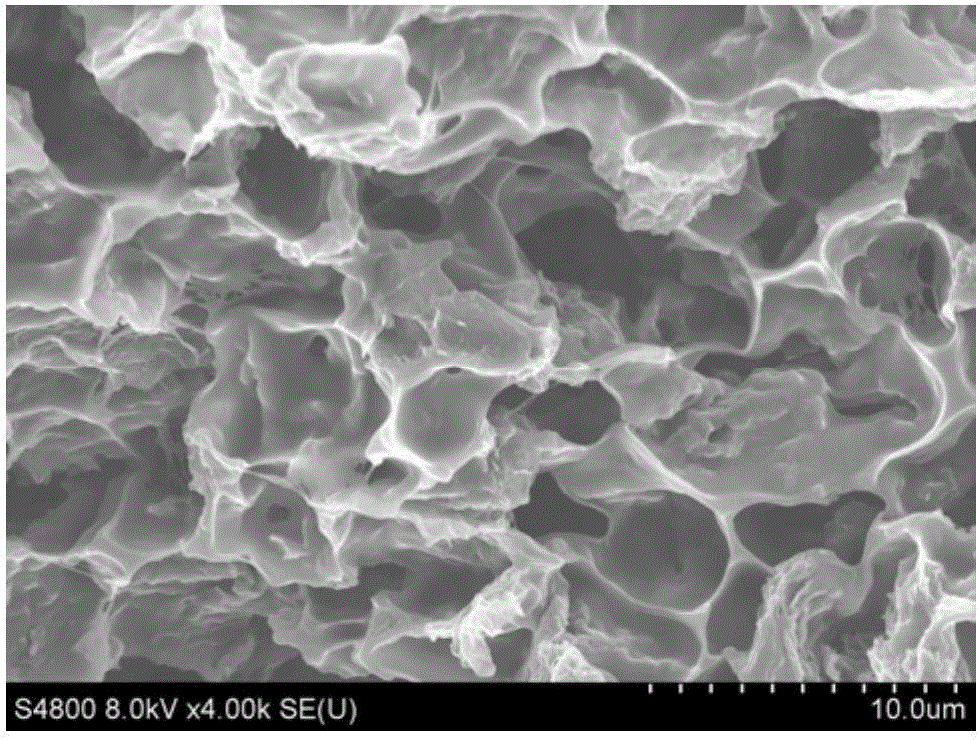

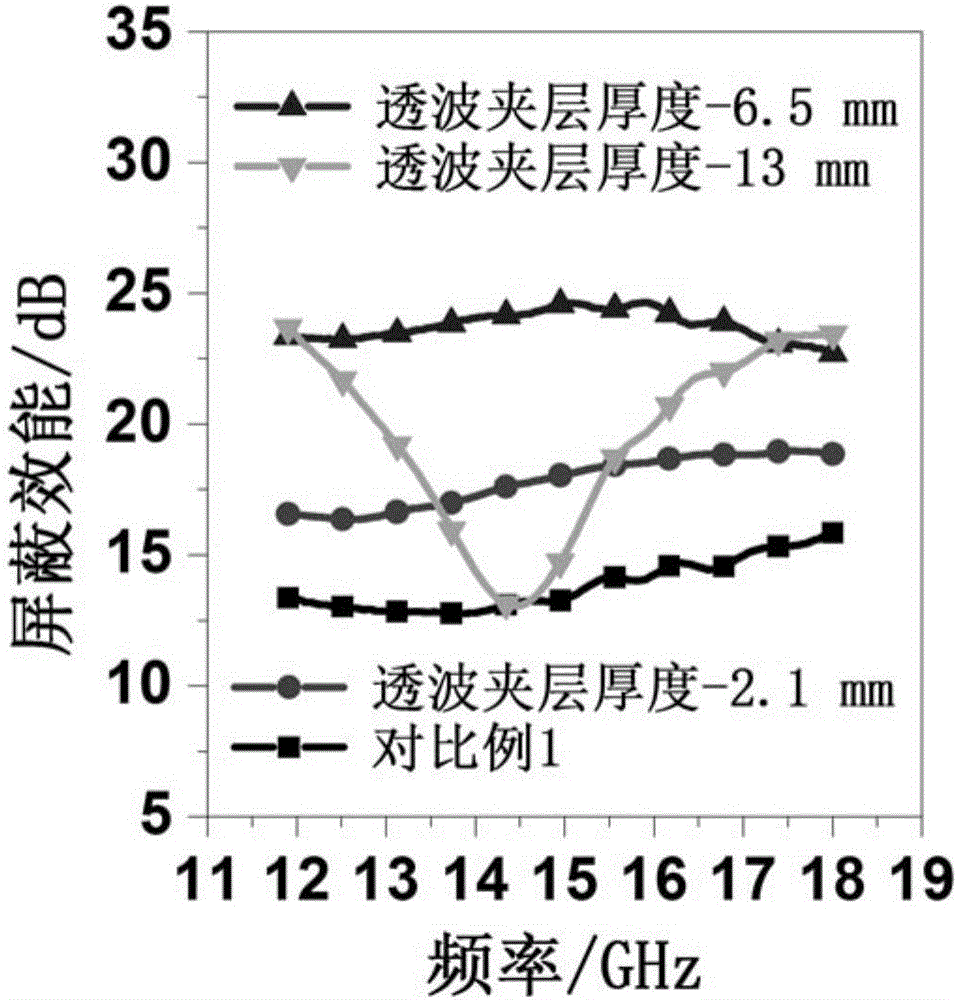

Polymer/graphene foamed material with electromagnetic shielding performance, and preparation method and application thereof

InactiveCN106564227AHigh electromagnetic shieldingAchieve high content fillingLaminationLamination apparatusSeparation technologyElectromagnetic shielding

The invention discloses a polymer / graphene foamed material with electromagnetic shielding performance, and a preparation method and an application thereof. The method is characterized in that a thermoplastic polymer / graphene micro-foamed film is produced mainly by using a solution blending and phase separation technology, and the thermoplastic polymer / graphene micro-foamed film and a wave transmitting material are bonded by glue to form the integral material with a sandwich structure. The polymer / graphene foamed material has good application prospect in the electromagnetic shielding field.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

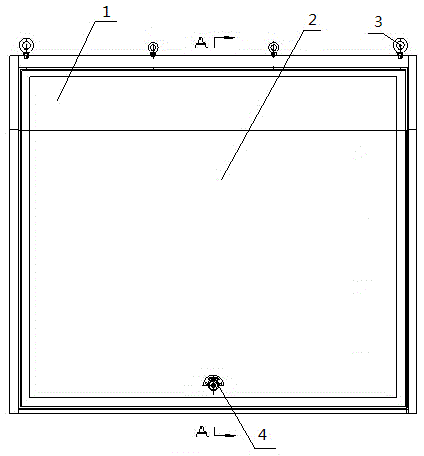

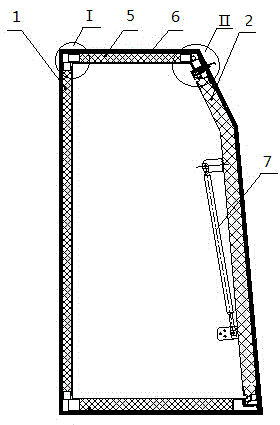

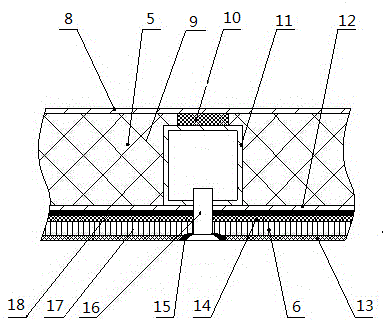

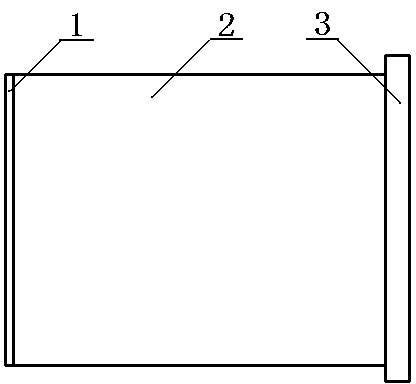

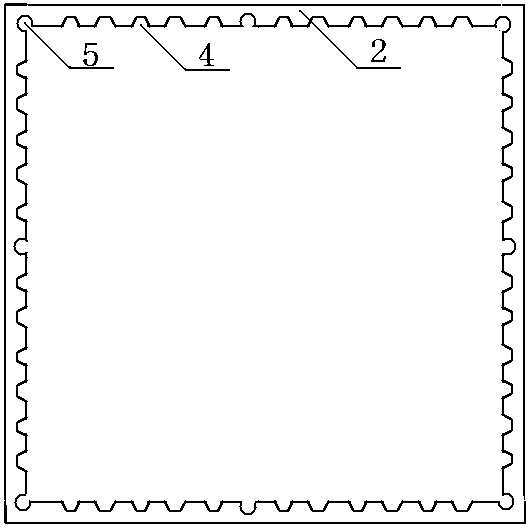

Special-shaped square cabin

InactiveCN104457432AHas a stealth effectWith electromagnetic shieldingArmoured vehiclesThermal insulationEaves

A special-shaped square cabin comprises a square cabin body composed of an upper wallboard, a lower wallboard, a left wallboard, a right wallboard, a front wallboard and a right wallboard. The square cabin body is provided with a door. Each wallboard comprises an inner covering board, a metal frame and an outer covering board; the metal frame is scattered between the inner covering board and the outer covering board and is connected with the outer covering board; a thermal insulating layer is disposed between the metal frame and the inner covering board; light filler is provided between the inner covering board and the outer covering board. The outer surface of the square cabin body is provided with an invisible board which is seamlessly connected to the outer surfaces of the wallboards and the outer surface of the door in a bonding manner and in the mechanical fixation manner without steps; the upper end of the door is provided with an eaves board. The whole cabin body of the special-shaped square cabin has good thermal insulation, electromagnetic shielding performance and invisibility, and a missile launching vehicle is imparted better mobility and environmental adaptability.

Owner:衡阳泰豪通信车辆有限公司

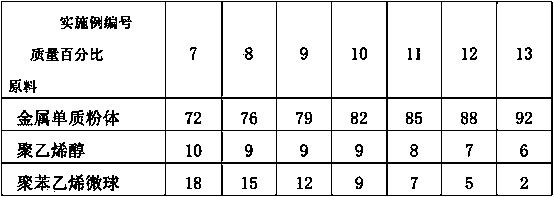

Preparation method for low-density porous metal material

The invention discloses a preparation method for a low-density porous metal material. The preparation method is characterized by comprises the following steps: according to mass percent, taking raw materials of 70-95% of metal elementary substance powder, 5-10% of polyvinyl alcohol and 0-20% of polystyrene microsphere; preparing the polyvinyl alcohol into a polyvinyl alcohol aqueous solution with the mass percent concentration of 5-10%; adding the polystyrene microsphere into the polyvinyl alcohol aqueous solution, adding the metal elementary substance powder, stirring and mixing uniformly to obtain a pulp material; pouring the pulp material into a tubular pillar polytetrafluoroethylene tube mould, freezing, drying, molding and demoulding; placing a dried material into a pipe furnace with flowing inert atmosphere, and sintering at the temperature of 400-500 DEG C for 2-6 h to obtain the low-density porous metal material. The porous metal prepared by the preparation method has a relative density which can be as low as 5%; most part of the metal is through-hole; the hole diameters have the characteristic of bimodal distribution; the poriness and the microstructure are uniform and adjustable, and a certain mechanical strength is achieved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

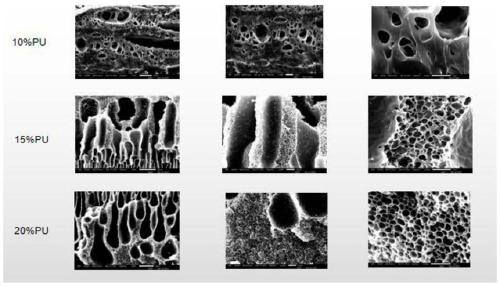

Composite foam film and preparation method thereof

PendingCN110358136ALarge apertureGood conductive pathMagnetic/electric field screeningFreeze-dryingNanoparticles dispersion

The invention discloses a composite foam film and a preparation method thereof. Nano-particles are used as a filler, a polymer is used as a base material, the nano-particles are dispersed in a solution of the polymer, and then curing film formation and freeze-drying treatments are carried out to prepare the nano-particle / polymer composite foam film with a light, soft and porous structure and an electromagnetic shielding property. The addition of the nanoparticles increases the pore size of the composite foam film, improves the conductive pathway of the composite foam film and significantly improve the electrical conductivity and the electromagnetic shielding property of the composite foam. The composite foam film prepared in the invention has a great application scenario in the field of electromagnetic shielding.

Owner:WUHAN TEXTILE UNIV

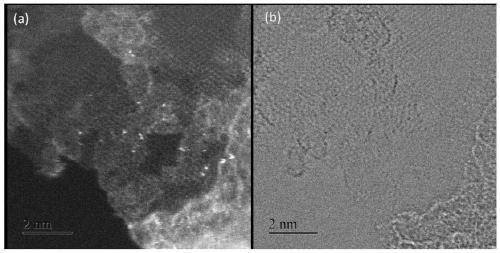

Graphene provided with polynitrogen coordination structure and preparation method and application thereof

ActiveCN110371957ALow costEfficient catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsGrapheneInfraredElectromagnetic shielding

The invention discloses graphene provided with a polynitrogen coordination structure and a preparation method and application thereof. The graphene contains 1-5 atomic layers, contains elements such as carbon, oxygen, nitrogen and hydrogen, and meanwhile contains at least one ofmetallic elements of iron, cobalt and nickel; the graphene has a catalytic active site of a polynitrogen coordination transition metal, and the coordination number of the nitrogen to metal is between 4 and 5, the graphene has efficient and stable monoatomic metal catalytic active site, and the graphene has high electrocatalytic performance for carbon dioxide, oxygen and formaldehyde. The graphene has the characteristics of easy dispersibility, easy processing and easy functioning, and functions of electric conduction, heat dissipation, infrared ray electric heating releasing and electromagnetic shielding are easily achieved.

Owner:ANHUI UNIVERSITY

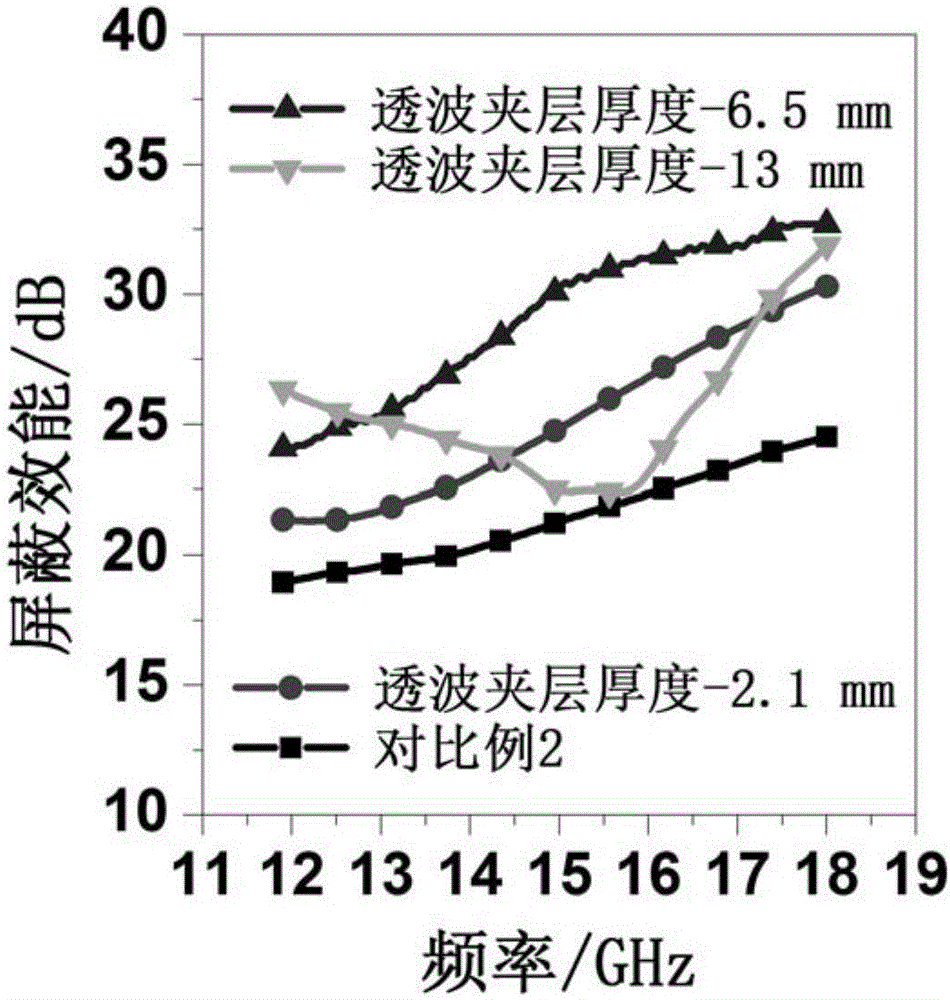

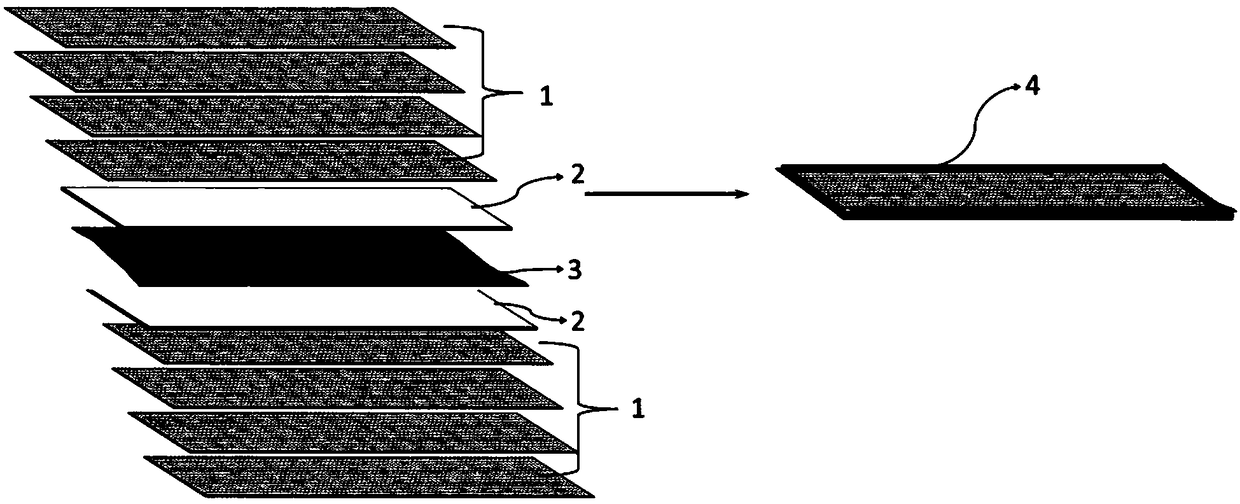

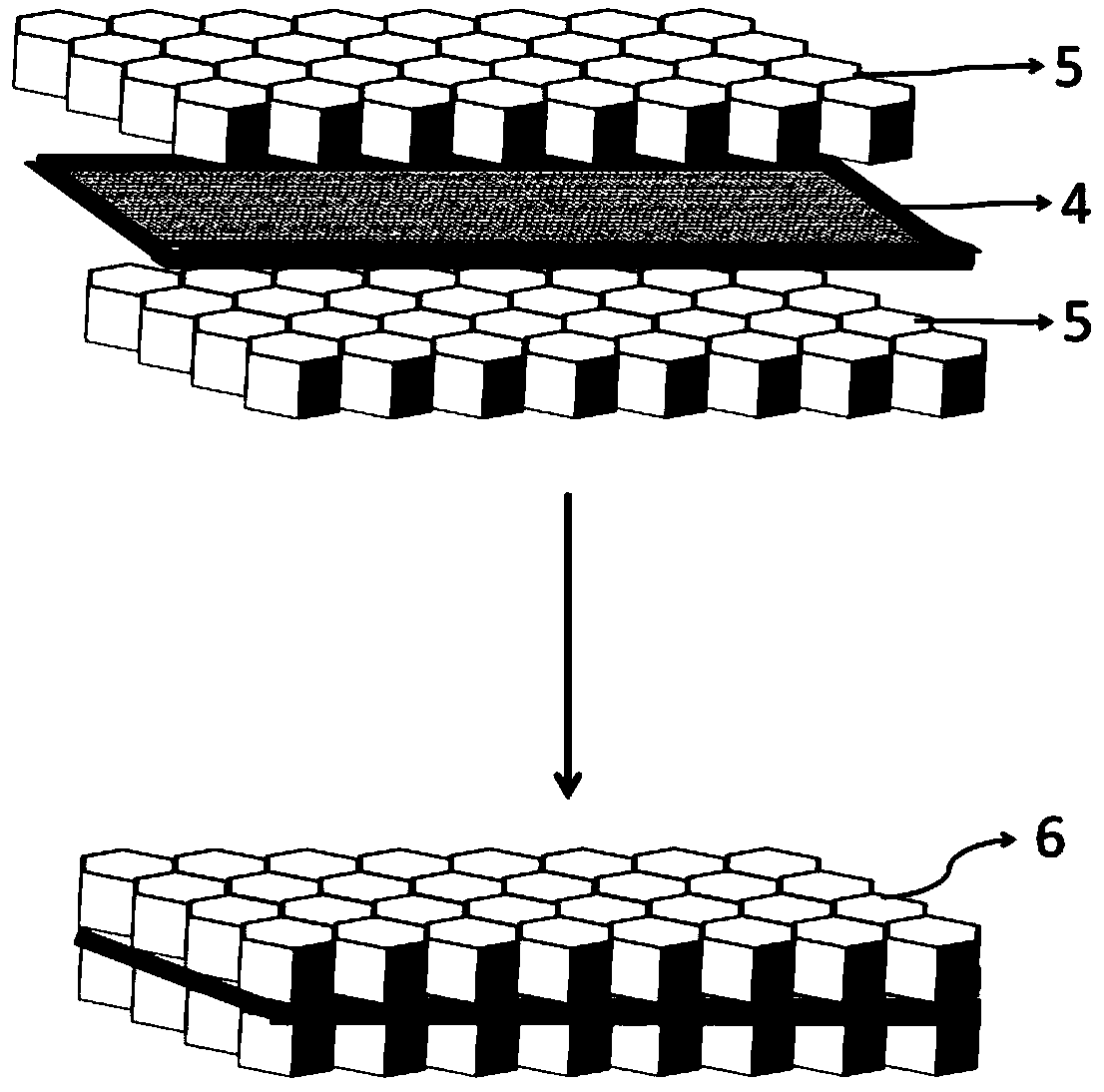

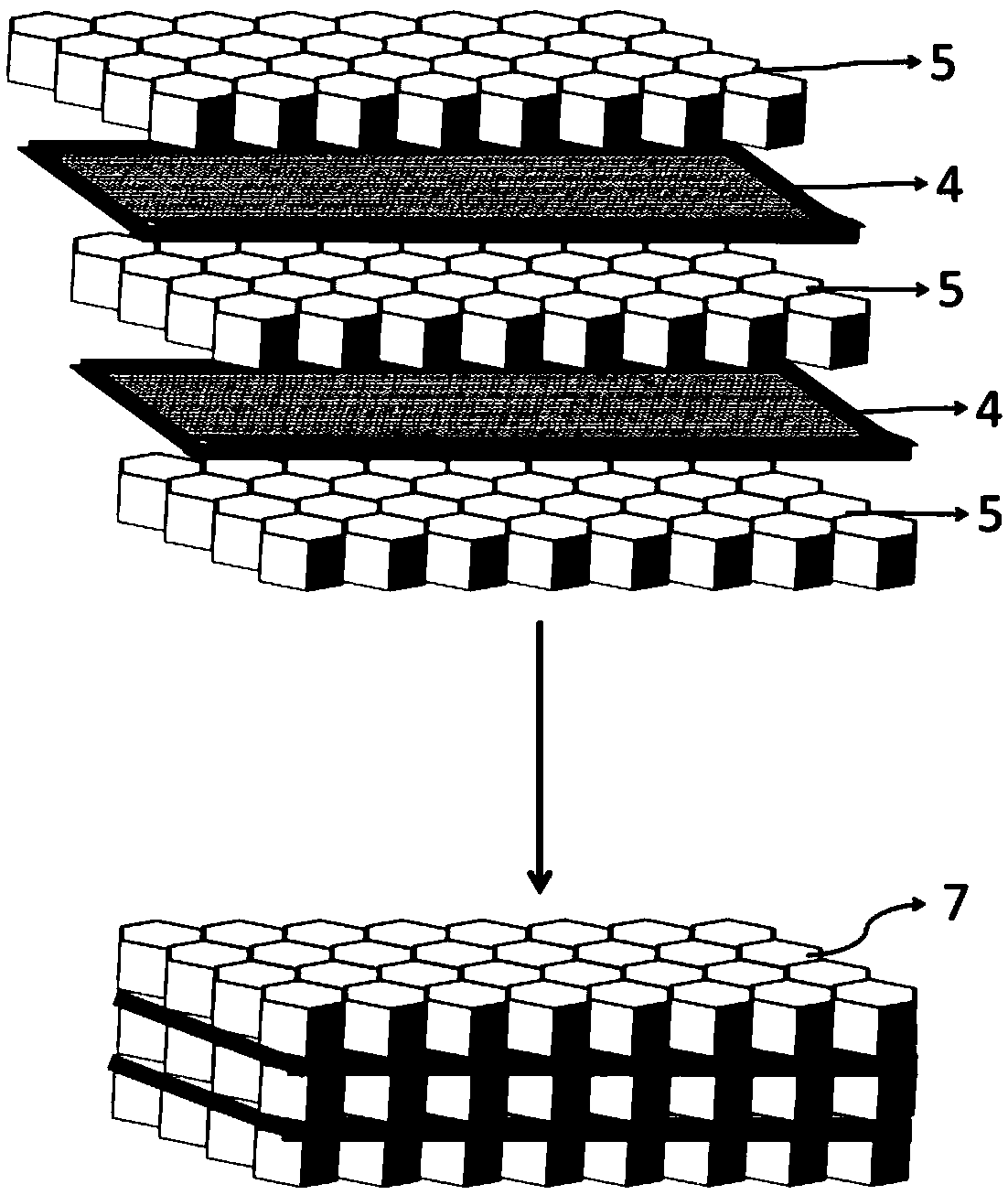

Preparation method of electromagnetic shielding honeycomb core material

ActiveCN108724822AIntegration of structure and functionLightweight structure and functionGlass/slag layered productsMature technologyCvd graphene

The invention belongs to the technical field of composites and relates to a preparation method of an electromagnetic shielding honeycomb core material. According to the method, a graphene / ferrite hybrid material is prepared, then graphene / ferrite hybrid granules are uniformly attached to a fabric carrier through magnetic deposition, and graphene / ferrite hybrid granular electromagnetic shielding fabric is formed; an electromagnetic shielding interlayer is prepared from prepreg, adhesive films and the electromagnetic shielding fabric; finally, the electromagnetic shielding interlayer and a honeycomb core material are composited through adhesion to form a C-sandwich electromagnetic shielding honeycomb structure. According to the technical process, related mature technologies are integrated, and low-cost design and manufacture and technology-integrated comprehensive utilization of the electromagnetic shielding honeycomb core material are realized.

Owner:AVIC BASIC TECH RES INST

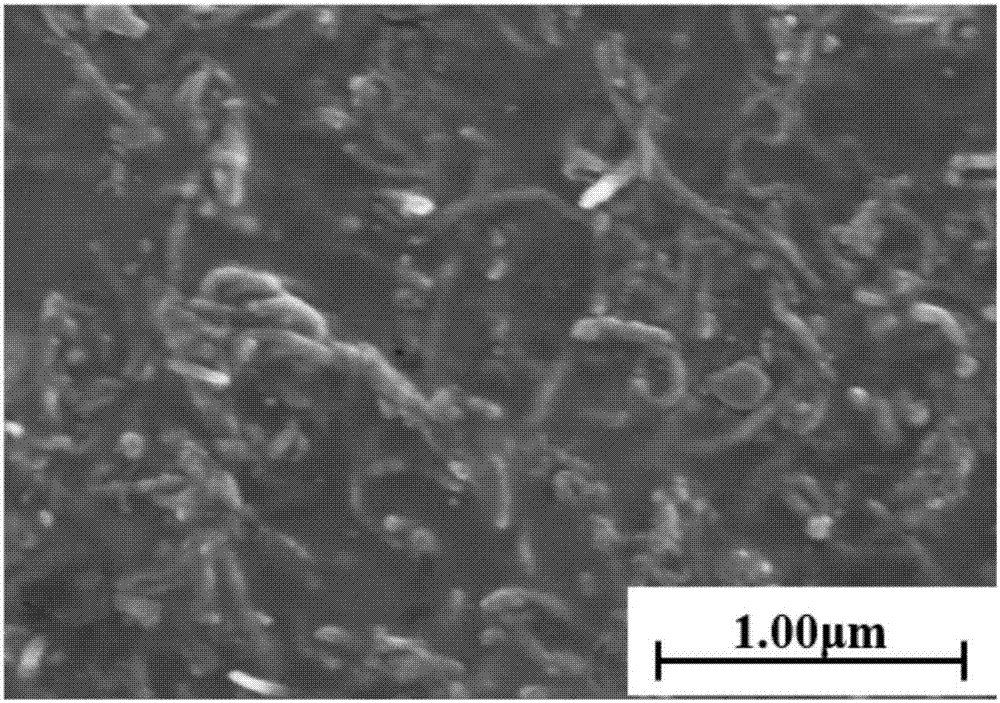

Carbon nano tube toughened SiBCN(O) metal-based ceramic coating and preparation method thereof

The invention discloses a carbon nano tube toughened SiBCN(O) metal-based ceramic coating and a preparation method thereof. The preparation method comprises the following steps: ammonolyzing vinyl chlorosilane and phenyl chlorosilane with ammonia, and then carrying out reaction for 1 to 3 hours; removing a solvent through evaporation, thus obtaining liquid polysilazane, and dropwise adding boranedimethyl sulfide for continuous reaction, thus obtaining polyborosilazane; dropwise adding a carbon nano tube solution into the polyborosilazane solution, and carrying out stirring, thus obtaining polymer slurry; coating the surface of a matrix with the slurry, and carrying out pyrolysis at high temperature to obtain the SiBCN(O) metal-based ceramic coating. According to the carbon nano tube toughened SiBCN(O) metal-based ceramic coating disclosed by the invention, the polyborosilazane synthesized by the vinyl chlorosilane, the phenyl chlorosilane and the borane dimethyl sulfide is used as a raw material, and carbon nano tubes are added to prepare the slurry; after immersion coating is carried out, high-temperature pyrolysis is carried out, thus obtaining the high-temperature-resistant andcorrosion-resistant ceramic coating. The process is easy to operate, and the sintering temperature is low; the energy consumption is reduced, and the cost is saved.

Owner:国科广化(南雄)新材料研究院有限公司 +1

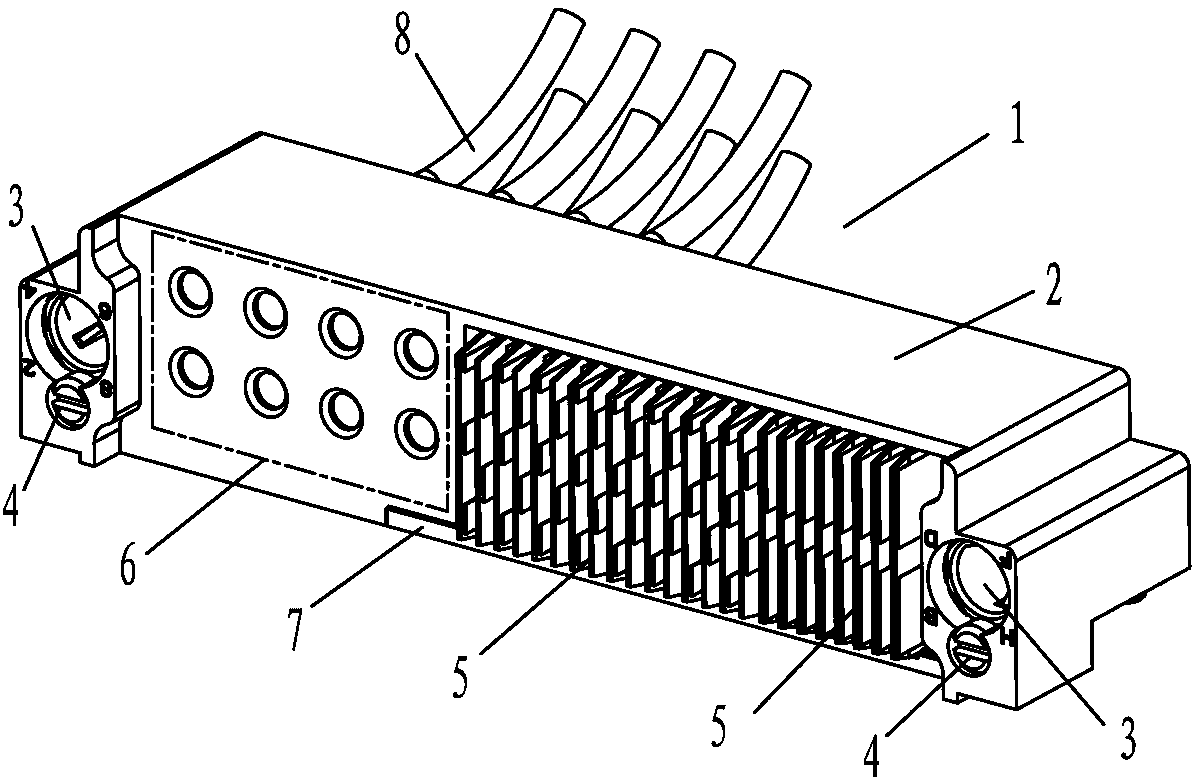

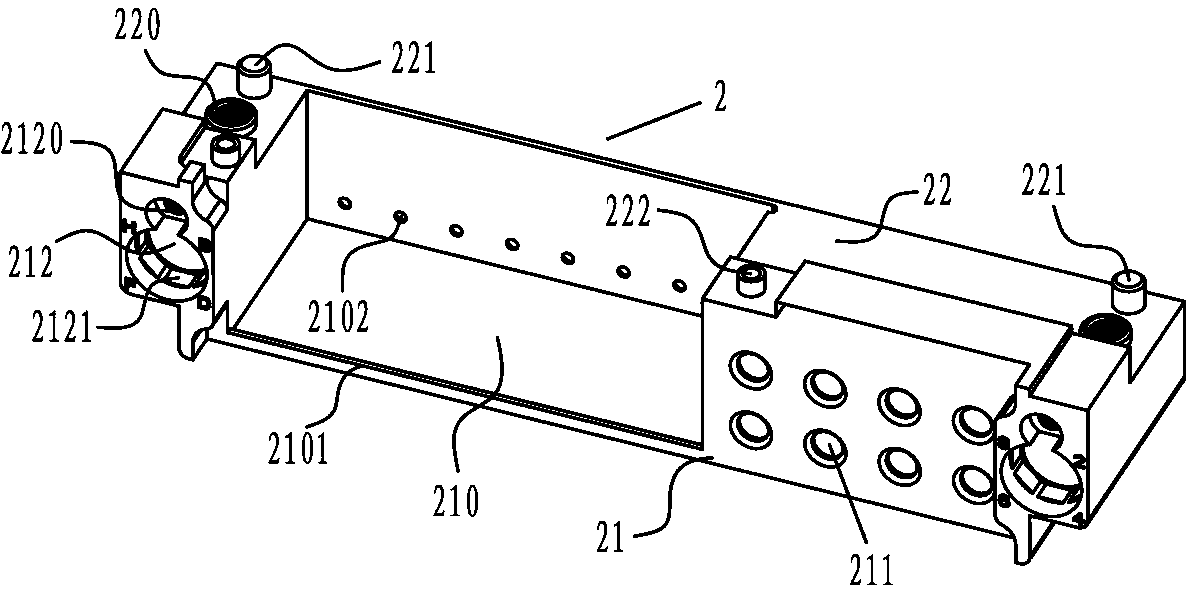

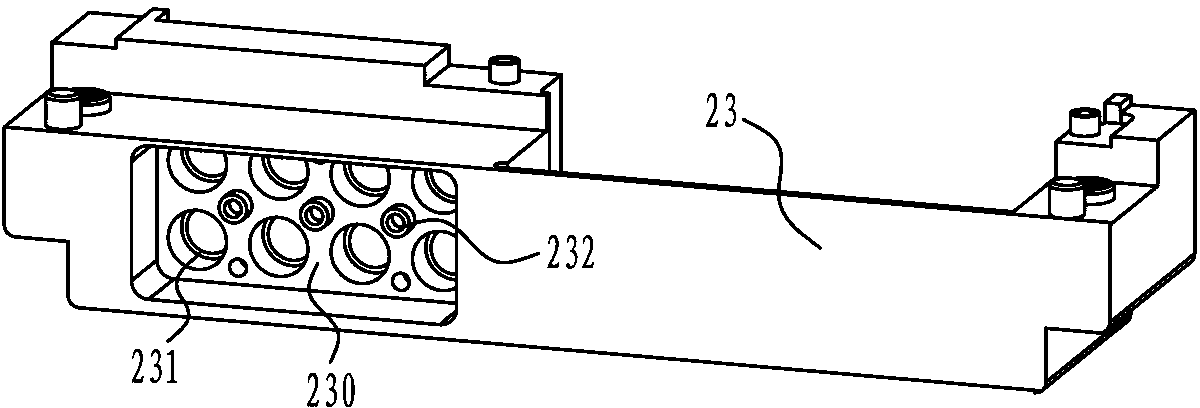

Mixed type connector plug

ActiveCN103441392AAchieve connectionHigh positioning accuracyCoupling device detailsElectromagnetic interferenceEngineering

The invention discloses a mixed type connector plug. The plug comprises a housing portion, a guide portion, a connector module portion and a function terminal portion, wherein the housing portion is composed of a fixed cover and a clamping plate; the connector module portion comprises a digital module and a function module; the function module comprises a reinforcing unit and an accessory unit; the reinforcing unit and the fixed cover are designed to form one body; the digital module is installed in the inner cavity of the fixed cover in a clamping manner and is limited by the clamping plate; the guide portion is arranged at the two ends of the fixed cover; and the function terminal portion is installed in the reinforcing unit of the function module through the accessory unit of the function module in a clamping manner. By using the mixed type connector plug, a radio frequency line, a fiber line, a power line and a digit line can be connected, the positioning precision is high, the product installation is convenient, and the mixed type connector plug also has the advantages of electromagnetic shielding, guiding adjustment, wrong plugging prevention, good mechanical properties such as vibration resistance, impact resistance and the like, and anti-electromagnetic interference capability.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

Heat dissipation type electromagnetic shielding wave-absorbing adhesive tape

PendingCN111808545AAbsorbing hasHeat dissipationMagnetic/electric field screeningFilm/foil adhesivesPolymer scienceAdhesive belt

The invention relates to the field of adhesive tapes, and in particular, relates to a heat dissipation type electromagnetic shielding wave-absorbing adhesive tape which comprises a release film, a wave-absorbing material, a copper foil and a heat dissipation material; the copper foil is arranged above the wave-absorbing material, and a pressure-sensitive adhesive is arranged between the copper foil and the wave-absorbing material; the heat dissipation material is arranged above the copper foil; the release film is arranged on the lower surface of the wave-absorbing material, and a plurality oflayers of PET double faced adhesive tapes are arranged between the release film and the wave-absorbing material. The wave-absorbing material is used as a base material and is compounded with the copper foil, the heat dissipation material is treated on the surface of the copper foil, and the ultrathin acrylic pressure-sensitive adhesive is compounded on one surface of the wave-absorbing material,so that the heat dissipation type electromagnetic shielding wave-absorbing adhesive tape is simple in structure, good in heat dissipation effect, good in electromagnetic shielding effect, high in wave-absorbing capacity and convenient to use.

Owner:GUANGDONG HONGQING ELECTRONICS MATERIALS TECH CO LTD

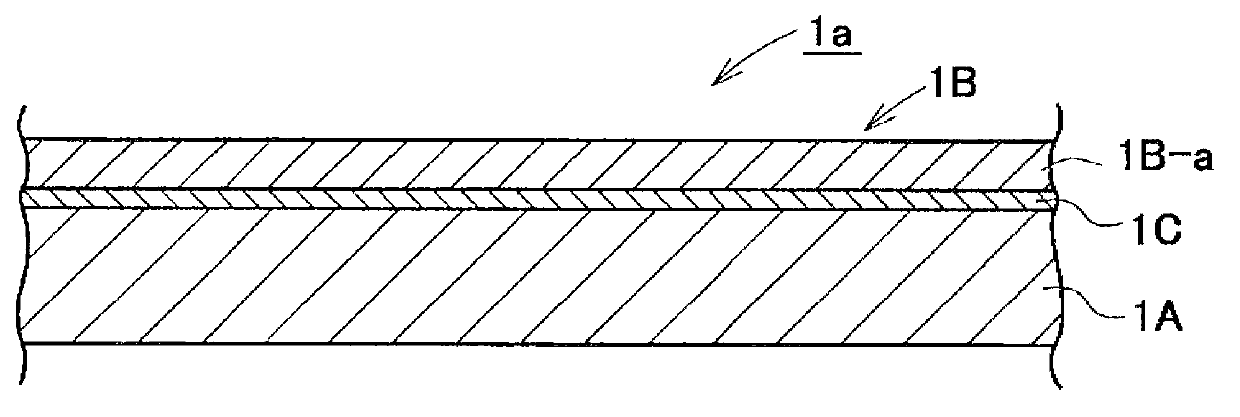

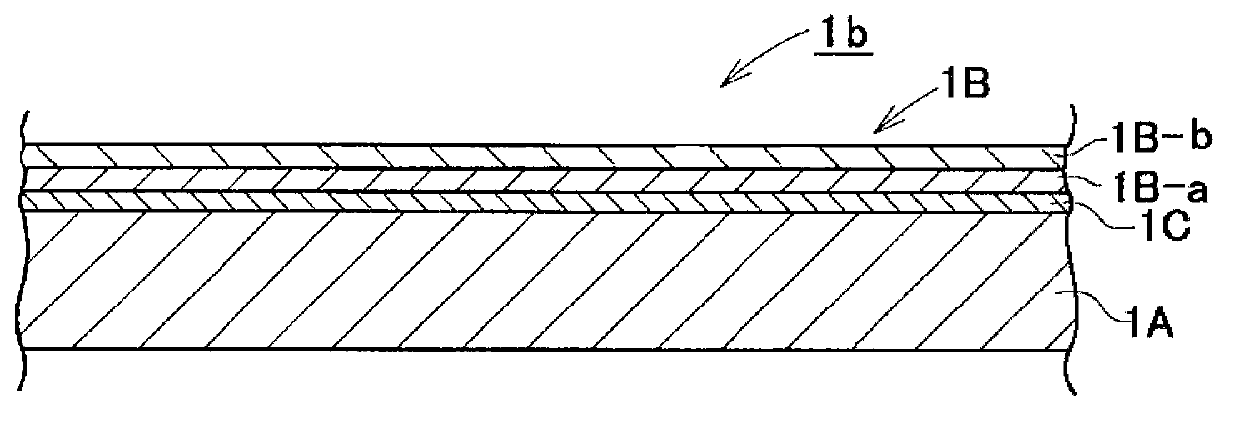

Resin/metal composite laminate material, resin/metal composite injection moulding body, and manufacturing method for same

ActiveCN102753342AGood adhesionHeat resistanceProtective equipmentSynthetic resin layered productsComposite laminatesMetal sheet

Disclosed is a resin / metal composite laminate material in which a resin layer is laminated on the surface of a metal sheet, and in which convex sections composed of a synthetic resin can be integrally formed on the resin layer with high bonding strength by injection moulding. The resin / metal composite laminate material has a metal plate, and a resin layer (a) laminated on at least one side of the metal plate, said resin layer (a) having a polyamide resin as the main component. The crystallisation index (I) of the resin layer (a) is 0.40-0.80. (Hm1, Hc1, and Hm2 are the first crystal melting heat, the first crystallisation heat, and the second crystal melting heat as measured by DSC.)

Owner:MITSUBISHI CHEM CORP

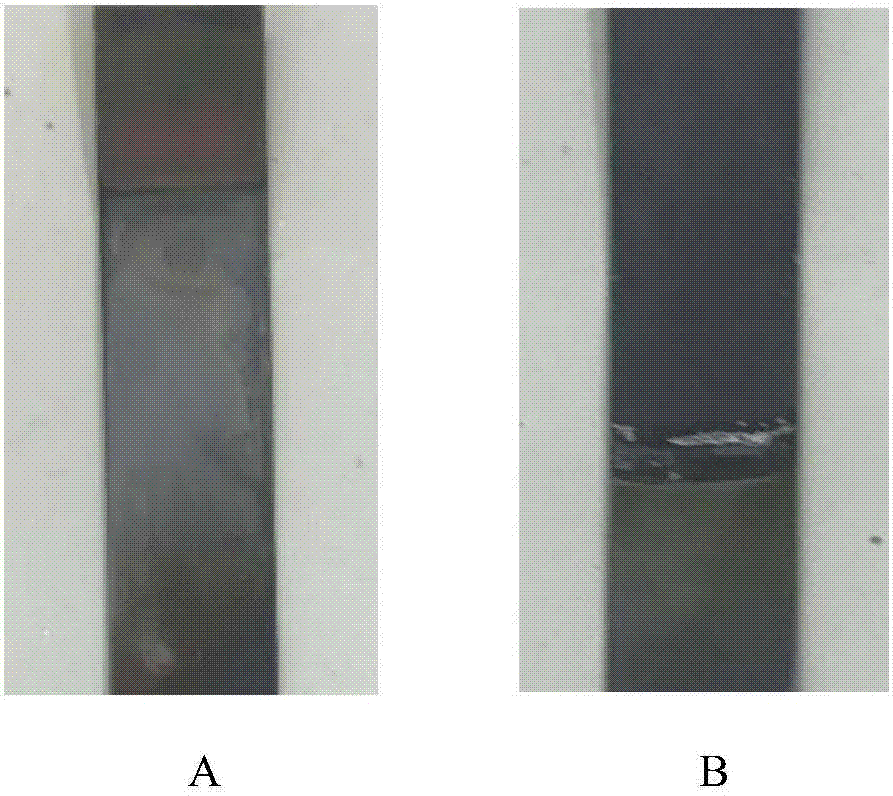

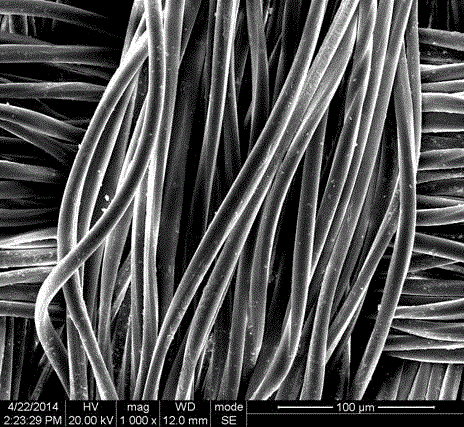

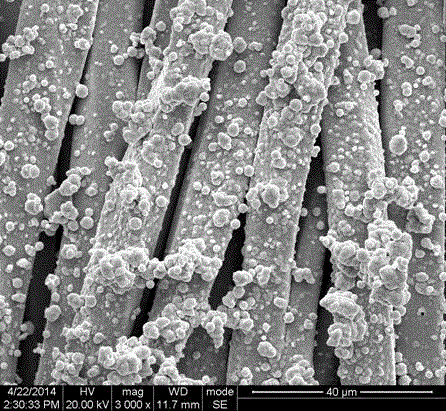

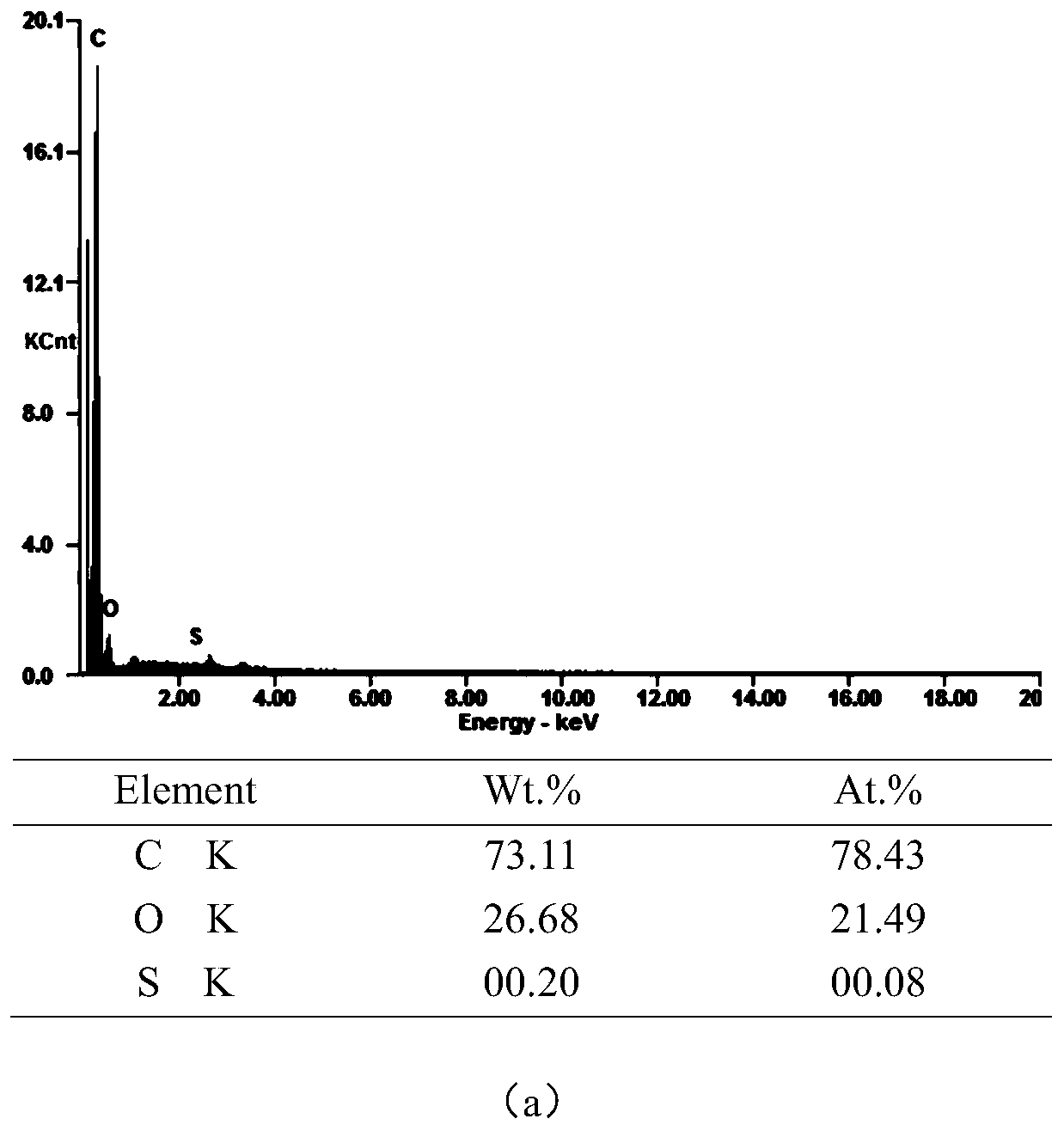

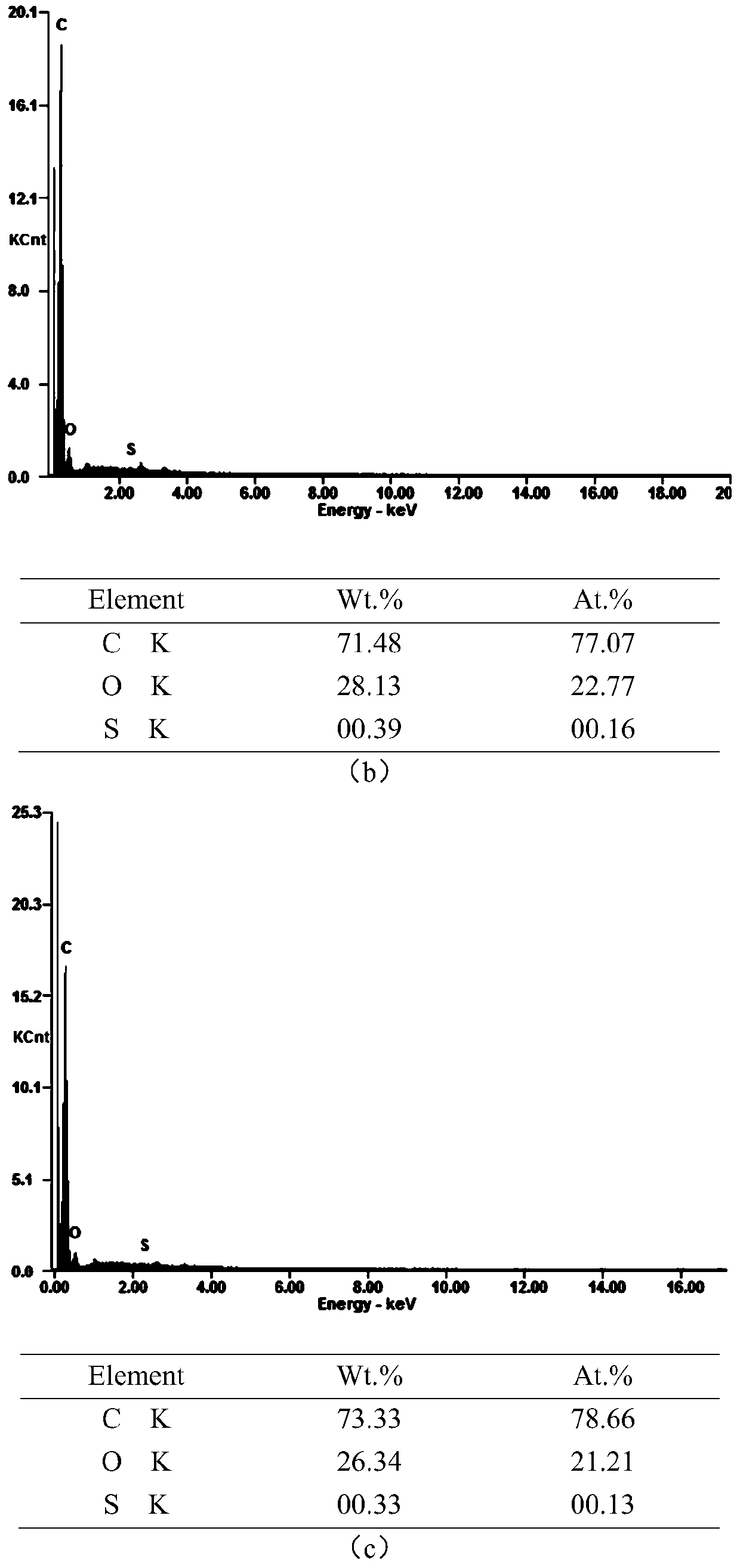

Chemical plating activation process for fabric by using supercritical carbon dioxide fluid

ActiveCN104695211AConductiveAntistaticFibre treatmentLiquid/solution decomposition chemical coatingPolyesterActivation method

The invention belongs to the field of functional textile fabrics, in particular relates to a conductive metalized textile fabric treated by supercutical fluid activation, and provides a supercutical fluid activation method of the conductive metalized textile fabric. The conductive metalized textile fabric comprises raw materials, including acetylacetone nickel, carbon dioxide, copper sulfate, ethylenediamine tetraacetic acid disodium, glyoxylic acid, potassium ferrocyanide and the textile fabric. The supercutical fluid activation method comprises the following steps: firstly, performing activation pretreatment on the textile fabric by using acetylacetone nickel through supercritical carbon dioxide, soaking in sodium borohydride solution, and putting the textile fabric into a chemical copper plating solution for chemical plating. The supercritical carbon dioxide is adopted for pretreatment, andglyoxylic acid is used as a reducing agent, so that the conductive metalized textile fabric has the characteristics of environment friendliness, no pollution, low cost and repeatability, and the obtained copper polyester fabric has functions of good conductivity, electromagnetic shielding, electrostatic resistance and the like.

Owner:SICHUAN UNIV

Electroconductive woodceramic powder and its manufacturing method

InactiveCN102515778AWith electromagnetic shieldingChange the amount of platingCeramicwareChemical platingFiltration

Relating to woodceramic materials and their preparation methods, the invention provides electroconductive woodceramic powder and its manufacturing method, and solves the technical problems of great brittleness and easy cracking in bulk woodceramic materials. The electroconductive woodceramic powder of the takes woodceramic powder as the core, the surface of which is chemically plated with electroconductive powder of a layer of metal film, and the metal attaching amount is 1%-50% of the mass of the woodceramic powder, wherein, the metal is nickel, iron or cobalt. The preparation method consists of: subjecting the woodceramic powder to oil removal, oxidation, sensitization, activation, and dispergation, then placing the woodceramic powder into a chemical plating solution for chemical plating, and conducting filtration and washing by deionized water to neutral, then carrying out drying, thus obtaining the electroconductive woodceramic powder with volume resistivity of 4.5*10<-2>omega.cm-5.5*10<-1>omega.cm. The electroconductive woodceramic powder in the invention can be added into coatings for preparing electroconductive coatings, or the powder can be added into resin-based materialsfor preparing molding materials, thus having a wide application range. The electroconductive woodceramic powder in the invention can be used as an electromagnetic shielding material.

Owner:NORTHEAST FORESTRY UNIVERSITY

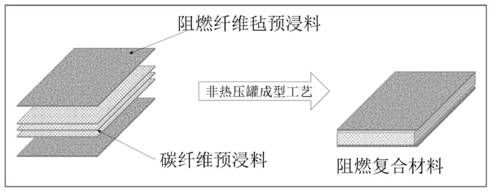

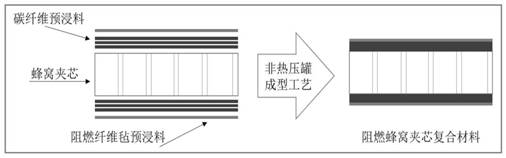

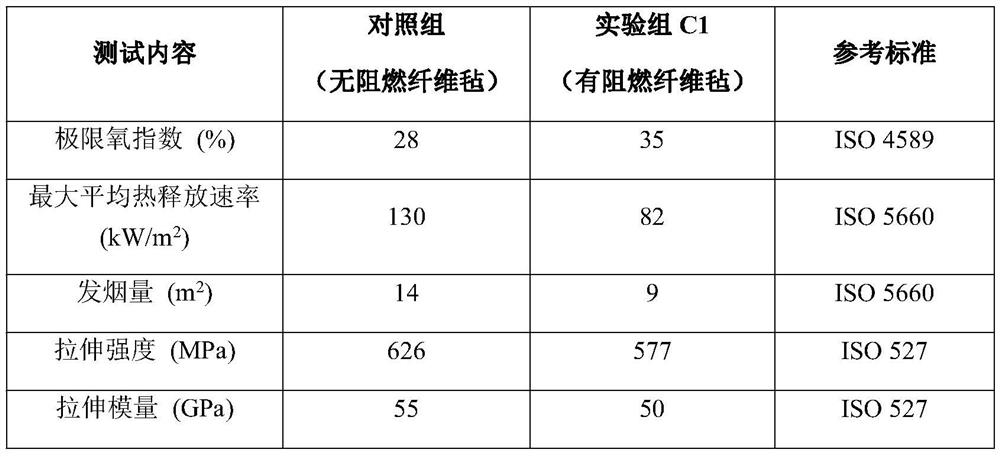

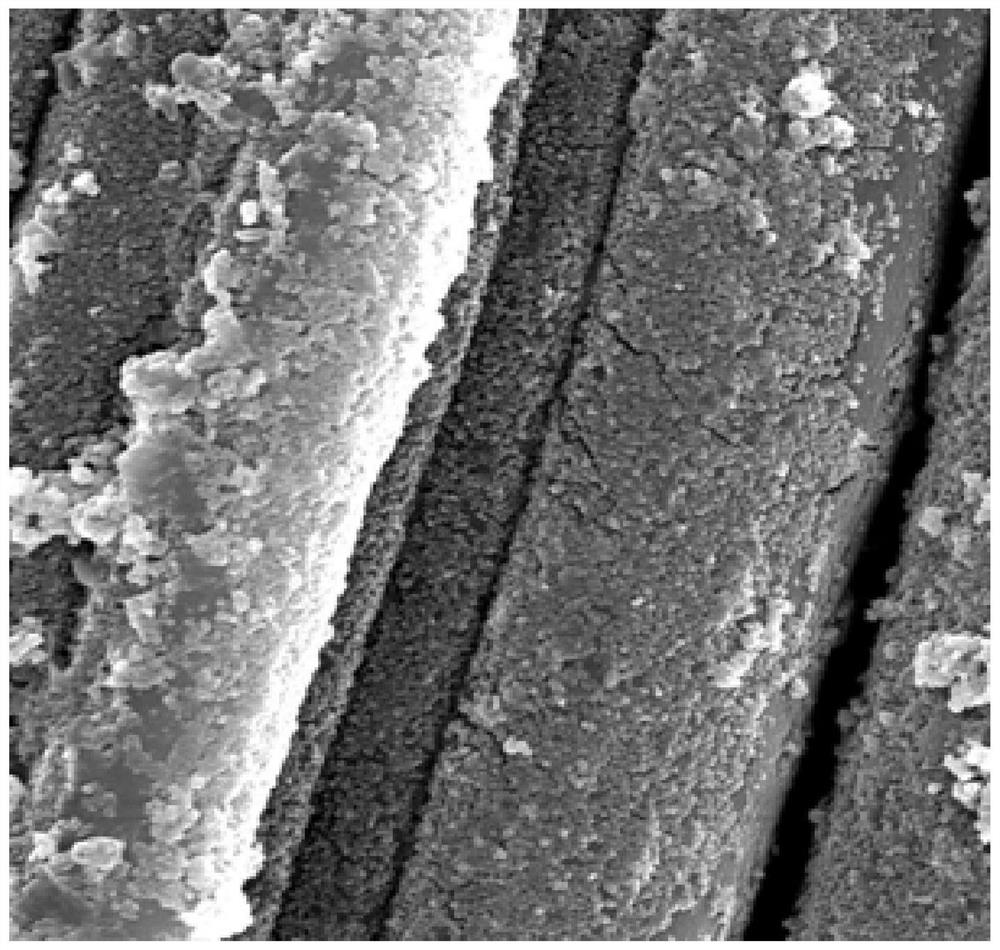

Structural flame-retardant functional composite material and preparation method thereof

ActiveCN112009038AAvoid destructionImprove flame retardant performanceSynthetic resin layered productsLaminationFiberCombustion

The invention provides a structural flame-retardant functional composite material which comprises a flame-retardant fireproof fiber felt and a composite material, and the surface of the composite material body is coated with the flame-retardant fireproof fiber felt. The invention further provides a preparation method of the structural flame-retardant functional composite material. The preparationmethod comprises the following steps: (1) preparing the flame-retardant fireproof fiber felt; (2) pre-impregnating the fiber felt; and (3) preparing the flame-retardant composite material. Compared with the prior art, a surface flame-retardant structure is adopted, the flame-retardant functional structure layer with the functions of flame retardance, heat insulation, smoke suppression and the likeis concentrated on the surface of the composite material based on the combustion behavior that the composite material expands from outside to inside after being ignited, and in the process that the composite material is on fire, the structure can be used as a fireproofing suit to isolate flame and heat outside the composite material so that the internal structure of the material is protected, andthe damage of a flame retardant to the composite material matrix is avoided.

Owner:NINGBO NOTTINGHAM NEW MATERIALS INST CO LTD +1

Impregnation or supercritical fluid pretreatment assisted metal plating textile preparation method

PendingCN112832020AGood UV resistanceIncrease productivityFibre treatmentWoven fabricPolymer chemistry

The invention relates to an impregnation or supercritical fluid assisted metal plating textile preparation method, and belongs to the technical field of textiles. The method provided by the invention comprises the following steps of a, textile pretreatment; b, impregnation or supercritical treatment with a coupling agent: dipping the textile in an acetone solution of the coupling agent, treating at 20-80 DEG C for 0.5-3 hours, and then drying, wherein the supercritical treatment comprises the following steps of soaking the textile in an ethanol solution of a coupling agent, carrying out supercritical static treatment for 10-60 minutes under the conditions of 5-20 Mpa and the temperature of 10-80 DEG C, and then taking out and drying; C, preparation of the metal plated textile: mixing a stabilizer, metal salt and a reducing agent to obtain a solution A; and putting the textile dried in the step b into the solution A for microwave treatment, taking out, washing with water, and drying. The product obtained by the method disclosed by the invention has the functions of static electricity resistance, ultraviolet resistance, electric conduction, electromagnetic shielding and the like, and is better in ultraviolet resistance. The method is environment-friendly, high in production efficiency and simple in process.

Owner:四川警察学院 +1

Polyether-ether-ketone fiber composite paper with electromagnetic shielding performance and preparation method thereof

ActiveCN111535071AInhibition of agglomerationGood dispersionShielding materialsPaper coatingFiberPolymer science

The invention discloses polyether-ether-ketone fiber composite paper with electromagnetic shielding performance and a preparation method thereof, and belongs to the technical field of composite papers. The problems that in the prior art, a polyether-ether-ketone fiber paper is poor in paper forming performance and low in paper performance, carbon nano tubes in a dipping spraying liquid of the paper are prone to agglomeration, and the adding content is limited are solved. The invention discloses a preparation method of the fiber composite paper. The preparation method comprises the following steps: firstly, coating a multi-walled carbon nanotube with a soluble polymer precursor of polyether-ether-ketone, preparing conductive polyetheretherketone fibers by using a crystalline polyetheretherketone-coated multi-walled carbon nanotube as a spinning filler, preparing a polyetheretherketone conductive fiber paper from the conductive polyetheretherketone fibers, and spraying the conductive fiber paper by using an impregnation spraying liquid to obtain the polyetheretherketone fiber composite paper with electromagnetic shielding performances. The fiber composite paper has good mechanical strength, heat resistance, heat dissipation performance, flame retardance, voltage resistance and electromagnetic shielding performance, and can be applied to the fields of high-temperature electromagnetic shielding protection, electrical insulation and the like.

Owner:SINO HIGH CHINA

Polyiner/laminate inorganic nano composite material and its milling shearing preparation method

A nanometre-class polymer / laminated inorganic substance composite material features that it is prepared by use of the millstone-shaped force chemical reactor, which has a unique 3-D shear structure to provide strong squeeze-shear force field for grinding inserting, dispersing, and mixing to prepare the polymer / laminated inorganic substance composite powder, and then the said nanometre-class composite material is prepared by the universal processing method.

Owner:SICHUAN UNIV

High-thermal-conductivity carbon fiber/polyetheretherketone electromagnetic shielding composite material

The invention discloses a high-thermal-conductivity carbon fiber / polyetheretherketone electromagnetic shielding composite material, and belongs to the field of high-performance composite materials. The composite material is prepared by uniformly mixing 10-50 wt% of sulfonated polyetheretherketone and its sodium salt, 40-80 wt% of polyetheretherketone and 5-30 wt% of a carbon fiber in proportion and then carrying out a hot pressing process. The sulfonated polyetheretherketone and its sodium salt is prepared by reacting sulfonated polyetheretherketone with an alkaline sodium salt solution to neutralize a part of sulfonate radicals, wherein the neutralization ratio of the sulfonate radicals is 30-70%. Compared with traditional carbon fiber / polyetheretherketone composite materials, the composite material prepared in the invention has obviously enhanced thermal conductivity, and the heat conductivity of the composite material at a low filling amount exceeds 2 W / (m.K). In addition, the composite material has very excellent electromagnetic shielding property and mechanical properties.

Owner:JILIN UNIV

Modulus slot type aluminum profile enclosure

InactiveCN102831936ALess consumablesSimplify the assembly processInstrument housingElectromagnetic shieldingEngineering

The invention discloses a modulus slot type aluminum profile enclosure which consists of a panel, a rear plate and a modulus slot type frame, wherein round grooves or convex columns are arranged at the four corners in the modulus slot type frame, and multiple dovetail grooves are uniformly arranged on the walls inside; and the panel and the rear plate are fixed in the round grooves or convex columns of the modulus slot type frame by bolts. The dovetail grooves can realize stable insertion of electrical appliances, instruments, meters and electronic circuit boards; and the modulus slot type aluminum profile enclosure can save multiple parts, consumes a few materials, is very simple to assemble, can save energy and reduce consumption, has the characteristics of electromagnetic shielding, strong deformation resistance, safety, reliability and the like, and can realize quick batch production.

Owner:江苏省长虹电器实业有限公司

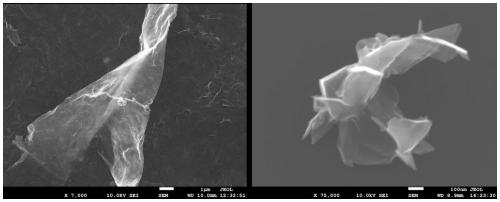

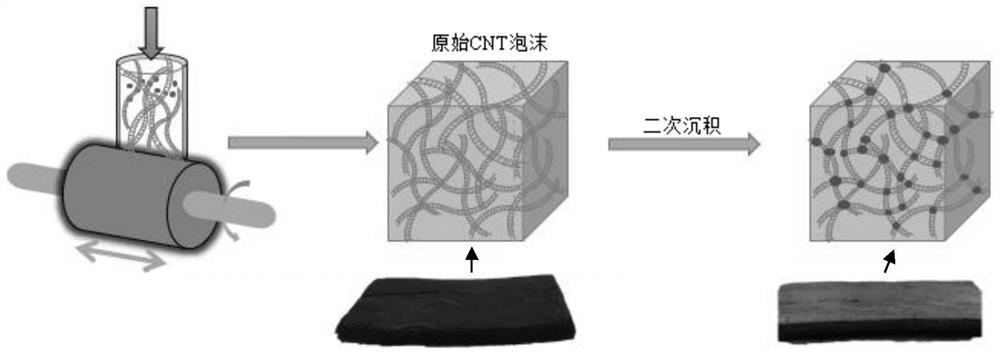

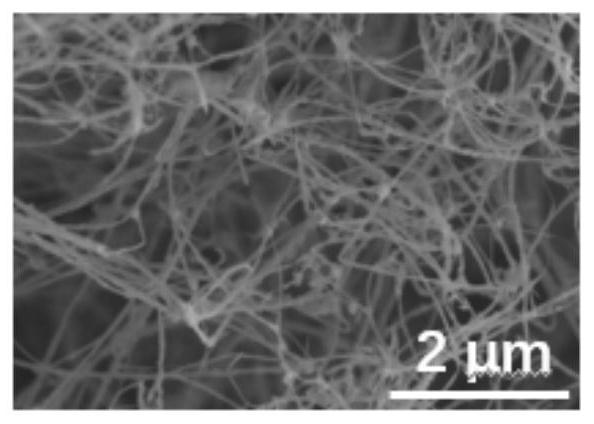

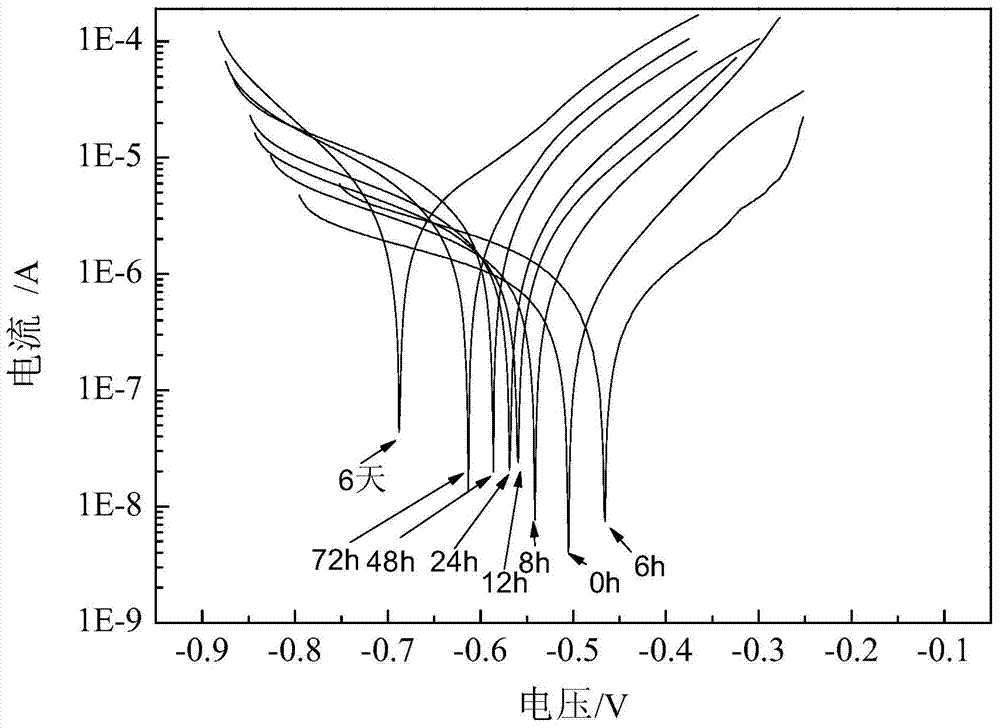

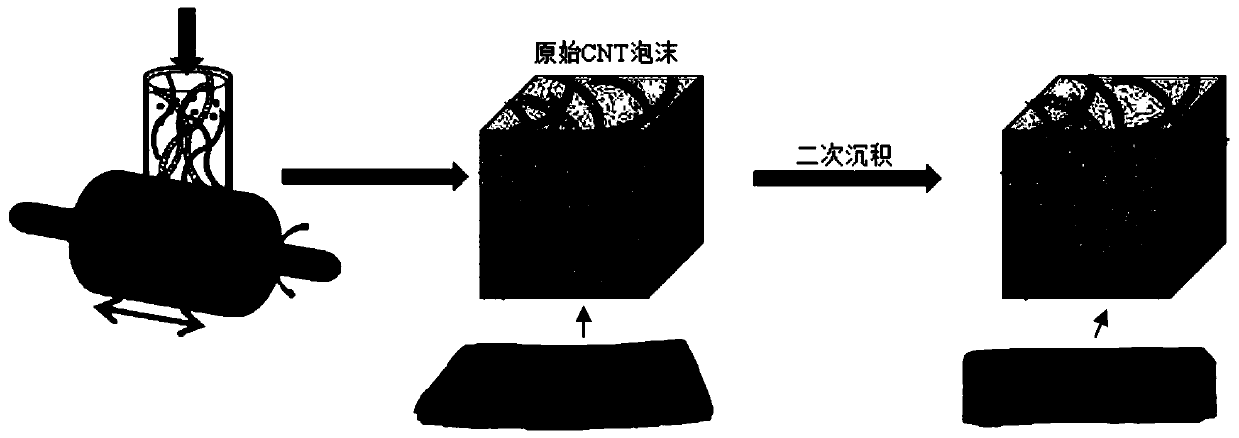

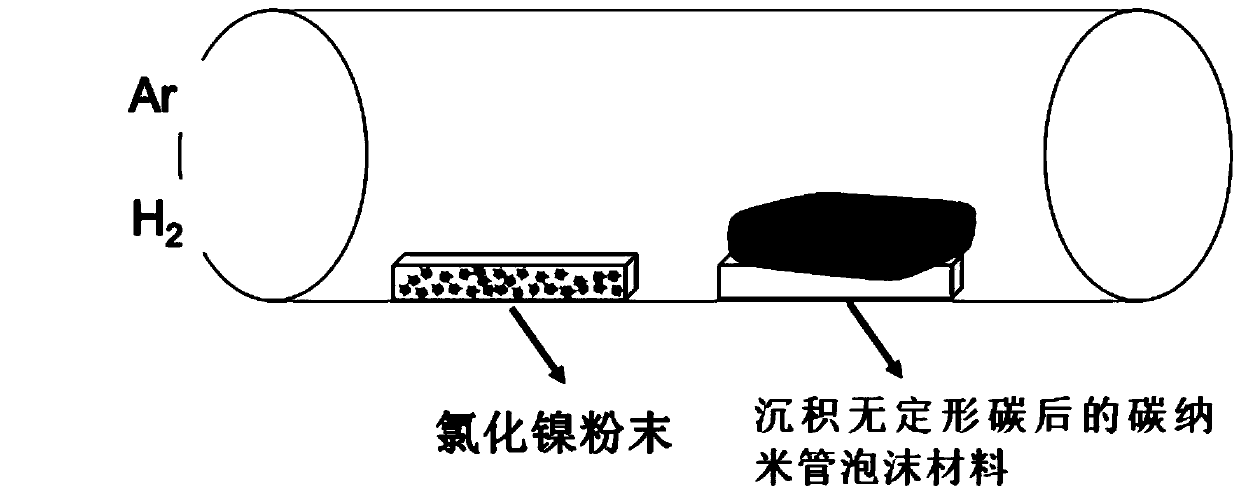

Carbon nanotube foam material with electromagnetic shielding performance, and preparation method and application thereof

ActiveCN112210766AImprove shielding effectControllable densityMagnetic/electric field screeningChemical vapor deposition coatingCarbon nanotubeNetwork structure

The invention discloses a carbon nanotube foam material with electromagnetic shielding performance, and a preparation method and application thereof. The preparation method of the carbon nanotube foammaterial with the electromagnetic shielding performance comprises the following steps: placing carbon nanotube foam into a reaction chamber of chemical vapor deposition equipment; and heating the reaction chamber to 1000-1100 DEG C, and then at least introducing a carbon source and a reducing gas into the reaction chamber, so as to carry out secondary deposition of amorphous carbon on the carbonnanotube foam, thereby obtaining the carbon nanotube foam material with the electromagnetic shielding performance, wherein the carbon nanotube foam material comprises a porous structure composed of a3D network structure with self-supporting capability. According to the invention, the prepared carbon nanotube foam material with the electromagnetic shielding performance has excellent shielding effectiveness, controllable density and thickness, small mass, good flexibility and excellent shielding effectiveness stability; and the preparation process is simple, and batch production can be expanded.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

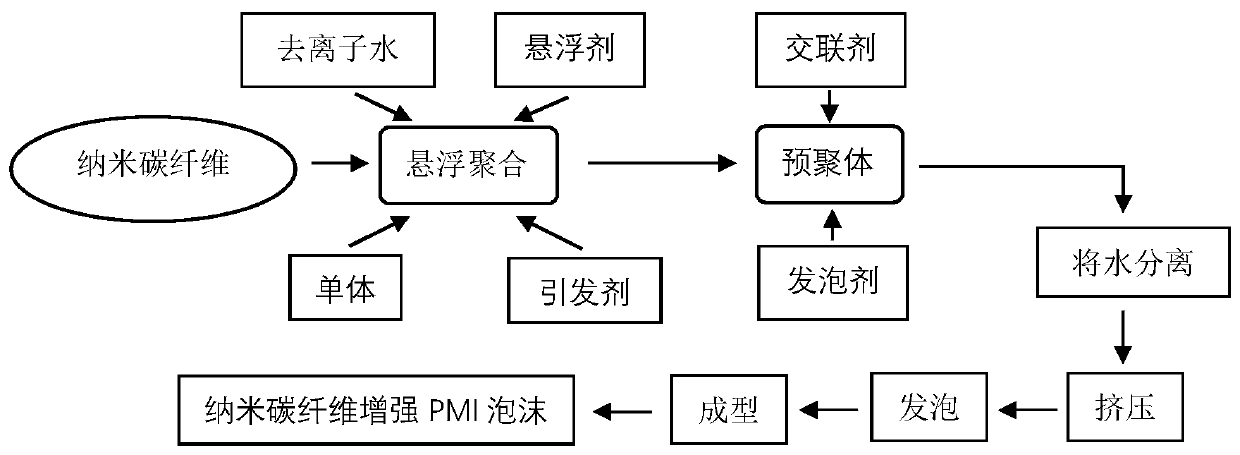

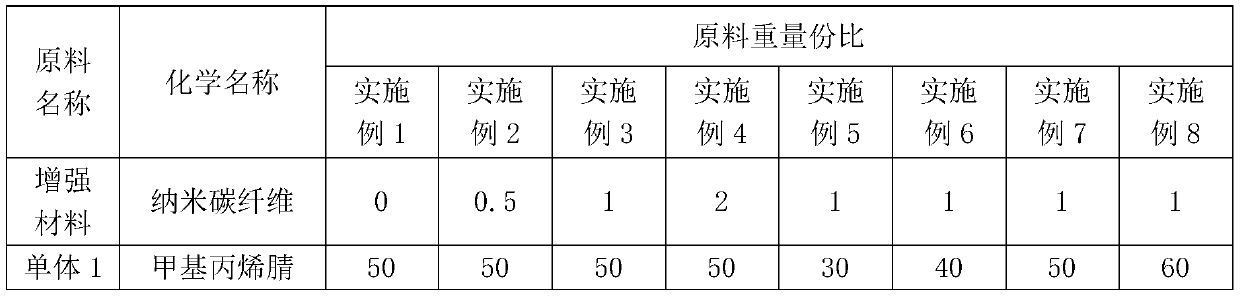

Method of preparing carbon nanofiber reinforced polymethacrylimide foam through suspension polymerization

The invention discloses a method of preparing carbon nanofiber reinforced polymethacrylimide foam through suspension polymerization. The method comprises the steps that firstly, a dispersion medium and a suspension agent are added into a first reactor, and stirring is performed; secondly, monomers are added into a second reactor, the second reactor is heated to a reaction temperature, then an initiator and carbon nanofibers are added, and then the second reactor is placed in an ultrasonic dispersion instrument for ultrasonic dispersion under a constant-temperature condition; thirdly, a mixed liquid obtained after dispersion in the second reactor is poured into the first reactor which is heated to the reaction temperature, stirring is performed for a suspension polymerization reaction, anda prepolymer is obtained; fourthly, a cross-linking agent and a foaming agent are added into the prepolymer, and an extruding machine is adopted to extrude the mixture; and fifthly, the extruded mixture is placed in a mold for foaming heat treatment molding, and the carbon nanofiber reinforced polymethacrylimide foam is obtained. The foam has the advantages that mechanical properties are excellent, reaction time is short, the finished product rate is high, and large-scale production is easy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

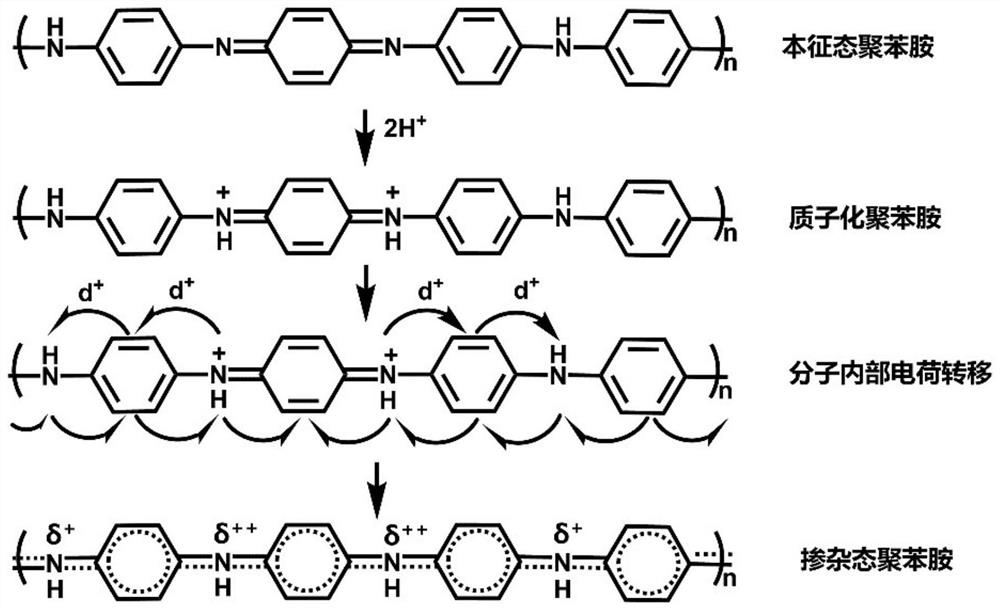

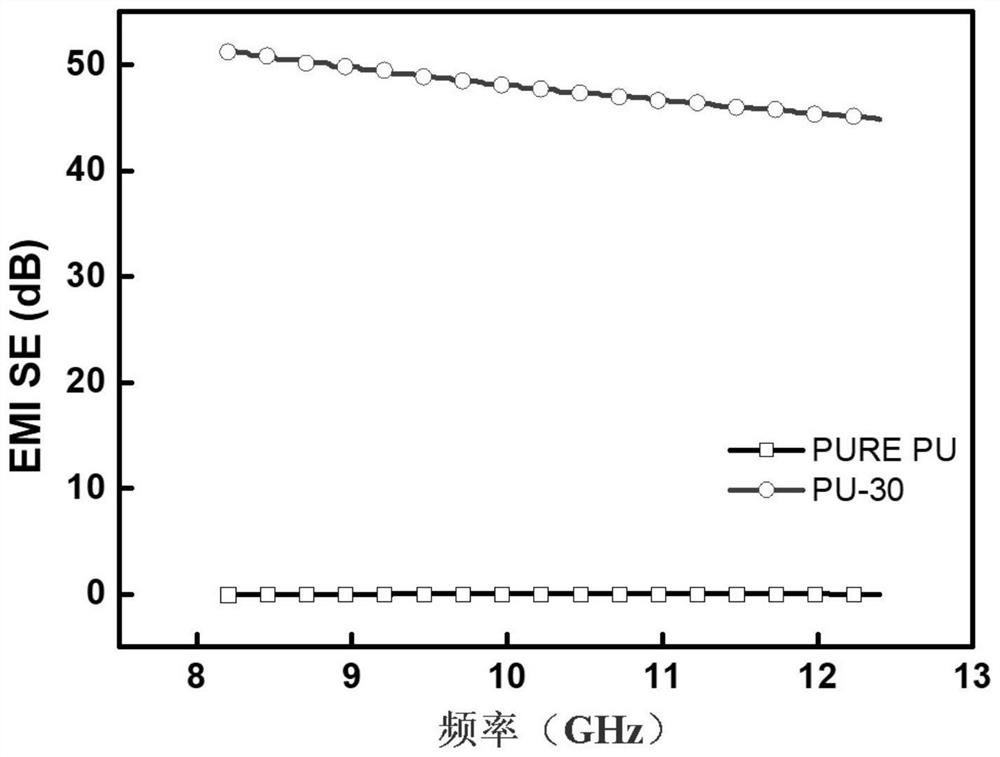

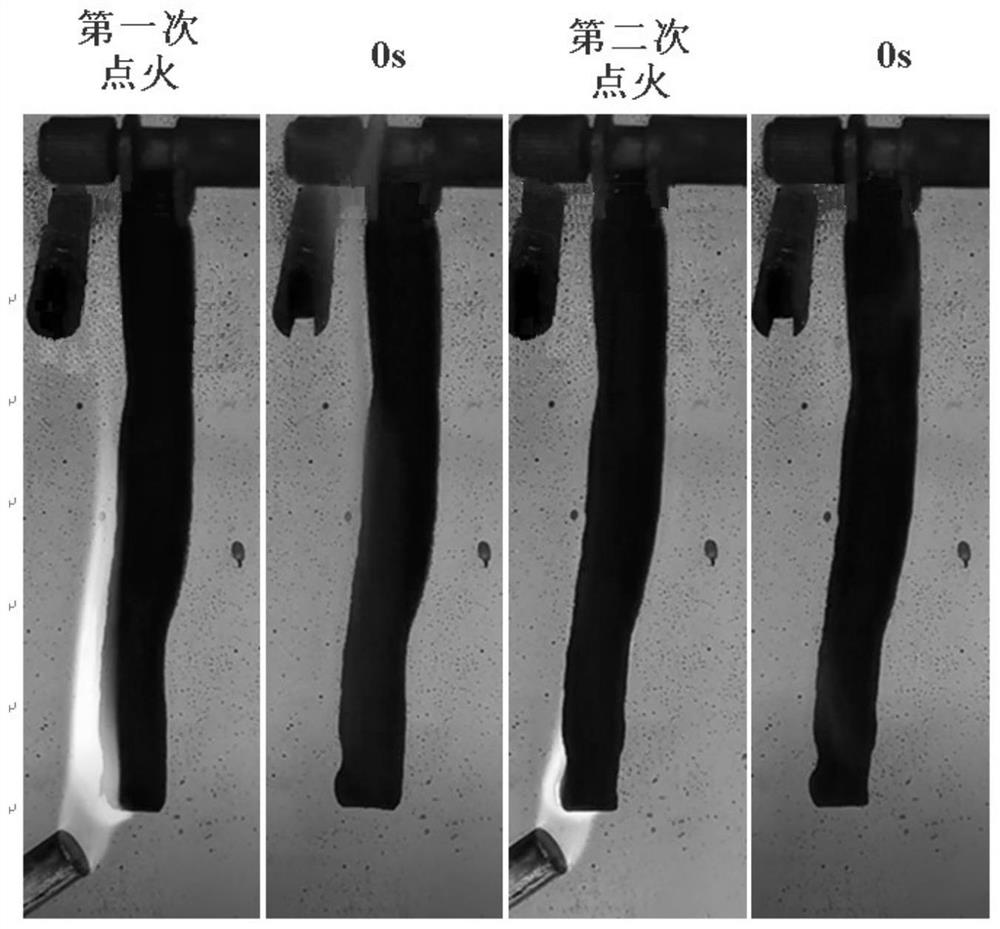

Flame-retardant polyurethane foam with electromagnetic shielding function and preparation method of flame-retardant polyurethane foam

ActiveCN112159548AAvoid problems such as destructionWith electromagnetic shieldingMagnetic/electric field screeningO-Phosphoric AcidIn situ polymerization

The invention discloses flame-retardant polyurethane foam with an electromagnetic shielding function and a preparation method of the flame-retardant polyurethane foam.The preparation method comprisesthe following steps that 1, placing polyurethane foam in a mixed solution A to be soaked, wherein the mixed solution A is obtained by mixing a phosphoric acid-containing solution and an aniline solution, and the substance amount ratio of phosphoric acid to aniline in the mixed solution A is 1: 10-1.5: 1; 2, adding ammonium persulfate into the mixed solution A in the step 1 for in-situ polymerization, and fully reacting to obtain polyurethane foam coated with phosphoric acid doped polyaniline, wherein the mass ratio of the ammonium persulfate to the aniline is 1: 1-1.5: 1; and 3, dip-coating the polyurethane foam coated with the phosphoric acid doped polyaniline in a conductive solution for N times, and drying to obtain the required flame-retardant polyurethane foam with the electromagneticshielding function. The obtained polyurethane foam is good in electromagnetic shielding effect and good in flame retardant property and can pass a vertical combustion test, and the oxygen index can reach 34.2%; and the preparation method is simple and environment-friendly.

Owner:SICHUAN UNIV

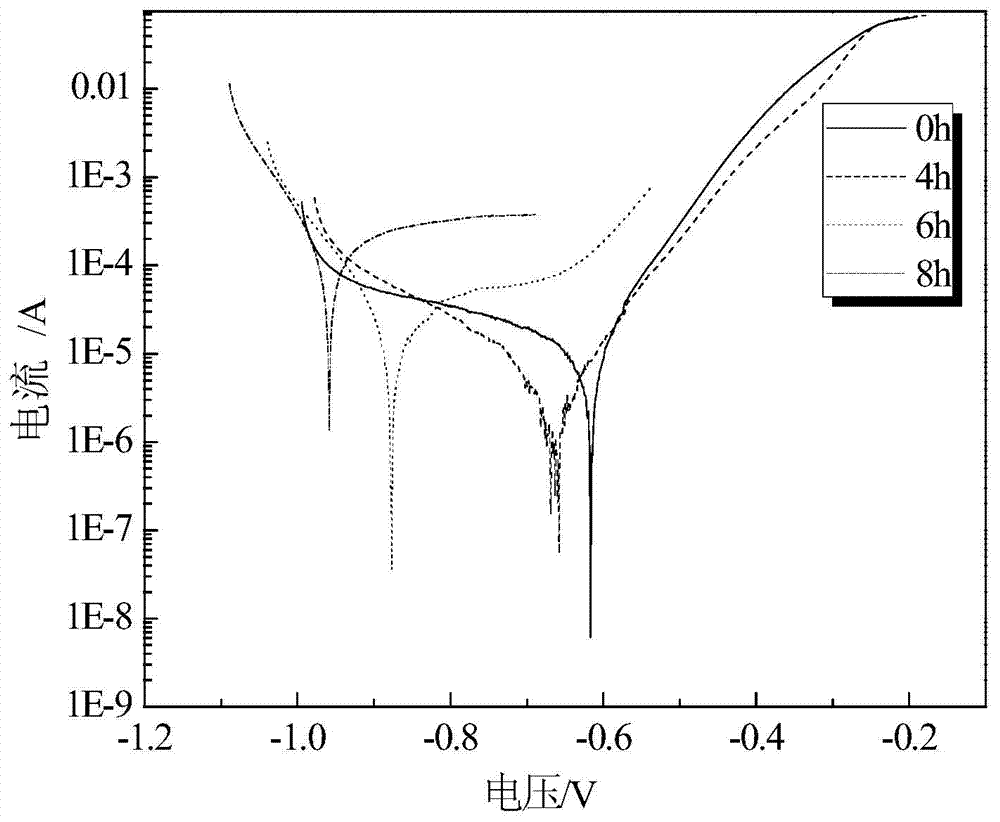

Coal-based polyaniline and anti-corrosive paint

InactiveCN104513394AReduce usageEasy to operateAnti-corrosive paintsEpoxy resin coatingsFiltrationMicrometer

The invention provides a method for preparing coal-based polyaniline. The method comprises the following steps: (1) feed coal is deashed and crushed until a particle size d97 is smaller than or equal to 20 micrometers, preferably, the particle size d97 is smaller than or equal to 10 micrometers, and ultra-fine coal powder with ultra-low ash content is obtained; (2) the ultra-fine coal powder with ultra-low ash content is mixed with aniline and a protonic acid solution, an initiator is added into the mixture, and then a mixture containing coal-based polyaniline in situ polymerization is obtained after a reaction; (3) the mixture is subjected to suction filtration and is washed and dried, and coal-based polyaniline is obtained. The invention further provides coal-based polyaniline prepared with the method, a method for preparing anti-corrosive paint through coal-based polyaniline and the anti-corrosive paint. The anti-corrosive paint prepared with the method has good film forming performance, durability, stability, good anti-corrosive effect and low cost.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Metal-carbon nanotube foam composite material as well as preparation method and application thereof

ActiveCN111517831AWith electromagnetic shieldingWith mechanical strengthMagnetic/electric field screeningCeramicwareAmorphous carbonReaction chamber

The invention discloses a metal-carbon nanotube foam composite material as well as a preparation method and an application thereof. The preparation method comprises the following steps: carrying out secondary deposition of amorphous carbon on original carbon nanotube foam to obtain a deposited carbon nanotube foam material, putting the deposited carbon nanotube foam material and a metal precursorinto a reaction chamber of chemical vapor deposition equipment, and distributing the metal precursor at the upstream of the carbon nanotube foam material; and heating the reaction chamber to 1050-1150DEG C, and then at least introducing a reducing gas into the reaction chamber to thermally reduce the metal precursor, thereby uniformly loading metal particles on the surface and inside of the deposited carbon nanotube foam material to obtain the metal-carbon nanotube foam composite material. The metal-carbon nanotube foam composite material disclosed by the invention has excellent shielding effectiveness, certain mechanical strength, flexibility and compression stability and low density, and has a wide application prospect in preparation of elastic electromagnetic shielding materials.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com