Heat dissipation type electromagnetic shielding wave-absorbing adhesive tape

An electromagnetic shielding and heat-dissipating technology, applied in the fields of magnetic/electric field shielding, adhesives, electrical components, etc., can solve problems such as failures, electronic products are easily interfered, and the use of electronic products is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

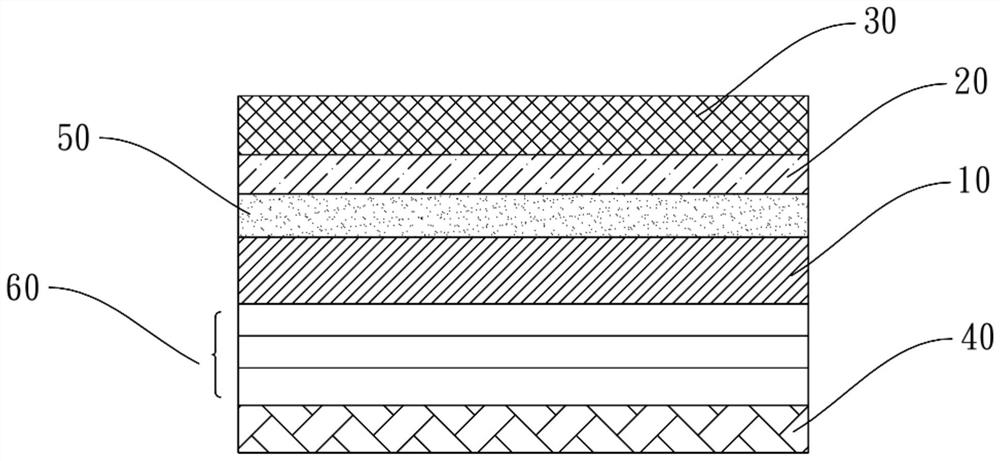

[0029] like figure 1 As shown, a heat-dissipating electromagnetic shielding wave-absorbing tape includes a release film 40, and also includes a wave-absorbing material 10, a copper foil 20, and a heat-dissipating material; the copper foil 20 is arranged above the wave-absorbing material 10, and the A pressure-sensitive adhesive 50 is arranged between the copper foil 20 and the wave-absorbing material 10; the heat dissipation material is arranged above the copper foil 20; the release film 40 is arranged under the wave-absorbing material 10 On the surface, several layers of PET double-sided adhesive tape 60 are arranged between the release film 40 and the wave-absorbing material 10 .

[0030] The wave-absorbing material 10 is a ferrite film, and the ferrite film is a casting sheet of one or two of carbonyl iron powder, sendust powder, and Mn—Zn ferrite.

[0031] The heat dissipation material is heat dissipation coating 30 .

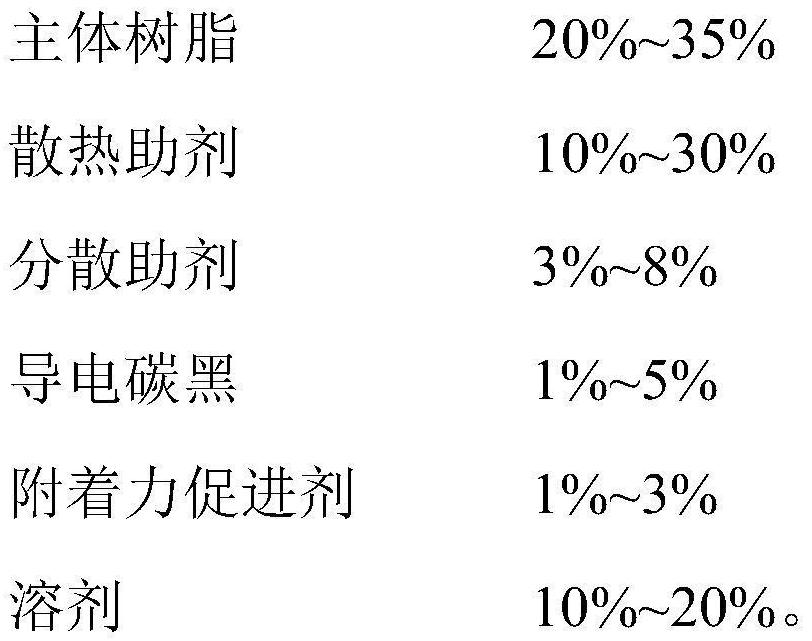

[0032] When the heat dissipation material is a heat...

Embodiment 2

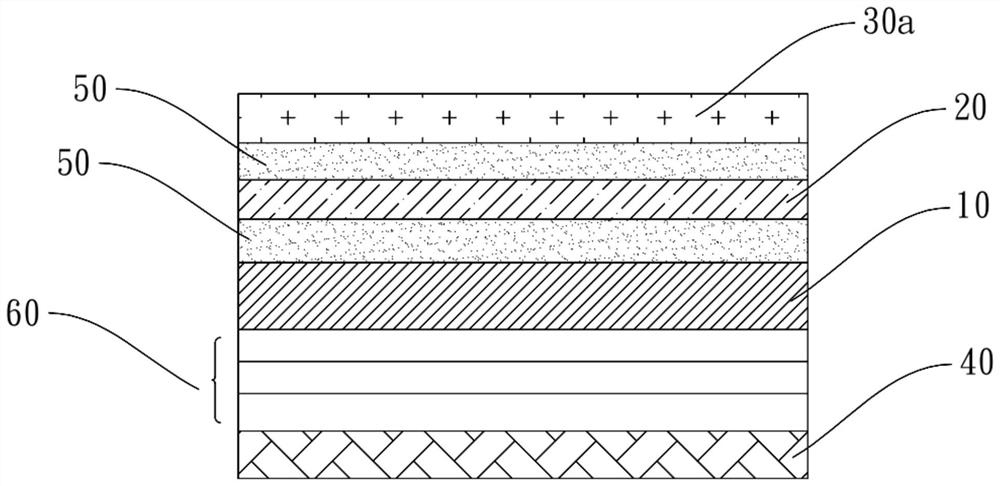

[0037] like figure 2 As shown, a heat-dissipating electromagnetic shielding wave-absorbing tape includes a release film 40, and also includes a wave-absorbing material 10, a copper foil 20, and a heat-dissipating material; the copper foil 20 is arranged above the wave-absorbing material 10, and the A pressure-sensitive adhesive 50 is arranged between the copper foil 20 and the wave-absorbing material 10; the heat dissipation material is arranged above the copper foil 20; the release film 40 is arranged under the wave-absorbing material 10 On the surface, several layers of PET double-sided adhesive tape 60 are arranged between the release film 40 and the wave-absorbing material 10 .

[0038] The wave-absorbing material 10 is a ferrite film, and the ferrite film is a casting sheet of one or two of carbonyl iron powder, sendust powder, and Mn—Zn ferrite.

[0039] The difference from Embodiment 2 is that when the heat dissipation material is a graphite sheet 30a, the graphite sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com