Patents

Literature

196results about How to "Improve Microwave Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

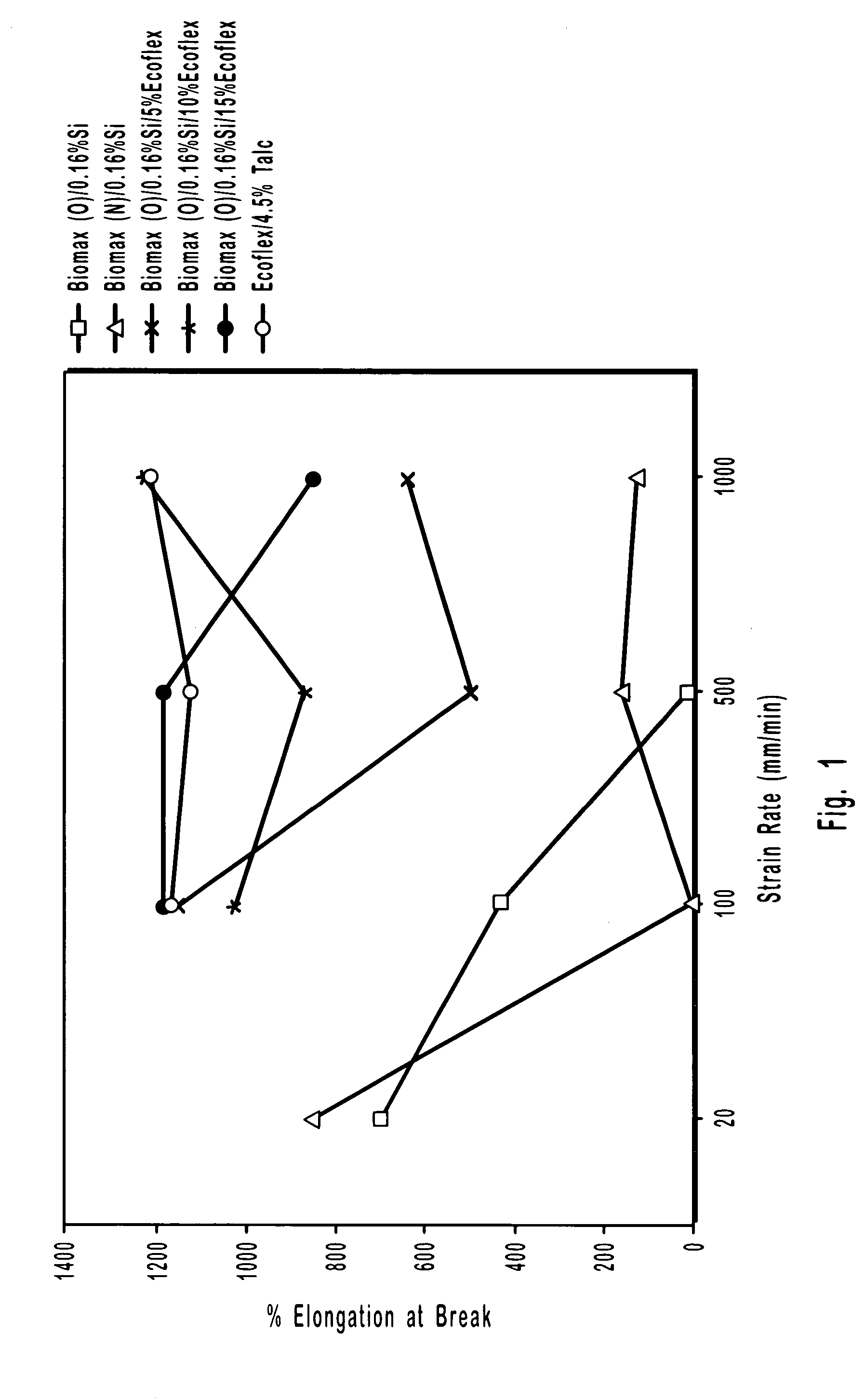

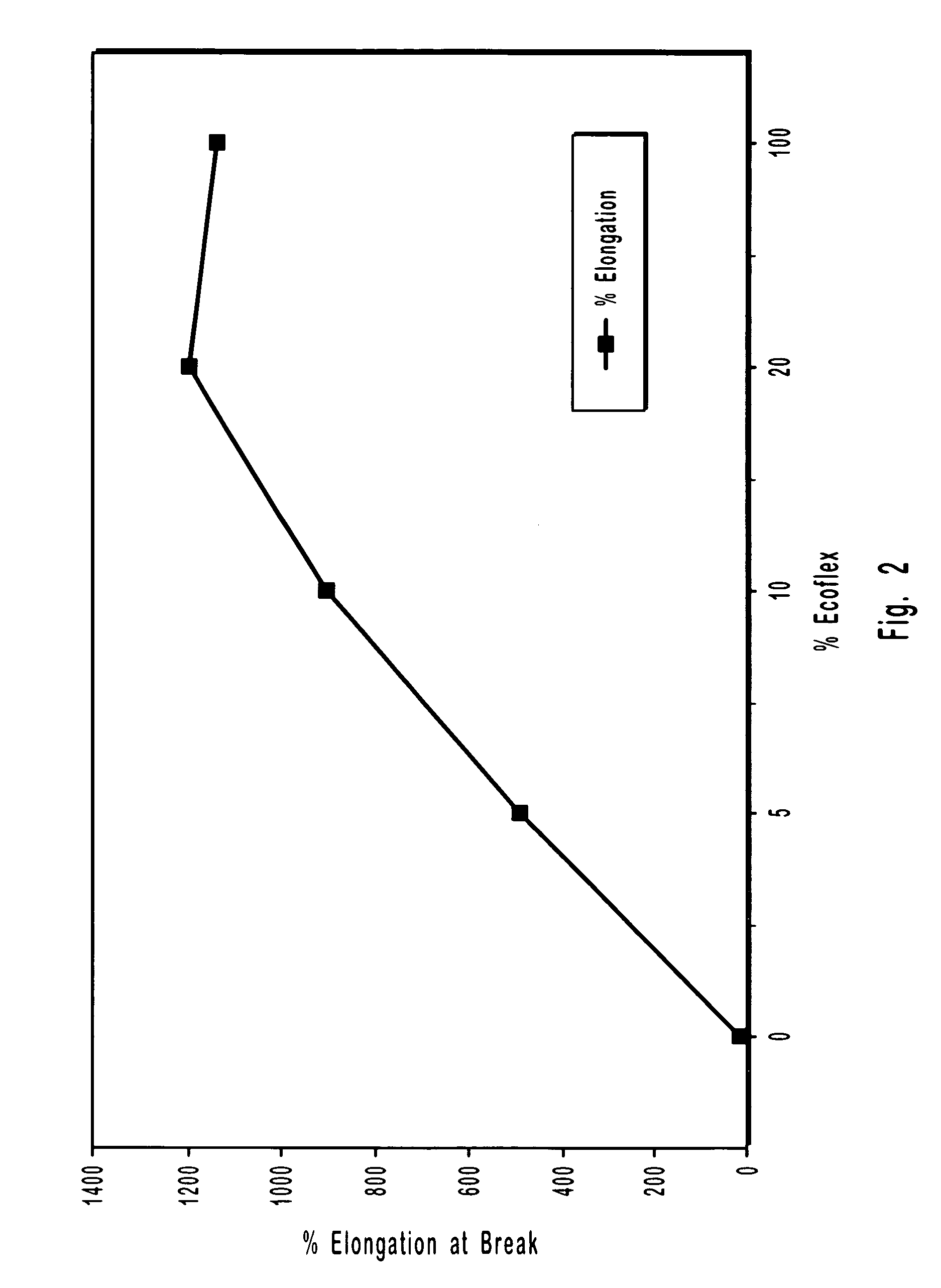

Fibrous sheets coated or impregnated with biodegradable polymers or polymers blends

ActiveUS7172814B2High glass transition temperatureImprove the crystallization processBio-packagingPaper coatingPolymer scienceBiopolymer

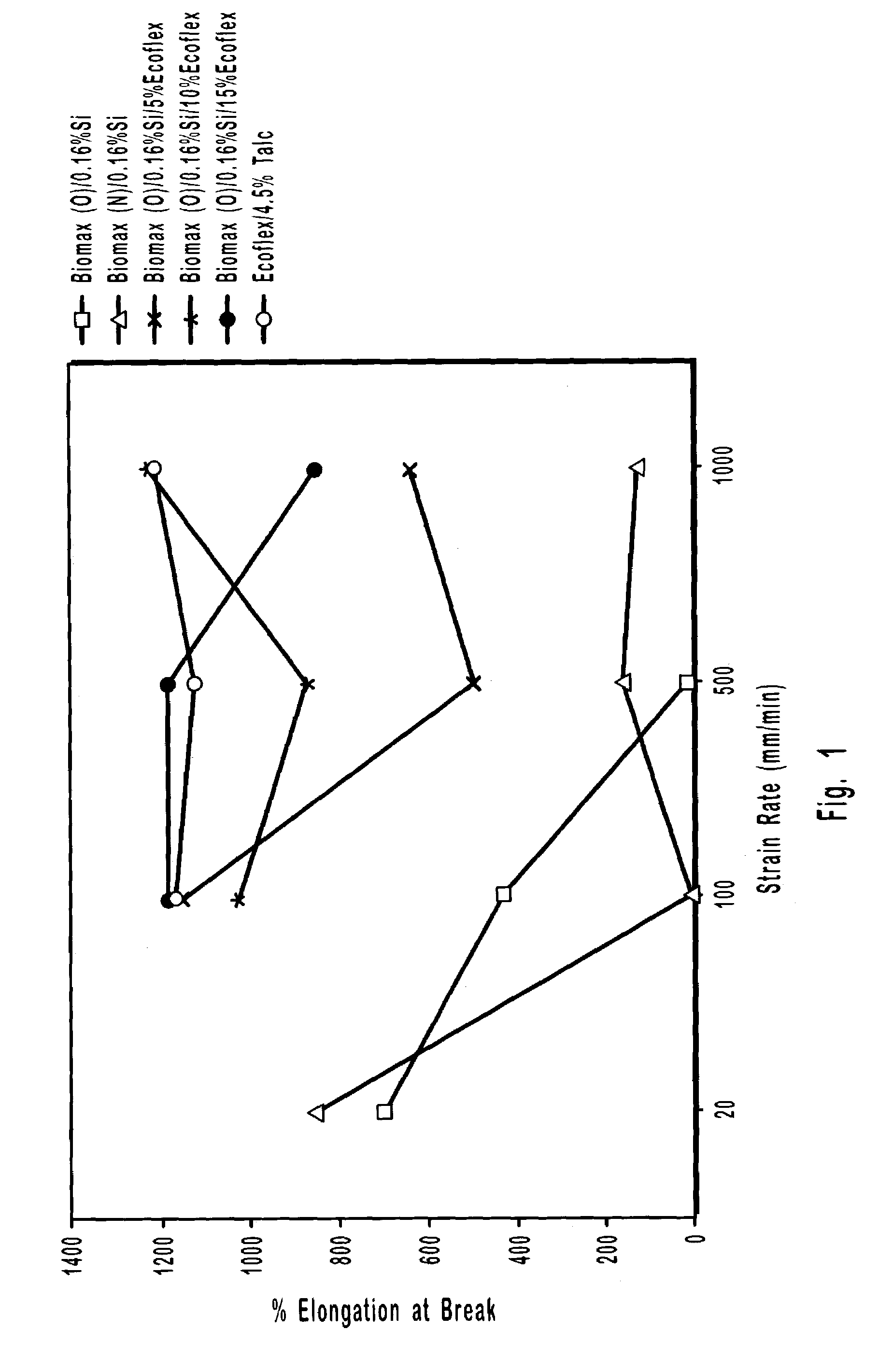

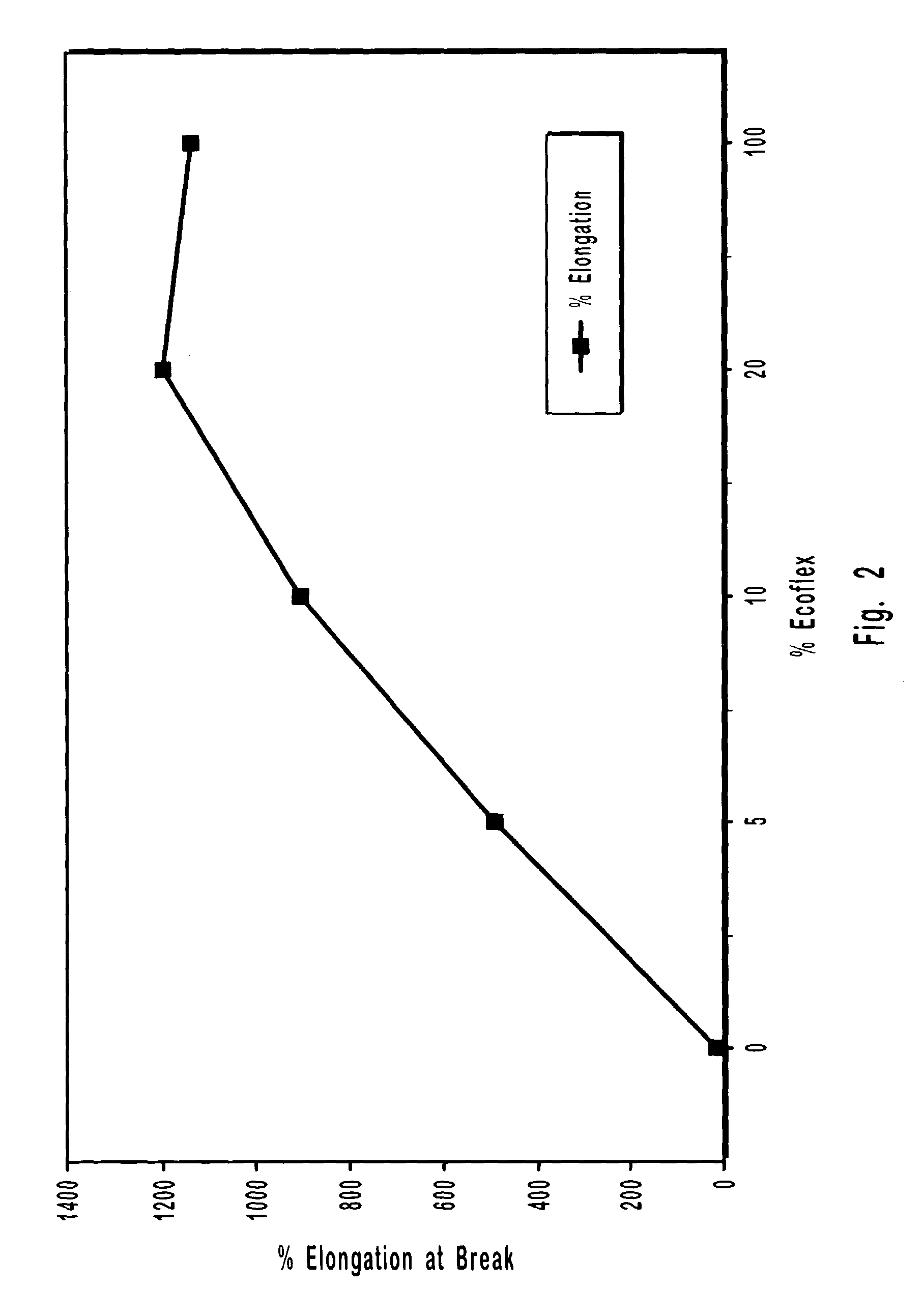

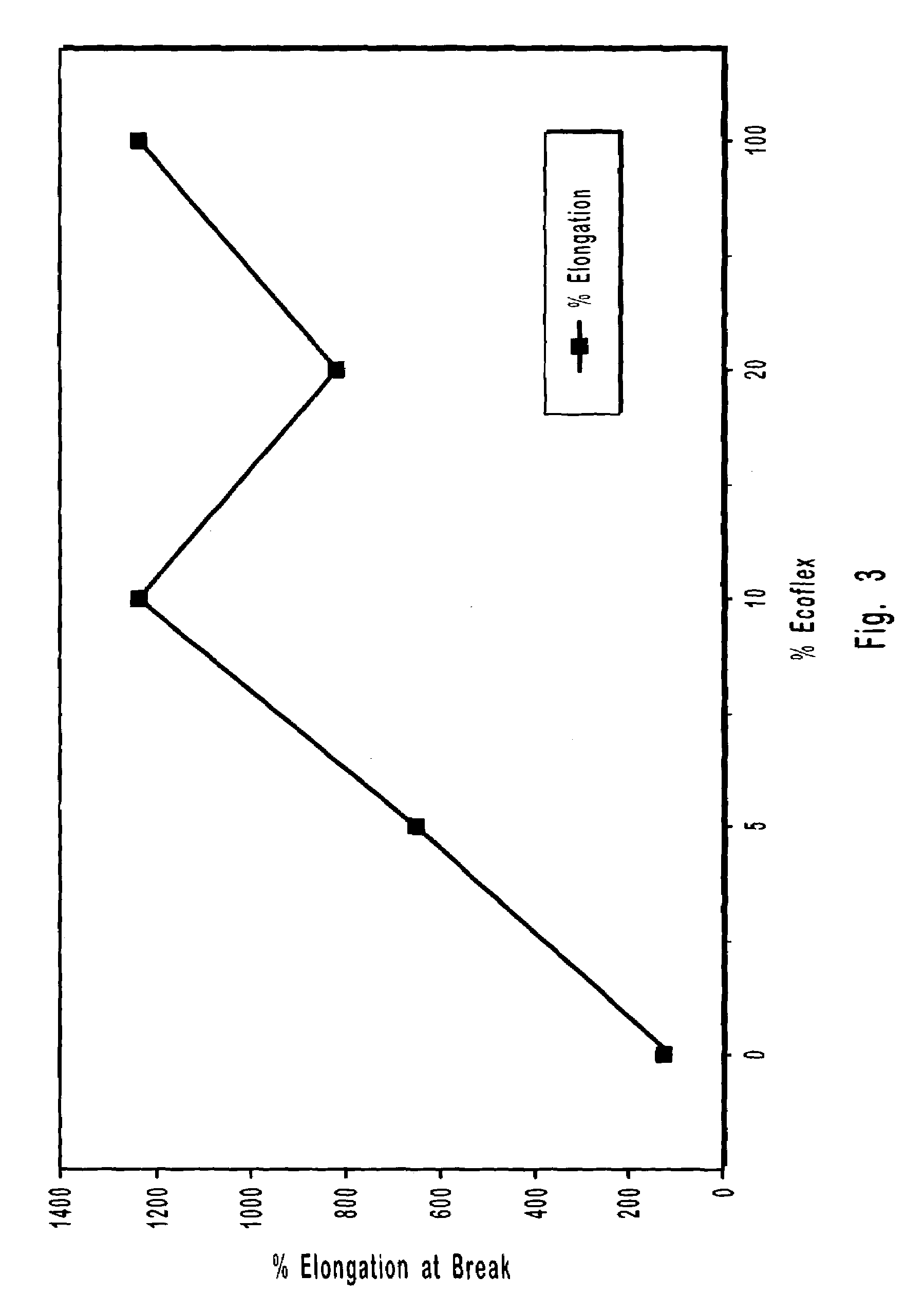

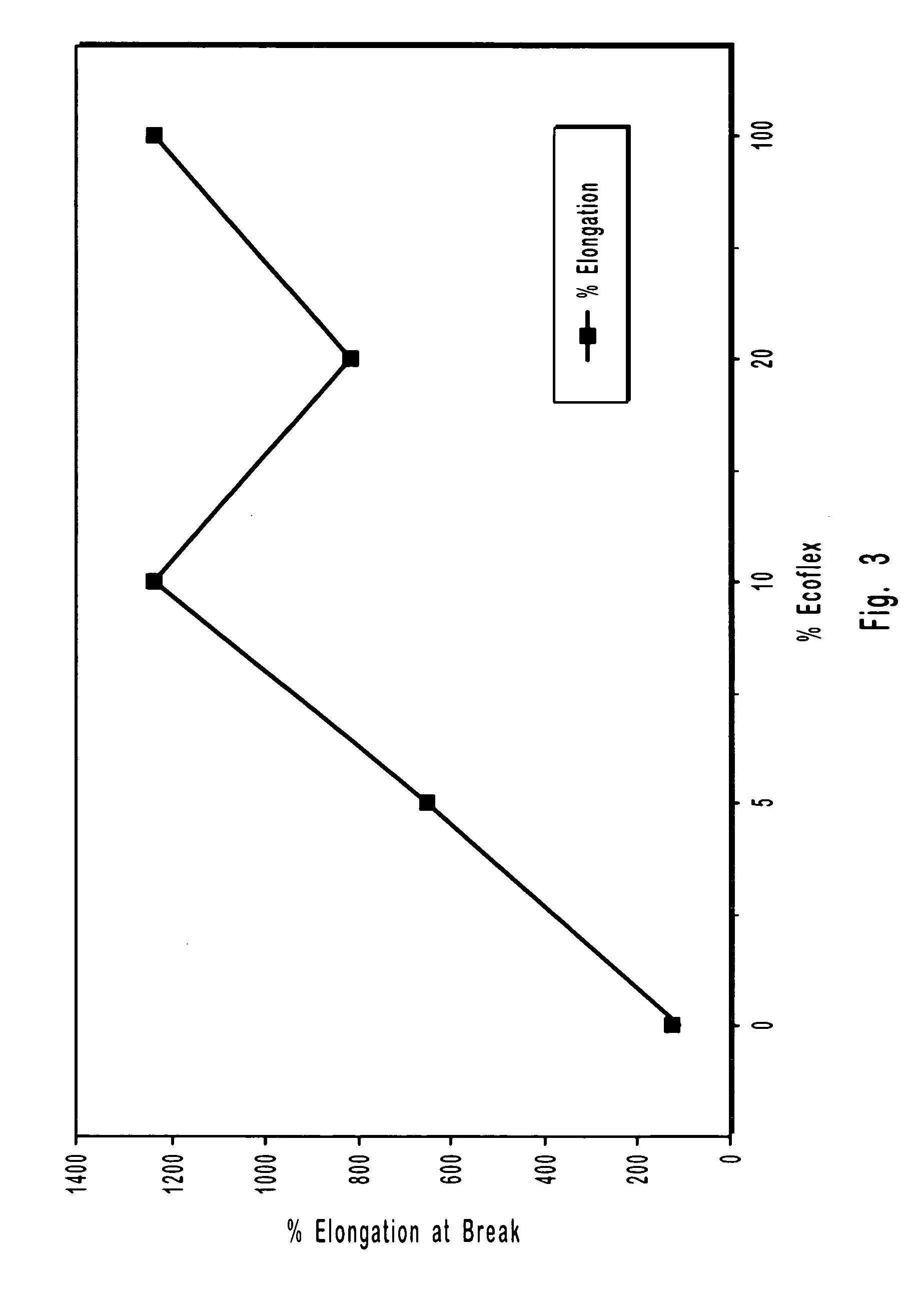

Fibrous sheets are coated or impregnated with a biodegradable composition to render the sheets more resistant to penetration by liquids. Biodegradable polymer blends suitable for use in coating or impregnating a fibrous sheet can be manufactured from at least one “hard” biodegradable polymer and at least one “soft” biodegradable polymer. “Hard” biopolymers typically have a glass transition temperature of at least about 10° C. “Soft” biodegradable polymers typically have a glass transition temperature less than about 0° C. Another useful biodegradable polymer composition includes one or more biodegradable polymers and sufficient inorganic filler so as to render the treated sheet microwaveable. The biodegradable polymer compositions are especially well-suited for coating or impregnating paper sheets, e.g., 12–15 lb / 3000 ft2 tissue paper to yield food wraps. Food wraps will typically be manufactured to have good “dead-fold” properties so as to remain in a wrapped position and not spring back to an “unwrapped” form.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

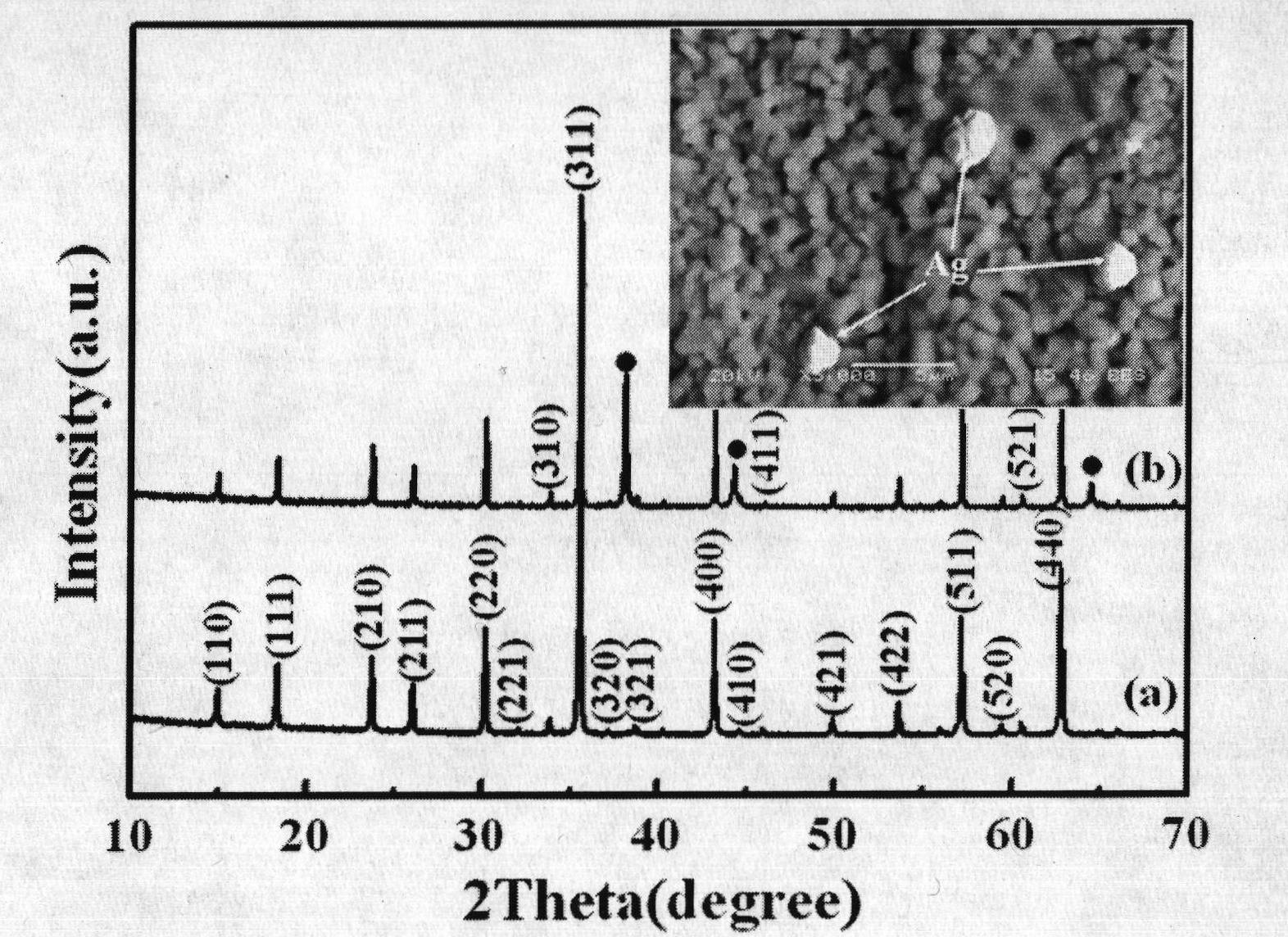

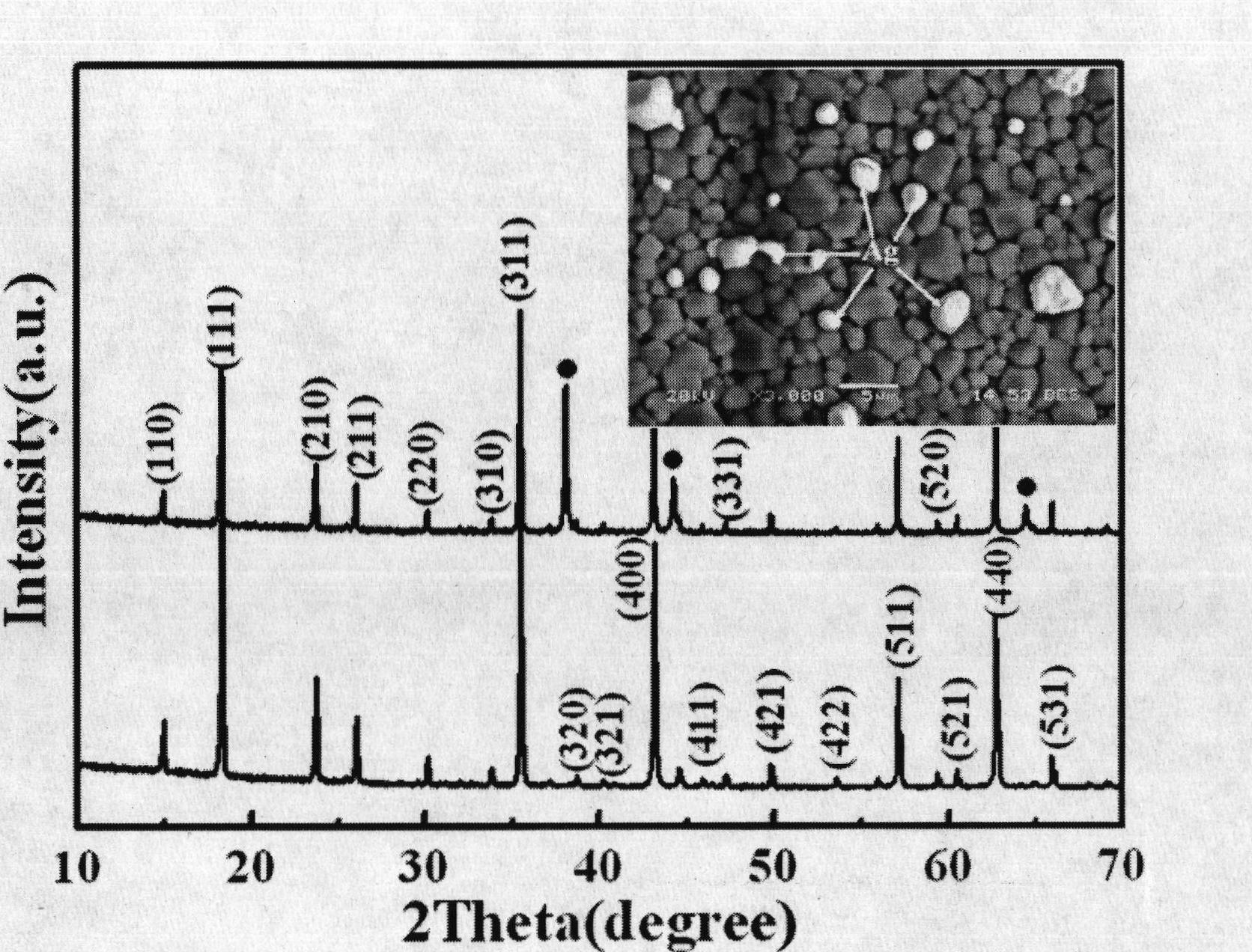

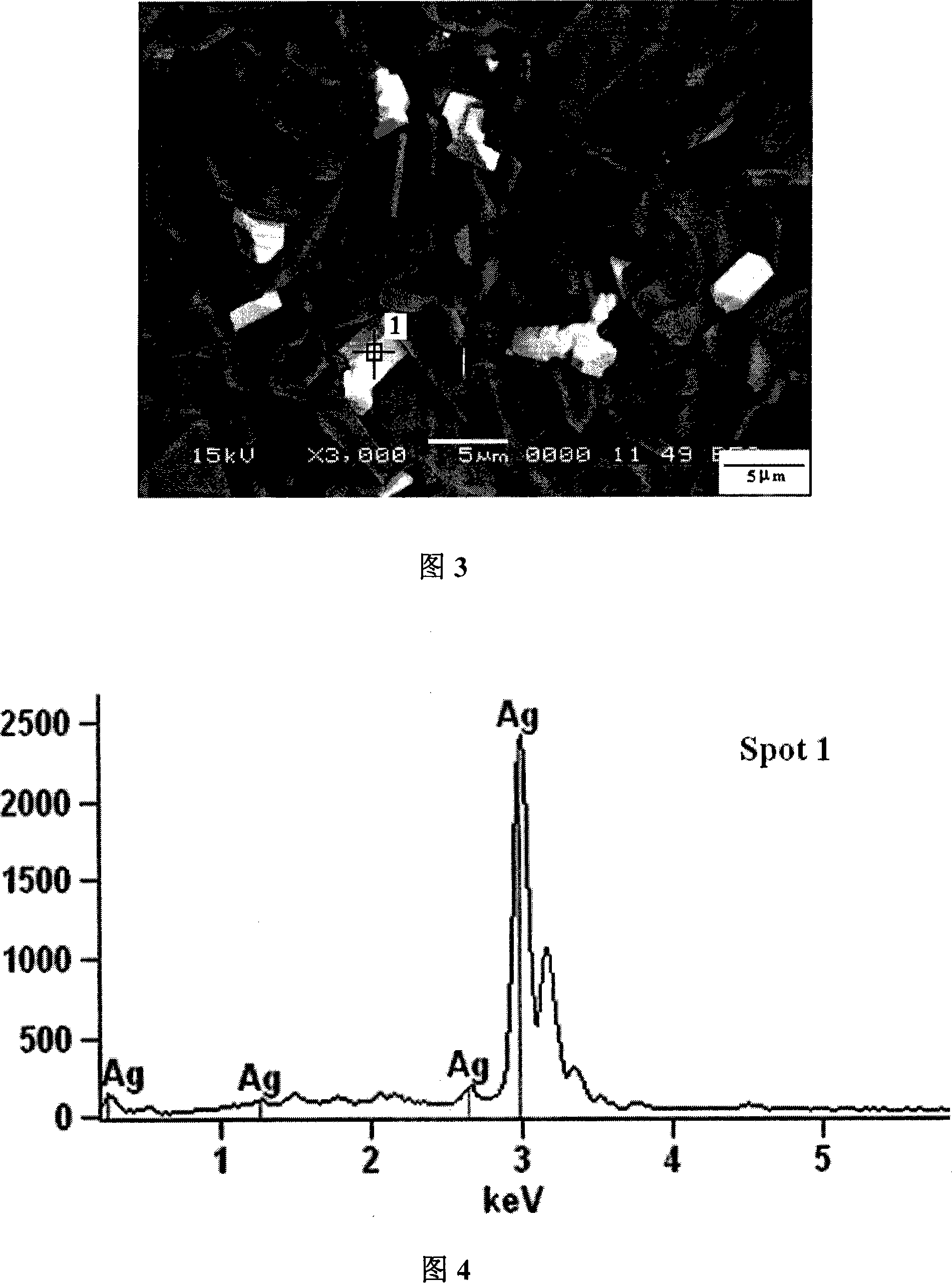

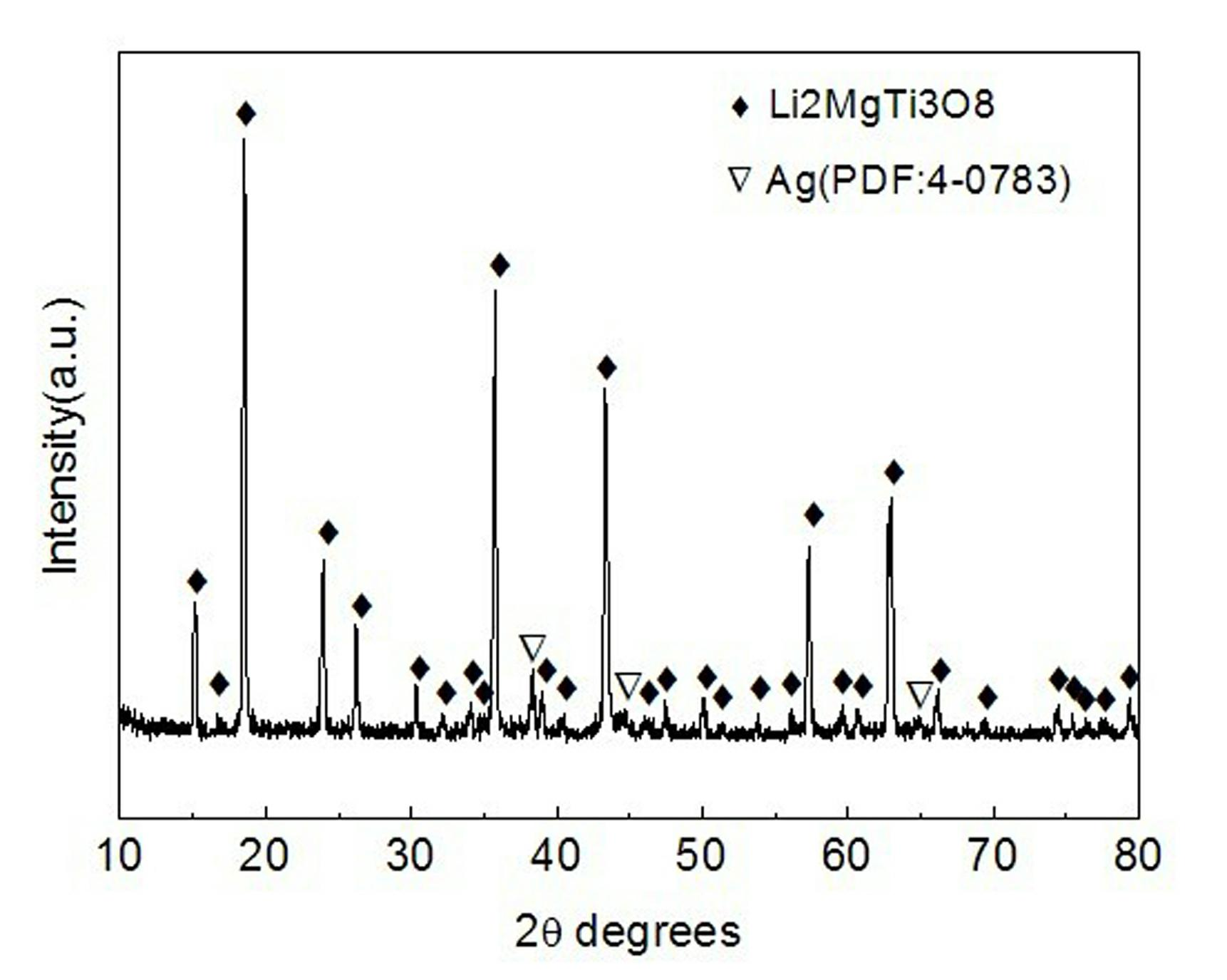

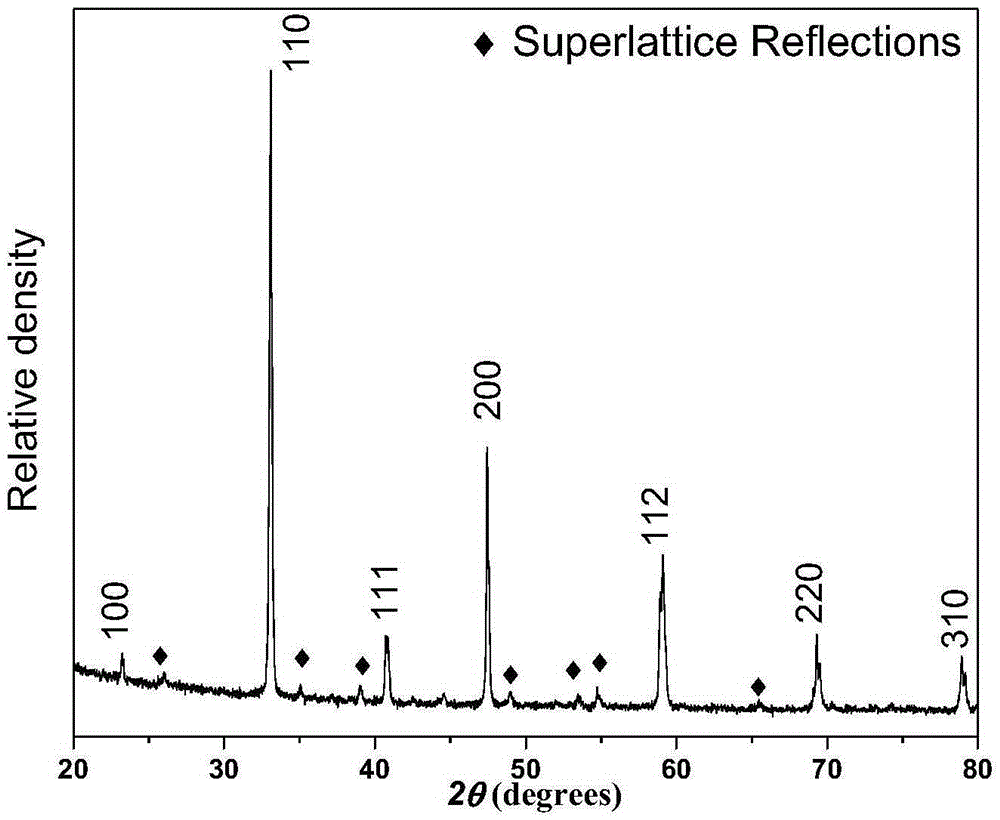

Microwave medium ceramic material with low-temperature sintering spinel structure and preparation method thereof

The invention discloses a microwave medium ceramic material with a low-temperature sintering spinel structure and a preparation method thereof. The microwave medium ceramic material with the low-temperature sintering spinel structure contains 97-100 percent by weight of Li2MTi3O8 and 0-3 percent by weight of material with low melting point, wherein M is Zn or Mg; and the material with the low melting point is B2O3 or BaCu(B2O5) or V2O5. The material can be obtained by a solid-phase reaction. The microwave medium ceramic with a low-temperature sintering spinel structure (LTCC) has low sintering temperature (about 900DEG C) and excellent microwave performance: large dielectric constant (epsilon r), high Q*f value and small tau f; the microwave medium ceramic material does not react with Ag and can be co-fired by using pure Ag as an electrode; in addition, the invention can greatly reduce the manufacturing cost of a device, can be used for manufacturing a low-temperature cofiring ceramic system (LTCC), a multilayer medium resonator, a microwave antenna, a filter and other microwave devices.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

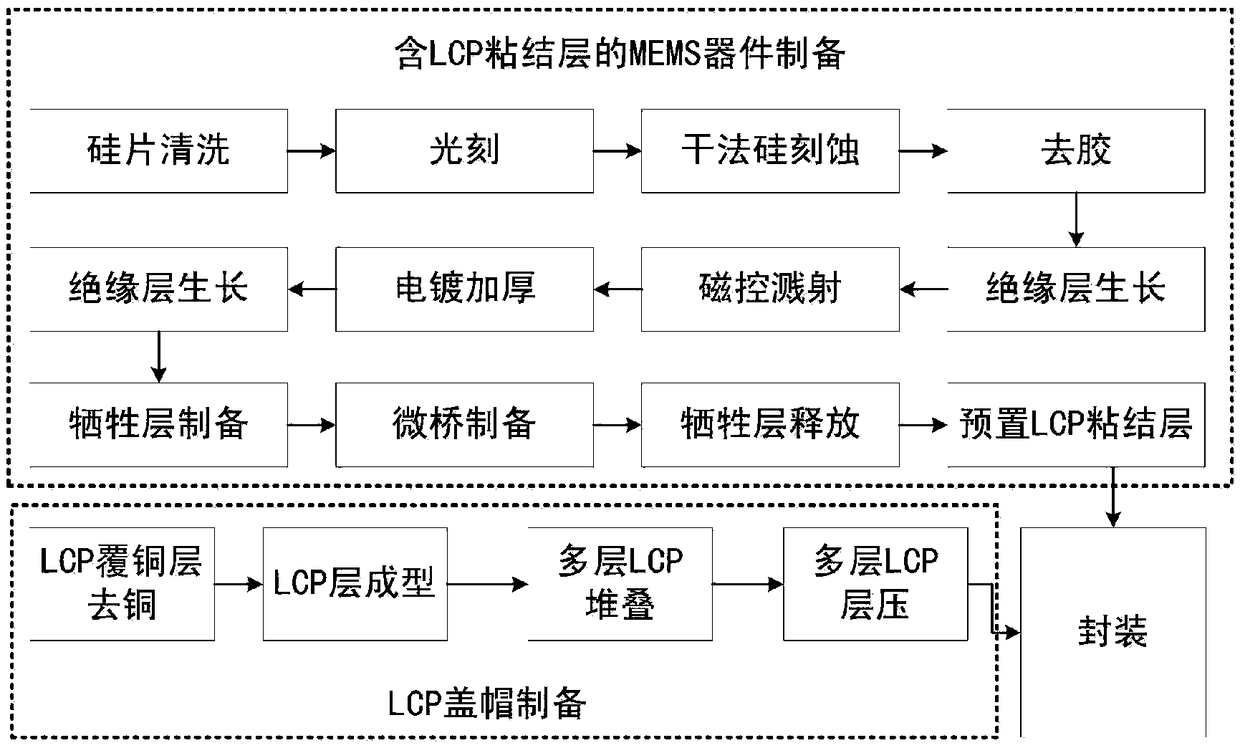

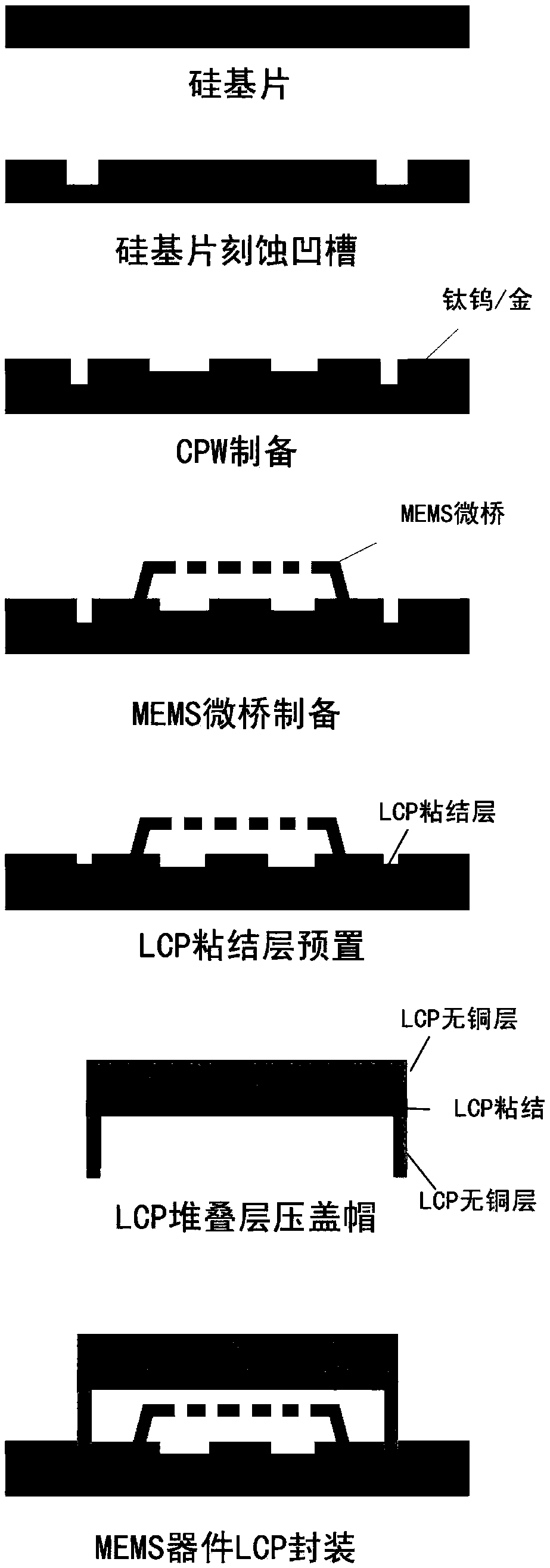

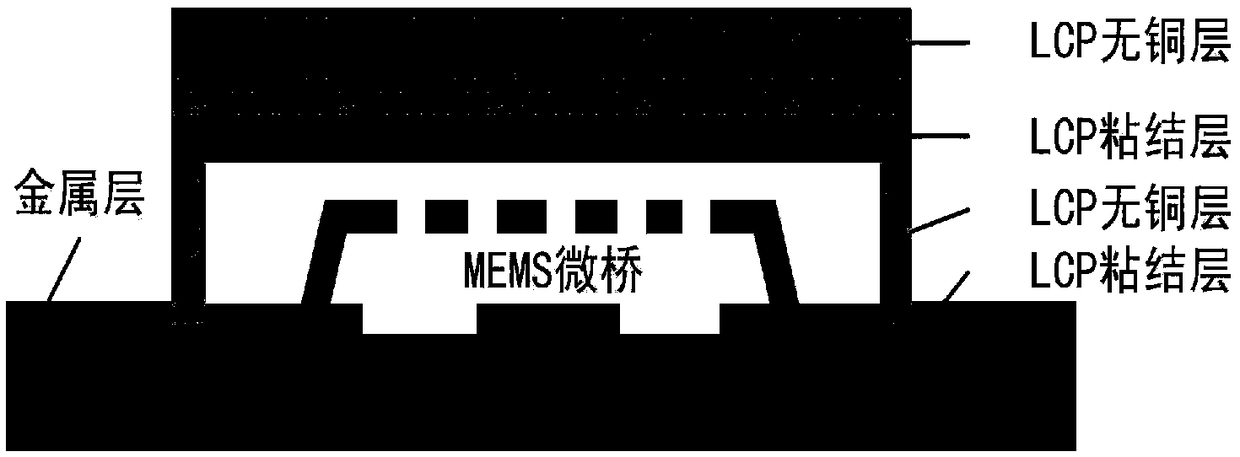

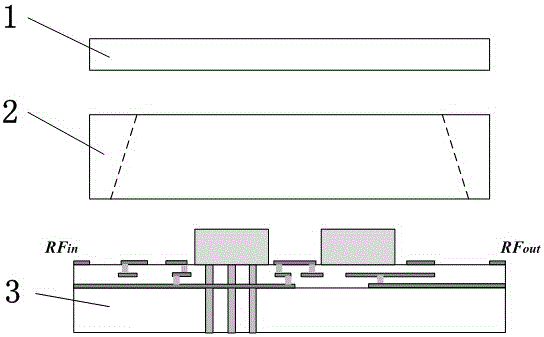

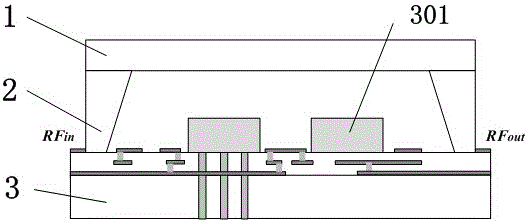

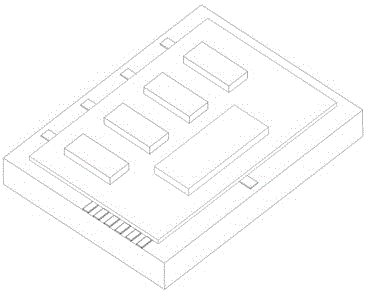

A packaging method for mems devices based on lcp multilayer stacking technology

ActiveCN107324273BImprove insulation performanceLow moisture absorptionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesRadar systemsMicrowave

The invention discloses a MEMS device packaging method based on LCP multilayer stacking technology, which is characterized in that the MEMS device is obtained by sputtering, photolithography, etching, electroplating and other processes on a double-sided polished silicon substrate, and at the same time Form silicon grooves that are easy to lead out and have accurate alignment; based on the LCP multilayer stacking technology, on the multilayer LCP substrate, the cap part of the device package is obtained through laser scribing, alignment, lamination and other processes; the device and the cap Package without assistance, high-precision integration, and obtain MEMS devices with low loss and good airtightness. The MEMS device of the invention has the advantages of low loss, high isolation and good airtightness. This method can better provide packaging protection for MEMS devices with movable parts, and is especially suitable for miniaturization applications of microwave, millimeter wave communication, radar and other systems / subsystems, and belongs to the realization of miniaturization, high performance microwave communication, radar systems / The key technology of the subsystem.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Molybdenum-based ultralow-temperature sintering microwave medium ceramic materials and preparation method thereof

The invention discloses molybdenum-based ultralow-temperature sintering microwave medium ceramic materials and a preparation method thereof. Based on a general structural formula of A4B3O12, a series of ceramic materials, which can be sintered at a temperature lower than 7,000 DEG C and have excellent microwave dielectrical properties ( a dielectric constant of 8.5 to 11.1 and a quality factor Qfof between 36,000 and 108,000GHz), can be obtained by using low-valence cation (such as Li<+>, Zn<2+>, Ca<2+>, Cu<2+>, Mg<2+>, Al<3+>, In<3+>, Cr<3+> and Ga<3+>) composite at a position A and a high-valence cation Mo<6+> at a position B and by using the conventional solid-phase reaction sintering method. The concrete structural expression of the ceramic material comprises Li2M<2+>2(MoO4)3(M<2+> may be Zn<2+>, Ca<2+>, Cu<2+> and Mg<2+>) and Li3M<3+>(MoO4)3(M<3+> may be Al<3+>, In<3+>, Cr<3+> and Ga<3+>).

Owner:XI AN JIAOTONG UNIV

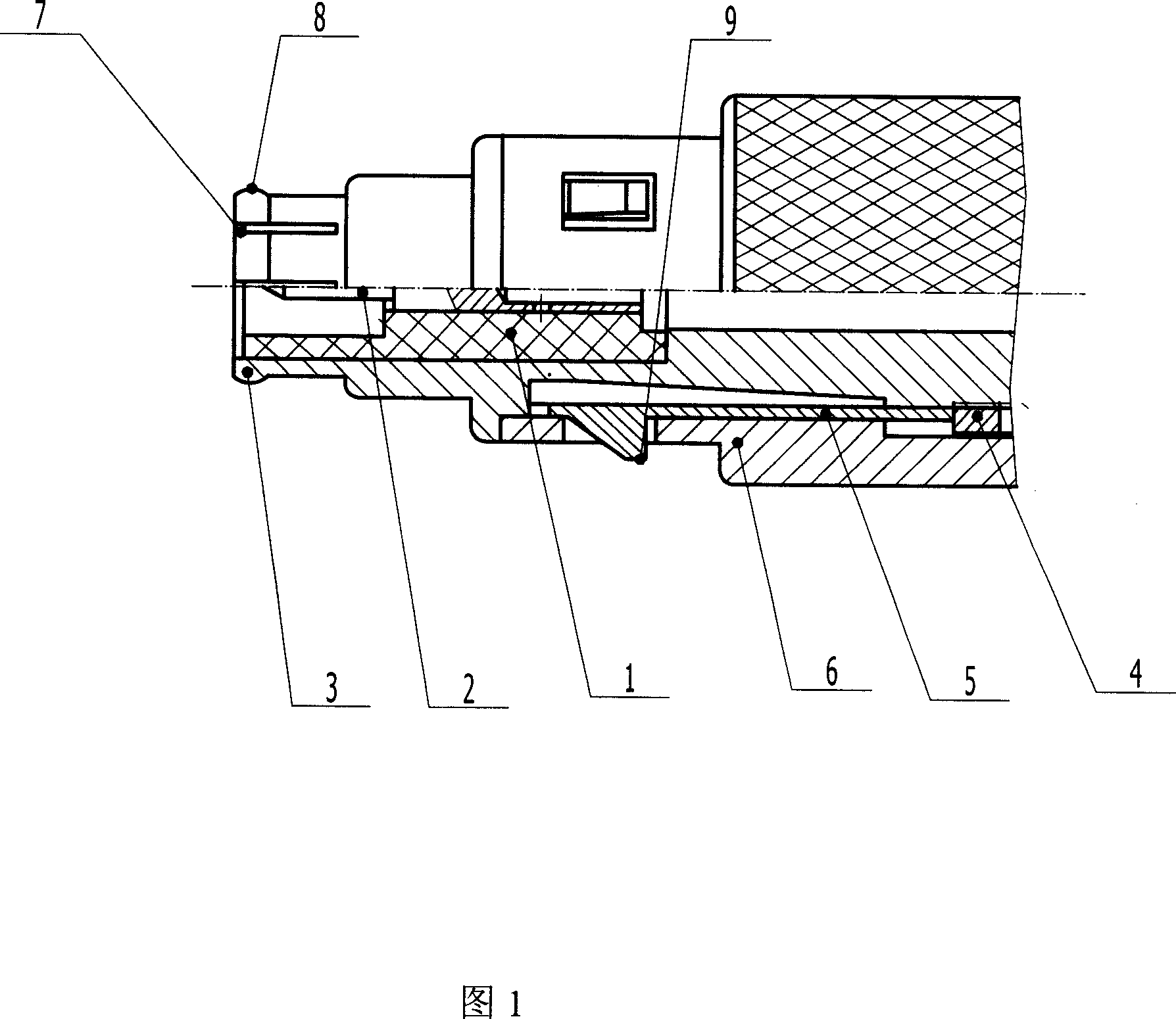

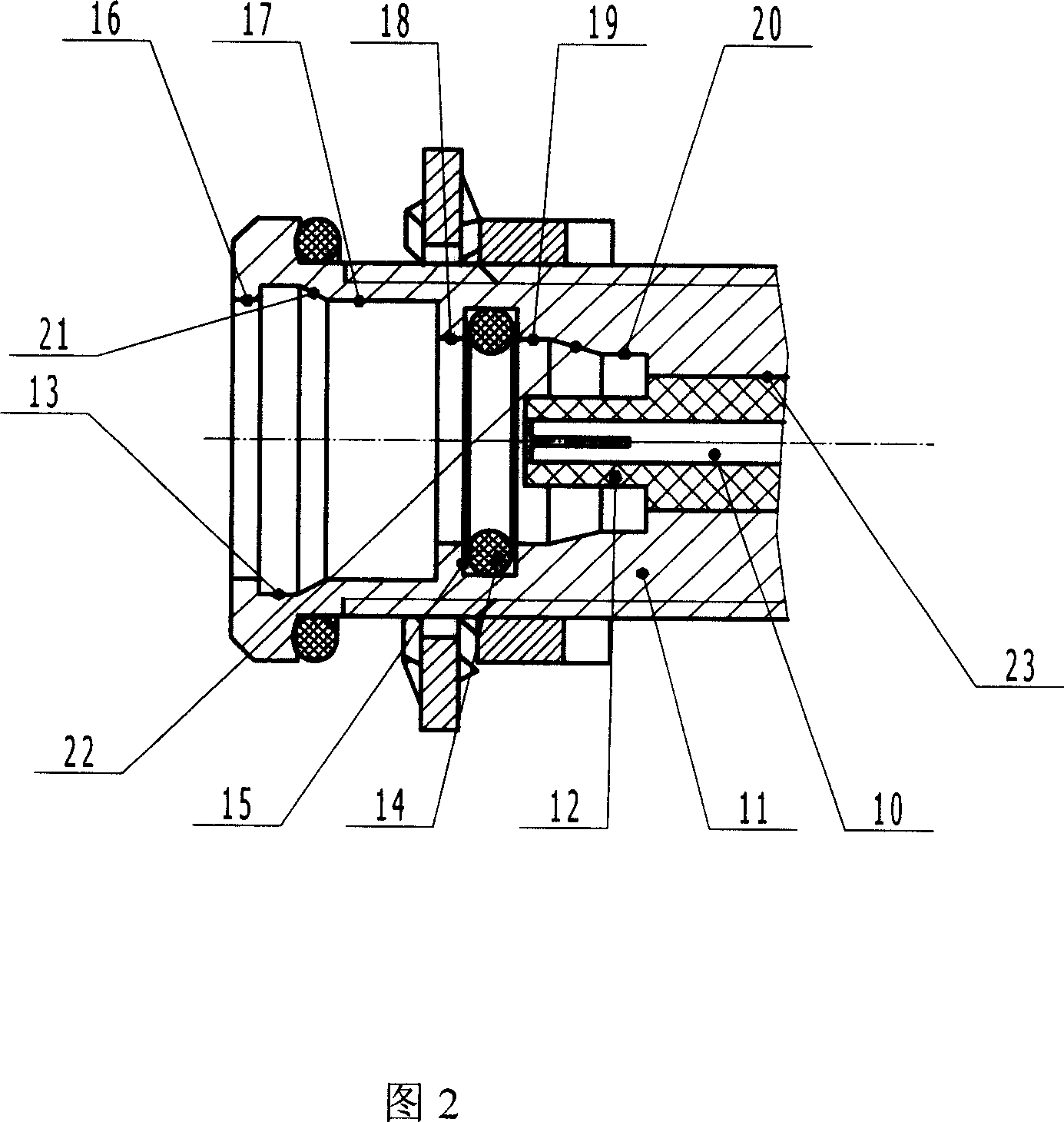

Seal radiofrequency coaxial connector with self locking mechanism

InactiveCN101005180ARealize the sealing functionQuick plugCoupling device detailsTwo-part coupling devicesLocking mechanismSelf locking

Six slots along axial line are made on head of plug body. The head portion is an arc shaped male tab. Claws are located outside the body case, and outer sheath is located outside the claws. Nut is screwed on postmedian portion of the body case. Three claws with barbs are placed between inner male tab of the body case and the nut in order to restrict axial drunkenness of claws. Radial clearance is kept between the outer sheath and the claws. There are five straight holes with different diameters and two cone shaped bores inside head of socket shell. The holes are matched to diameters of plug. The cone-shaped bores are guide holes. Outline of insulator is in step shape, where small end is extended out of the straight hole, and large end is stopped by the inner hole of shell. Full escaping lock connection between socket and plug is adopted in the invention so as to guarantee quick plugging in or out, and provide firm bond between socket and plug under execrable mechanical condition.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

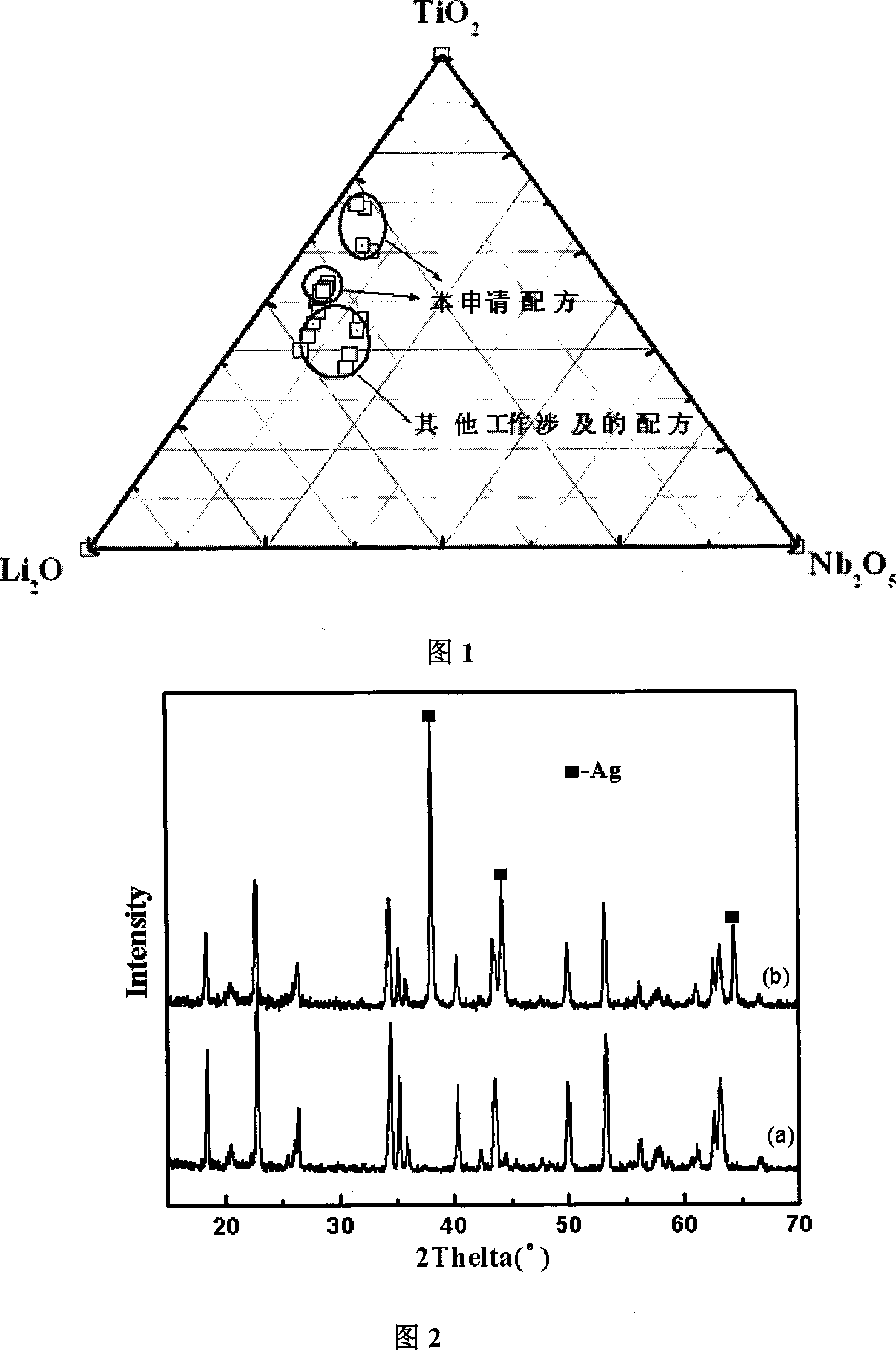

Low-temperature sintered LTCC microwave dielectric ceramics material and preparation method thereof

InactiveCN101224977AImprove performanceInherently low sintering temperatureDielectric ceramicsCo-fired ceramic

The invention discloses a low temperature co-fired ceramic LTCC microwave dielectric ceramic MWCD material, which is prepared by Li2CO3, Nb2O5 and TiO2 by the moral ratio that Li2CO5:Nb2O5:TiO2 = x:1:y, wherein, x is more than 5.5 and less than or equal to 6, y is more than 7 and is less than or equal to 7.5; the expression of structure for the made up modular is Li1+m-nNb1-m-3nTim+4nO3, wherein m is more than or equal to 0.1 and is less than or equal to 0.15, n is more than or equal to 0.2 and less than or equal to 0.25. The LTCC MWCD prepared by the invention has low sintering temperature (approx. 1,100 DEG C) and excellent microwave performance: the dielectric constant (Epsilon r) is that x is more than 32 and less than or equal to 52, Q multiplied by f value is high and Tf is small; the sintering temperature can be decreased to 900 DEG C and the microwave dielectric property can be maintained for excellence without any reaction to a Ag by adding a plurality of low melting point oxides. The pure silver can be taken as a electrode for sintering which can greatly reduce manufacturing cost for the components and applied in manufacturing of the microwave components such as a low temperature co-fired ceramic LTCC system, a multi-layer media resonator, a microwave antenna and a wave filter etc.

Owner:XI AN JIAOTONG UNIV

Bismuth-based molybdenum-based microwave dielectric ceramic material sintered at ultra low temperature and manufacture of the same

InactiveCN101318815ALower sintering temperatureLow dielectric lossCeramicsPermittivityStructural formula

The invention discloses a bismuthino molybdenum ultralow temperature sintering microwave medium ceramic material. A phase map of Bi2O3-MoO3 binary system is taken as a beginning, a single-phase compound is taken as a basis, and a series of microwave medium material which has good microwave dielectric property (the permittivity is between 10 and 45, and the Qf is between 4,000 and 25,000GHz) and can be sintered into ceramics at a low temperature of between 550 and 900 DEG C is prepared through the methods of adjusting the proportion of the binary system and substitution for equivalent and unequivalent ions. The structural formula is (1-x)[(Bi1-yAy)2O3]-x[(Mo1-zBz)O3], wherein, A is equal to La<3+>, Nd<3+>, and Sm<3+>, B is equal to W<6+>, Nb<5+>, Ta<5+>, Sb<5+>, Ti<4+>, Zr<4+>, and Sn<4+>, x is more than or equal to 0.01 and less than or equal to 1, y is more than or equal to 0 and less than or equal to 0.20, and z is more than or equal to 0 and less than or equal to 0.20.

Owner:XI AN JIAOTONG UNIV

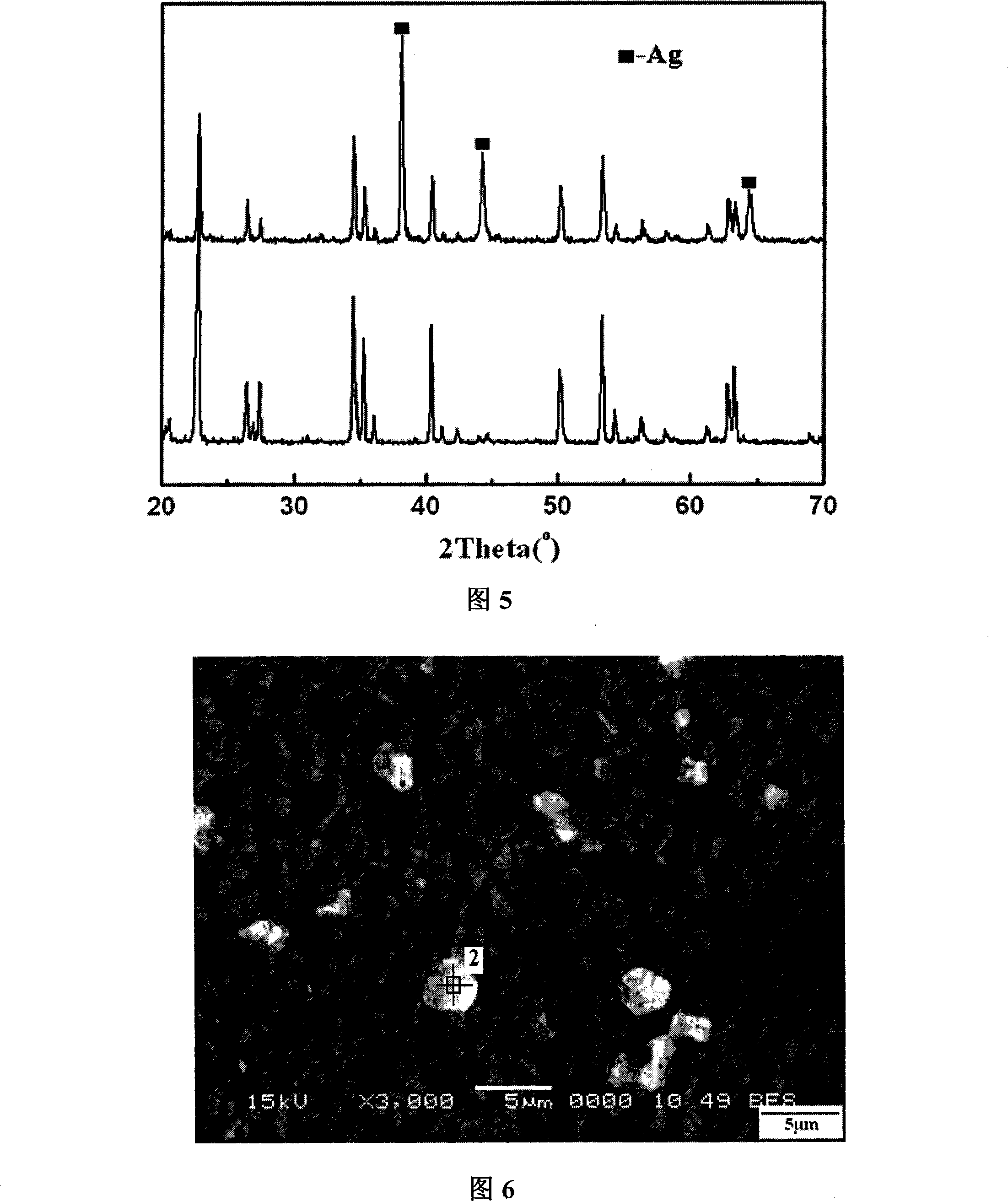

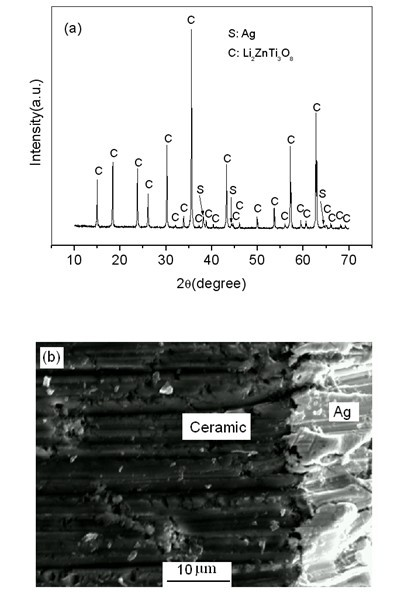

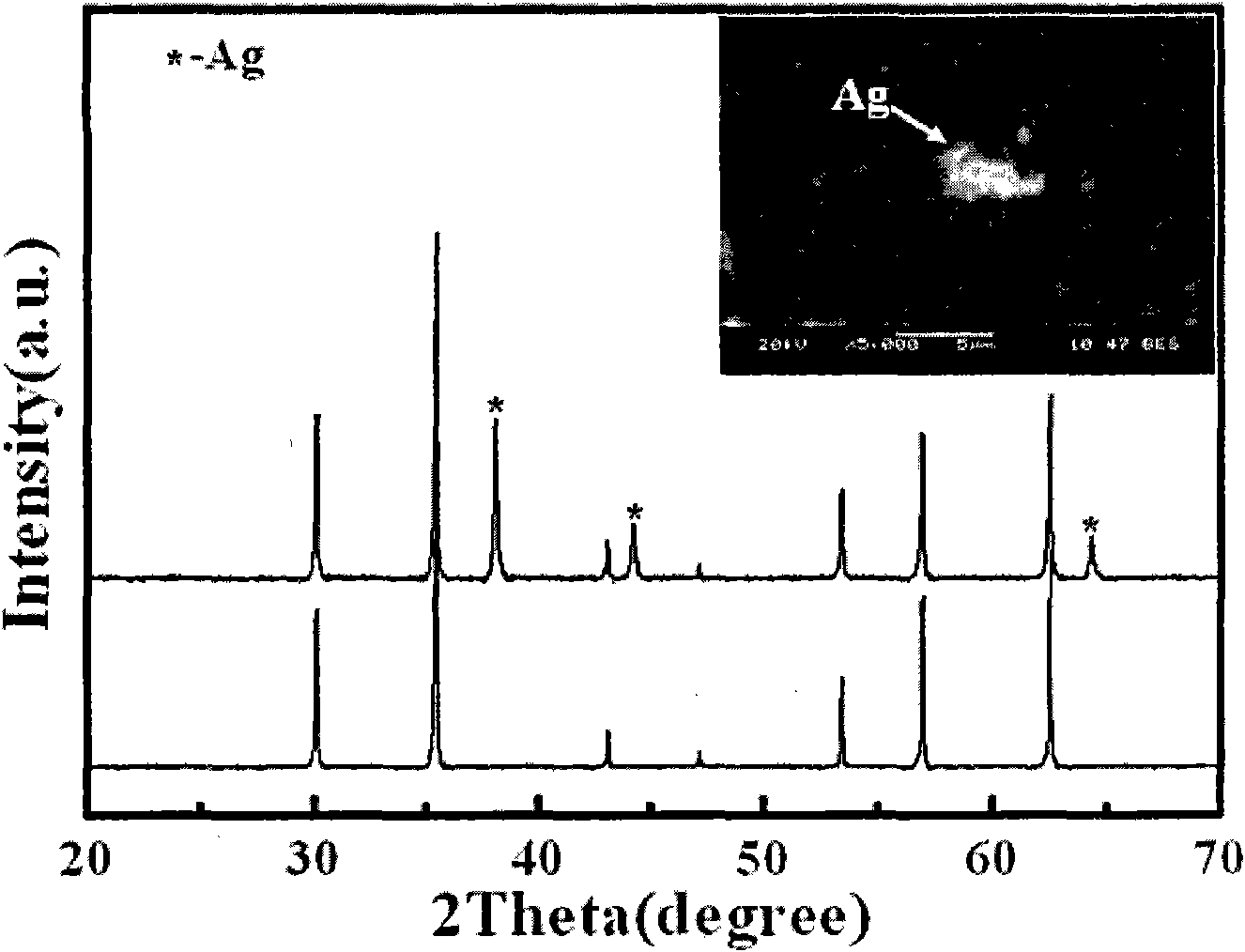

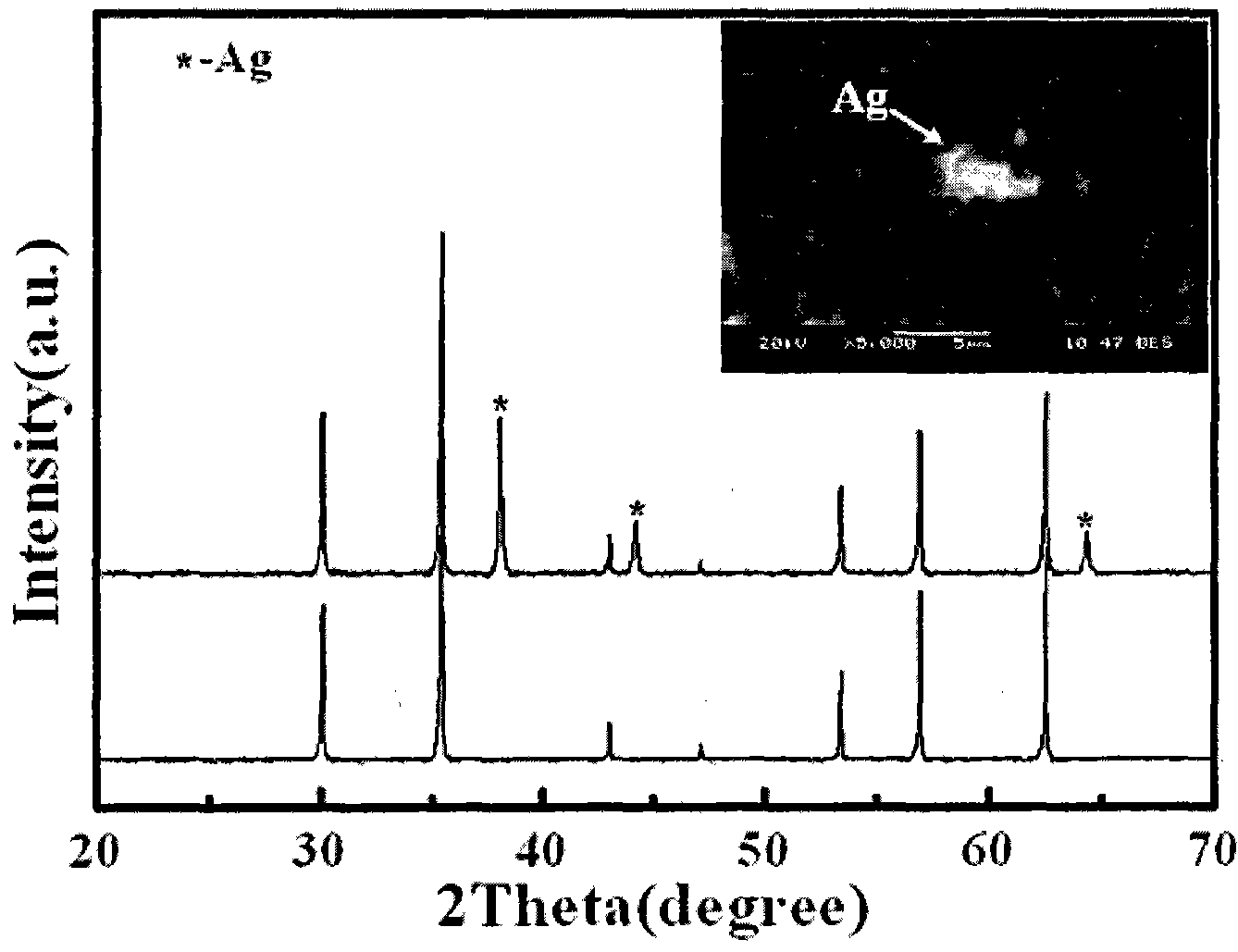

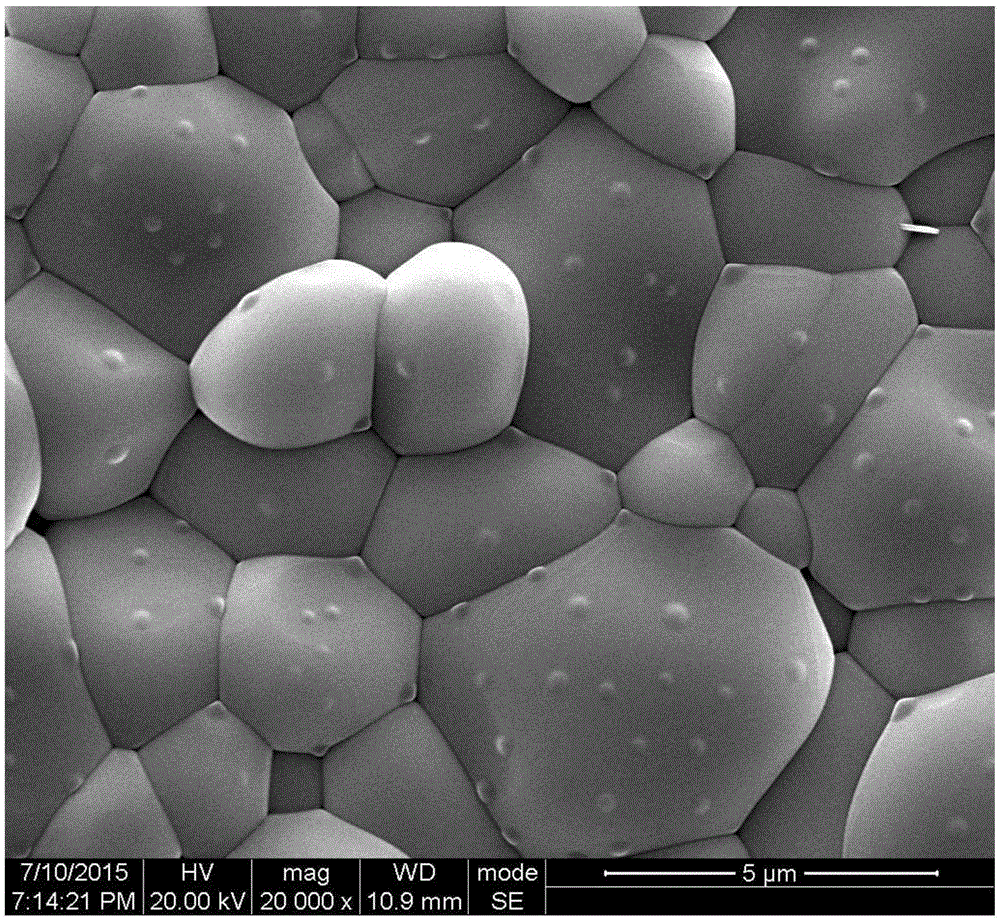

Low temperature co-fired microwave dielectric ceramic material and preparation method thereof

InactiveCN102381874ALower sintering temperatureThe sintering temperature drops toCeramicsDielectric resonatorSolid state reaction method

The invention discloses a low temperature co-fired microwave dielectric ceramic material and a preparation method thereof. The ceramic material comprises a main powder material Li2ZnTi3O8, an auxiliary component TiO2 and low-melting-point LZB (Li2O-ZnO-BiO2) or LBS (Li2O-B2O3-SiO2) glass powder. The preparation method comprises the following steps of: adding TiO2 and the glass powder into the Li2ZnTi3O8 powder in a powder form; and then evenly mixing in a ball mill, drying, pelleting and sintering so as to obtain the ceramic material. In the invention, based on the Li2ZnTi3O8 powder as a reference, batching is carried out according to the proportions that the mass of the glass powder is 0.5-3wt% of that of Li2ZnTi3O8 and the mass of the TiO2 powder is 0-5wt% of that of Li2ZnTi3O8; and thematerial of the invention can be obtained by a traditional solid phase reaction method. The low temperature co-fired microwave dielectric ceramic material prepared by the method of the invention has low sintering temperature (about 875 DEG C) and good microwave dielectric property, and can be well co-fired with a Ag electrode; pure silver with high electricity conductivity and low cost is used asan electrode material, thus the manufacturing cost of a device can be greatly reduced; and the low temperature co-fired microwave dielectric ceramic material can be used for a low temperature co-fired ceramic (LTCC) system and manufacturing of microwave devices such as multilayer dielectric resonators, microwave antennas, filters and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

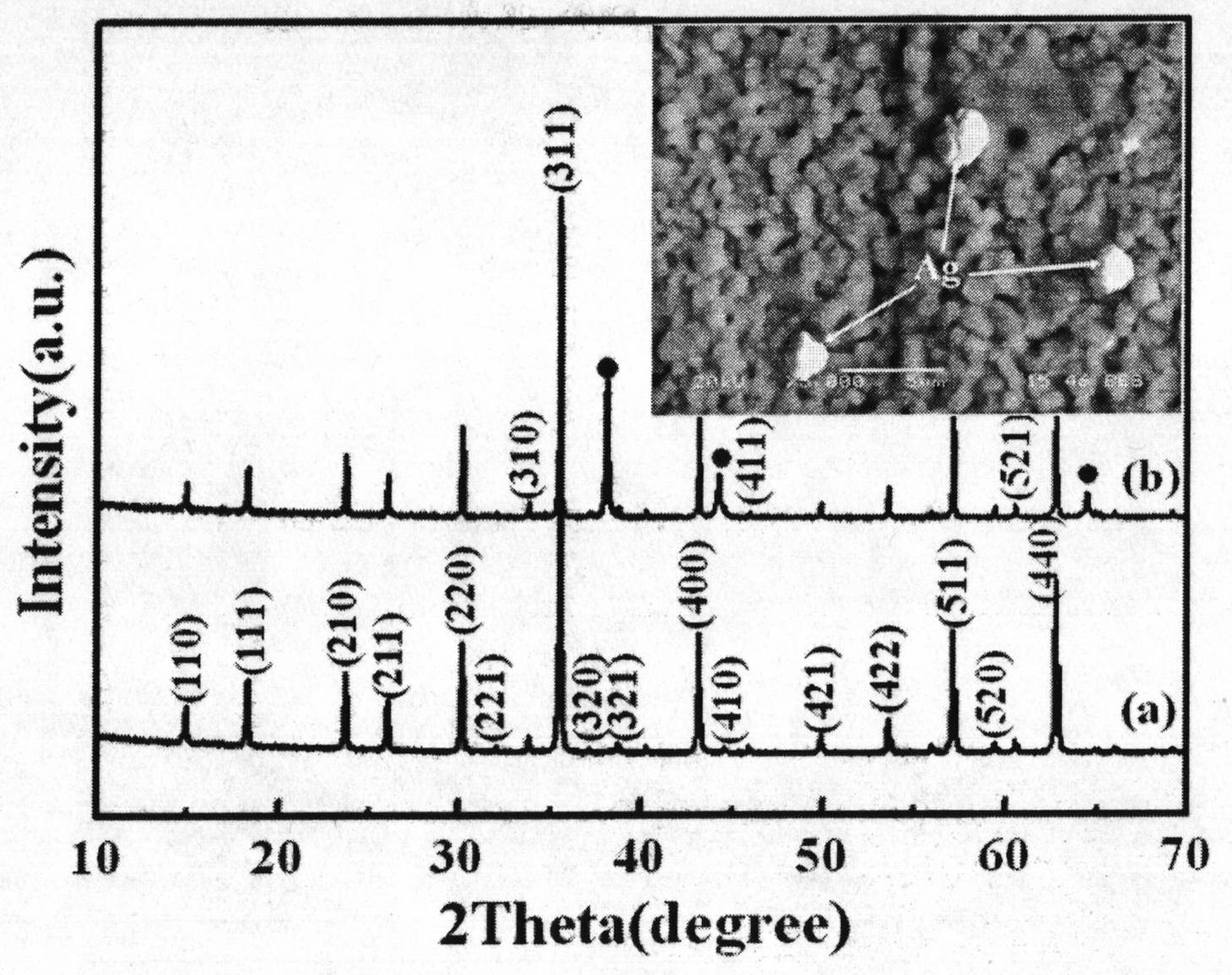

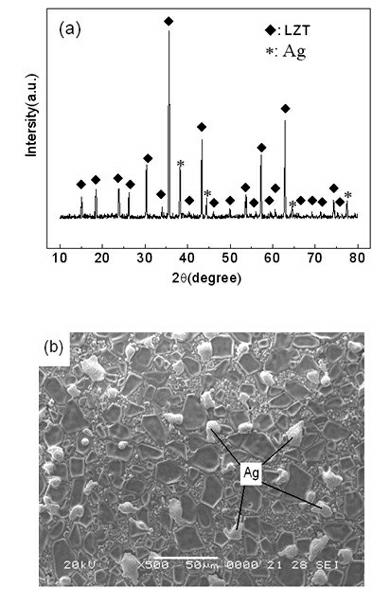

Li2Zn3Ti4O12 microwave dielectric ceramic material and low temperature sintering method thereof

ActiveCN101913859AGood microwave performanceSimple chemical composition and preparation processCo-fired ceramicMicrowave

The invention discloses a Li2Zn3Ti4O12 microwave dielectric ceramic material and a low temperature sintering method thereof. The Li2Zn3Ti4O12 microwave dielectric ceramic material comprises 95% to 99.75% of Li2Zn3Ti4O12 and 0.25% to 5% of low melting point material by weight percent, wherein the low melting point material is one of H3BO3, BaCu(B2O5), V2O5 and Bi2O3. The method comprises the stepsof: firstly pre-calcining to synthesize a main powder body according to a molar ratio of Li2CO3: ZnO: TiO2=1:3:4; adding BaCu(B2O5), H3BO3, Bi2O3 or V2O5 to the main powder body; and granulating, tabletting and sintering. The prepared microwave dielectric ceramic material has low sintering temperature (about 900 DEG C), excellent microwave performance, large microwave constant (epsilon r), high Q*f value and small tau f, does not react with silver (Ag), and can be co-fired with pure silver as an electrode, largely reduce the manufacturing cost of a device, and be used for manufacturing microwave devices, such as low temperature co-fired ceramic (LTCC) system, multilayer dielectric resonators, microwave antennae, filters and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Potassium-based vanadium-based low-temperature sintered microwave dielectric ceramic material and preparation method thereof

InactiveCN102249664AImprove performanceLow and low frequency dielectric lossElectricityDielectric loss

The invention discloses potassium-based vanadium-based low-temperature sintered microwave dielectric ceramic materials and a preparation method thereof. Based on the structure of typical scheelite of ABO4, low-valent K+ ions and Bi3+ are selected to occupy an A site jointly, and high-valent Mo6+ and V5+ composite cations are selected to occupy a B site; a series of ceramic materials are obtained by a solid state reaction sintering method, wherein the ceramic materials can be sintered in a temperature range below 800 DEG C, have a high dielectric constant (34<=epsilon r<=80), an adjustable temperature coefficient of resonant frequency (-260 ppm / DEG C<=TCF<=+116 ppm / DEG C), and a low microwave dielectric loss (high quality factor Qf value, 4,000 GHz<=Qf<=9,700 GHz) in microwave frequency band. The specific structure expression is (K0.5xBi1-0.5x)(MoxV1-x)O4, wherein 0.05<=x<=0.99.

Owner:XIAN TECH UNIV

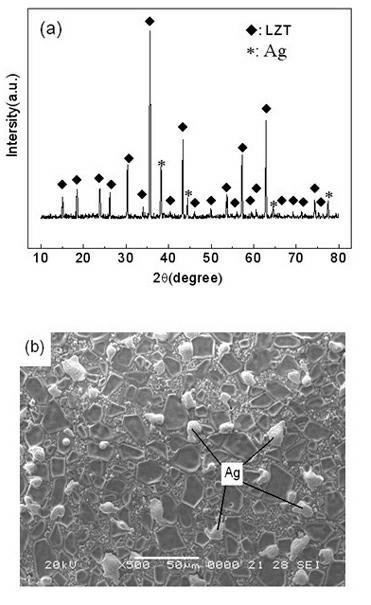

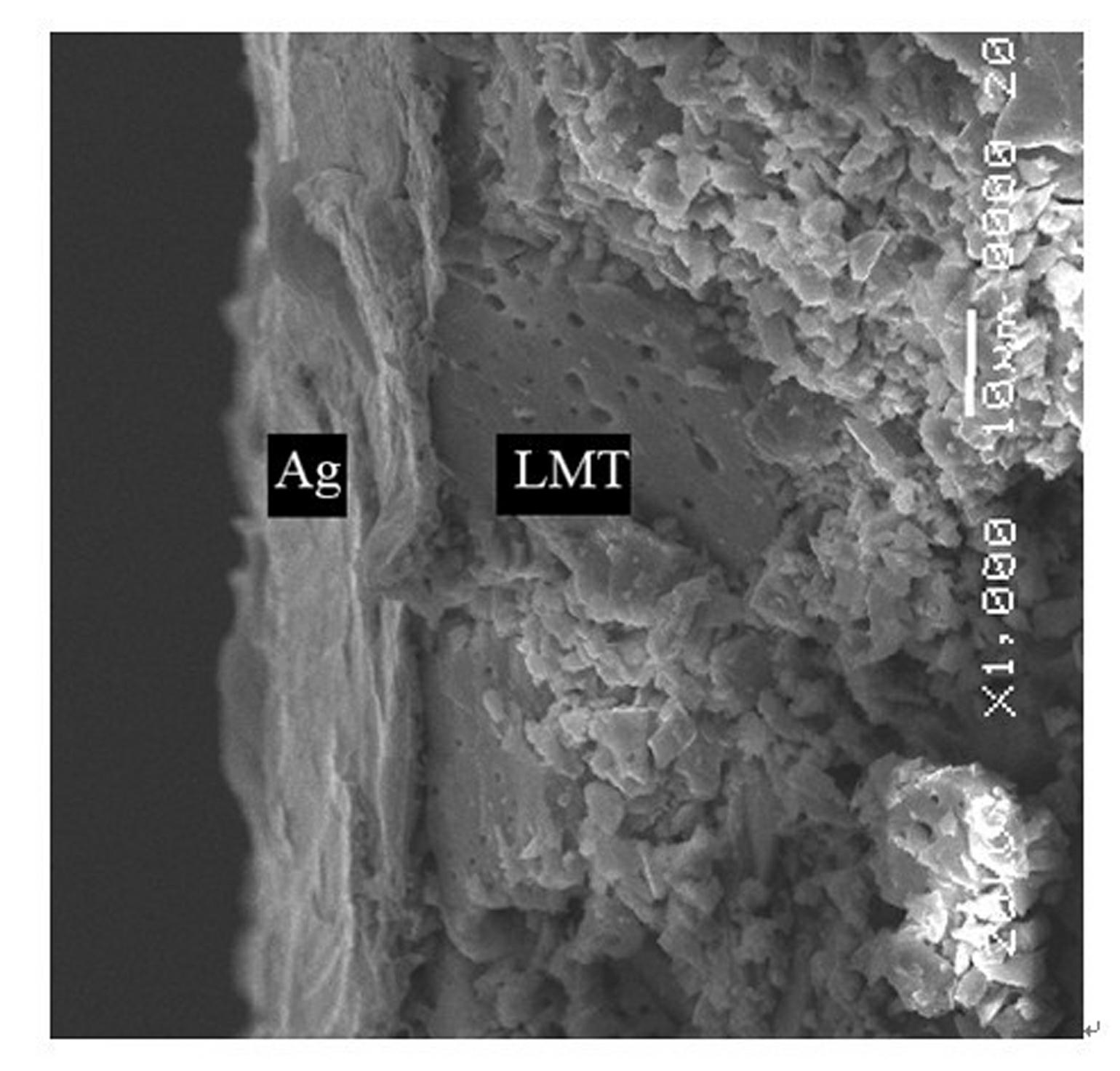

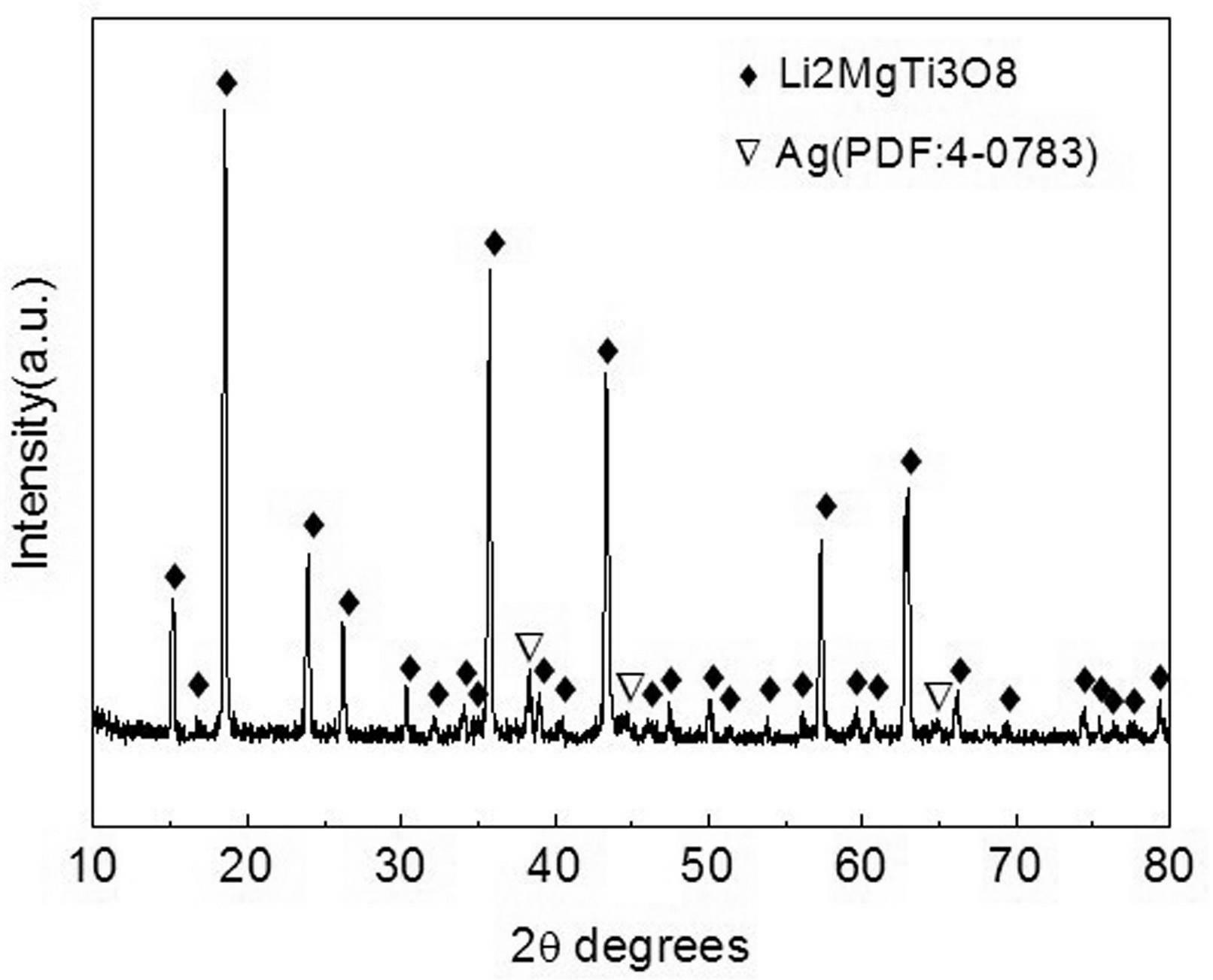

Low-temperature co-fired Li2MgTi3O8 microwave dielectric ceramic material and preparation method thereof

InactiveCN102674829ALower sintering temperatureImprove Microwave PerformanceCeramicsDielectric resonatorAg electrode

The invention discloses a low-temperature co-fired Li2MgTi3O8 microwave dielectric ceramic material and a preparation method thereof. The material comprises a main powder material Li2MgTi3O8 and low-melting-point Li2O-MgO-B2O3 (LMB) glass powder. The glass powder is added into Li2MgTi3O8 powder in the form of powder and then the mixture is evenly mixed in a ball mill and is dried, granulated and fired to obtain the material. The proportions of components for preparing the material are determined by taking the Li2MgTi3O8 powder as a reference, wherein the weight of the glass powder accounts for 0.5-3 percent of the weight of Li2MgTi3O8 powder. The material can be obtained through the traditional solid-phase reaction synthesis method. The low-temperature co-fired microwave dielectric ceramic material prepared by adopting the preparation method has the advantages that the firing temperature is low (approximate 875 DEG C), the microwave dielectric performance is excellent, the dielectric constant (epsilon r) is large, the quality factor (Q-f) is high, the resonant frequency-temperature factor (tf) is close to zero, the effect of co-firing with an Ag electrode is good, high-conductivity low-cost pure silver can be used as an electrode material, the manufacturing cost of devices can be greatly reduced, and the low-temperature co-fired microwave dielectric ceramic material can be used for manufacturing microwave devices such as low-temperature co-fired ceramic (LTCC) systems, multilayer dielectric resonators, microwave antennas and filters.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Temperature-stable low-cost microwave dielectric ceramic material and preparation method thereof

InactiveCN102417350ALower sintering temperatureImprove Microwave PerformanceDielectricChemical composition

The invention discloses a temperature-stable low-cost microwave dielectric ceramic material and a preparation method thereof. The microwave dielectric ceramic material has the following chemical composition formula of (1-x)Li2ZnTi3O8+xM, wherein x is more than or equal to 0.025 and less than or equal to 0.1, and M is TiO2 or CaTiO3. The preparation method comprises the following steps of: taking LiCO3, ZnO and TiO2 of which the purity is more than or equal to 99% as the main raw material at the following molar ratio: 1 mole of Li2CO3, 1 mole of ZnO and 3 moles of TiO2; pre-calcining to synthesize the main powder body of Li2ZnTi3O8; and then, adding TiO2 or CaTiO3 in the main powder body to regulate the temperature coefficient of resonance frequency of the main powder body so as to obtain the microwave dielectric material of which the dielectric constant, the Q*f value and the temperature coefficient of resonance frequency approach to zero. The sintering temperature of the microwave dielectric ceramic prepared with the preparation method is lower than 1100DEG C, the dielectric constant is 26-31, the Q*f value is 40000-70000GHz, and the temperature coefficient (tau f) of resonance frequency is small. The temperature-stable low-cost microwave dielectric ceramic material can be used for manufacturing microwave devices, such as resonators, antennae, filters and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

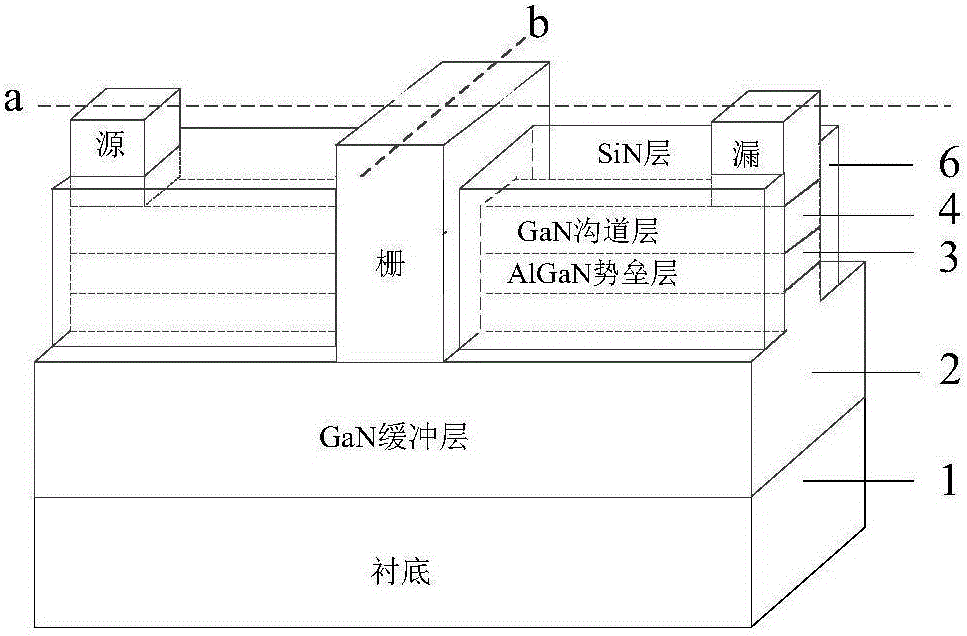

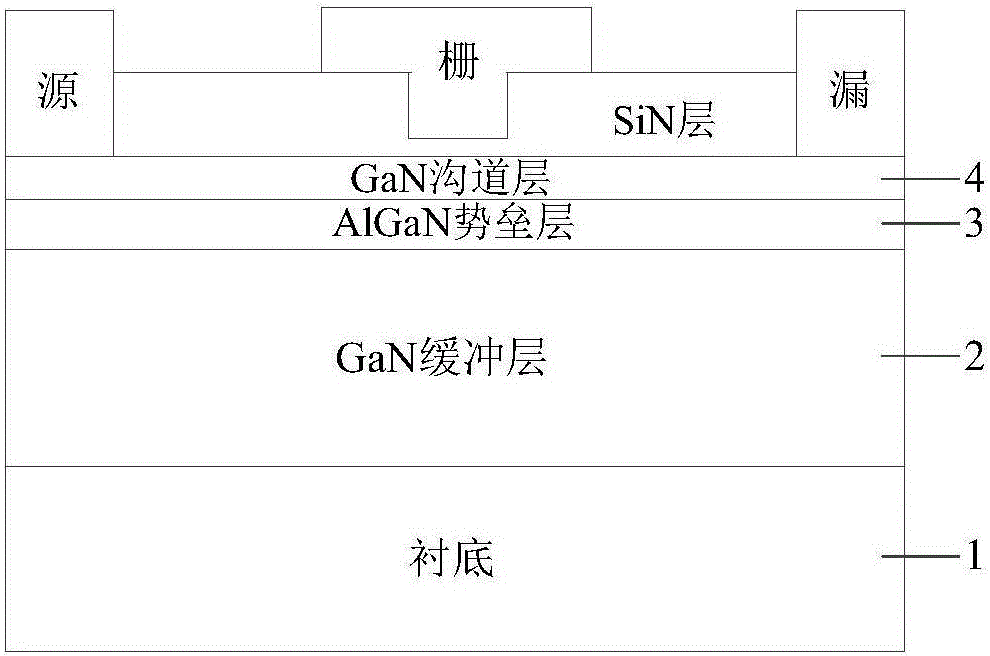

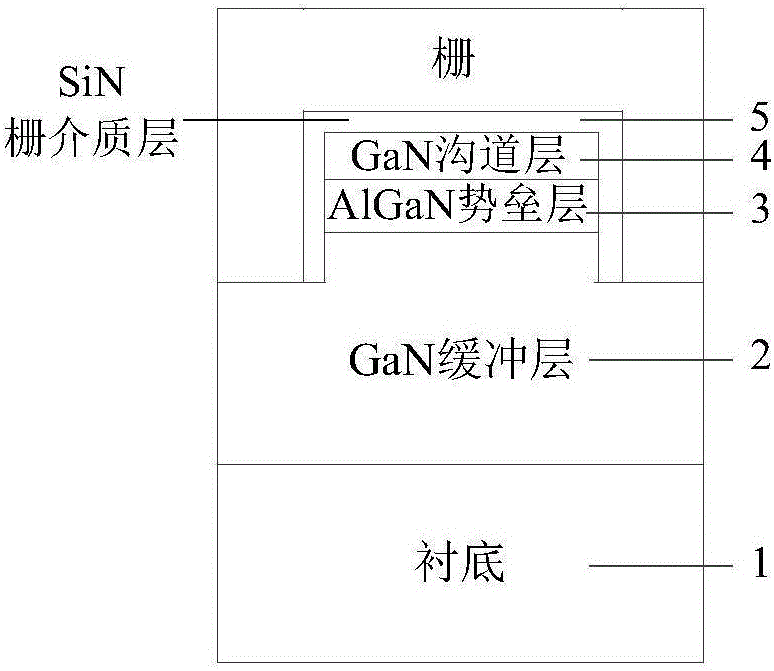

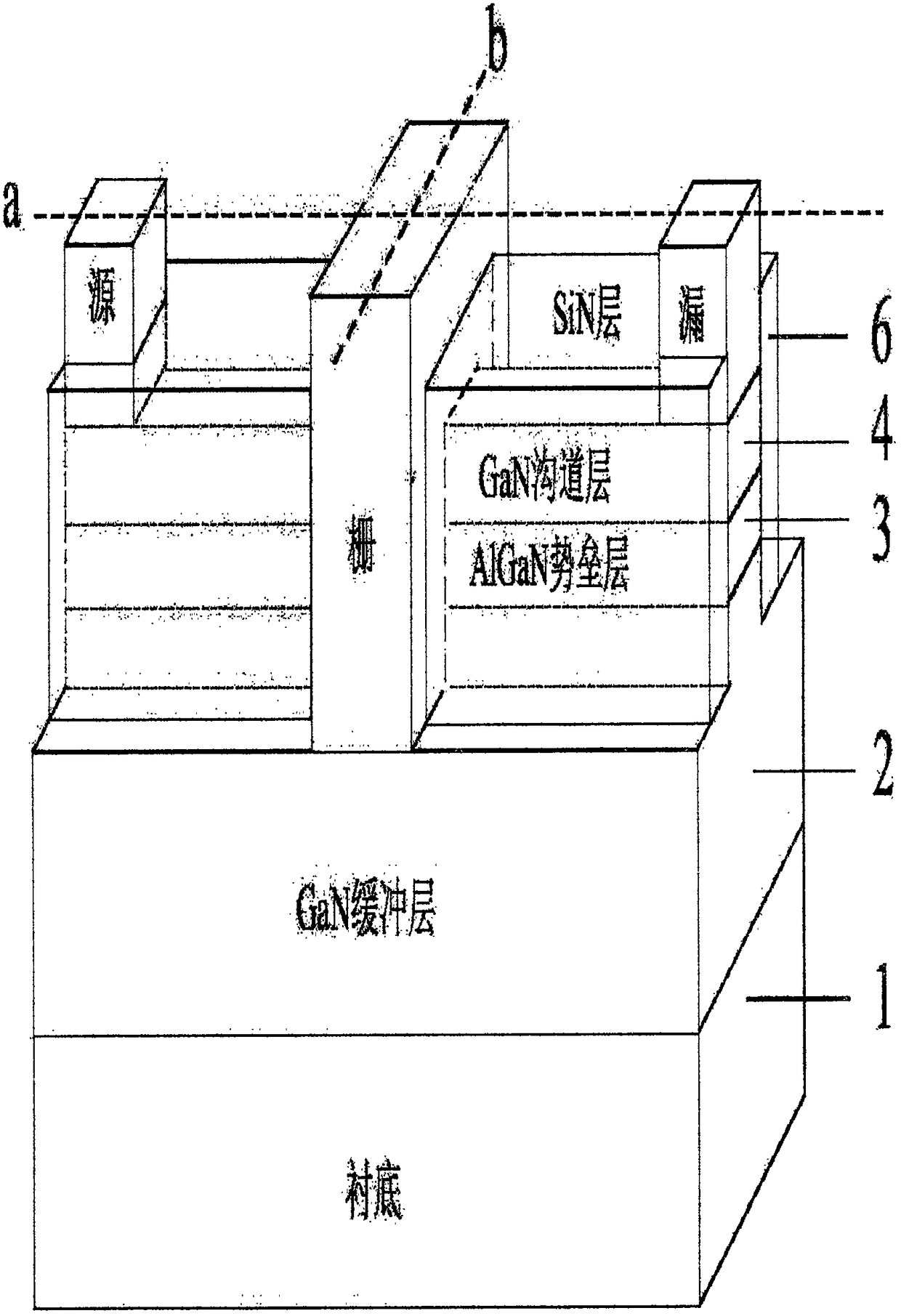

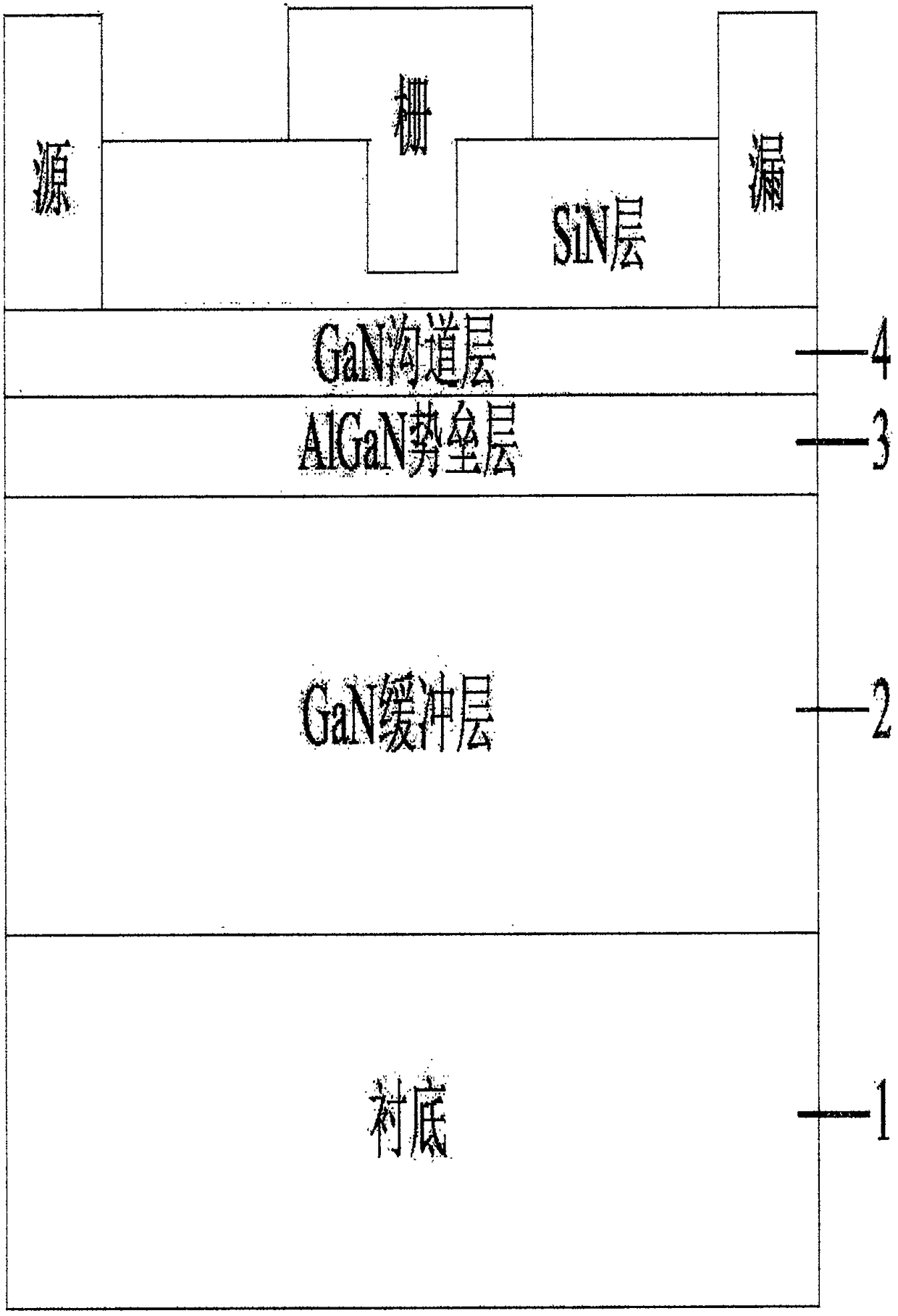

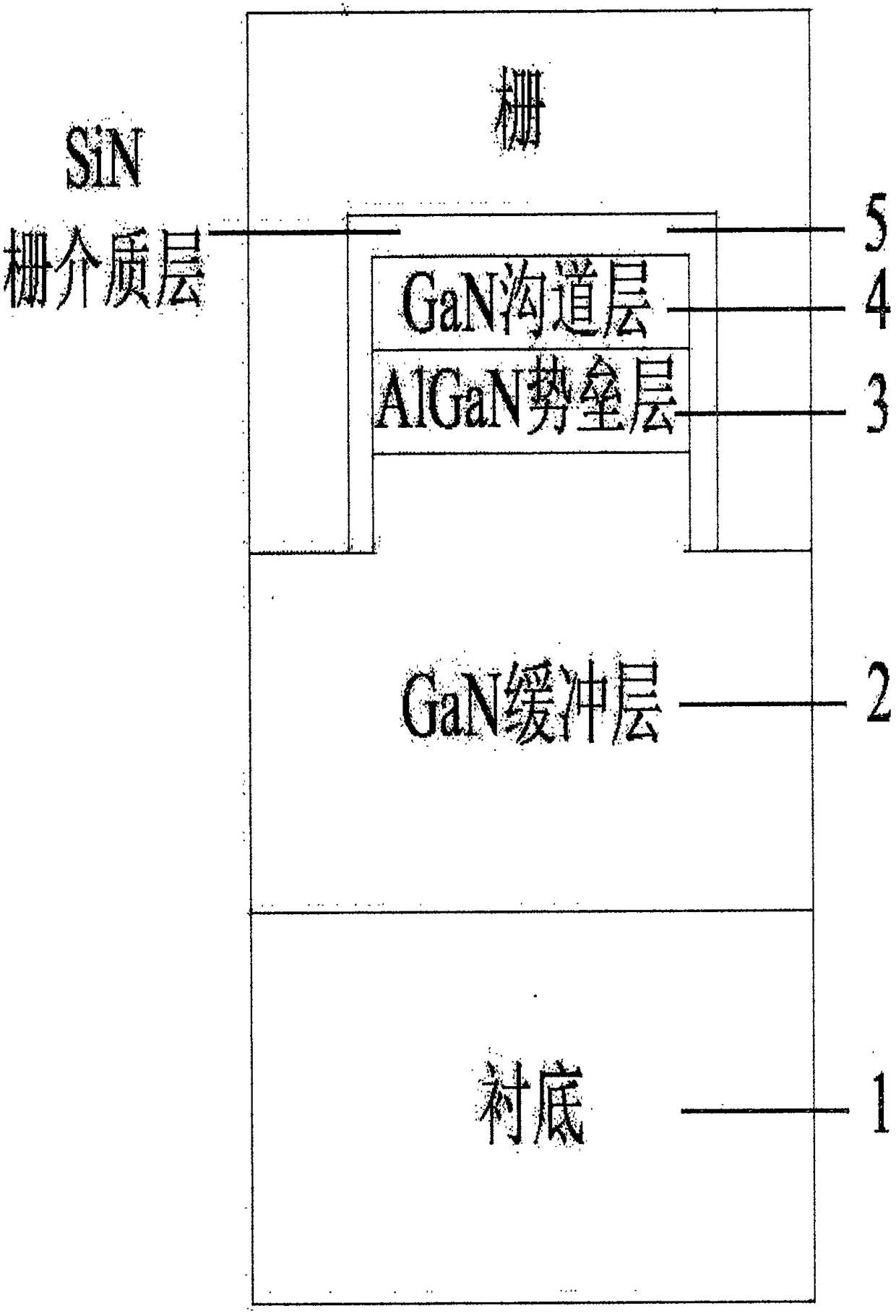

T-gate and N-surface GaN/AlGaN fin-type high electron mobility transistor

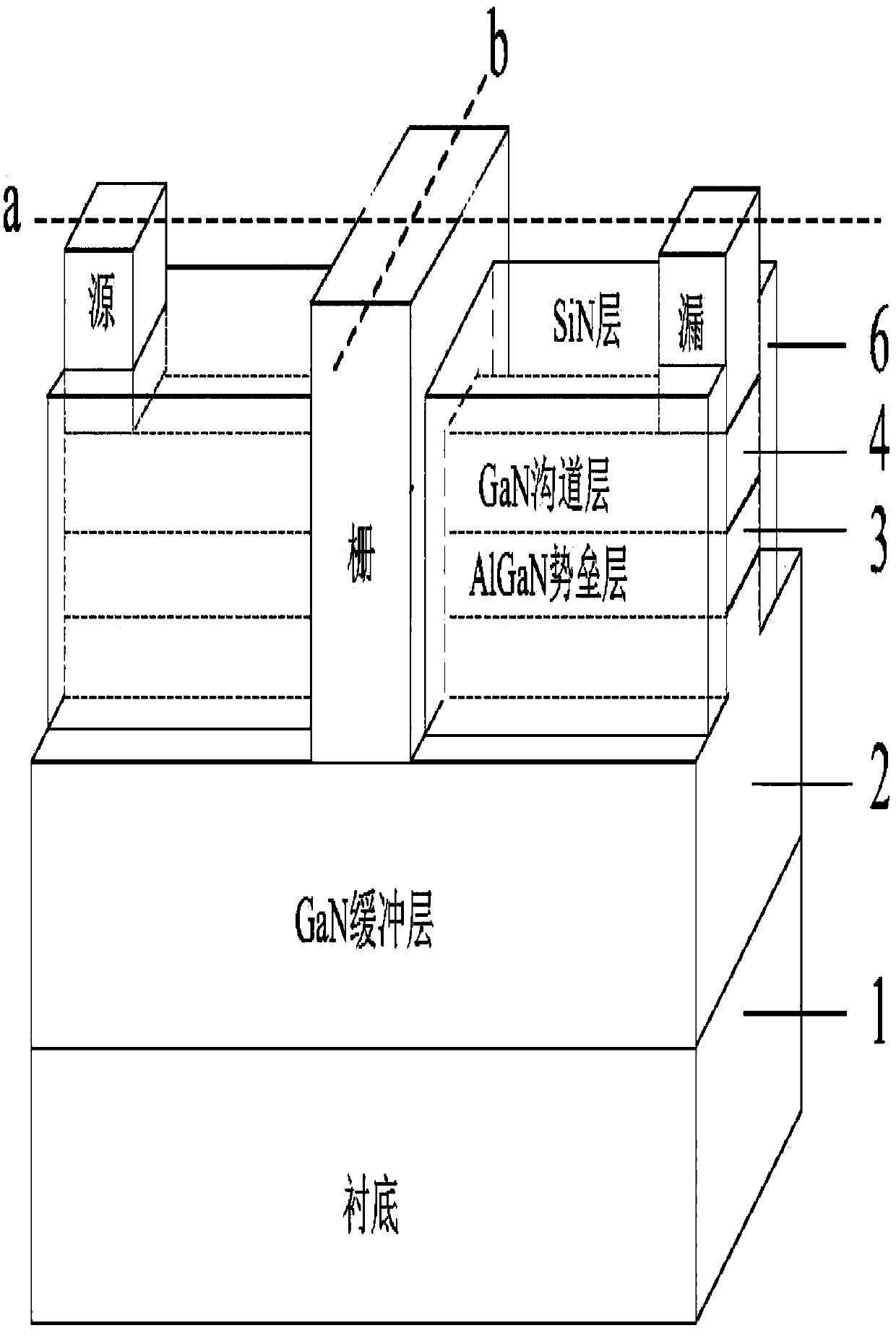

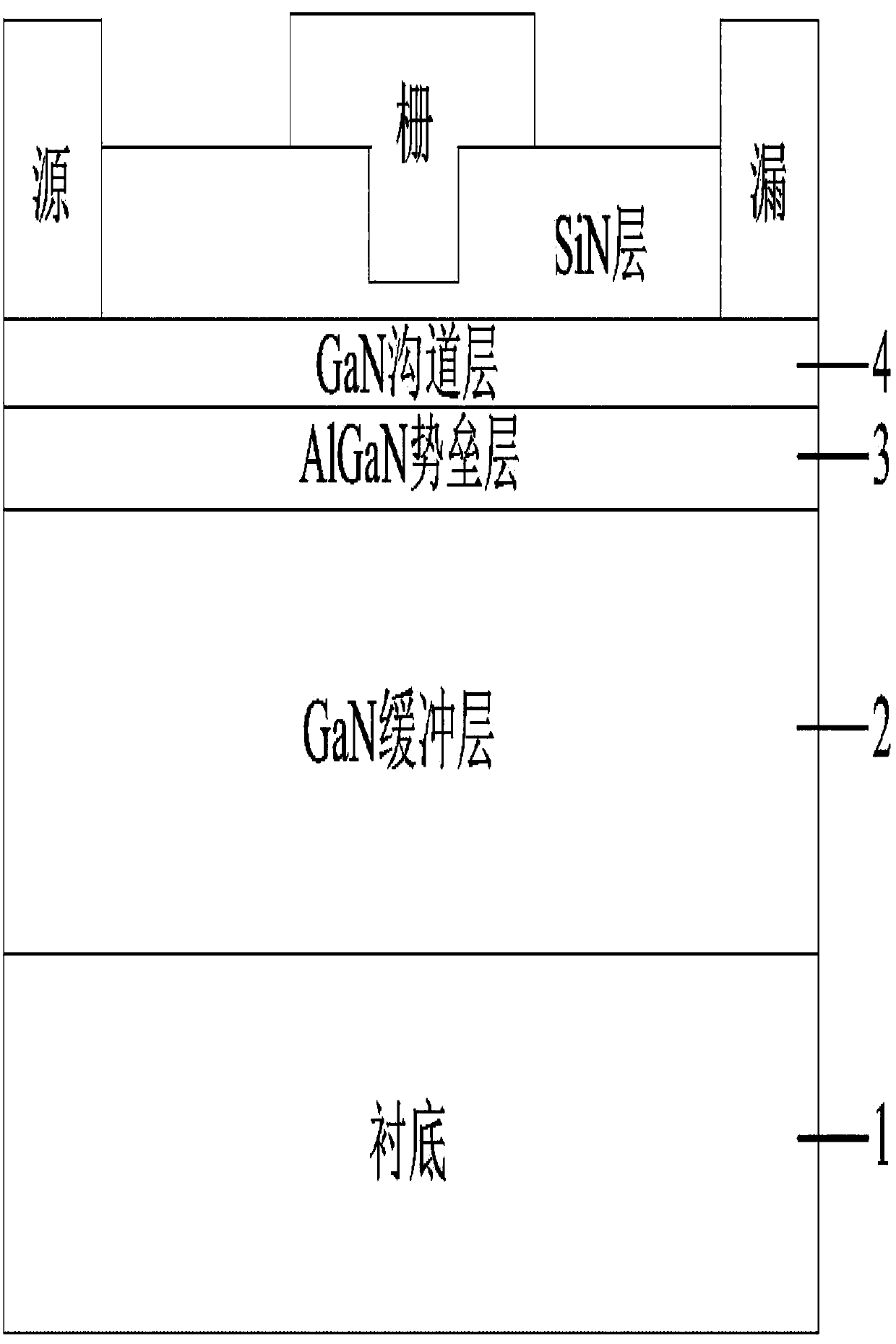

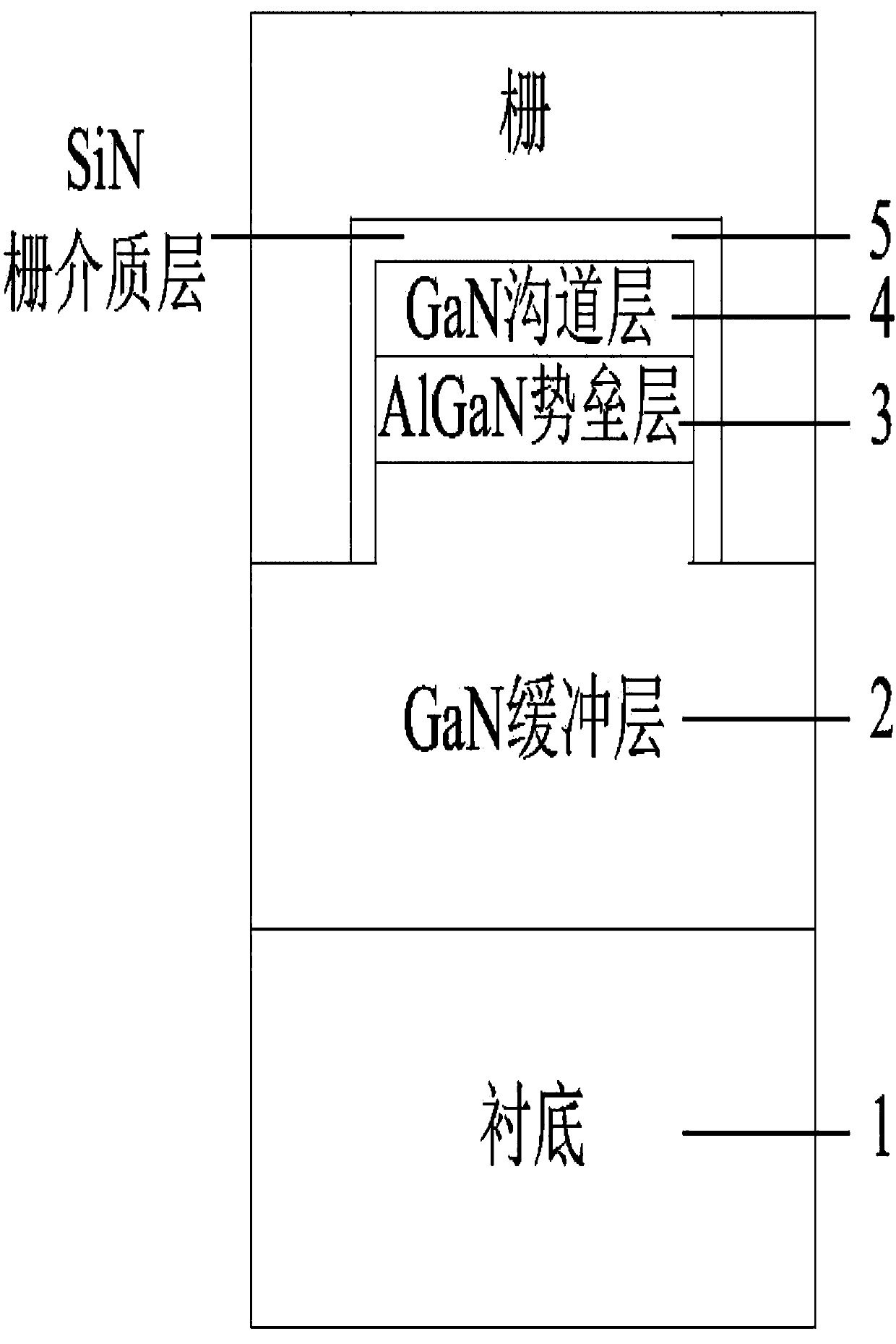

ActiveCN105914232AReduce contact resistanceFlexibility to reduce the distanceSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionOhmic contact

The present invention discloses a T-gate and N-surface GaN / AlGaN fin-type high electron mobility transistor. The problems are mainly solved that the maximum oscillating frequency of a current microwave power device is small, the ohmic contact resistor is large and the short channel effect is severe. The transistor comprises from down to up: a substrate (1), a GaN buffer layer (2), a ALGaN barrier layer (3), a GaN channel layer (4), a gate medium layer (5), a passivation layer (6), a source gate electrode and a drain gate electrode. The buffer layer and the channel layer employ N-surface GaN materials; the GaN channel layer and the ALGaN barrier layer form GaN / AlGaN heterojunction; the gate electrode employs T-type gate and is wrapped at two sides and the upper portion of the GaN / AlGaN heterojunction to form a three-dimensional gate structure. The T-gate and N-surface GaN / AlGaN fin-type high electron mobility transistor has good gate-control capability, small resistor and the maximum oscillating frequency, and is able to be a microwave power device with the small size.

Owner:XIDIAN UNIV

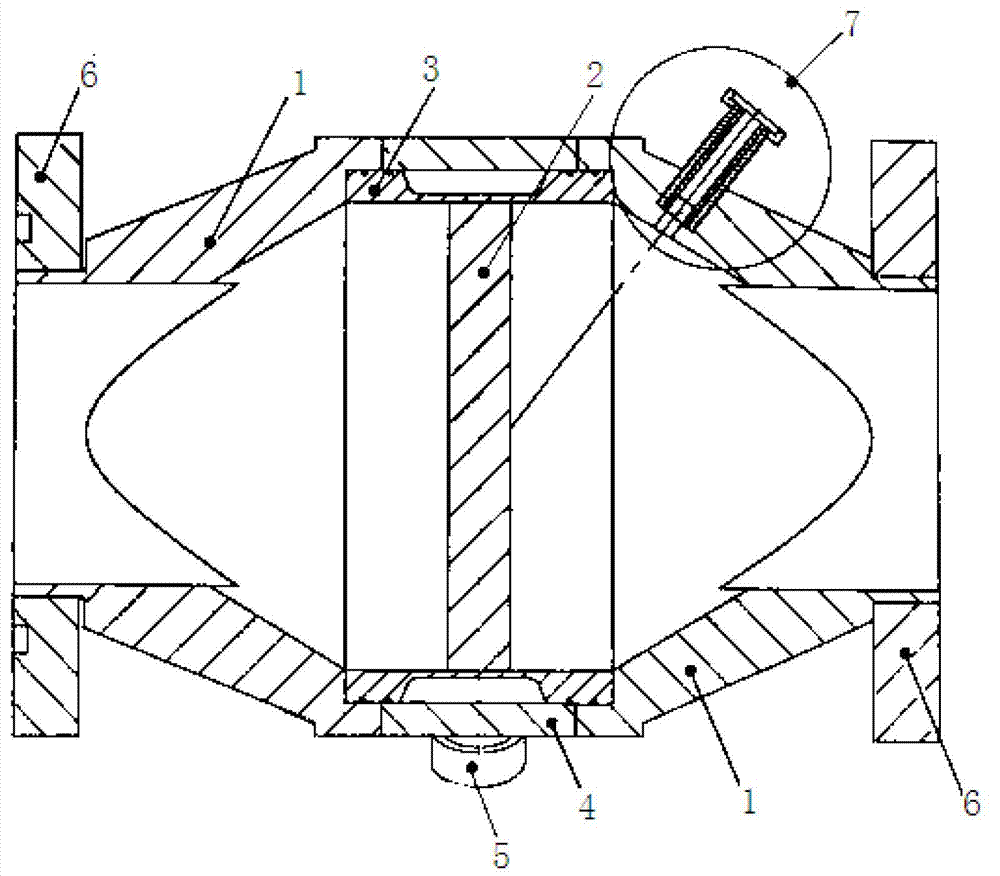

Novel high-power microwave vacuum ceramic window

ActiveCN103094645ASmall temperature differenceReduce the probability of ruptureWaveguide type devicesMicrowaveFlange

The invention discloses a novel high-power microwave vacuum ceramic window which comprises two cone-shaped window bodies which are symmetrically arranged in a left-and-right mode and a ceramic piece in a middle position. A circular waveguide window frame is arranged on the outer side of the ceramic piece, and the ceramic piece is arranged along the radial direction of the window frame. An outer water sleeve is sleeved on the outer side of the window frame, and a water inlet connector and a water outlet connector are welded in the outer water sleeve. The left and the right ends of the window frame and the outer water sleeve are respectively assembled and connected with round waveguides of the cone-shaped window bodies of the left side and the right side of the ceramic window. Rectangular waveguides of the cone-shaped window bodies are connected with flanges, a fire striking detecting device is arranged on the right window body, the rectangular waveguides are gradually transformed to be the round waveguides through the left window body, and the round waveguides are gradually transformed to be the rectangular waveguides through the right cone-shaped window body. The novel high-power microwave vacuum ceramic window has the advantages of being good in microwave performance, high in vacuum tightness, high in safety, high in reliability, not rigorous for machining requirements, capable of achieving one-off vacuum welding and the like, and is suitable for general application of vacuum systems.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Fibrous sheets coated or impregnated with biodegradable polyhydroxybutyrate polymers or polymer blends

InactiveUS20060240726A1High glass transition temperatureImprove the crystallization processBio-packagingSynthetic resin layered productsVitrificationPolymer science

Fibrous sheets are coated or impregnated with a biodegradable composition to render the sheets more resistant to penetration by liquids. Biodegradable polymer blends suitable for use in coating or impregnating a fibrous sheet can be manufactured from at least one type of polyhydroxybutyrate, optionally in combination with at least one additional biodegradable polymer (e.g., a “hard” biodegradable polymer having a glass transition temperature of at least about 10° C. and / or a “soft” biodegradable polymer having a glass transition temperature less than about 0° C. Sufficient inorganic filler may be included so as to render the treated sheet microwaveable. The biodegradable polymer compositions are especially well-suited for coating or impregnating paper sheets, e.g., 12-15 lb / 3000 ft2 tissue paper to yield food wraps. Food wraps will typically be manufactured to have good “dead-fold” properties so as to remain in a wrapped position and not spring back to an “unwrapped” form.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

AlGaN/GaN HEMT manufacturing method

InactiveCN103928324AImprove Microwave PerformanceGood lookingSemiconductor/solid-state device manufacturingSemiconductor devicesDopantMicrowave

The invention discloses an AlGaN / GaN HEMT manufacturing method. The method comprises the steps that (1) a first dielectric layer is deposited on an AlGaN barrier layer; (2) the first dielectric layer is coated with a first photoresist layer; (3) a metal mask layer used as an injection mask is evaporated until the metal mask layer is removed from the first dielectric layer of the first photoresist layer and removed from the surface of the first photoresist layer, and a metal layer left by the metal mask layer on the first photoresist layer is stripped and removed; (4) the metal mask layer is used as the mask to inject Si+ ions into an area where ions need to be injected to form an injection area; (5) after the first dielectric layer and the metal mask layer on the first dielectric layer are removed, a second dielectric layer is deposited on the surface of the AlGaN barrier layer, and high temperature annealing is conducted in protective gas to activate the injected Si+ ions to form a dopant. The AlGaN / GaN HEMT manufacturing method has the advantages that the appearance of the surface and the edge of an ohmic contact electrode of a manufactured device is good, the effective source-drain interval of the device is reduced through heavy doping, and therefore the microwave performance of the device is improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

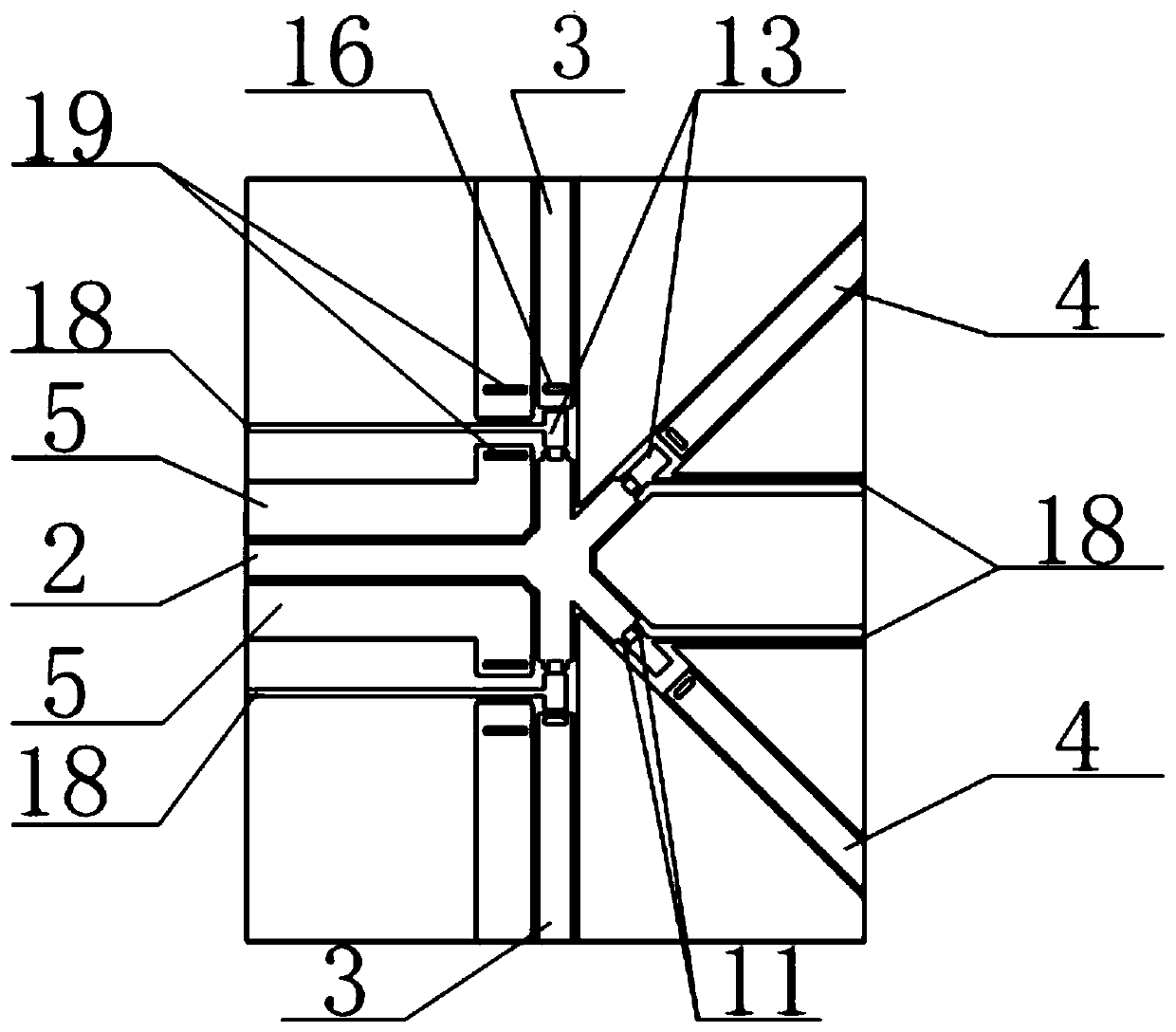

Silicon-based multichannel TR assembly and design method

ActiveCN105826275ARealize multiple functionsHigh precisionSemiconductor/solid-state device detailsSolid-state devicesSpecific functionHigh resistivity silicon

The invention discloses a silicon-based multichannel TR assembly. The silicon-based multichannel TR assembly, in the structure, comprises a multilayer silicon-based substrate 1 with signal transmission, passive element integration and chip carrier, a microwave single chip integrated circuit and a digital integrated circuit 2 for realizing various specific functions of the TR assembly, and a high-resistivity silicon cap 3 whose top is used for sealing and protection, wherein the multilayer silicon-based substrate at least comprises three layers of metal wiring, metal adopts a Cu material, the silicon-based surface uses multiple layers of dielectric materials with a low dielectric constant for isolation between metal layers and surface passivation protection, multiple through silicon vias (TSV) are made inside the silicon-based substrate as cooling channels for microwave chip grounding and inner high-power consumption elements and key parts for microwave signal vertical transmission; and external control and microwave interfaces are arranged around the silicon-based material. The silicon-based multichannel TR assembly and the design method have the advantages that a multichannel TR assembly within 40 GHz can be realized, the microwave performance is excellent, and miniaturization and low cost of the TR assembly can be realized.

Owner:南京国博电子股份有限公司 +1

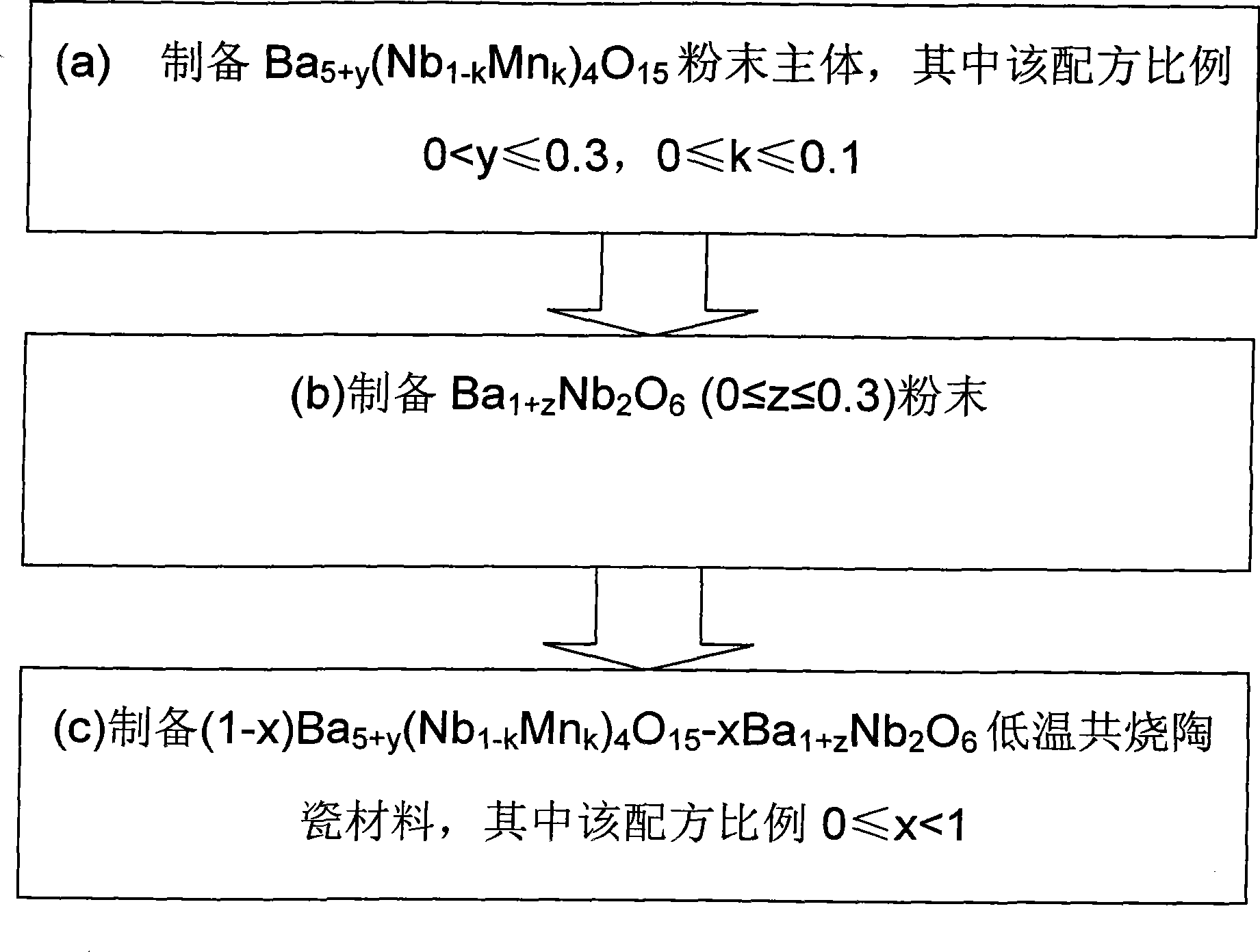

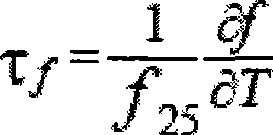

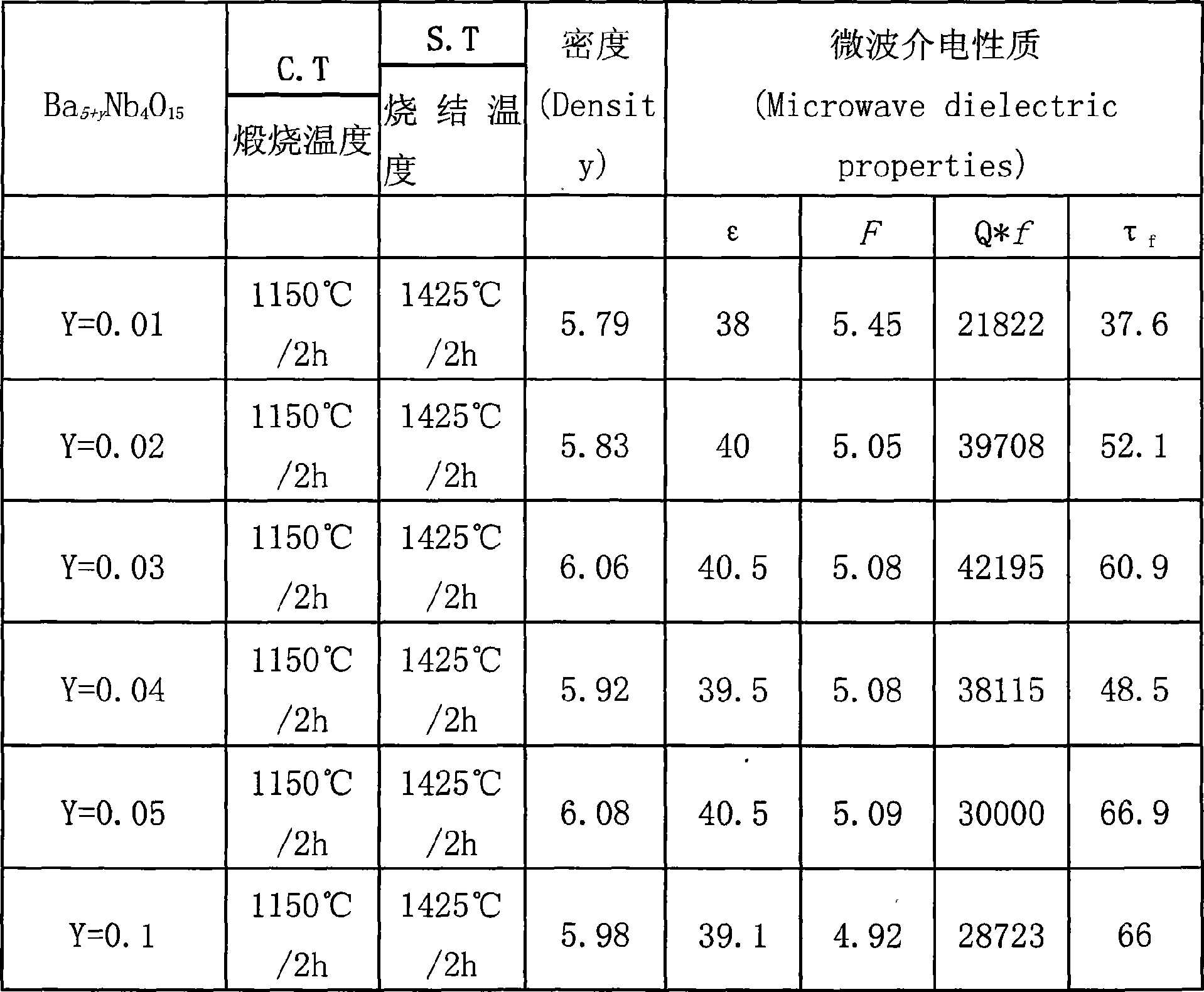

Low-temperature co-fired microwave dielectric ceramic materials and preparation method thereof

ActiveCN101423392AIntrinsic Microwave Performance ImprovementSimple chemical compositionDielectric resonatorCopper oxide

The invention relates to a low temperature co-fired ceramic microwave dielectric material and a method for preparing the same. The material proportion is as follows: (1-x)Ba5+y(Nb1-kMnk)4O15-xBa1+zNb2O6 is added with a burning auxiliary agent which is 0.3 to 2.8 weight percent of the total materials, wherein the burning auxiliary agent is boron oxide, the boron oxide and zinc oxide, the boron oxide and copper oxide, the boron oxide and barium oxide, or the barium oxide, the boron oxide and the copper oxide; and x is more than or equal to 0 and less than 1, y is more than 0 and less than or equal to 0.3, z is more than or equal to 0 and less than or equal to 0.3, and k is more than or equal to 0 and less than or equal to 0.1. With the addition of Ba1+zNb2O6 and small amount of low melting point oxide, the sintering temperature of the low temperature co-fired ceramic microwave dielectric material is lowered to about 900 DEG C to obtain excellent microwave dielectric properties: the dielectric constant is between 39 and 42, the microwave characteristic is more than 15,000, and the resonant frequency temperature coefficient is about 30; and the material can be applied to the manufactures of microwave devices such as low temperature co-fired ceramic systems, multi-layer dielectric resonators, microwave antennas, filters.

Owner:DONGGUAN HUAKE ELECTRONICS

Two-end heated microwave power sensor

InactiveCN101029912ASimple structureSignificant advantages of structurePower measurement by thermal methodsPower sensorTransducer

A microwave power transducer of two-ends heating type is prepared as using GaAs as substrate, arranging a layer of AIGaAs film on said substrate, setting thermoelectric stack formed by a group of series-connected GaAs / AuGe thermocouple on AIGaAs film, using coplanar waveguide A on GaAs substrate as input transmission line of microwave signal to be measured and connecting coplanar waveguide with two parallel-connected DC heating resistances.

Owner:SOUTHEAST UNIV

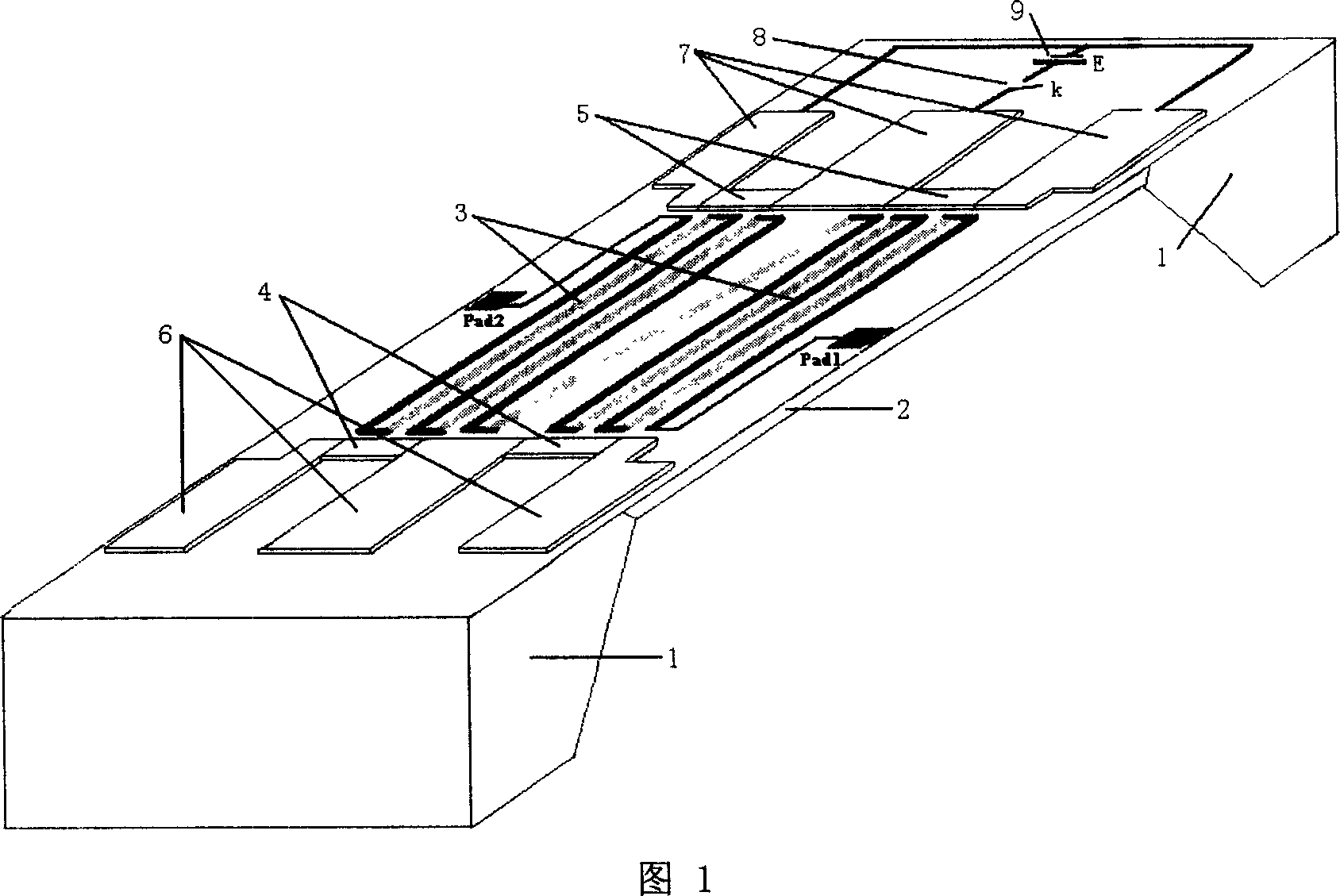

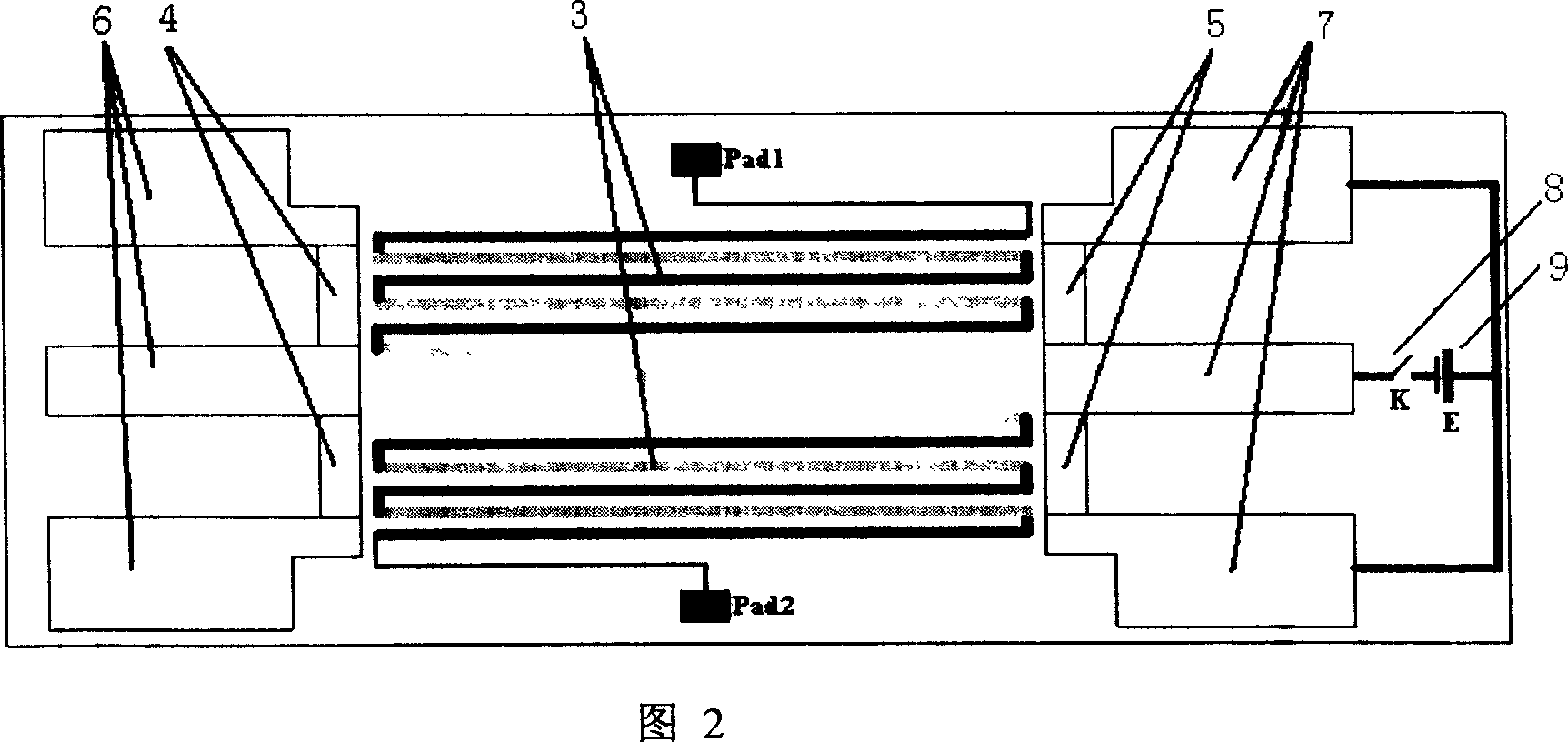

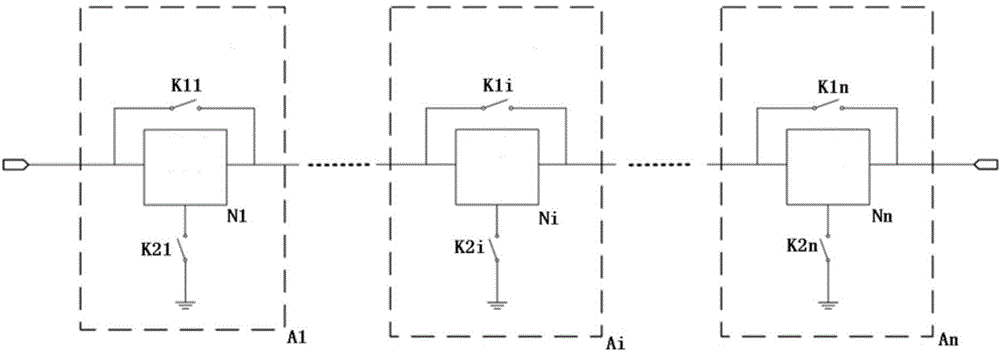

Micro-electromechanical system (MEMS) stepping type digital attenuator

ActiveCN104868868ASimple designLow insertion lossMultiple-port networksUltrasound attenuationElectrical resistance and conductance

The invention discloses a Micro-electromechanical system (MEMS) stepping type digital attenuator. The MEMS stepping type digital attenuator comprises a transmission line and n cascaded variable attenuation units, wherein n is greater than or equal to 1. The variable attenuation unit comprises a resistance attenuation network, an upper MEMS switch and a lower MEMS switch. The upper MEMS switch and the lower MEMS switch are in longitudinal symmetry relative to the resistance attenuation network. In the MEMS stepping type digital attenuator, the MEMS switch is adopted to replace a conventional electronic switch, the MEMS switches are symmetrical relative to the resistance attenuation network, so that a path which a signal pass through is the shortest, and the structure of the attenuator is more compact; access of different resistance attenuation networks is controlled through the MEMS switches, so that different attenuation is realized, the circuit topological structure is simple, the port impedance matching is good, the manufacture is simple, the technology compatibility is good, and mass production can be realized; in addition, an air bridge is introduced between two grounding metal faces of coplanar waveguide, so that the attenuation of the attenuator has better flatness in a broader frequency band.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

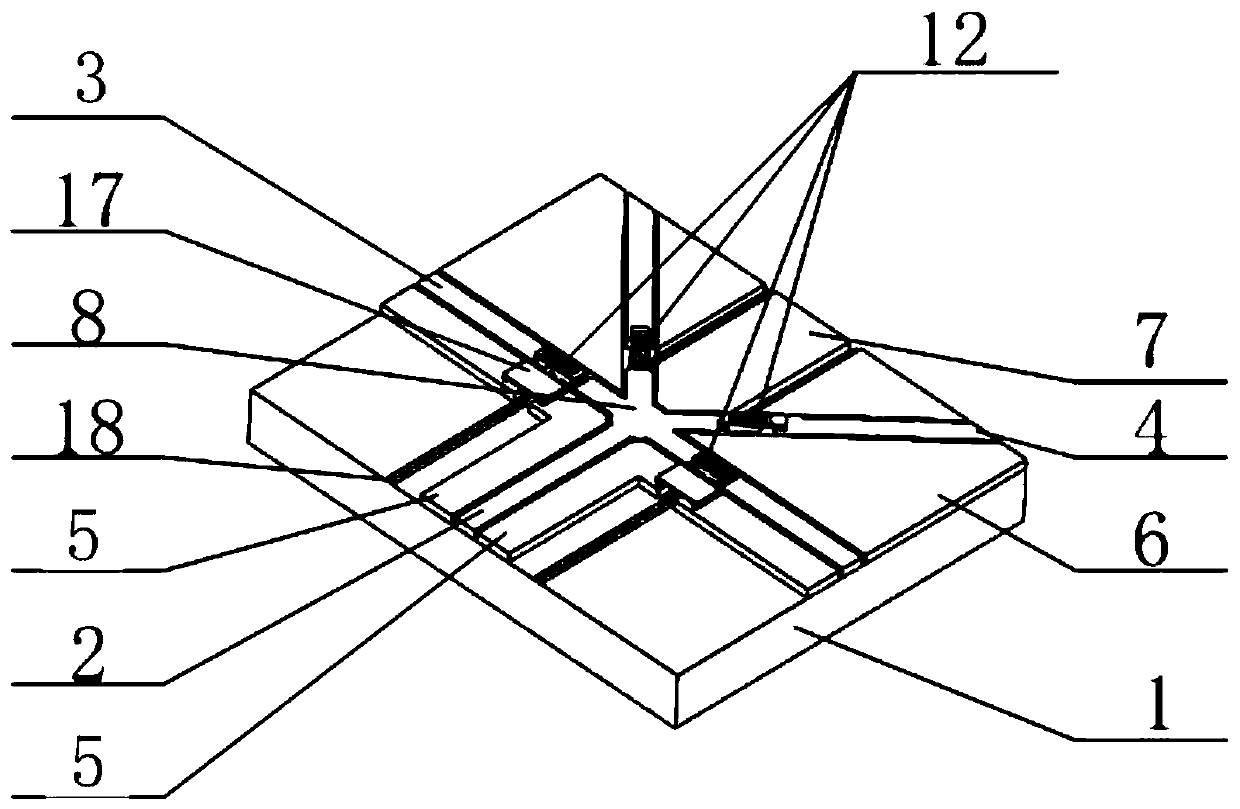

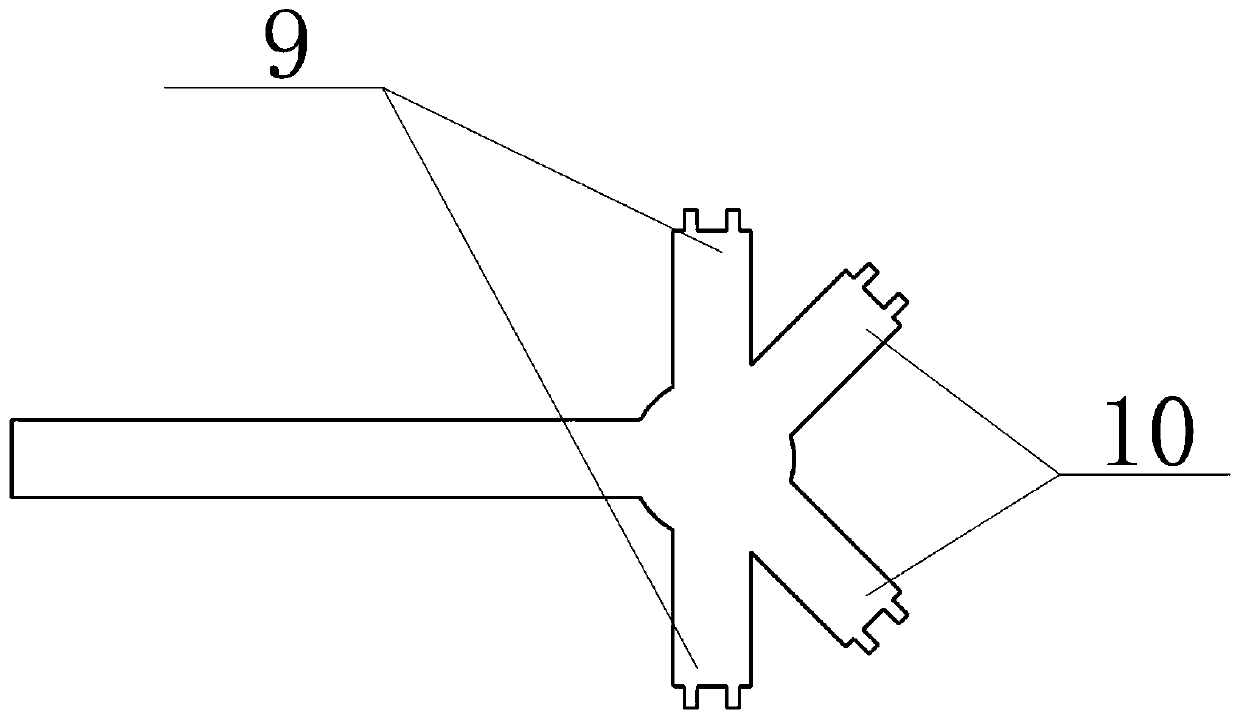

K-type single-pole four-throw radio frequency MEMS switch

PendingCN110137634ASimple structureReduce volumeWaveguide type devicesRadio frequencyTransmission performance

The invention belongs to the field of radio frequency MEMS, in particular to a K-type single-pole four-throw radio frequency MEMS switch. The K-type single-pole four-throw radio frequency MEMS switchis mainly composed of a substrate, a microwave transmission line, a driving electrode, an upper electrode, a lower electrode, a fixed anchor and contacts. The microwave transmission line and the driving electrode are arranged on the substrate. The upper electrode is of a straight plate structure, and the lower electrode is a double contact with an elastic beam. The microwave transmission line usesa power divider of a K-type structure to divide the input signal power into four equal signals for output. From the point of view of microwave transmission, the K-type structure is more efficient, and improves the smooth flow of current and the transmission performance between branches of the switch. The designed single-pole four-throw switch has smaller insertion loss and better isolation. In addition, release holes in cantilever beams reduce the stress on the whole cantilever beams and greatly improves the isolation of the switch.

Owner:ZHONGBEI UNIV

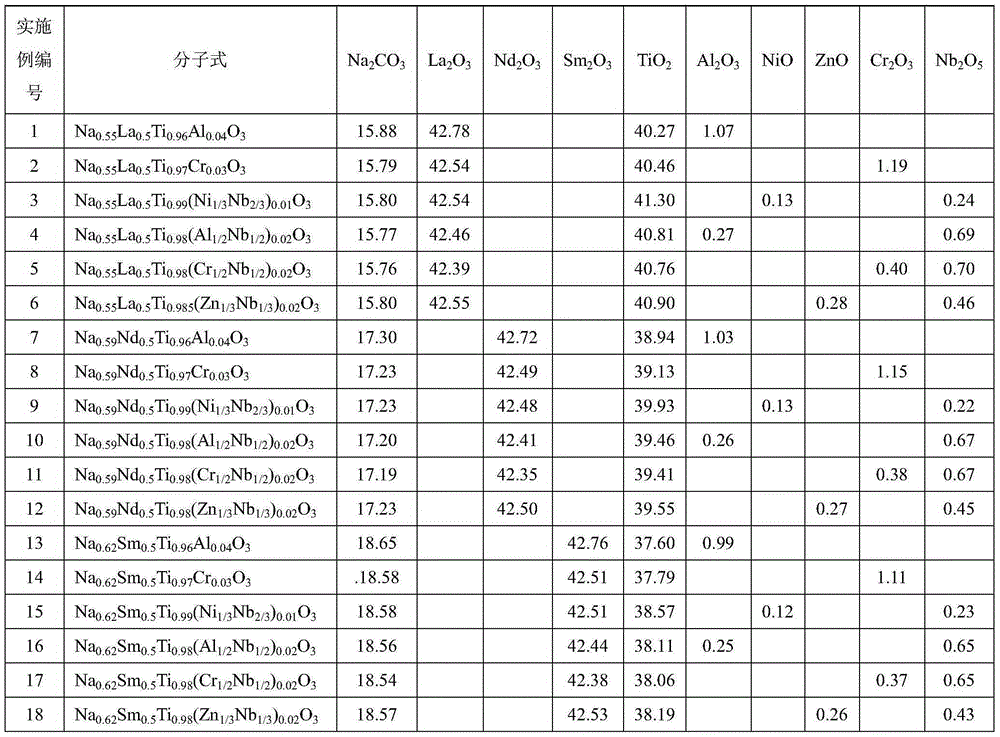

High-dielectric low-loss microwave dielectric ceramic material and preparation method thereof

The invention provides a high-dielectric low-loss microwave dielectric ceramic material. The general chemical formula of the material is (Na0.5+yLn0.5)(Ti1-xCx)O3, Ln=La or Nd or Sm, wherein x is larger than or equal to 0.01 and is smaller than or equal to 0.04, y is larger than or equal to 0.05 or is smaller than or equal to 0.12, the composition of C is VW, V represents Nb with the valence state higher than four, W represents a single ion or compound ions with the valence state lower than or equal to four and the average ion radius approximating to Ti4+, and V and M achieve simultaneous replacement or independent replacement. The invention further provides a preparation method of the high-dielectric low-loss microwave dielectric ceramic material. The preparation method comprises the steps of burdening, ball grinding, drying and sieving, presintering, pelleting, compression molding and sintering. The prepared material has the high dielectric constant and high Q*f value, contains no Pb or Cd or other volatile toxic metals in the formula, and is stable in performance and capable of meeting application requirements of modern microwave devices, raw materials are sufficiently supplied in China, the cost is relatively low, and the high-performance microwave ceramic can be low in cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Silicon-based suspended microstrip line structure for terahertz waves, and manufacturing method therefor

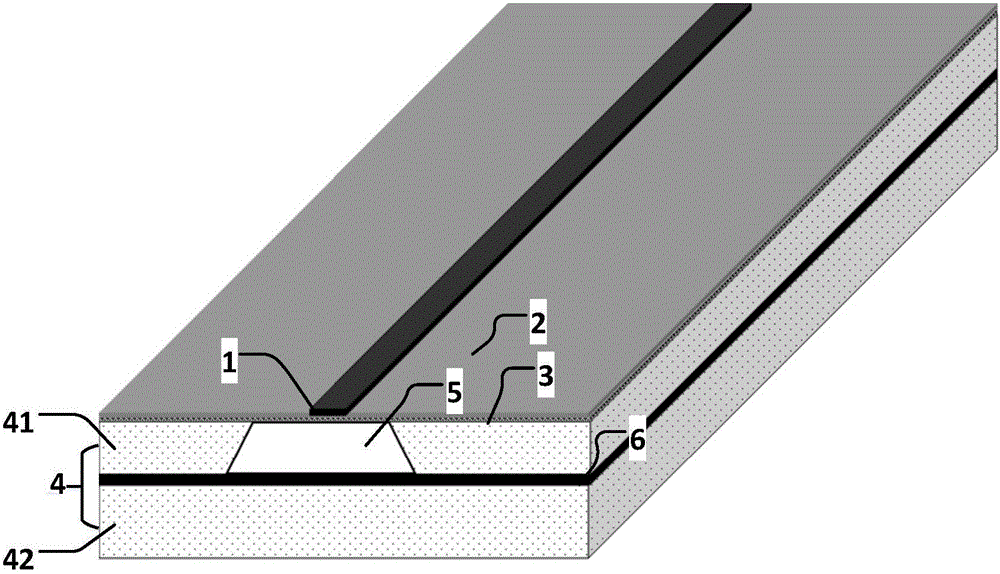

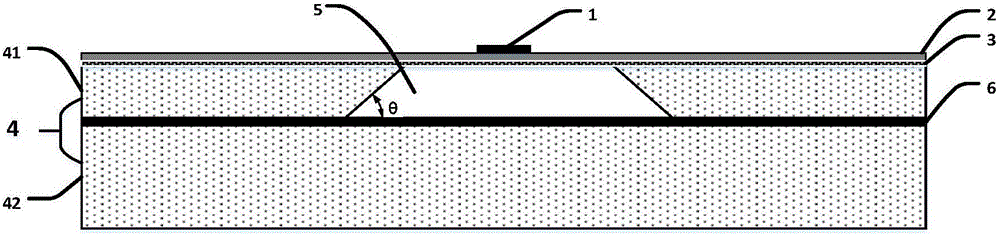

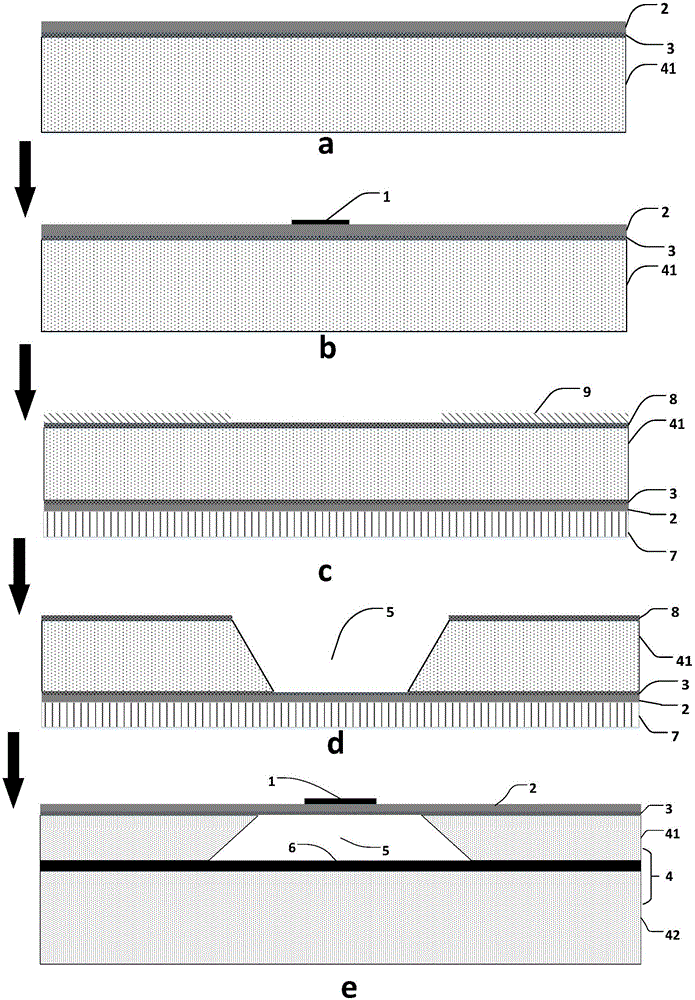

The invention discloses a silicon-based suspended microstrip line structure and a manufacturing method therefor, and mainly solves problems in the prior art that the transmission loss of terahertz waves is large and a terahertz suspended microstrip line is low in machining precision. The structure comprises a suspended microstrip line (1), a silicon substrate (4), an air cavity (5) and a metal floor layer (6), wherein the silicon substrate (4) comprises an upper silicon substrate (41) and a lower silicon substrate (42). The metal floor layer (6) is located between the upper silicon substrate (41) and the lower silicon substrate (42). The microstrip line (1) is prepared on a BCB (benzocyclobutene) photoresist layer (2), and a silicon nitride layer (3) grows between the BCB photoresist layer (2) and the upper silicon substrate (41). The air cavity (5) is disposed in the upper silicon substrate (41) in an etched manner, and is located exactly below the microstrip line (1). The structure is low in loss, is simple in structure, is easy to machine, and can be used for the active and passive circuits at the terahertz band.

Owner:XIDIAN UNIV

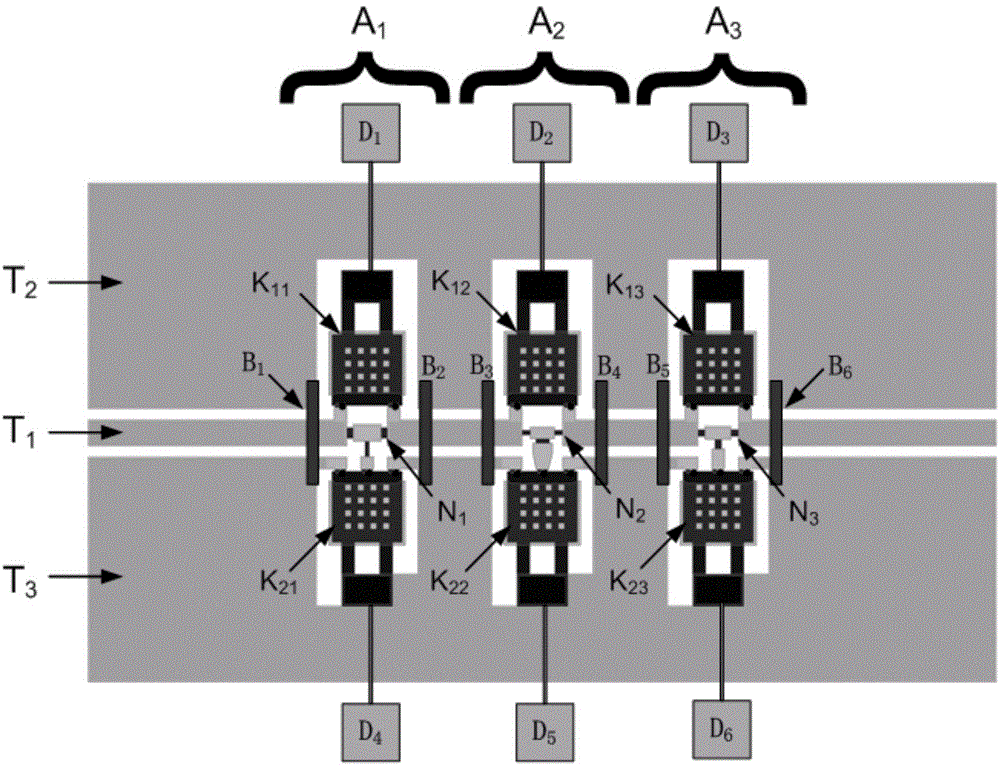

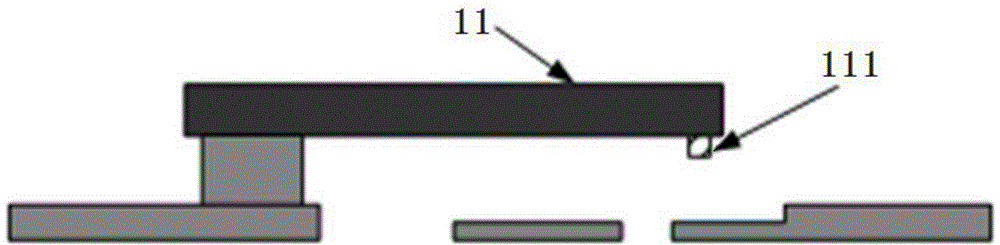

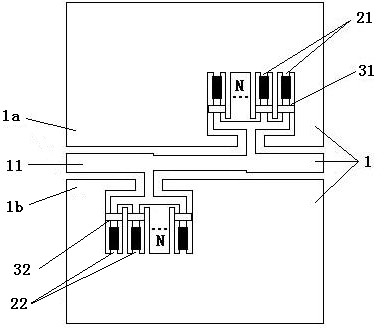

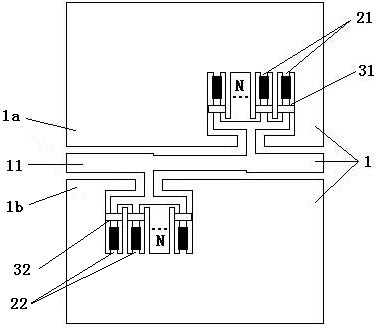

Microwave attenuator

InactiveCN102637935AImprove Microwave PerformanceImprove applicabilitySolid-state devicesFluid speed measurementCoplanar waveguideEngineering

The invention provides a microwave attenuator which comprises a substrate, and a coplanar waveguide (1), a first absorption resistor (21), a second absorption resistor (22), a first micro-mechanical switch (31) and a second micro-mechanical switch (32) which are arranged on the substrate, wherein the coplanar waveguide (1) comprises a coplanar waveguide signal wire (11), and a first coplanar waveguide earth wire (1a) and a second coplanar waveguide earth wire (1b) which are arranged symmetrically with respect to the coplanar waveguide signal wire (11); and one end of the first absorption resistor (21) is connected with the coplanar waveguide earth wire (1a), the other end of the first absorption resistor (21) is disconnected with the coplanar waveguide signal wire (11), and the first micro-mechanical switch (31) is placed in the disconnection position. The microwave attenuator controls the access of the absorption resistors by switching on or off the micro-mechanical switches, thereby realizing reconfiguration of multiple attenuations of the microwave attenuator, namely realizing reconfiguration of the attenuator structure.

Owner:SOUTHEAST UNIV

T-gate N-surface GaN/AlGaN fin-type high electron mobility transistor

InactiveCN109285883AReduce contact resistanceFlexibility to reduce the distanceSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionOhmic contact

The invention discloses a T-gate N-surface GaN / AlGaN fin-type high electron mobility transistor, which mainly solves the problems of small maximum oscillating frequency, large ohmic contact resistanceand severe short channel effect of the existing microwave power devices. The transistor comprises a substrate (1), a GaN buffer layer (2), an AlGaN barrier layer (3), a GaN channel layer (4), a gatedielectric layer (5), a passivation layer (6), a source electrode, a drain electrode and a gate electrode from the bottom up, wherein the buffer layer and the channel layer adopt N-surface GaN materials; the GaN channel layer and the AlGaN barrier layer form a GaN / AlGaN heterojunction; and the gate electrode adopts a T-type gate and is wrapped at two sides and the upper portion of the GaN / AlGaN heterojunction to form a three-dimensional gate structure. The T-gate N-surface GaN / AlGaN fin-type high electron mobility transistor has the advantages of good gate control capability, small ohmic contact resistance and high maximum oscillating frequency, and can be used as a small-size microwave power device.

Owner:吴绍飞

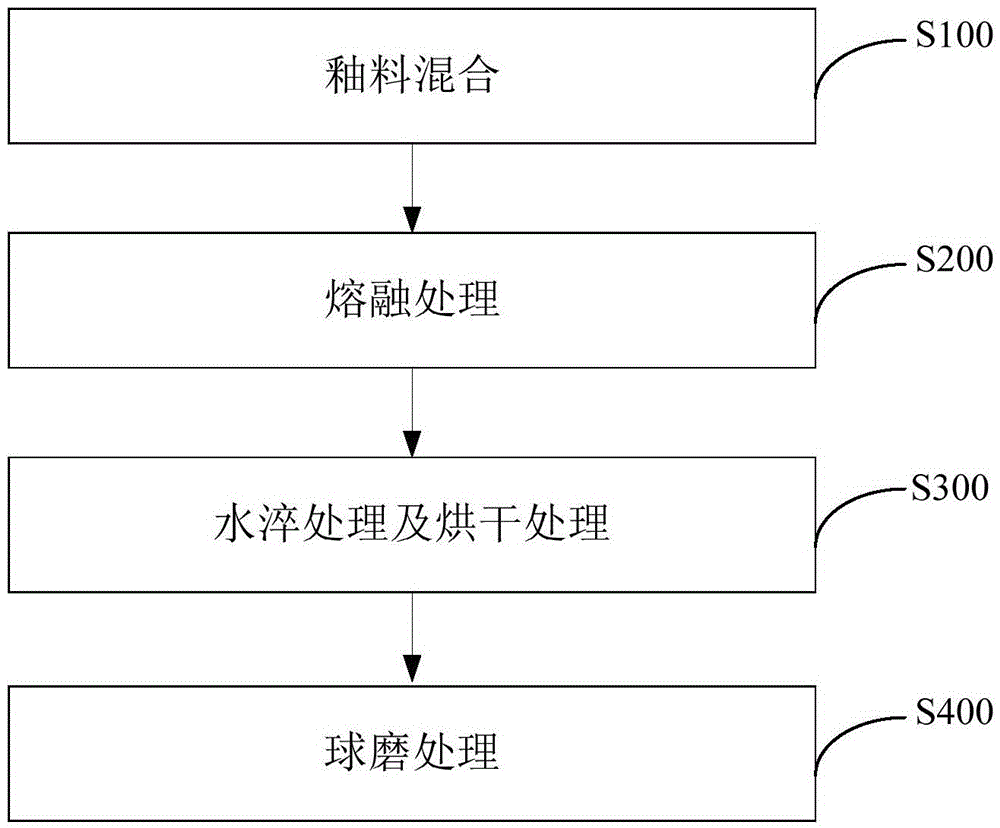

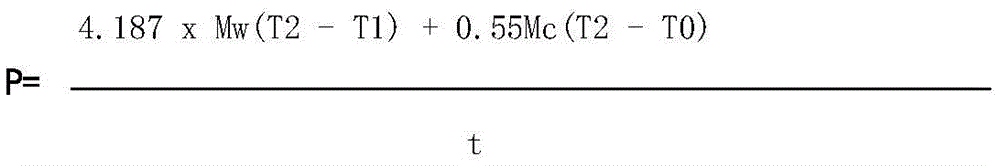

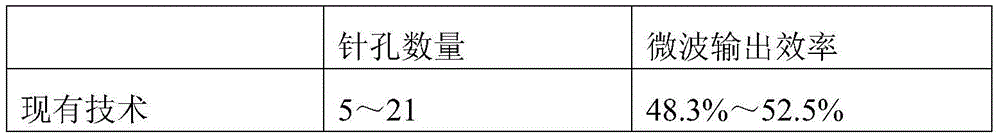

Antibacterial enamel material and preparation method and application thereof

ActiveCN105601113AImprove compactnessReduce pinhole rateDomestic stoves or rangesLighting and heating apparatusMicrowaveTemperature resistance

The invention provides an antibacterial enamel material and a preparation method and application thereof. The antibacterial enamel material is prepared from a matrix agent, an adhesive agent, an auxiliary agent and an antibacterial agent. The antibacterial enamel material has ideal antibacterial performance and low sintering temperature while good high-temperature resistance, acid and alkali resistance, scraping resistance, corrosion resistance and other performance are achieved, no gas is generated when the material is combined with a metal base material, the compactness of enamel is good, the pinhole rate is low, the adherence between the material and the metal base material is good, binding force between the material and the metal base material is high, the enamel material is not prone to falling off, and besides, the enamel material has small wave absorbing performance and is high in microwave outputting rate.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Ultralow-temperature-sintered composite microwave dielectric ceramic material and preparation method thereof

ActiveCN103232241AExcellent microwave dielectric propertiesLower sintering temperatureTemperature coefficientDielectric ceramics

The invention discloses an ultralow-temperature-sintered composite microwave dielectric ceramic material and a preparation method thereof. The formula of the ceramic material is (Ag0.5Bi0.5)(MoxW1-x)O4, wherein 0.3<=x<=0.7. The ultralow-temperature-sintered composite microwave dielectric ceramic material has the characteristics of finely adjustable relative dielectric constant (32.2-34.5), favorable microwave behavior microwave dielectric ceramics (Qf=11500GHz-12000GHz), adjustable temperature coefficient of resonance frequency (-32ppm / DEG C to +19ppm / DEG C) and simple chemical composition. By adopting the solid-phase reaction sintering method, the invention is simple in technological operation, environment-friendly and suitable for industrial production.

Owner:北京中科行运科技有限公司

Warping plate type intelligent detection microwave power sensor

InactiveCN103257268AGood microwave performanceSimple structurePower measurement by current/voltagePower sensorCoplanar waveguide

The invention discloses a warping plate type intelligent detection microwave power sensor. The sensor comprises a substrate, a first coplanar waveguide ground wire, a coplanar waveguide signal wire, a second coplanar waveguide ground wire, a sensing electrode, a driving electrode, an SOC circuit and a warping plate type double-end cantilever beam, wherein the substrate, the first coplanar waveguide ground wire, the coplanar waveguide signal wire, the second coplanar waveguide ground wire, the sensing electrode, the driving electrode and the SOC circuit are sequentially arranged on the substrate, and the warping plate type double-end cantilever beam is arranged on the coplanar waveguide ground wire and is perpendicular to coplanar waveguide. The lower side of the middle of the warping plate type double-end cantilever beam is connected with the second coplanar waveguide ground wire, one end of the warping plate type double-end cantilever beam is arranged above the coplanar waveguide signal wire in a suspension mode, the other end of the warping plate type double-end cantilever beam is arranged above the sensing electrode and the driving electrode, and the SOC circuit is respectively connected with the second coplanar waveguide ground wire, the sensing electrode and the driving electrode through wires. The warping plate type intelligent detection microwave power sensor reduces influence of a small power sensing structure on a device reflective coefficient to the largest extent, ensures good transmission performance of a microwave signal, and meanwhile can improve flexibility and intellectualization.

Owner:SOUTHEAST UNIV

T-gate N-plane GaN/AlGaN fin high electron mobility transistor

InactiveCN109560118AReduce contact resistanceFlexibility to reduce the distanceSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionGate dielectric

The invention discloses a T-gate N-plane GaN / AlGaN fin high electron mobility transistor. The objective of the invention is to mainly solve the problems that a current microwave power device is smallin the maximum oscillation frequency, large in ohmic contact resistance and serious in the short channel effect. The T-gate N-plane GaN / AlGaN fin high electron mobility transistor comprises from bottom to top: a substrate (1), a GaN buffer layer (2), an AlGaN barrier layer (3), a GaN channel layer (4), a gate dielectric layer (5), a passivation layer (6), a source, a drain, and a gate. The bufferlayer and the channel layer are made of N-plane GaN materials; the GaN channel layer and the AlGaN barrier layer form a GaN / AlGaN heterojunction; the gate employs a T-shaped gate and coats the two sides and the top portion of the GaN / AlGaN heterojunction to form a three-dimensional gate structure. The T-gate N-plane GaN / AlGaN fin high electron mobility transistor is good in gate control capacity,small in the ohmic contact resistance and high in maximum oscillation frequency, and can be used as a mini-type microwave power device.

Owner:南京誉凯电子科技有限公司

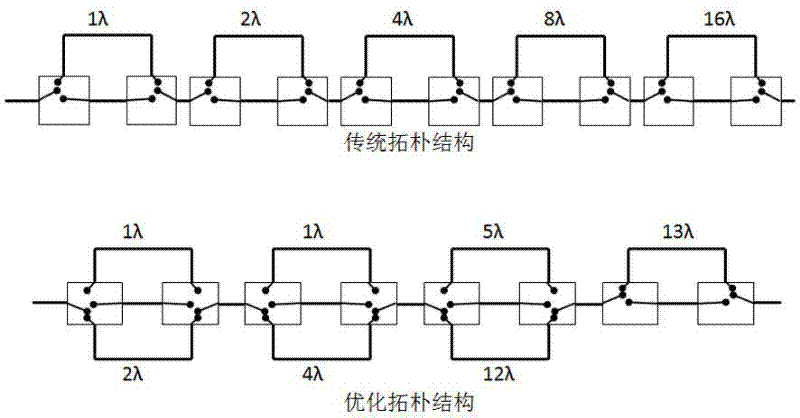

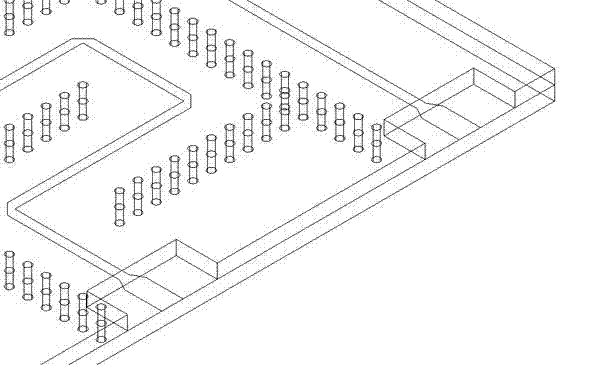

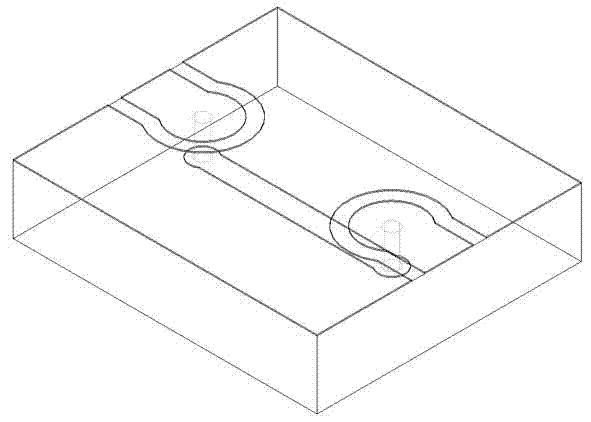

Method for miniaturizing delay line design based on low-temperature co-firing ceramic process

InactiveCN102340048AReduce layout areaImprove Microwave PerformanceDelay linesResonance oscillationMicrowave

The invention discloses a method for miniaturizing a delay time design by adopting a low-temperature co-firing ceramic process. By using the method, the difficult problems that the volume size is difficult to decrease in a conventional delay line design, the performance of a delay line is influenced by the resonance oscillation of a cavity more greatly, the chromatic dispersion phenomenon is caused by the intercoupling between the delay lines, and the like, are solved. In a routine delay line design adopting a way of a switch as well as a transmission line, the transmission line generally adopts the way of a plane microstrip line which is easy to process, but due to the semi-open field distribution of the microstrip line, the microstrip line can be caused to be easily influenced by the resonance oscillation of the cavity of the transmission line, further, the intercoupling is serious when the compact wiring is carried out between transmission lines, and the more obvious chromatic dispersion characteristic is caused. According to the method, a strip line which is not easy to influence is used as a main way of a delay transmission line; the topological structure of the delay line is optimized; by adopting a microwave multilayer circuit design technique, a switch control circuit and a microwave delay circuit are comprehensively designed on a low-temperature co-fired ceramic baseplate; the layout area of the circuits is greatly reduced; and the circuits also have better microwave performance synchronously.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com