AlGaN/GaN HEMT manufacturing method

A technology with high electron mobility and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as the inability to obtain thin lines and the decrease in lithography resolution, and achieve improved microwave performance and morphology good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

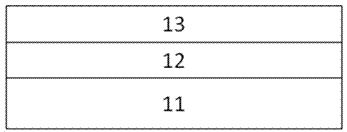

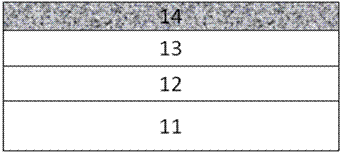

[0047] Such as Figure 2A As shown, a dielectric layer 14 is deposited on the AlGaN barrier layer 13, and the optional materials for the dielectric layer 14 include but are not limited to SiN, SiO 2 etc., preferably SiN, with a preferred thickness of 50 nm.

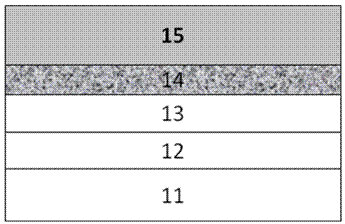

[0048] Such as Figure 2B A photoresist layer 15 is shown coated on the dielectric layer 14 . By exposing and developing the photoresist layer 15, the photoresist layer 15 above the area that needs to be protected by a mask during the ion implantation process, such as Figure 2C The metal layer 16 used as an implant mask is shown evaporated onto the dielectric layer 14 from which the photoresist layer 15 has been removed and on the surface of the photoresist layer 15 .

[0049] Such as Figure 2D As shown, the metal layer 16 can be made of a metal such as Ti, Pt, Ni, Au, etc., or can be made of an alloy of these metals, and their multi-layer composite metal layers, and its thickness depends on the Si that needs to be ...

Embodiment 2

[0062] Depend on Figure 3A-Figure 3G It is the implementation steps of another embodiment of the present invention, at first with embodiment 1 Figures 2A-2F As shown, the deposition of the dielectric layer 14, the coating of the photoresist layer 15 on the dielectric layer 14, the exposure and development to remove the photoresist layer 15 above the area that requires a mask to be protected during the ion implantation process, and evaporation as implantation The metal layer 16 used for the mask is removed on the dielectric layer 14 of the photoresist layer 15 and the surface of the photoresist layer 15, stripping and removing the photoresist layer 15 and the metal layer 16 on it, utilizing the remaining metal layer 16 is used as a mask to implant Si+ ions into the region to be ion-implanted to form an implanted region 17, remove the dielectric layer 14 and the metal mask layer 16 thereon, deposit the dielectric layer 18 to the surface of the AlGaN barrier layer 13, and Medi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com