Warping plate type intelligent detection microwave power sensor

A microwave power and intelligent detection technology, which is applied in the direction of electric power measurement through current/voltage, can solve the problems of microwave signal consumption and other problems, and achieve good transmission performance, wide operating frequency range, improved sensitivity and intelligent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

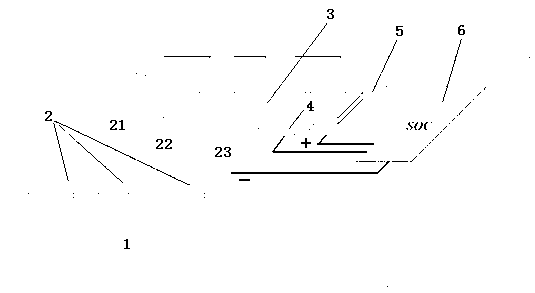

[0025] The seesaw type intelligent detection microwave power sensor of the present invention uses GaAs or Si material as the substrate 1, and the coplanar waveguide 2, sensing electrode 4, driving electrode 5 and SOC circuit 6 are arranged on the substrate 1, and the coplanar waveguide 2 is composed of The first ground line 21 of the coplanar waveguide, the signal line 22 of the coplanar waveguide and the second ground line 23 of the coplanar waveguide are formed. A seesaw-type double-ended cantilever beam 3 perpendicular to the coplanar waveguide 2 is connected to the second ground wire 23 of the coplanar waveguide. A sensing electrode 4 and a driving electrode 5 are placed under the other end of the plate-type double-ended cantilever beam 3 , and the other side of the driving electrode 5 is a voltage intelligent compensation and measurement SOC circuit 6 . The microwave power sensor senses the power level of the microwave signal transmitted on the coplanar waveguide 2 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com