Antibacterial enamel material and preparation method and application thereof

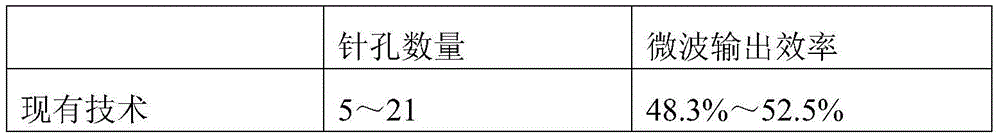

A technology of enamel and antibacterial agent, applied in the field of materials, can solve the problems such as the enamel technology needs to be improved, and achieve the effects of improving the physical and chemical effects of the surface, improving the compactness, and improving the adhesion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

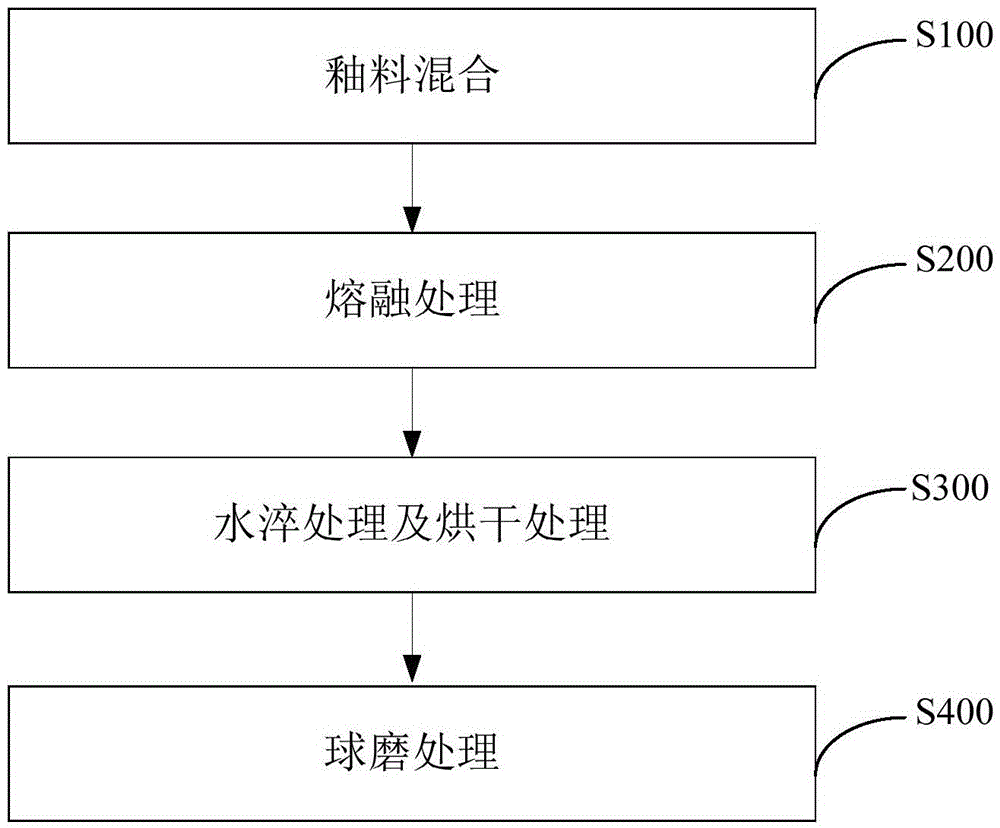

[0055]According to the following method, antibacterial enamel material is prepared:

[0056] 1) Alkali metal oxide 3% Li 2 O, 20% Na 2 O, 8% K 2 O, alkaline earth metal oxide 5% MgO, 3% SrO, the third main group metal oxide 8% Al 2 o 3 , 5% B 2 o 3 , the fourth main element oxide 20% SiO 2 , the fourth subgroup element oxide 15% TiO 2 , 2% ZrO 2 , the oxide of the fifth main group element 1% Sb 2 o 3 , 2% Bi 2 o 3 , oxides of subgroup V elements 3% V 2 o 5 , oxides of subgroup VI elements 1% MoO 3 , Group VIII metal oxide 2% Fe 2 o 3 , 1% cobalt oxide CoO, first subgroup metal oxide 1% CuO, lanthanide oxide 0.02% Ce 2 o 3 , Antibacterial agent 0.01% nano silver, 0.01% ZnO. Melt in a kiln at 1100°C, place the melted material in cold water for water quenching, put the water quenched frit in an oven to dry, and obtain the frit;

[0057] 2) The frit obtained in 1) is ball-milled to obtain a glaze powder with a mesh size of more than 300, and then an enamel mate...

Embodiment 2

[0059] According to the following method, antibacterial enamel material is prepared:

[0060] 1) Alkali metal oxide 2% Li 2 O, 15% Na 2 O, 5% K 2 O, alkaline earth metal oxide 3% MgO, 3% BaO, 2% SrO, the third main group metal oxide 10% Al 2 o 3 , 2% B 2 o 3 , the fourth main element oxide 30% SiO 2 , the fourth subgroup element oxide 12% TiO 2 , 5% ZrO 2 , the oxide of the fifth main group element 1% Sb 2 o 3 , 1% Bi 2 o 3 , oxides of subgroup V elements 2% V 2 o 5 , oxides of subgroup VI elements 2% MoO 3 , cobalt oxide CoO 3% of metal oxides of group VIII, CuO of 2% of metal oxides of the first subgroup, 0.01% Ce of lanthanide oxides 2 o 3 , 0.01% Yb 2 o 3 , antibacterial agent 0.01% AgNO 3 , 0.01% ZnO. Place it in a kiln at 1100°C for melting, put the melted material into cold water for water quenching treatment, put the water quenched frit in an oven for drying to obtain frit;

[0061] 2) The frit obtained in 1) is ball-milled to obtain a glaze powder...

Embodiment 3

[0063] According to the following method, antibacterial enamel material is prepared:

[0064] 1) Alkali metal oxide 5% Na 2 O, 10% K 2 O, alkaline earth metal oxide 5% MgO, 4% BaO, 3% SrO, the third main group metal oxide 10% Al 2 o 3 , 6% B 2 o 3 , the fourth main element oxide 32% SiO 2 , the fourth subgroup element oxide 7% TiO 2 , 8% ZrO 2 , the oxide of the fifth main group element 1% Sb 2 o 3 , 2% Bi 2 o 3 , oxides of subgroup V elements 2% V 2 o 5 , oxides of subgroup VI elements 1% MoO 3 , Group VIII metal oxide 2% cobalt oxide CoO, 1% Fe 2 o 3 , first subgroup metal oxide 1% CuO, lanthanide oxide 0.02% Yb 2 o 3 , antibacterial agent 0.01% nano silver, 0.01% AgNO 3 , 0.01% ZnO. Place it in a kiln at 1100°C for melting, put the melted material into cold water for water quenching treatment, put the water quenched frit in an oven for drying to obtain frit;

[0065] 2) The frit obtained in 1) is ball-milled to obtain a glaze powder with a mesh size of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com