Novel high-power microwave vacuum ceramic window

A high-power microwave and vacuum ceramic technology, applied in the microwave field, can solve the problems of inaccurate and rapid monitoring, strict precision requirements, small thermal conductivity, etc., to reduce the probability of rupture, less demanding processing requirements, and vacuum tightness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

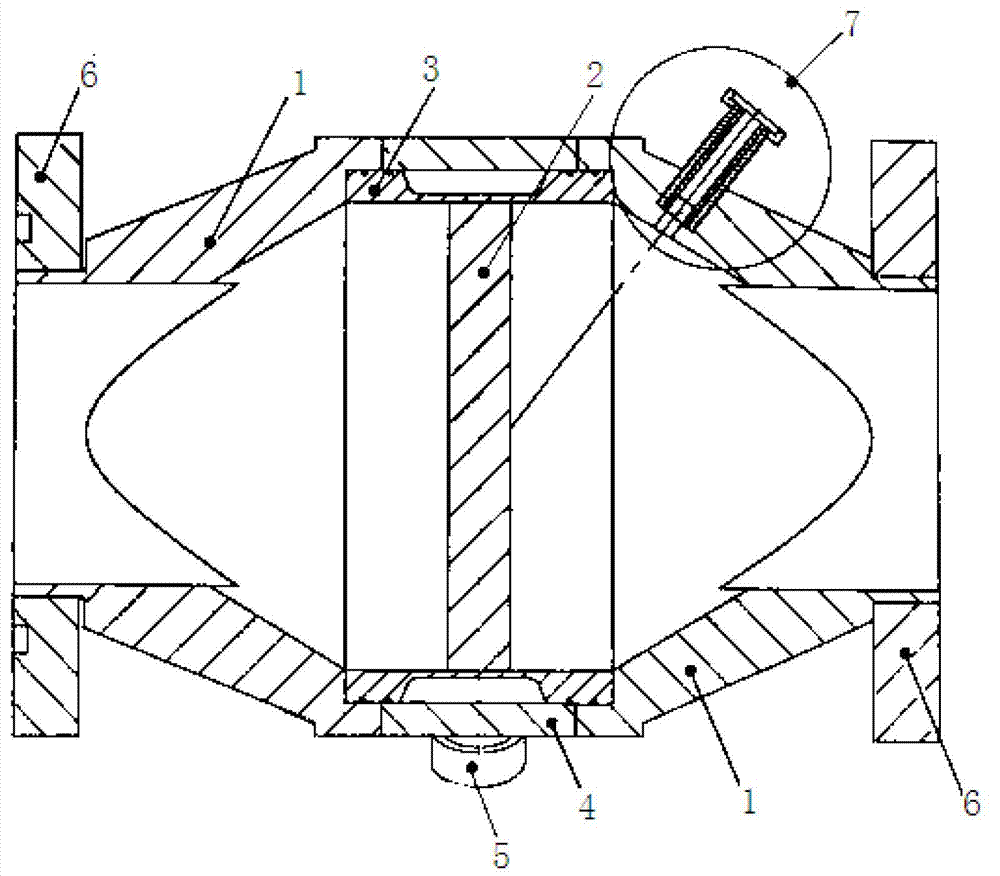

[0010] like figure 1 As shown, a new type of high-power microwave vacuum ceramic window includes two tapered windows 1 placed symmetrically on the left and right and a ceramic sheet 2 in the middle. The opening of the tapered window 1 is small at one end It is a rectangular waveguide, one end with a large opening is a circular waveguide, and a thick-walled structure is used to increase the heat capacity. The outer side of the ceramic sheet 2 is provided with a circular waveguide window frame 3, and the ceramic sheet 2 is along the radial direction placed, the outside of the window frame 3 is covered with an outer water jacket 4, and the outer water jacket 4 is welded with a water inlet joint 5 and a water outlet joint. The cooling water enters the ceramic window water tank from the water inlet joint 5 to cool the ceramic sheet The joint flows out, and the left and right ends of the window frame 3 and the outer water jacket 4 are assembled and connected with the circular wavegu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com