Silicon-based multichannel TR assembly and design method

A multi-channel, silicon-based technology, applied in the field of radio frequency microsystems, can solve the problems of reduced volume, processing accuracy affecting component volume, cost increase, etc., and achieves the effect of high precision and excellent microwave performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

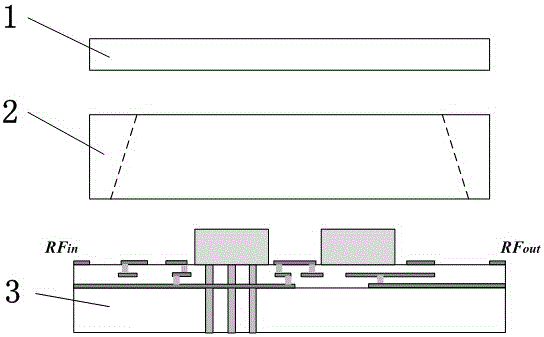

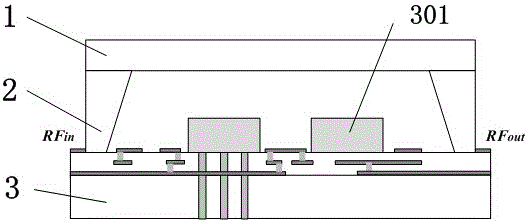

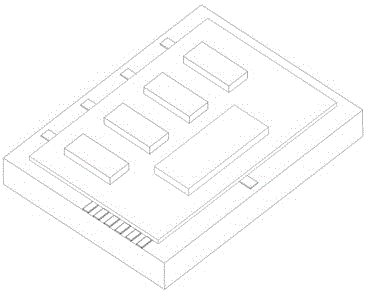

[0027] Such as Figure 1-5 As shown, silicon-based multi-channel TR components include silicon-based substrates, microwave and digital monolithic integrated circuits, and high-resistance silicon silicon caps; the top metal of the silicon-based substrate adopts a three-layer wiring design, and the surface of the silicon-based substrate uses multiple layers of low dielectric constant The dielectric material is used for isolation between metal layers and surface passivation protection. Metal through holes are used between the upper and lower metals to achieve interconnection. The surface of the silicon-based substrate integrates resistors, capacitors, power dividers, and filter passive components to achieve Miniaturization of the source device, multiple silicon-based metal vias (TSV) are made inside the silicon-based substrate as the grounding of the microwave chip, the heat dissipation channel of the internal high-power components, and the vertical transmission of microwave signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com