Double-lug sealing multifunctional high-locking nut

A high-lock nut, multi-functional technology, applied in the direction of nuts, engine seals, threaded fasteners, etc., to achieve the effect of controlling material utilization, high safety and reliability, and light material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

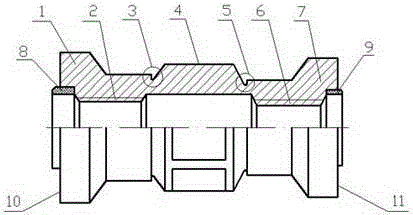

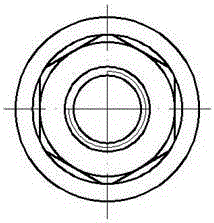

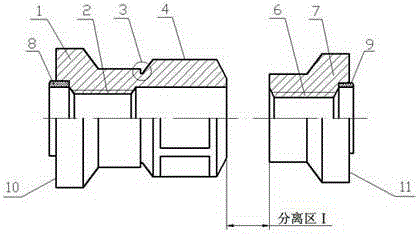

[0026] A double-ear sealed multifunctional high-lock nut, including nut body A1, thread A2, broken neck groove A3, hexagon 4, broken neck groove B5, thread B6, nut body B7, nylon ring A8, nylon ring B9, nut body End face A10, nut body end face B11; said nut body A1 is provided with threads A2; said nylon ring A8 is arranged on the nut body A1 close to the nut body end face A10; said nut body A1 is connected to one end of the hexagon 4; A broken neck groove A3 is provided between the body A1 and the hexagonal body 4; the nut body B7 is provided with a screw thread B6; the nylon ring B9 is arranged on the nut body B7 close to the nut body end face B11; the nut body B7 and The other ends of the hexagon 4 are connected, and a broken neck groove B5 is provided between the nut body B7 and the hexagon 4 .

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com