Patents

Literature

60results about How to "Meet air tightness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

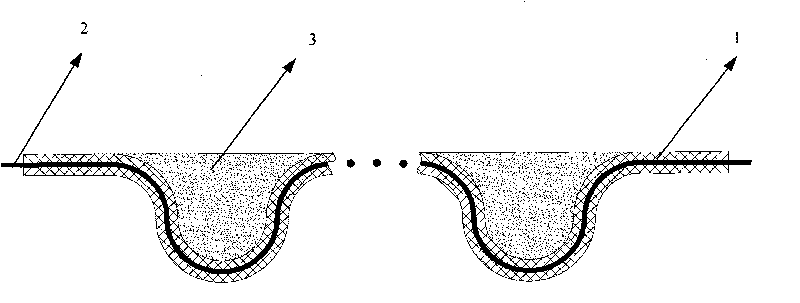

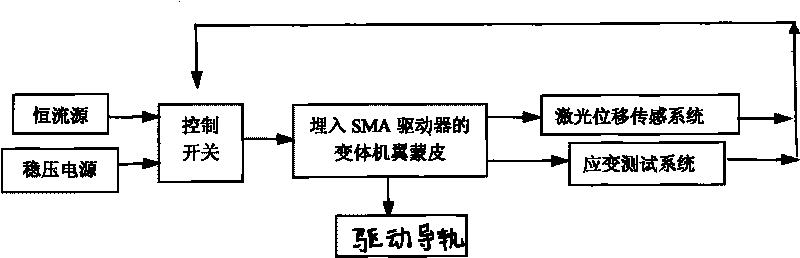

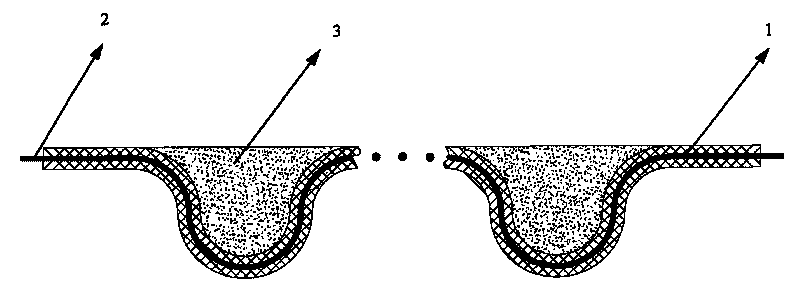

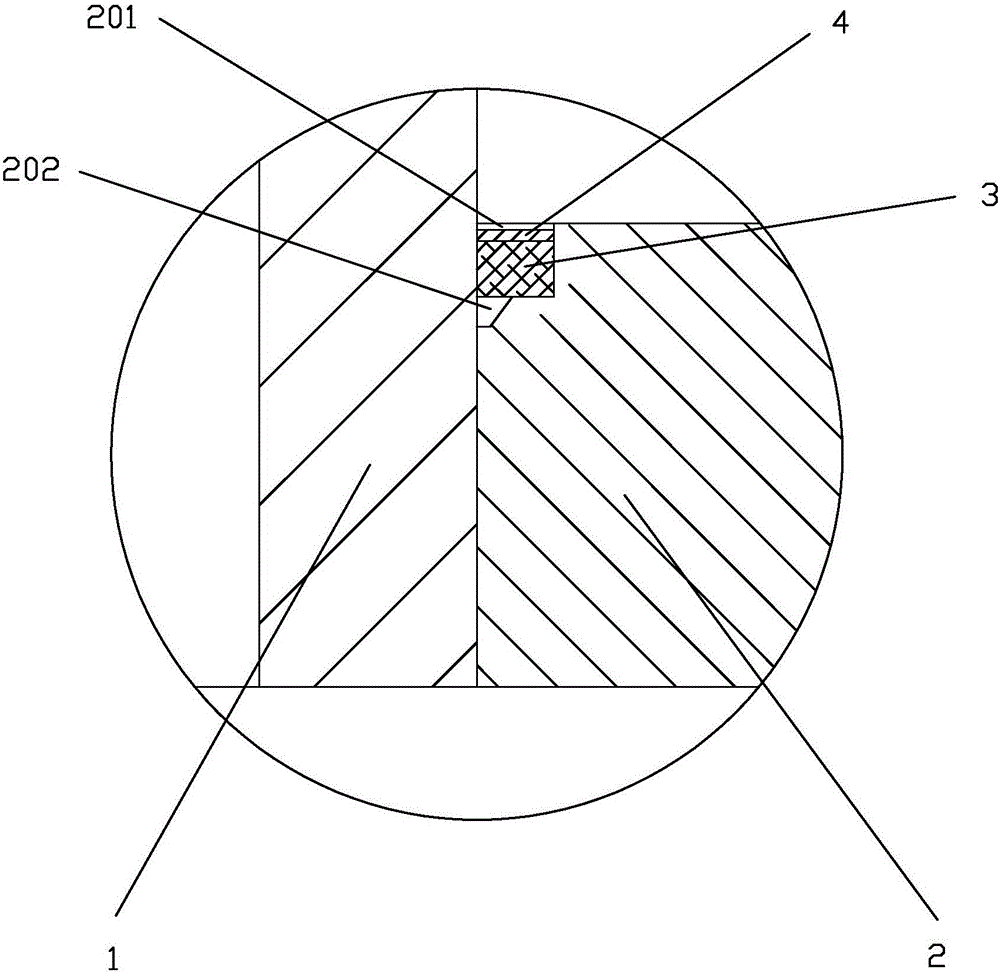

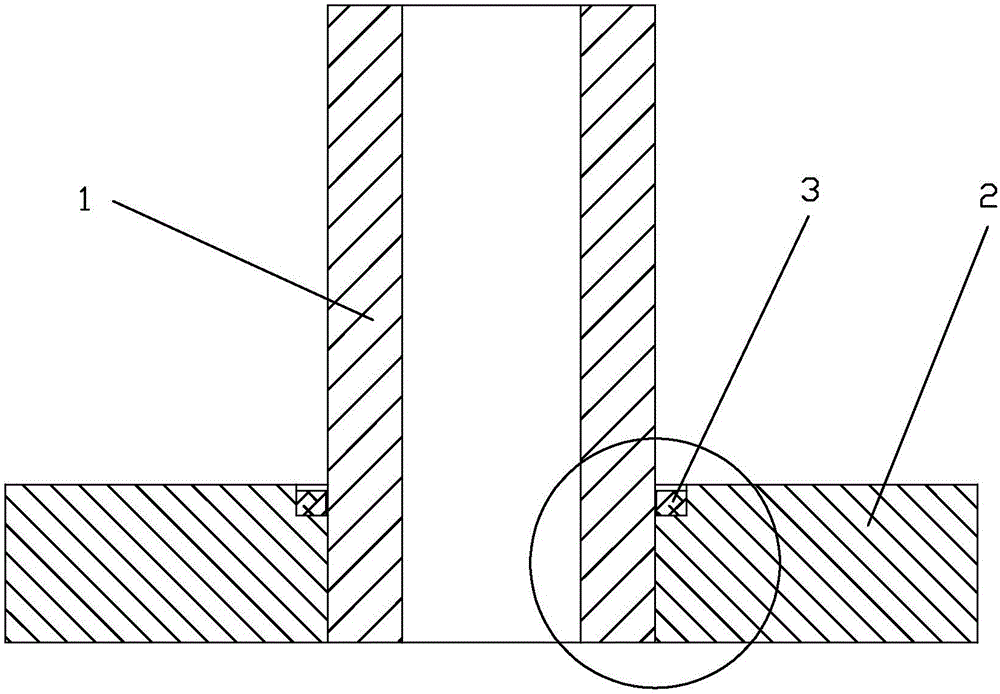

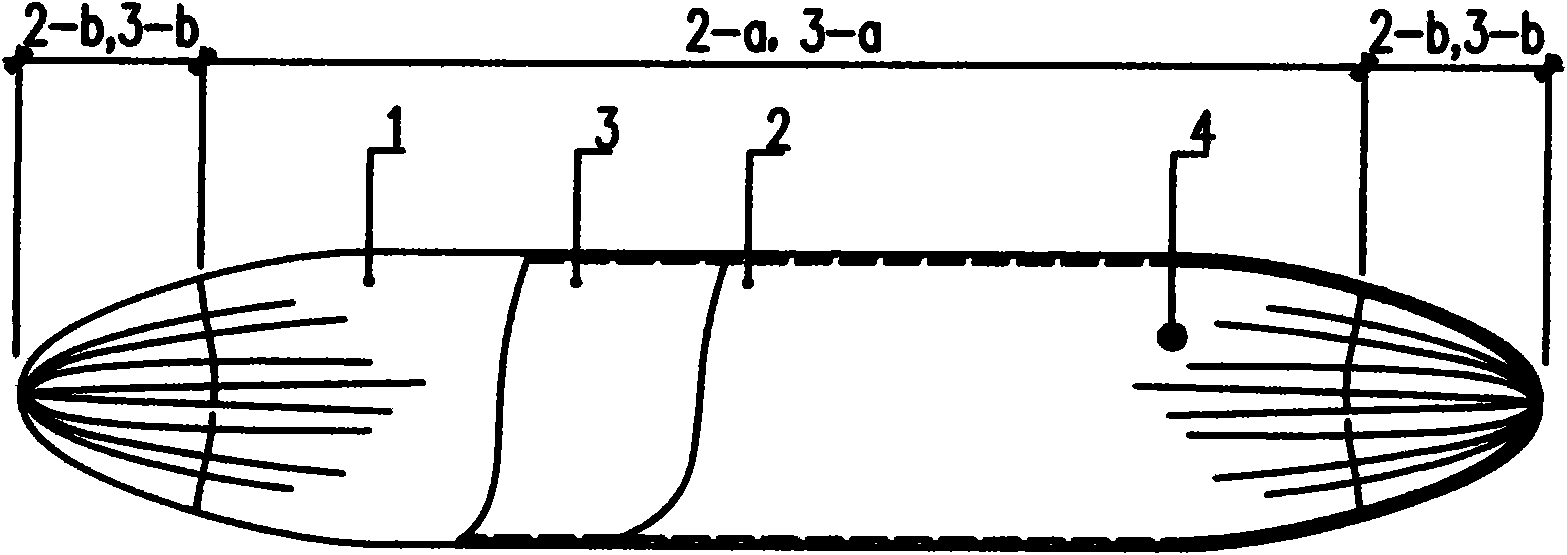

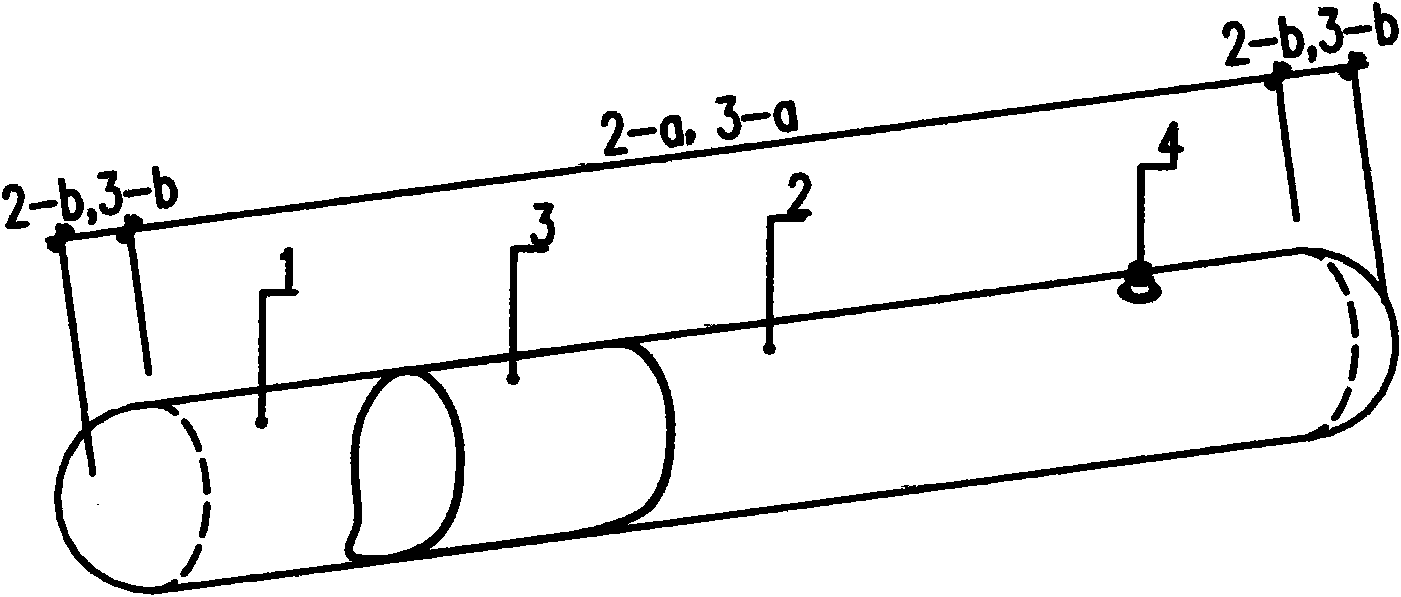

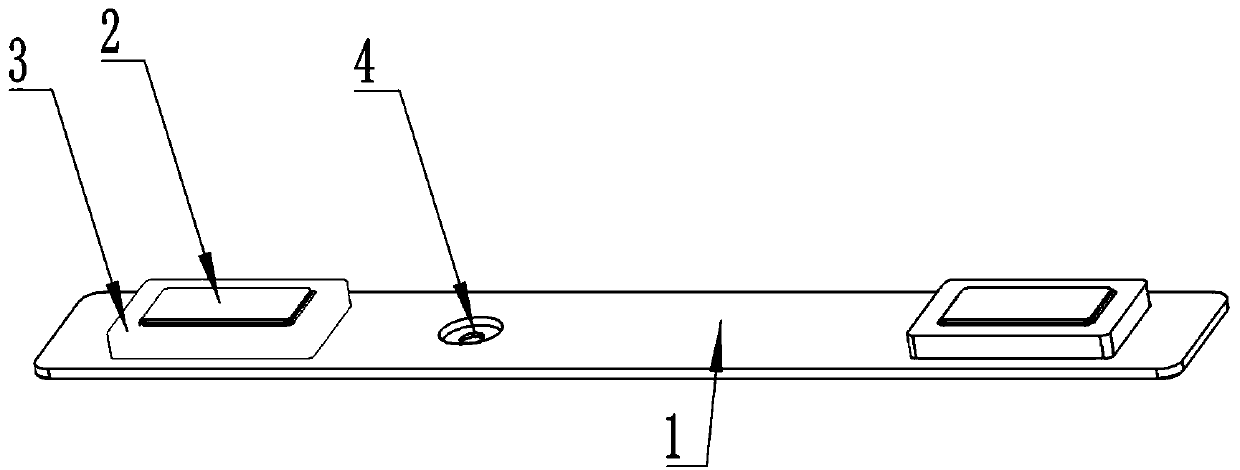

Skin of morphing wing and drive method thereof

InactiveCN101708772AImprove flexibilityLarge amount of deformationWingsMorphing wingRoom temperature

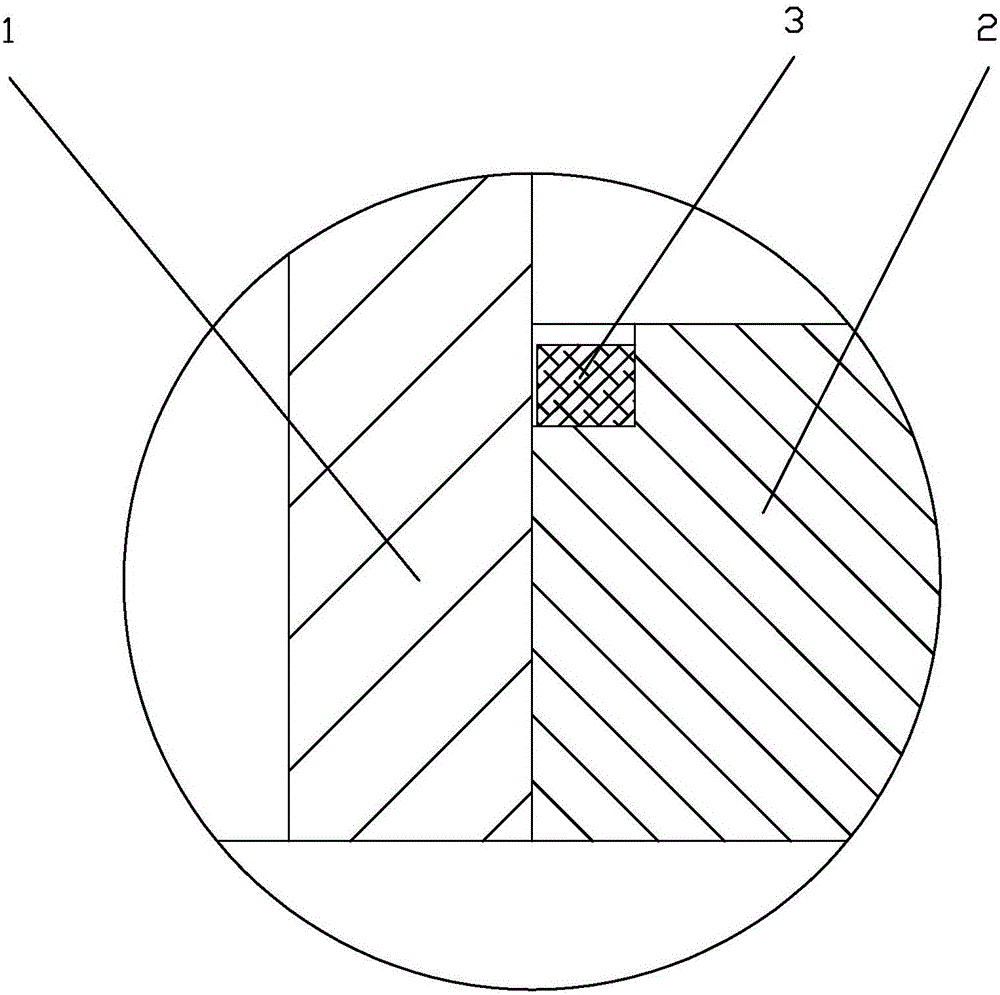

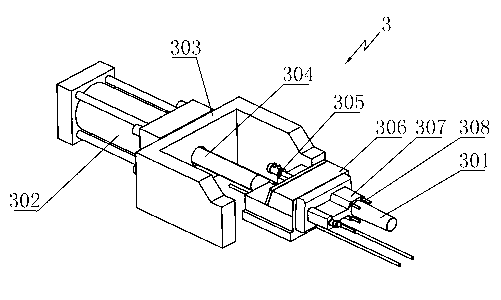

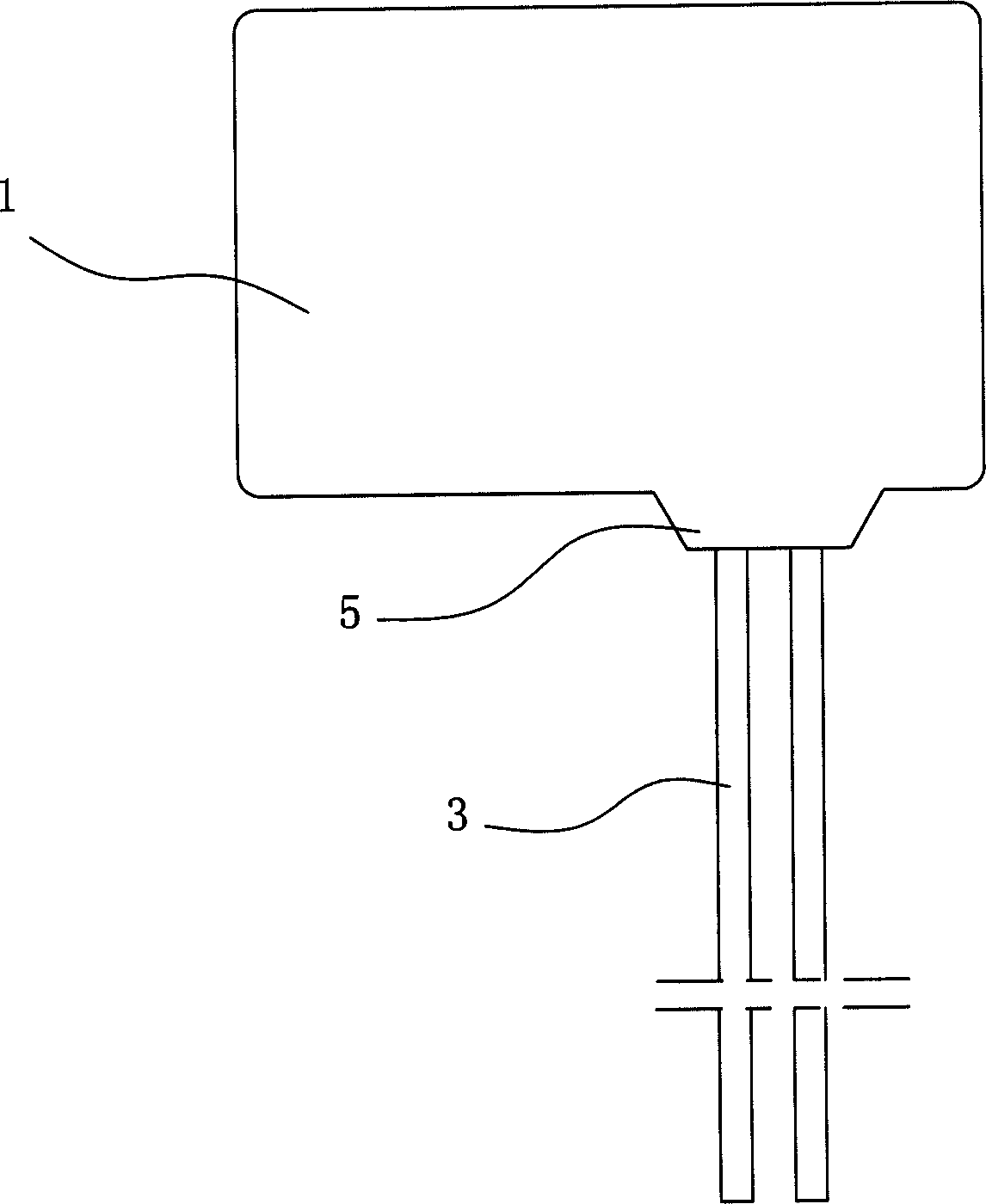

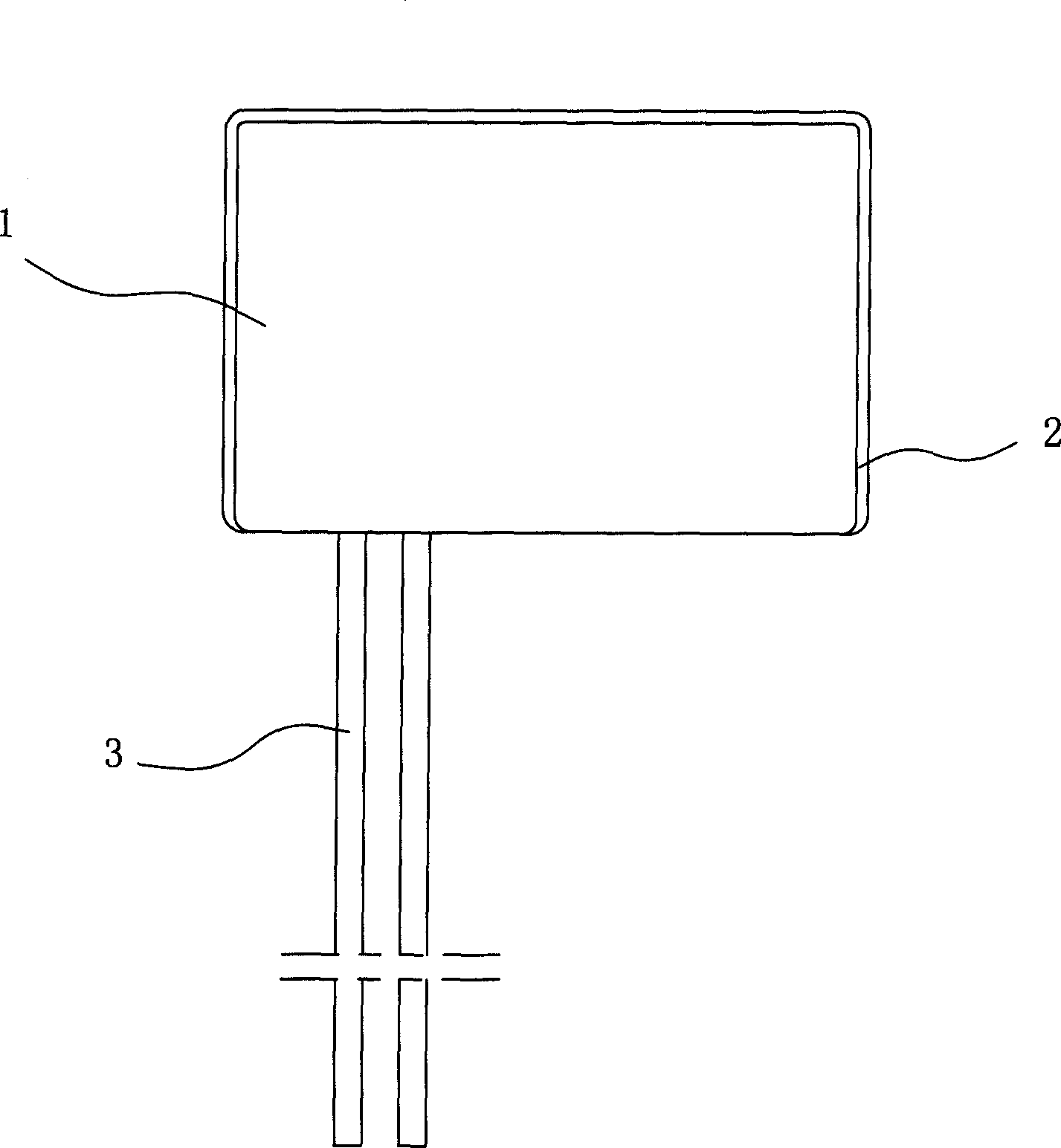

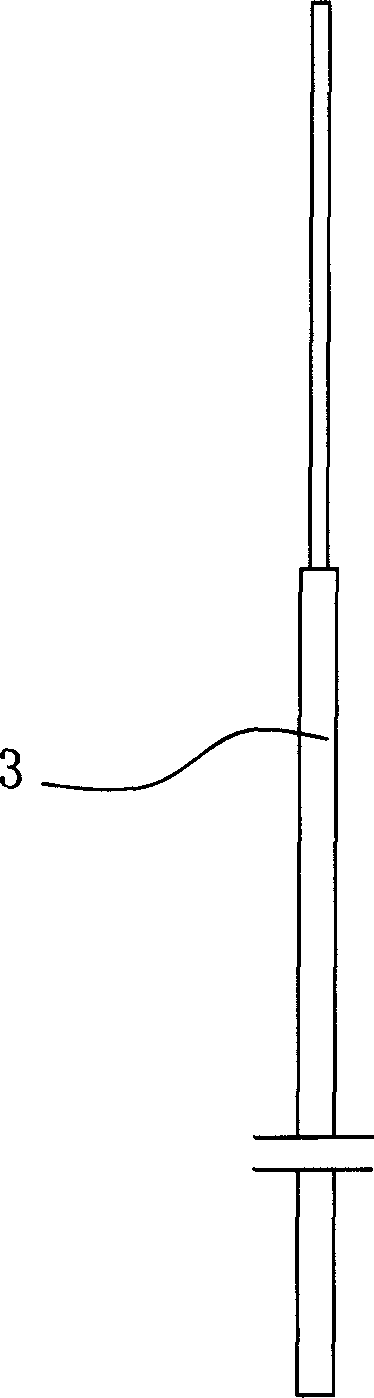

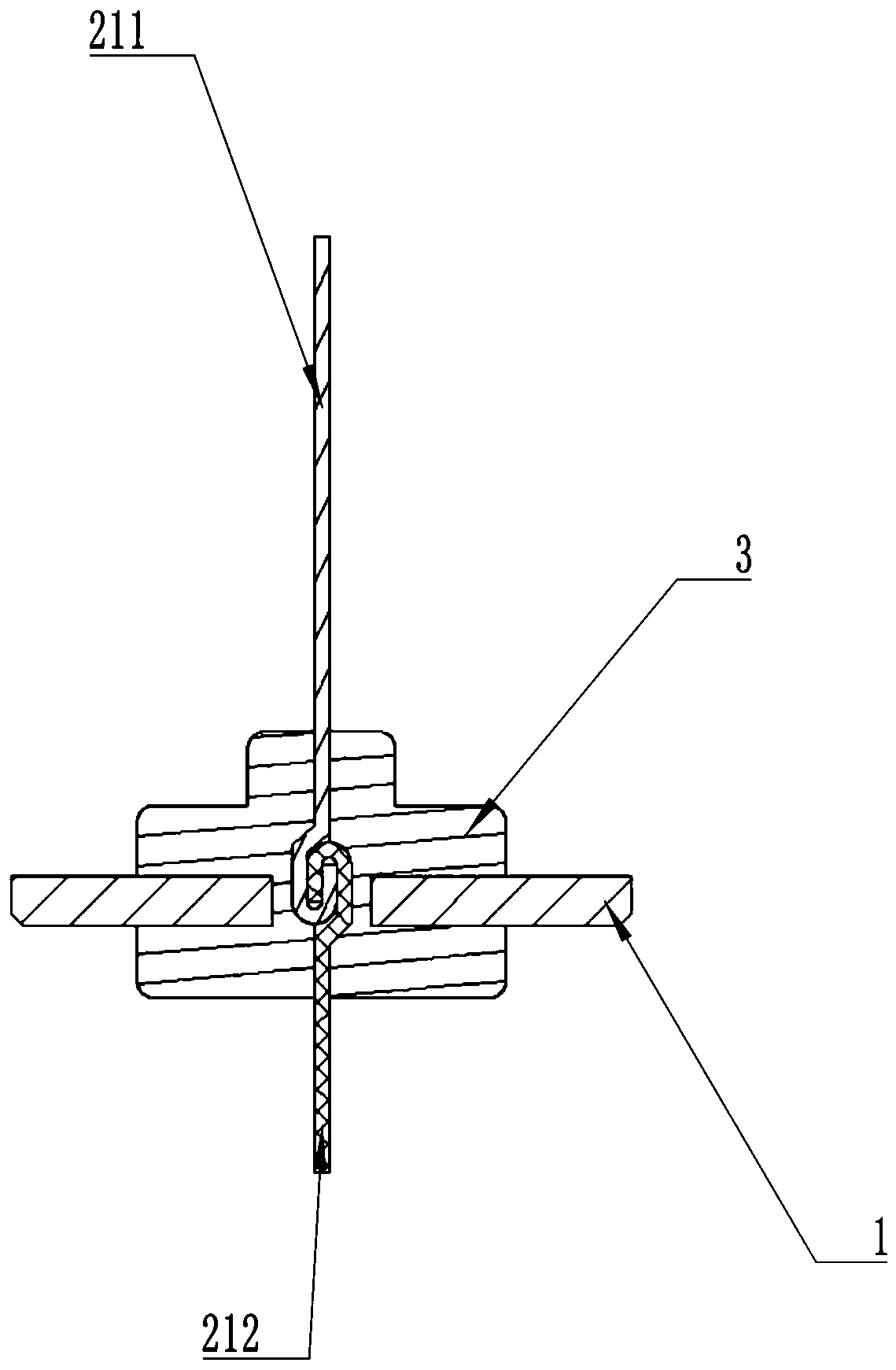

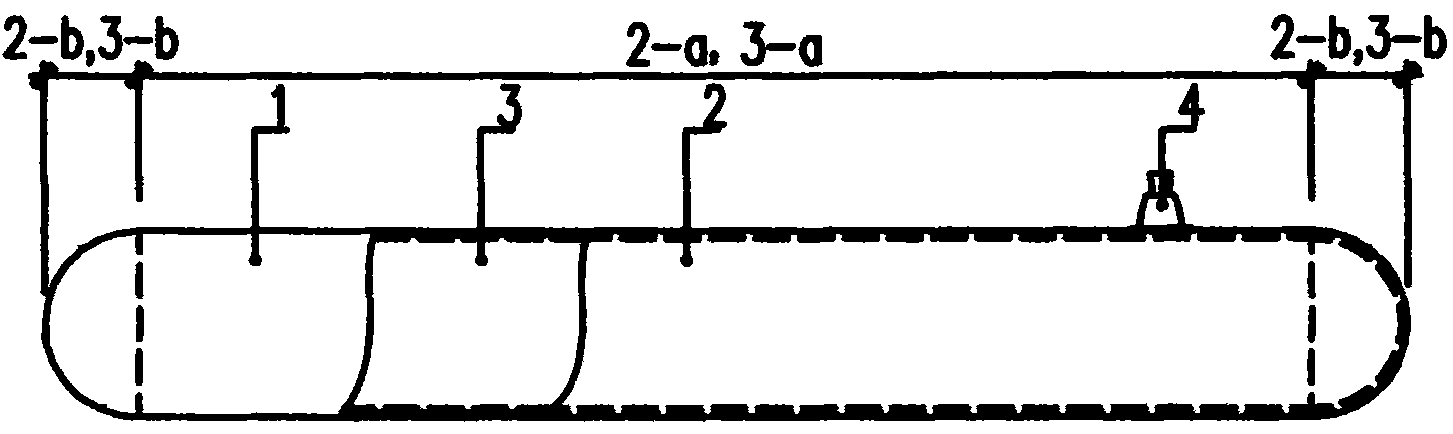

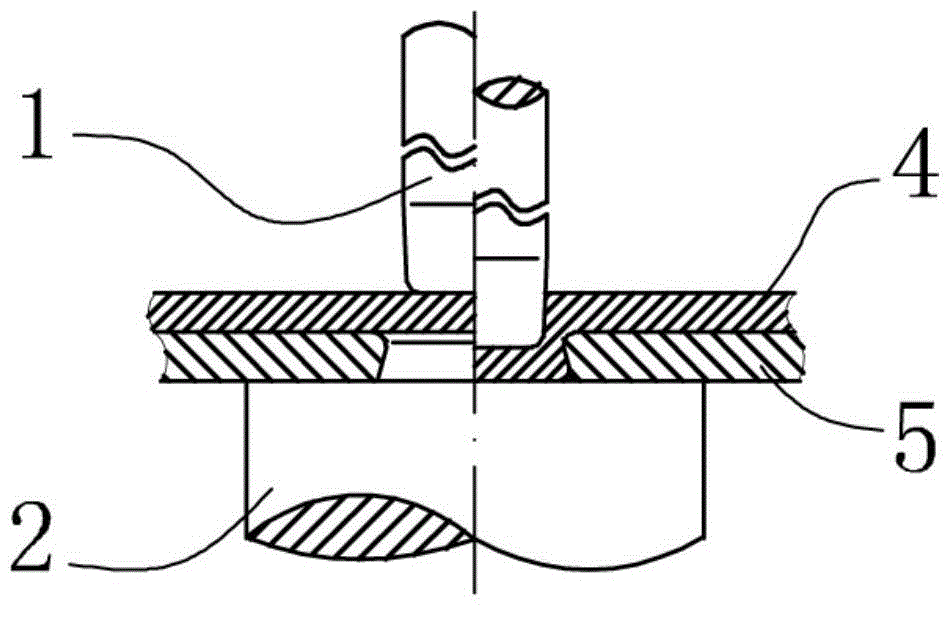

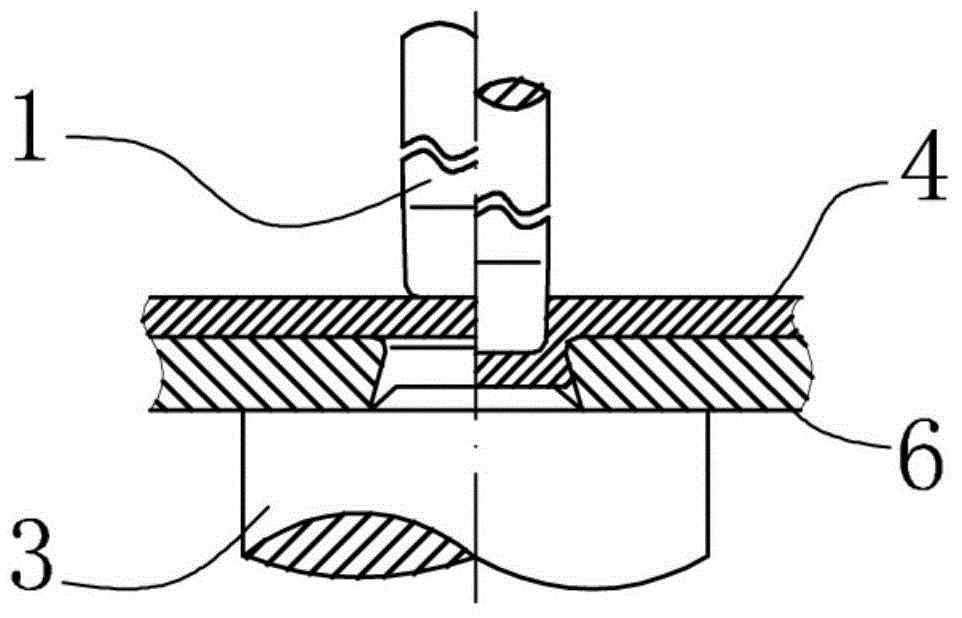

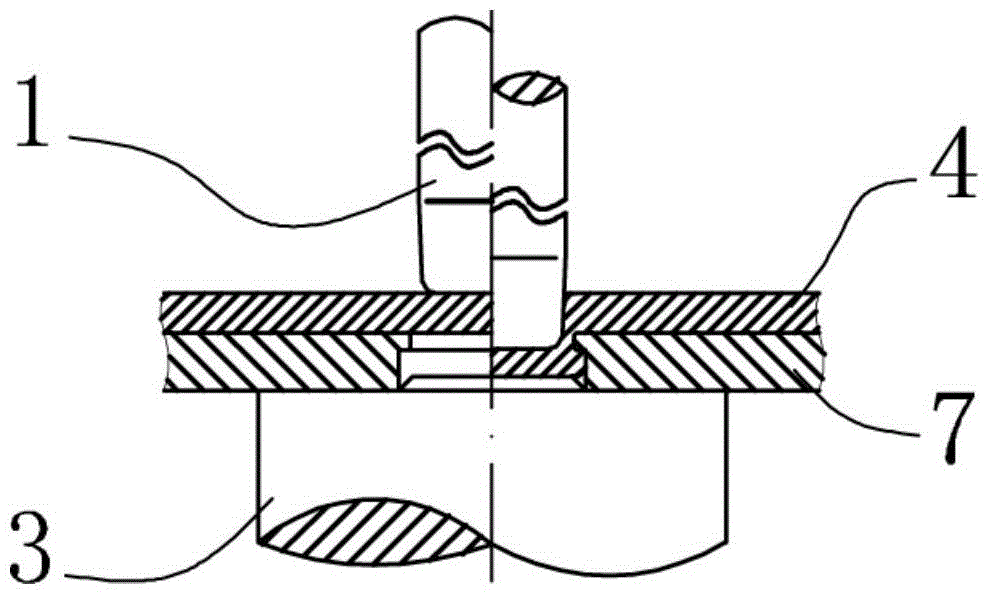

The invention provides a skin of a morphing wing, which is made from fiber-reinforced composite material (1). The skin is characterized in that: a shape memory alloy driver (2) is arranged between the two layers of the fiber-reinforced composite material (1); the wave trough of the upper layer fiber-reinforced composite material is internally filled with silica-based rubber (3) for meeting the requirements of smoothness, continuity and whole gas tightness on the surface of the wing; the fiber-reinforced composite material (1) and the shape memory alloy driver (2) are jointly pressed into to a corrugated structure under room temperature; the shape memory alloy driver (2) is in the shape of a high-temperature memory straight line; and the silica-based rubber (3) can be solidified under normal temperature. The invention also provides a drive method of the skin of the morphing wing. The skin of the morphing wing has the corrugated structure, thereby having high flexibility, large morphing amount and fast morphing response speed on the morphing direction, having high carrying capability on the perpendicular morphing direction, and having simple structure, light weight and reliable performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

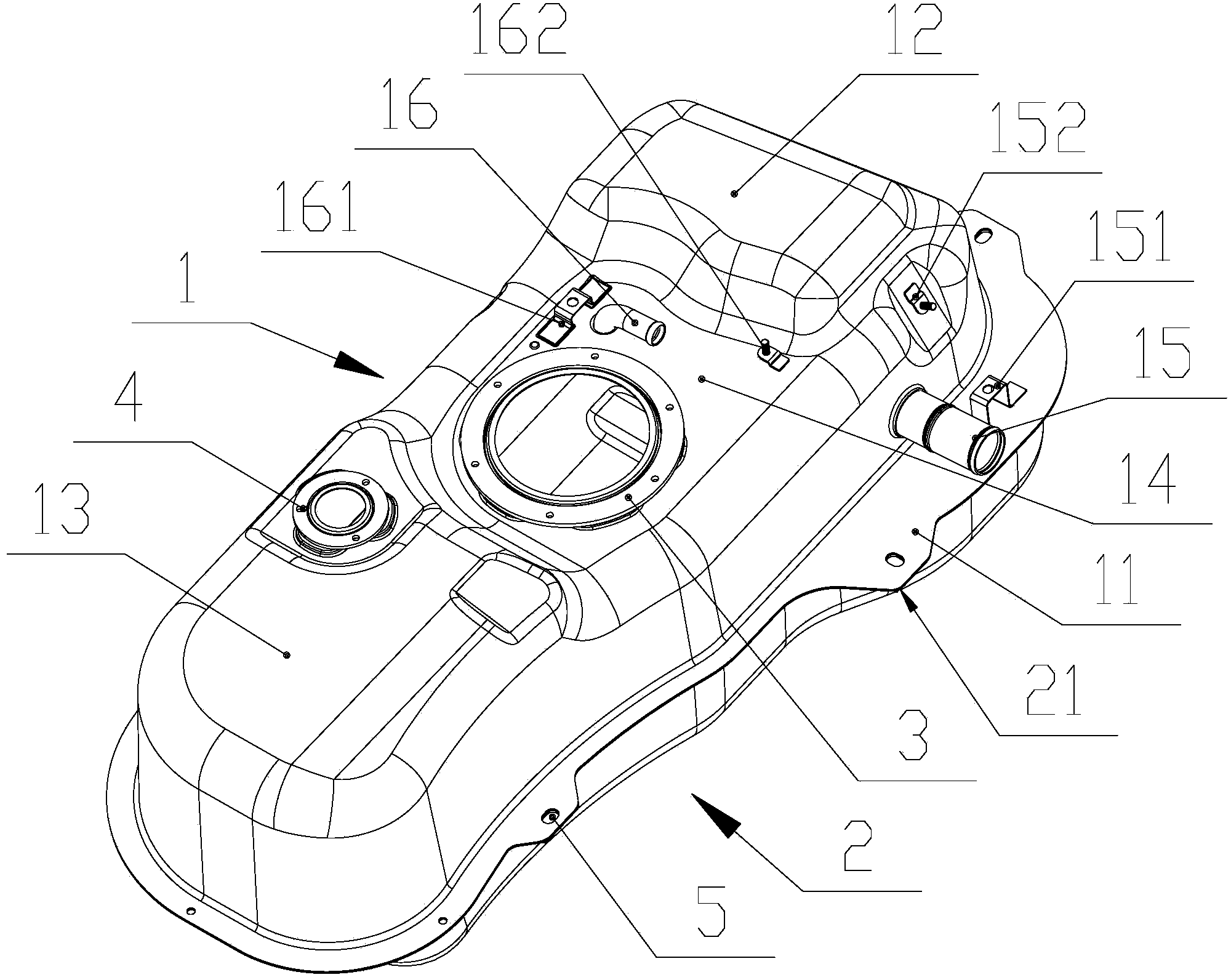

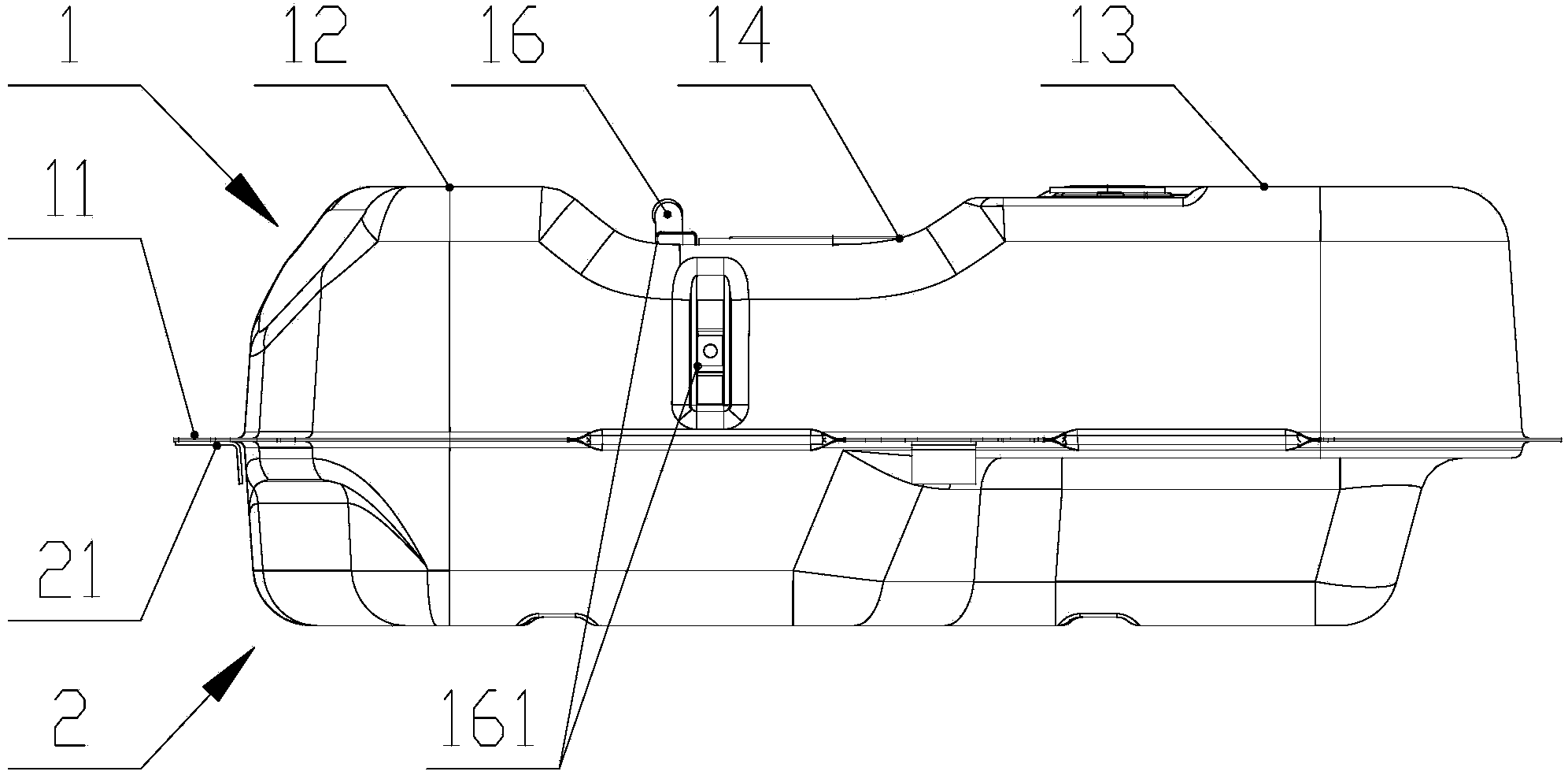

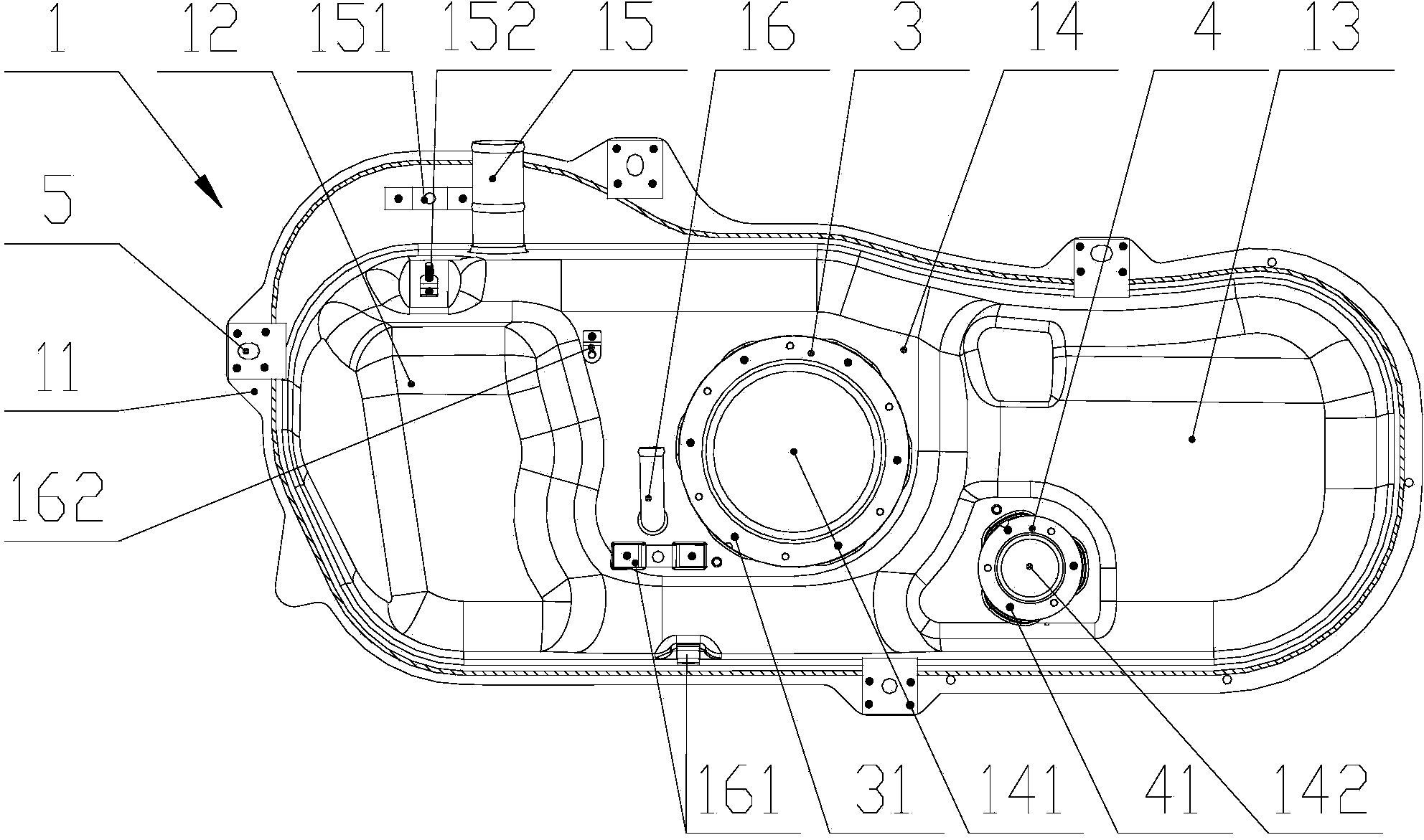

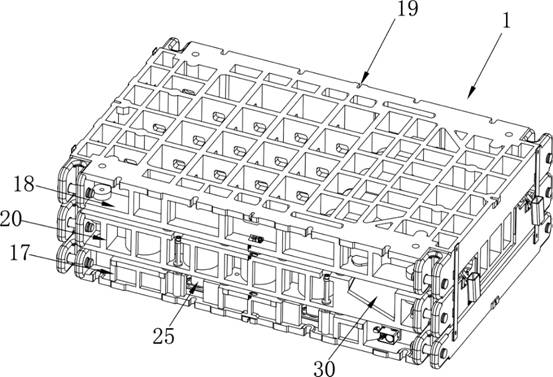

Automobile fuel tank

ActiveCN104175871AMeet air tightness requirementsSmall footprintFuel supplyInterior spaceMetallic materials

The invention discloses an automobile fuel tank which is low in cost. An upper tank body and a lower tank body are connected firmly and stably. The occupied vehicle interior space is small after a fuel pump and a turning-over valve are installed. The fuel tank comprises the upper tank body and the lower tank body arranged on the lower side of the upper tank body. The upper tank body and the lower tank body are made of metal materials respectively. An upper tank-closing ring edge is arranged on the portion, along the edge of the lower side, of the upper tank body. A lower tank-closing ring edge is arranged on the portion, along the edge of the upper side, of the upper tank body. The upper tank-closing ring edge and the lower tank-closing ring edge are matched and welded together in a rolling mode. The upper tank body is a concave casing with the front end and the rear end being protruding faces and the middle portion being a sunken face. The sunken face of the upper tank body is provided with a fuel pump installing flange and a turning-over valve installing flange. The upper tank body is further provided with an oil filling pipe and a ventilation pipe. The cost of the fuel tank is far smaller than that of a plastic fuel tank. The upper tank body and the lower tank body are connected firmly and stably, and influence of vibration is small; due to the sunken face, the tail portion of the installed fuel pump and the tail portion of the turning-over valve are prevented from protruding or protruding excessively.

Owner:重庆双五汽车零部件有限公司

Sintering welding process of high-air-tightness powder metallurgical part

ActiveCN105880771AHigh strengthImprove air tightnessWelding/cutting media/materialsSoldering mediaWater coolingCopper

The invention discloses a sintering welding process of a high-air-tightness powder metallurgical part. The process comprises the following steps: a, combining powder metallurgical forming green bodies, and assembling and positioning the two green bodies, wherein a clearance between the two green bodies is 0.1 to 0.4mm according to the requirement; b, feeding welding flux; c, arranging a red copper sheet used for welding, wherein the red copper sheet is arranged on the welding flux; d, sintering through a furnace, wherein four areas are arranged in the furnace and include, in order, a pre-sintering dewaxing area which is at the temperature of 580 to 630 DEG C, a first welding area which is at the temperature of 950 to 1000 DEG C, a sintering and secondary welding area which is at the temperature of 1100 to 1200 DEG C, and a circulating water cooling area; e, moving out from the furnace, and cooling.

Owner:GUANGDONG DONGMU NEW MATERIALS

Silicon-based multichannel TR assembly and design method

ActiveCN105826275ARealize multiple functionsHigh precisionSemiconductor/solid-state device detailsSolid-state devicesSpecific functionHigh resistivity silicon

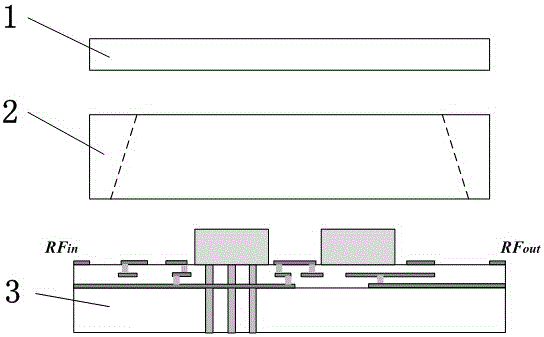

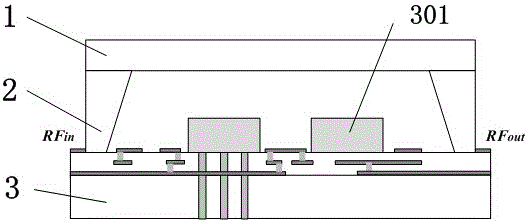

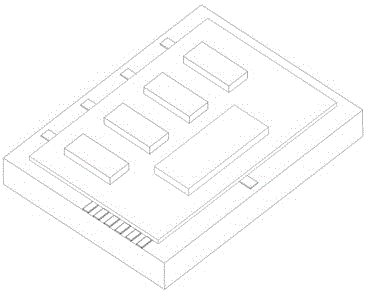

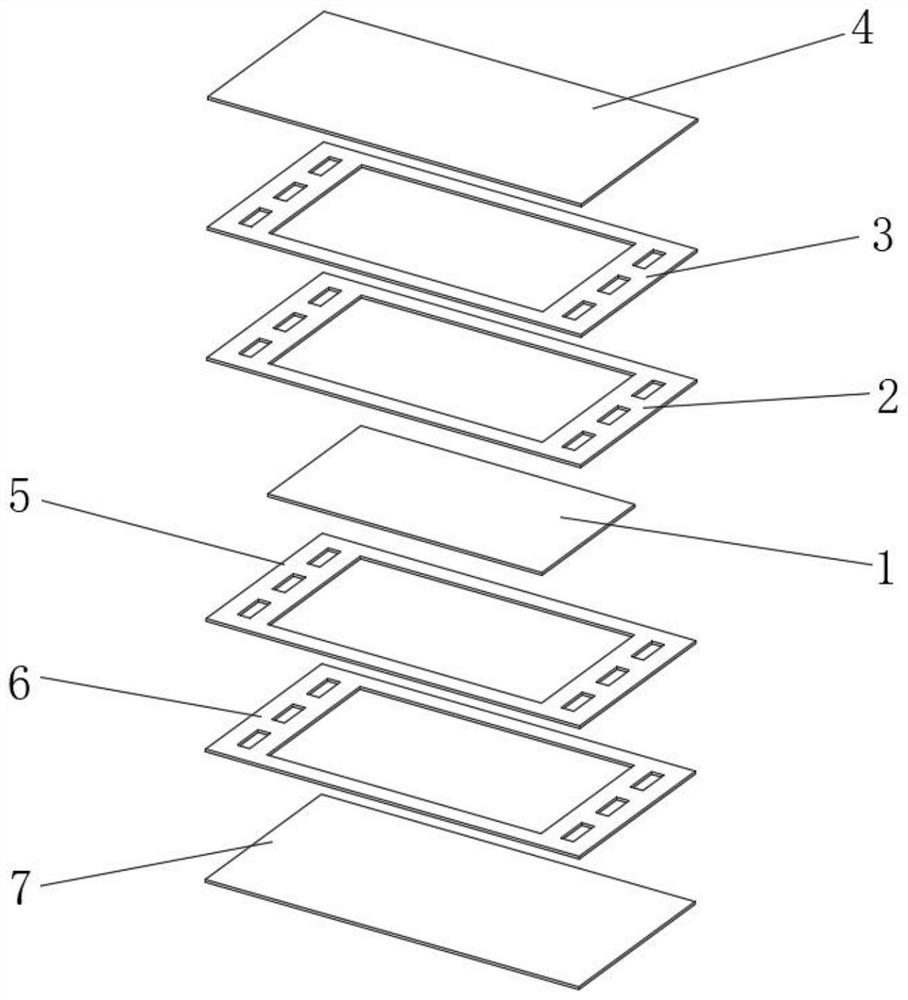

The invention discloses a silicon-based multichannel TR assembly. The silicon-based multichannel TR assembly, in the structure, comprises a multilayer silicon-based substrate 1 with signal transmission, passive element integration and chip carrier, a microwave single chip integrated circuit and a digital integrated circuit 2 for realizing various specific functions of the TR assembly, and a high-resistivity silicon cap 3 whose top is used for sealing and protection, wherein the multilayer silicon-based substrate at least comprises three layers of metal wiring, metal adopts a Cu material, the silicon-based surface uses multiple layers of dielectric materials with a low dielectric constant for isolation between metal layers and surface passivation protection, multiple through silicon vias (TSV) are made inside the silicon-based substrate as cooling channels for microwave chip grounding and inner high-power consumption elements and key parts for microwave signal vertical transmission; and external control and microwave interfaces are arranged around the silicon-based material. The silicon-based multichannel TR assembly and the design method have the advantages that a multichannel TR assembly within 40 GHz can be realized, the microwave performance is excellent, and miniaturization and low cost of the TR assembly can be realized.

Owner:南京国博电子股份有限公司 +1

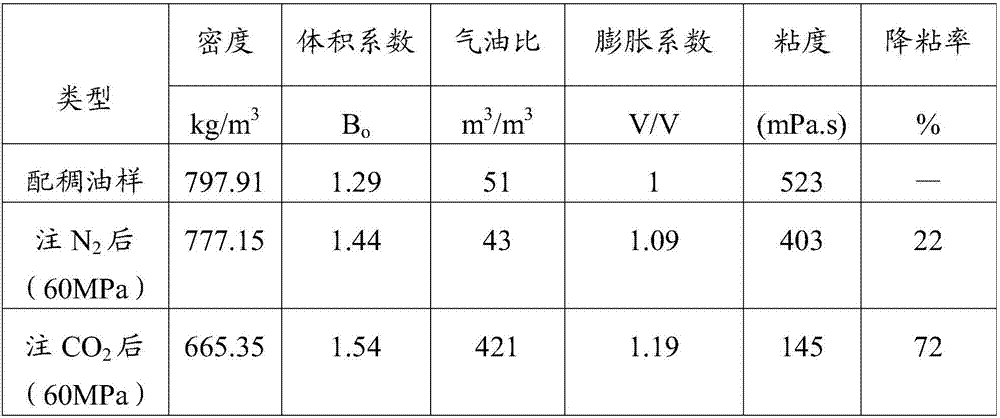

Oil production method of nitrogen and carbon dioxide composite huff and puff

InactiveCN106968651AAchieve solubilityRealize functionDrilling rodsFluid removalDissolutionOil production

The invention discloses an oil production method of nitrogen and carbon dioxide composite huff and puff. The oil production method comprises the following steps that an injection-production integrated pipe column is put downward to a target oil layer in an oil well; the top of the injection-production integrated pipe column is connected with gas injection devices and thin oil injection device on the ground, wherein the gas injection devices comprises the nitrogen injection device and the carbon dioxide injection device; the gas injection devices inject gas into the oil well through the injection-production integrated pipe column; after nitrogen, carbon dioxide and thin oil are injected, shut in well is conducted; when the pressure of an wellhead after shut in well is stable, blow-off is controlled through an oil nozzle; and after the wellhead pressure and the blow-off well liquid amount both are smaller than predetermined values, extracting starts to be conducted through the injection-production integrated pipe column. The nitrogen and the carbon dioxide jointly serve as one-time injection media, the nitrogen replaces attic oil in the high positions of the periphery of the well, the carbon dioxide achieves the functions of dissolution, viscosity reducing and expansion energy increasing on stratum thick oil, and by utilizing the double composite functions of gas cap energy increasing of the nitrogen and stratum viscosity reducing of the carbon dioxide, the recovery efficiency of an ultra-deep fracture-cavity type thick oil reservoir is increased.

Owner:CHINA PETROLEUM & CHEM CORP

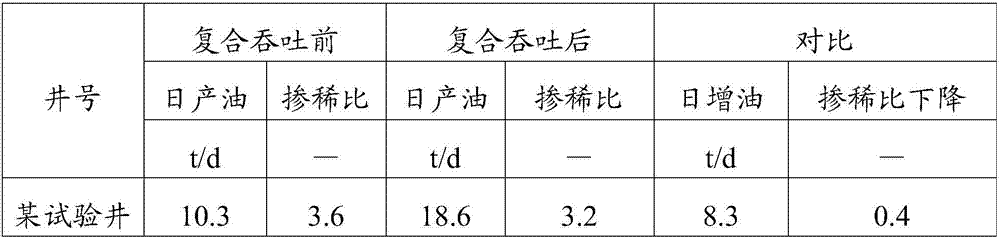

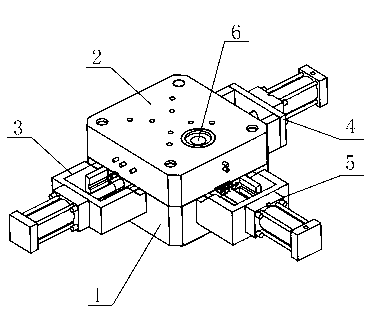

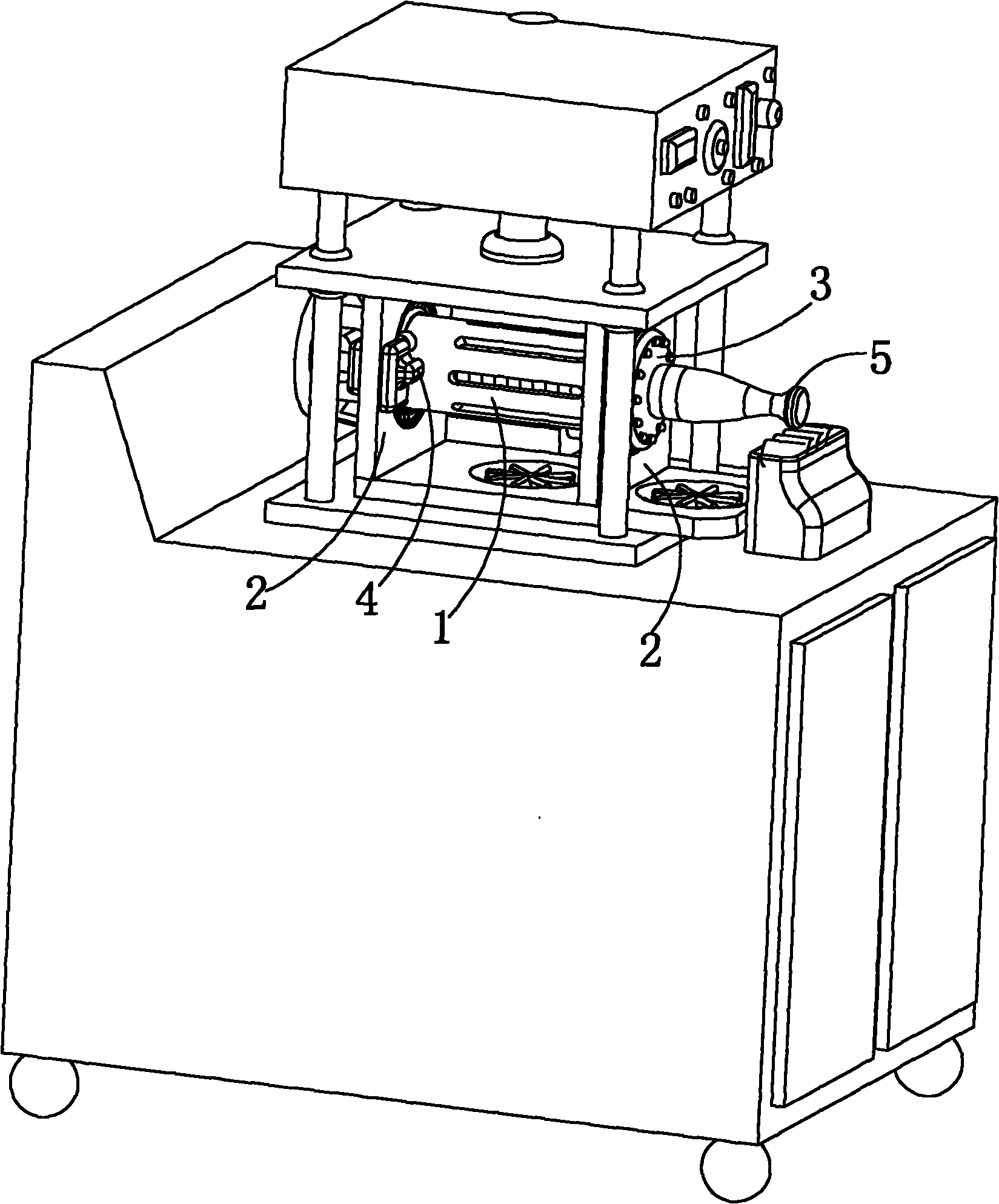

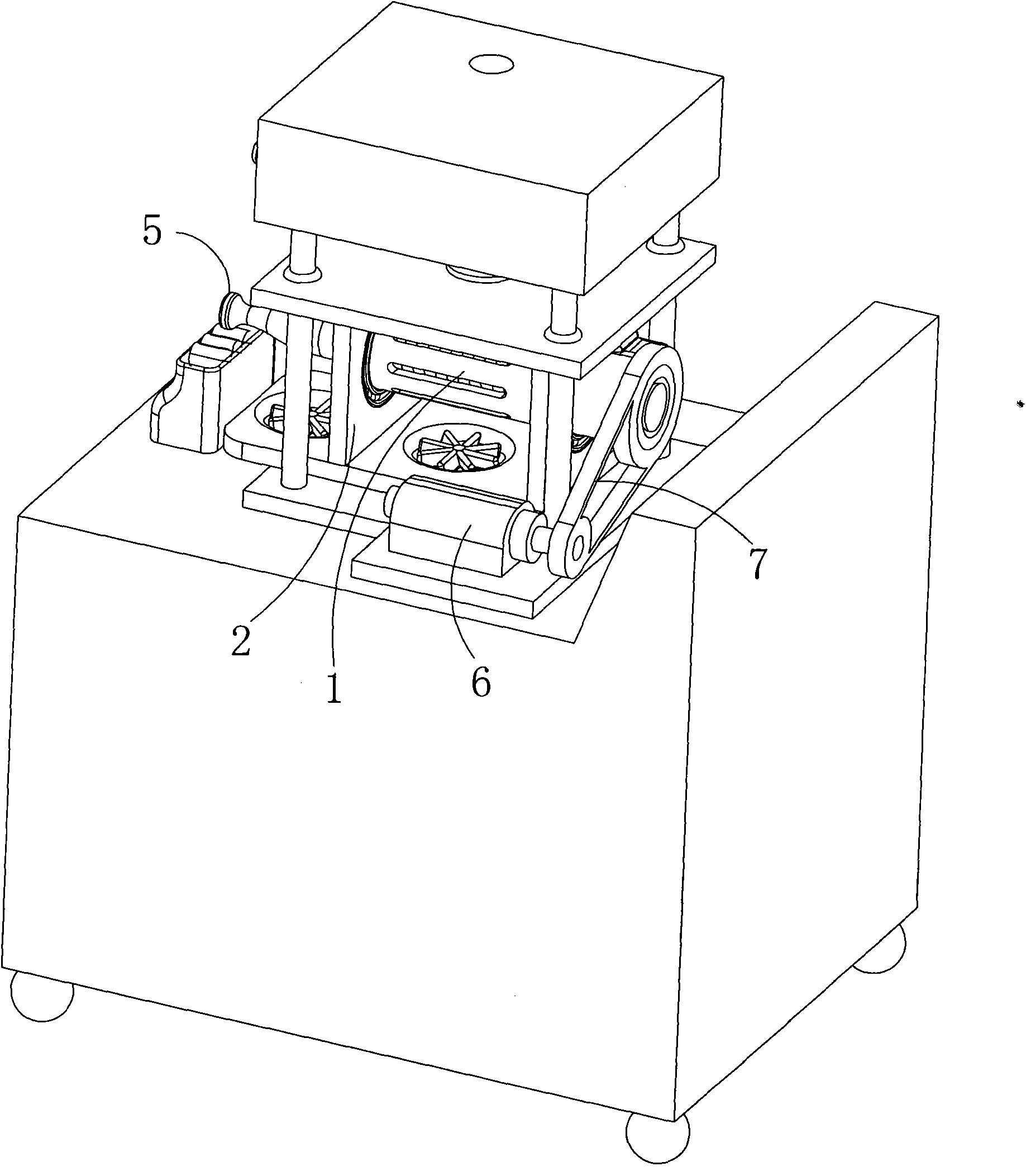

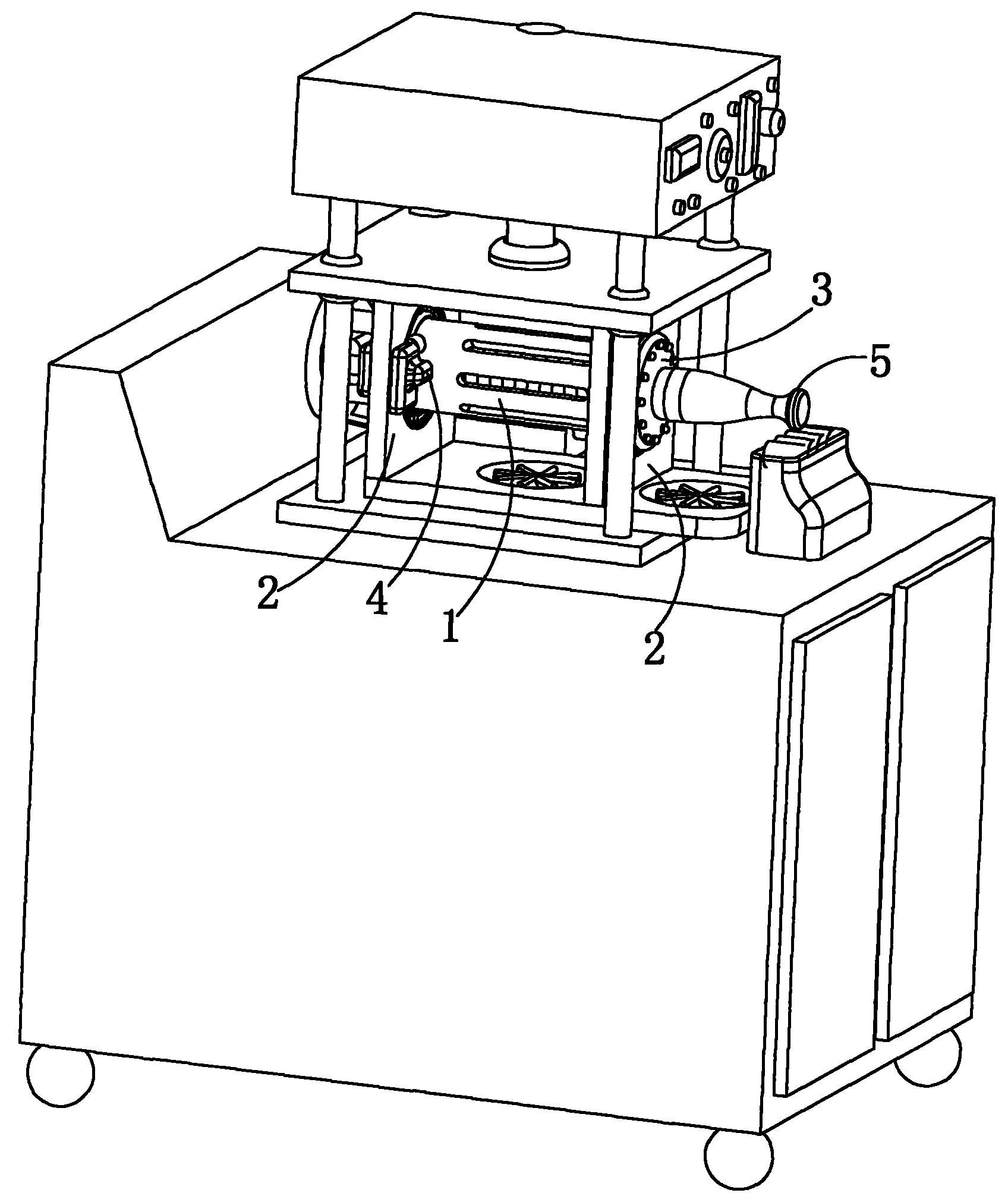

Die-casting die for pump bodies

The invention relates to a die-casting die for pump bodies and a method for manufacturing a pump body by using the die-casting die. The die-casting die comprises a fixed die frame, a fixed die, a movable die and a movable die frame, square slide rails are arranged between three side walls of the fixed die frame and three side walls of a corresponding fixed die groove respectively, a left core extracting device and a right core extracting device are mounted at two opposite slide rails respectively, a lower core extracting device is mounted at the other slide rail and comprises a fixed frame, an oil cylinder is fixedly connected to the fixed frame, the end of a pull rod of the oil cylinder is connected with a lower slider, the front end face of the lower slider is fixedly connected with a lower core block, a running gate is arranged at the top of the lower slider, a runner gate butted against the running gate is arranged on the rear side of the top of the lower core block, and the front end face of the lower core block is fixedly connected with multiple core rods. The die-casting die for the pump bodies is high in production efficiency, less prone to generation of air holes of the pump bodies, and low in production cost.

Owner:WUXI BOJIN PRECISION MACHINERY MFG

Air-inflated bag for measuring blood pressure and production method thereof

InactiveCN1849999AAchieve replacementSolve the pollution of the environmentEvaluation of blood vesselsAngiographyPhysical well beingBlood pressure

The present invention discloses an inflatable bag for measuring blood pressure and its making method. It includes a rectangular closed bag body and two air tubes which are fixedly connected with said bag body and communicated each other. It is characterized by that the described bag body is made up by using polyvinyl chloride, and the described air tubes are rubber tubes.

Owner:严文俊

Full-steel radial ply tyre inner liner air/tight layer rubber composition, and its mixing method

InactiveCN1850896AHigh molecular weightEvenly dispersedPneumatic tyre reinforcementsNaphthaHeat resistance

The invention relates to a gum innerliner for all-steel radial tyre inner covering. It is made up from 20 weight portions of natural glue, 80 portions bromination butyl glue, 0-0.5 weight portions chemical peptizer SJ-103, 50-70 weight portions of reinforcing agent black carbon, 1-5 portions magnesia, 1-3 portions stearic acid, 0-6 portions C5 petroleum resin, 0-6 portions equal dispersing agent UB4000, 10-15 portions aromatic naphtha, 1-5 portions white zinc, 1.0-2.0 portions accelerating agent DM, and 0.5-2.0 portions sulfur. It has good the thermal endurance, and good binding property.

Owner:JIANGSU GENERAL SCI TECH

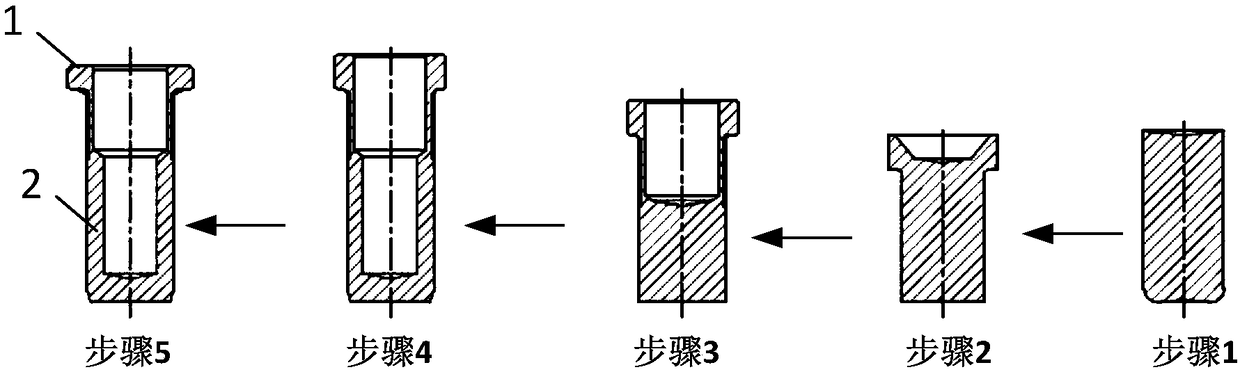

Process for manufacturing powder metallurgy pump shell

The invention discloses a process for manufacturing a powder metallurgy pump shell. The process for manufacturing the powder metallurgy pump shell specifically comprises the following steps of: 1) mixing powder and performing cold molding; 2) sintering; 3) performing steam processing; and 4) machining. The process for manufacturing the powder metallurgy pump shell provided by the invention is used for manufacturing cylinder shells of various pumps, the characteristic that a high-accuracy complex shape can be formed by a powder metallurgy mould at one time is utilized, the amount of machining is greatly reduced, the production efficiency is improved, and the energy consumption is reduced so as to fulfill the aim of producing products of the type by replacing the conventional casting mode.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

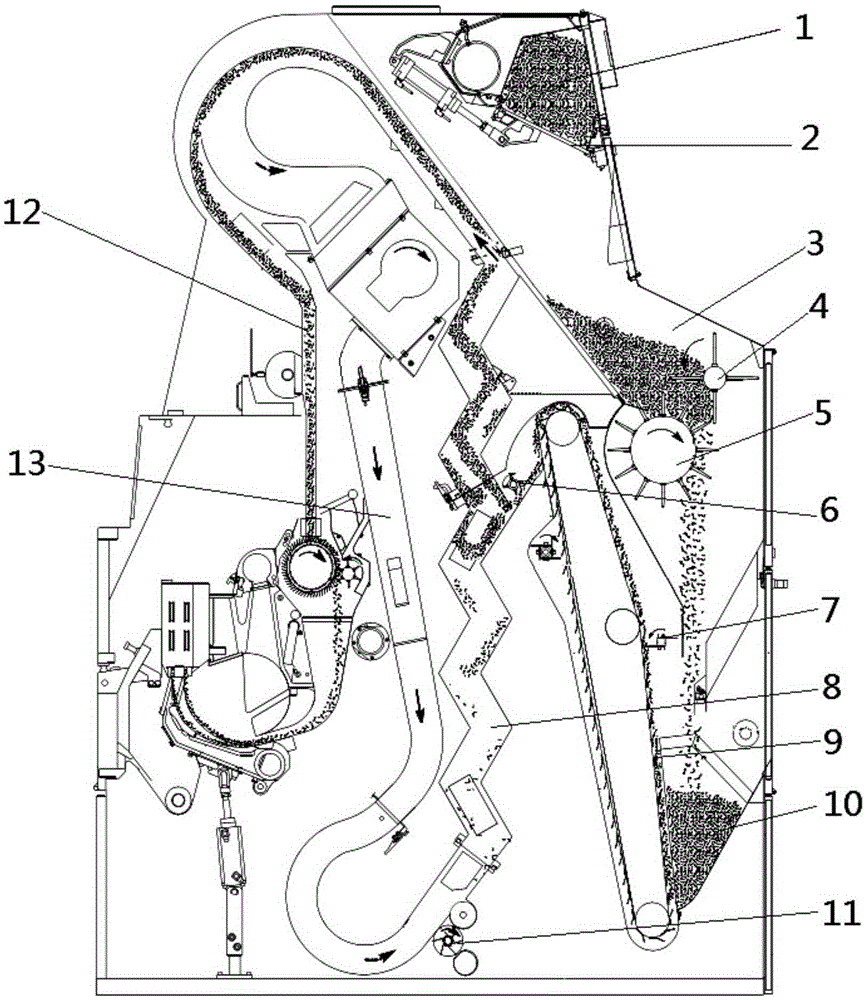

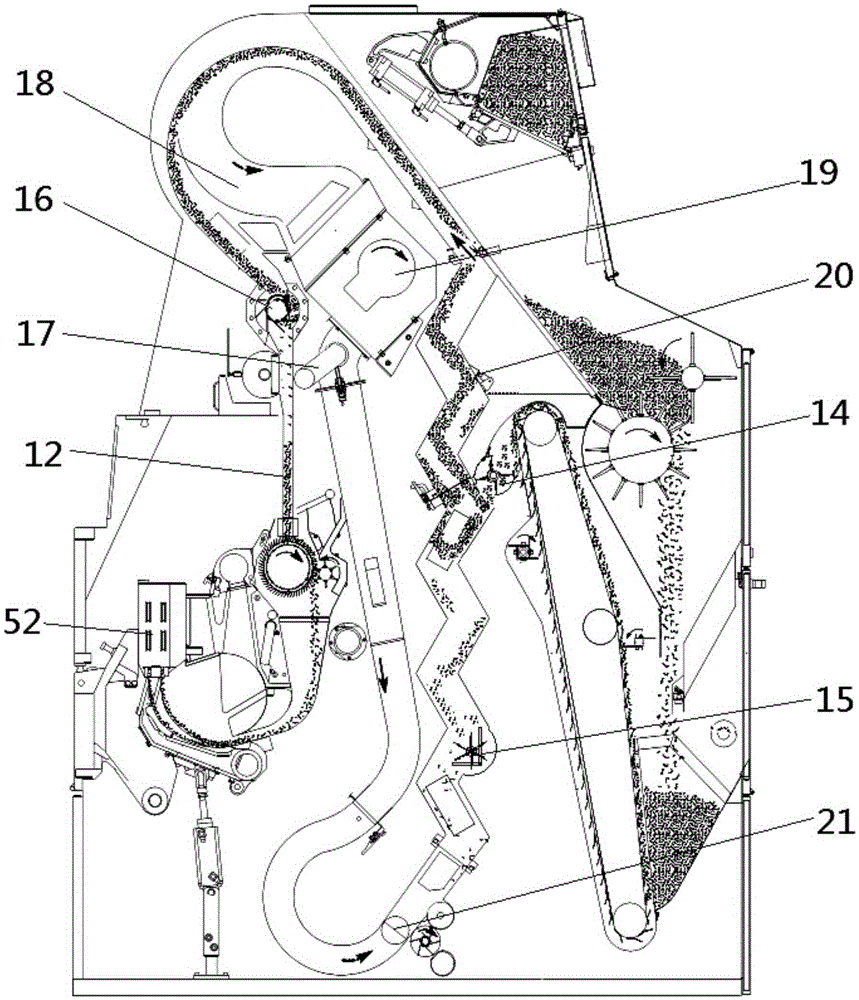

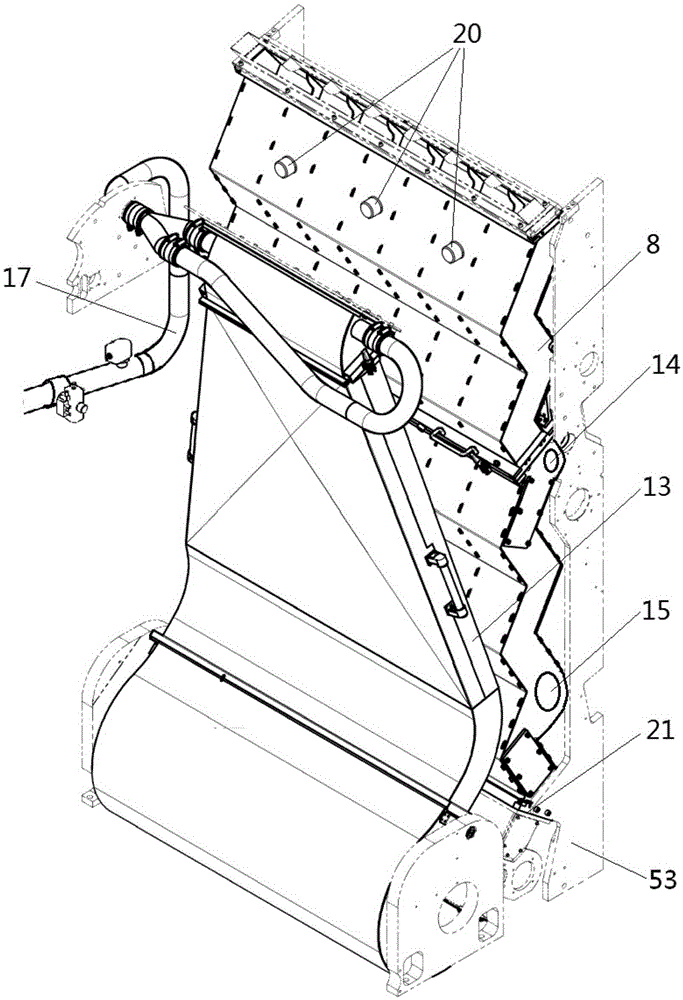

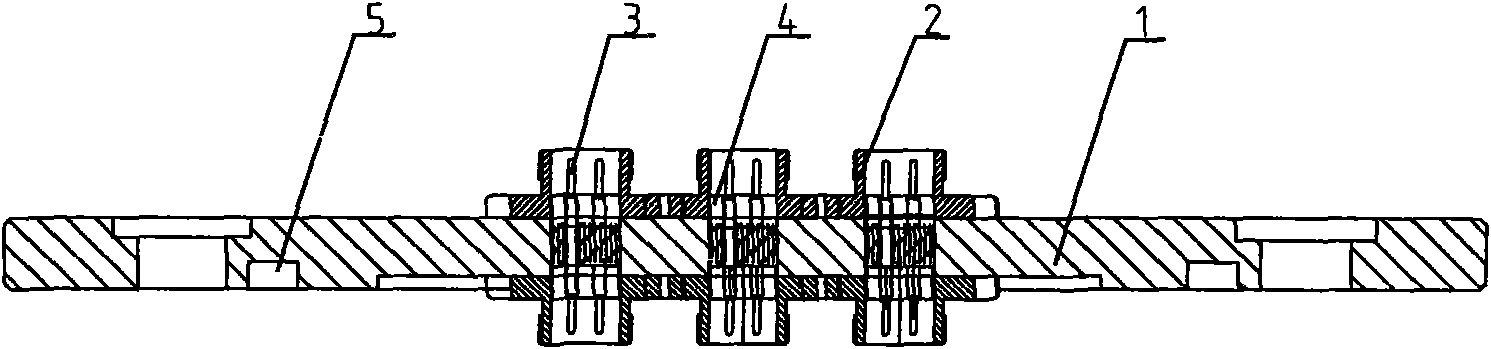

Sealed conveying device and flexible cut tobacco conveying device and method of feeding system of cigarette making machine

ActiveCN105310105AGuaranteed air tightnessStable airflowCigarette manufactureEngineeringTransmission channel

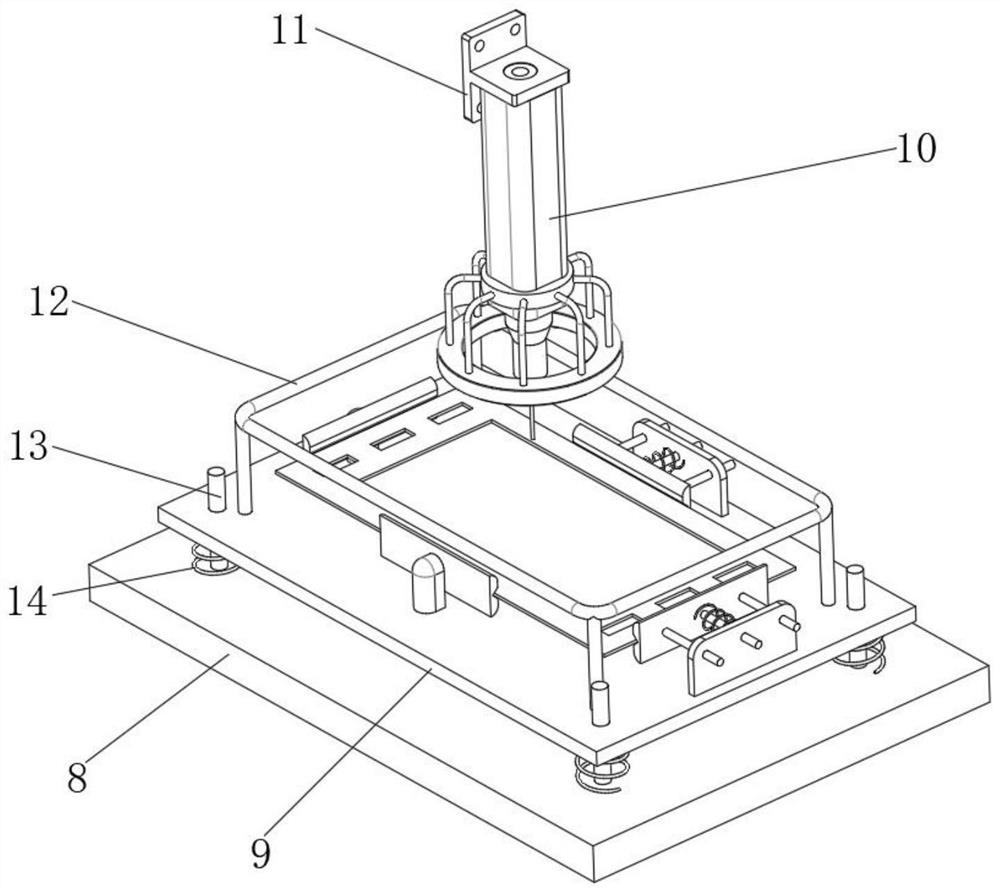

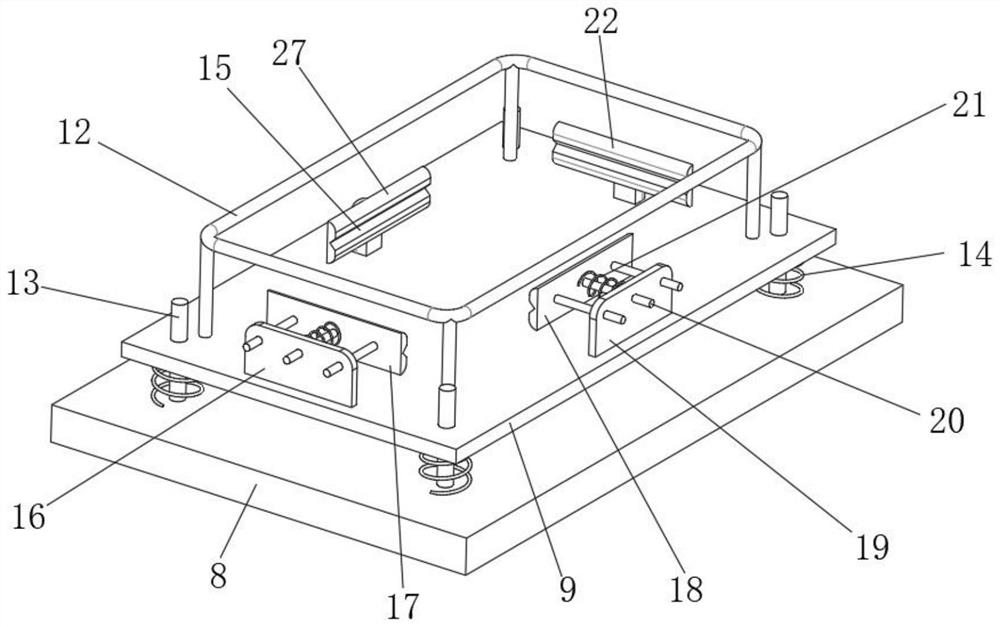

The invention relates to a sealed conveying device and a flexible cut tobacco conveying device and method of a feeding system of a cigarette making machine. The sealed conveying device comprises a shell, a scraping blade shaft (27) and a plurality of scraping blades (22), wherein the shell is provided with an inlet (24) and an outlet (25); the plurality of scraping blades (22) are distributed at the periphery of the scraping blade shaft (27) at intervals and the end parts of the scraping blades (22) can be in contact with an inner wall of the shell; the inner wall of the shell is wrapped to form a cylinder; and the scraping blade shaft (27) and the cylinder are concentrically arranged and the plurality of scraping blades (22) are driven to rotate, so that materials falling from the inlet (24) are led out from the outlet (25) in a sealed manner. According to the sealed conveying device provided by the invention, the scraping blade shaft rotates to drive the plurality of scraping blades to rotate, and the materials falling from the inlet of the shell are led out from the outlet of the shell, so that a sealed conveying function of the materials is realized and the airtight requirements in a transmission channel are met.

Owner:LONGYAN CIGARETTE FACTORY

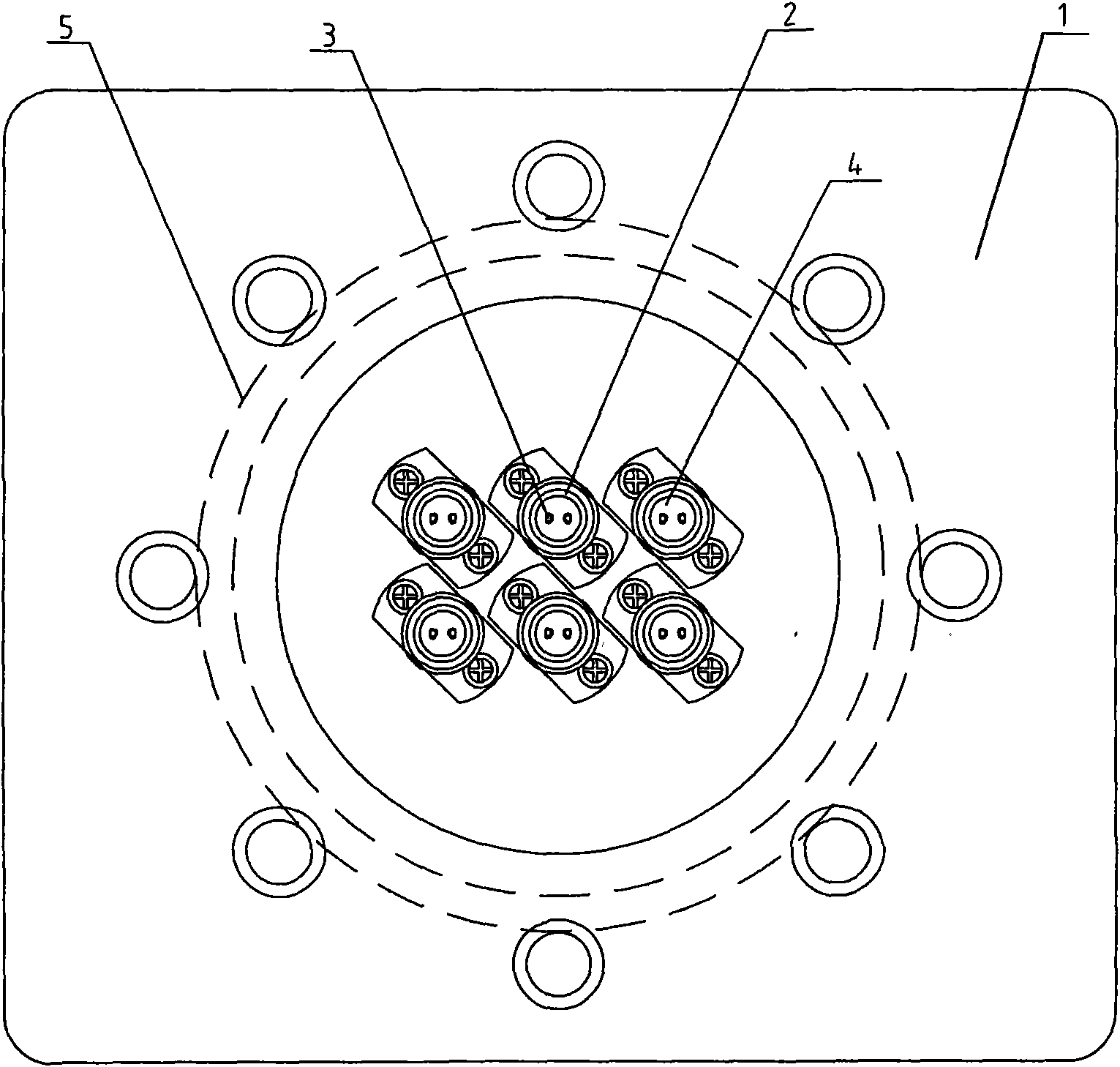

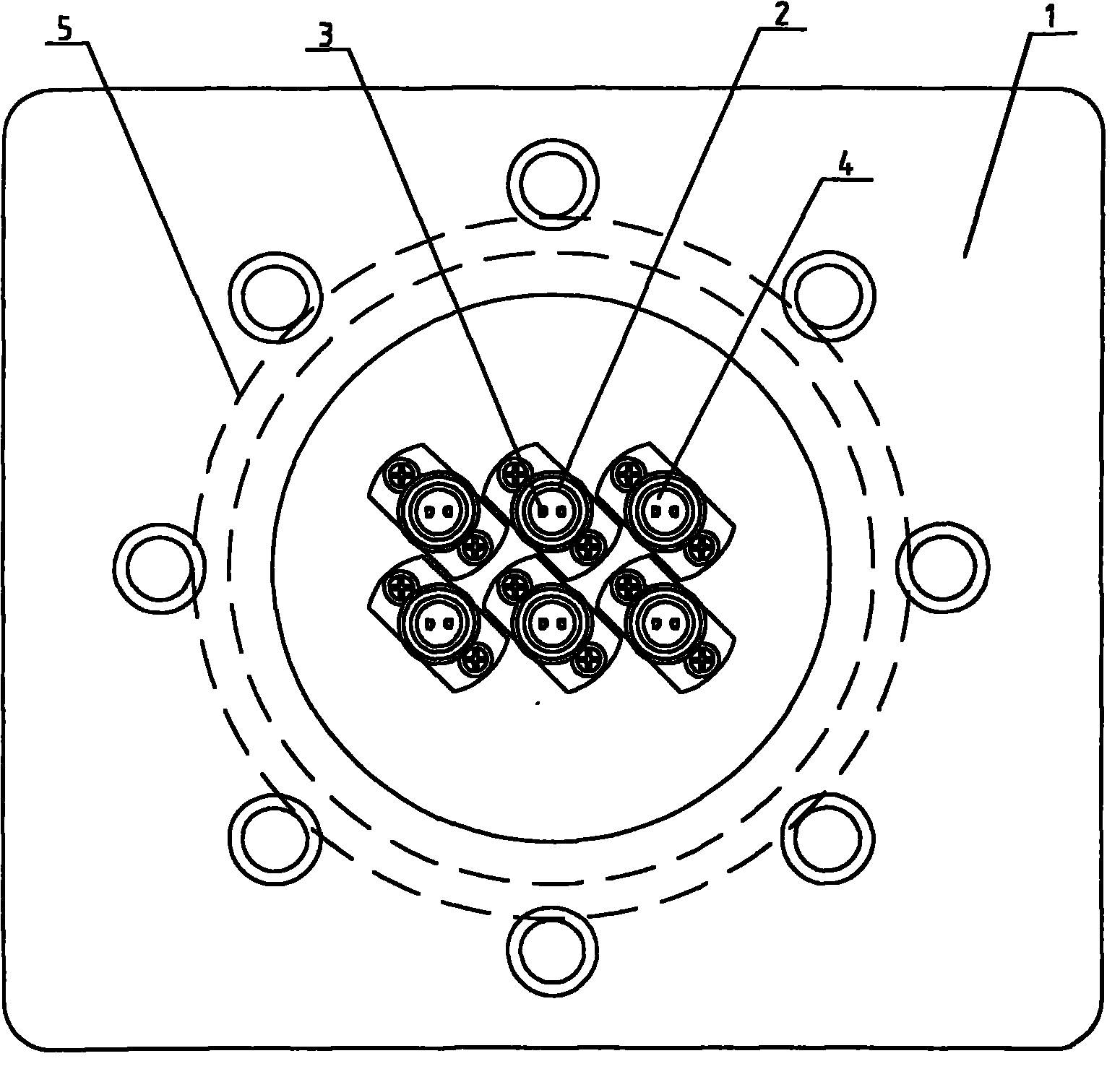

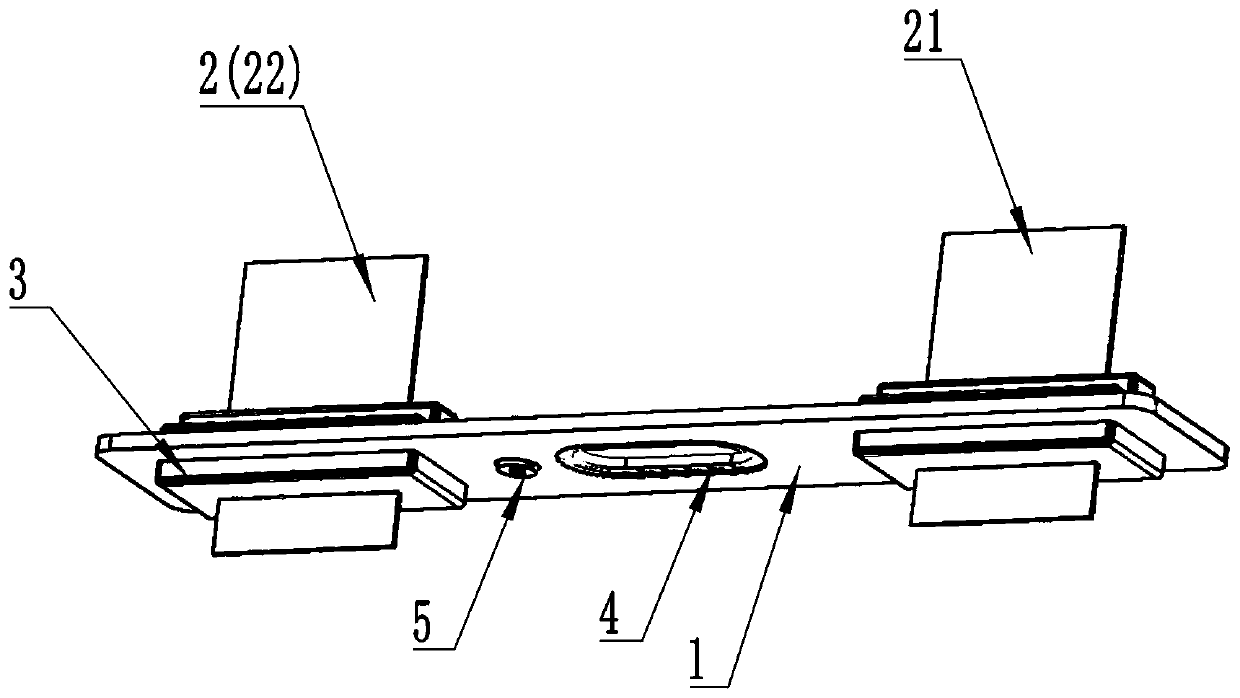

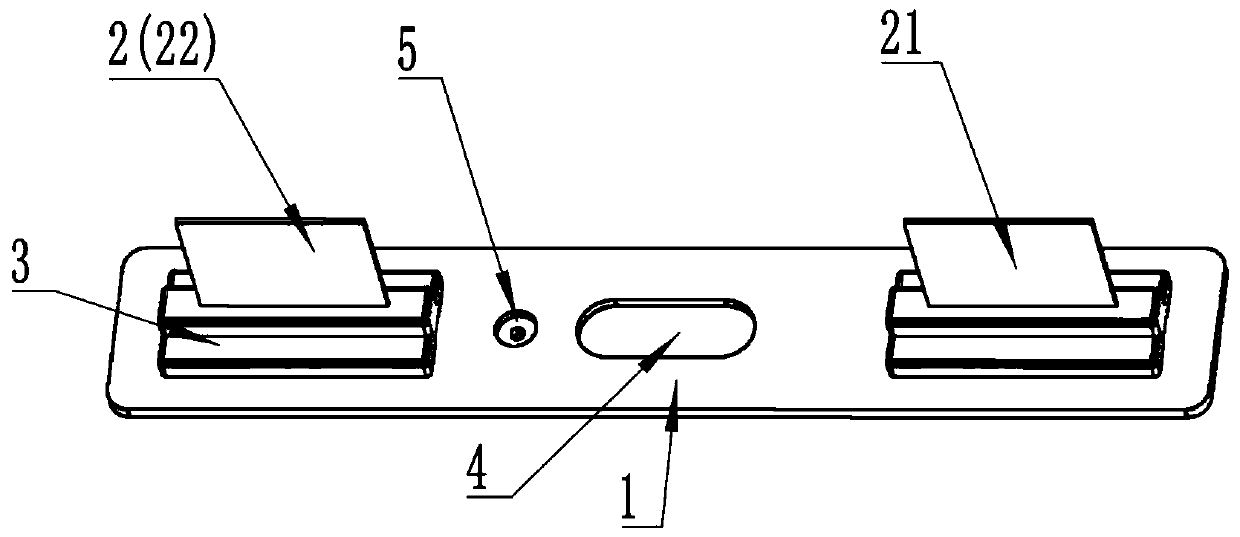

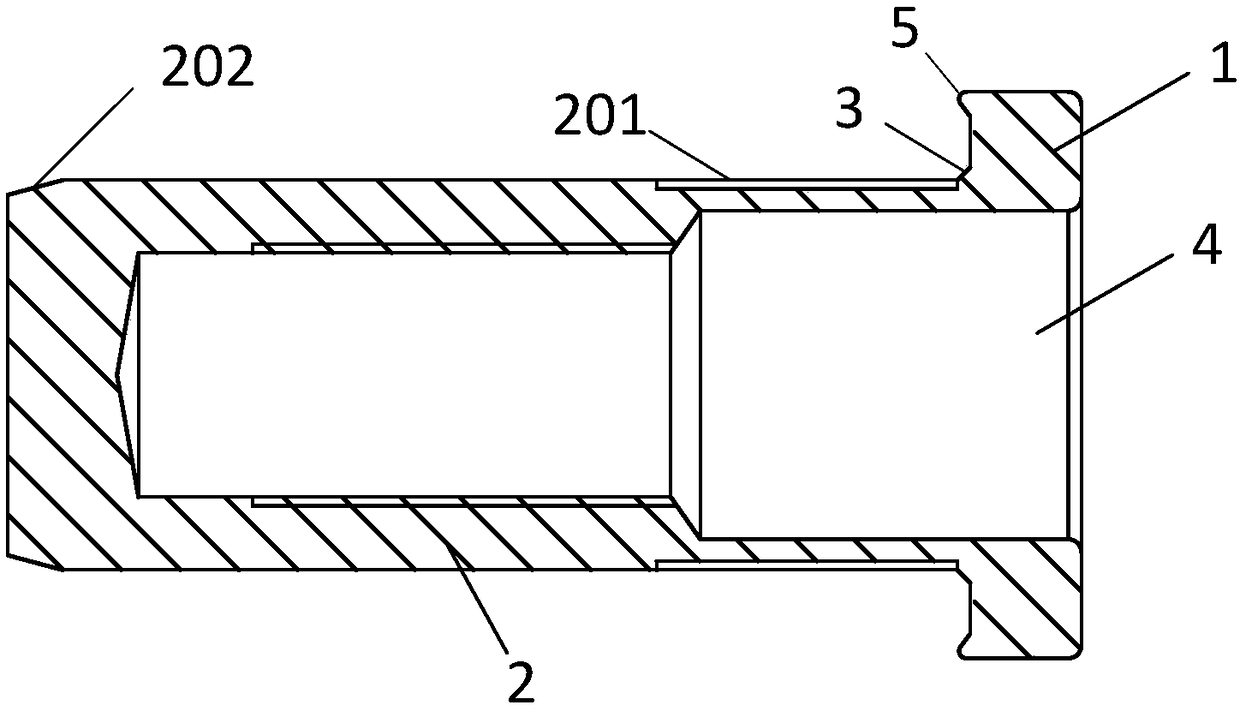

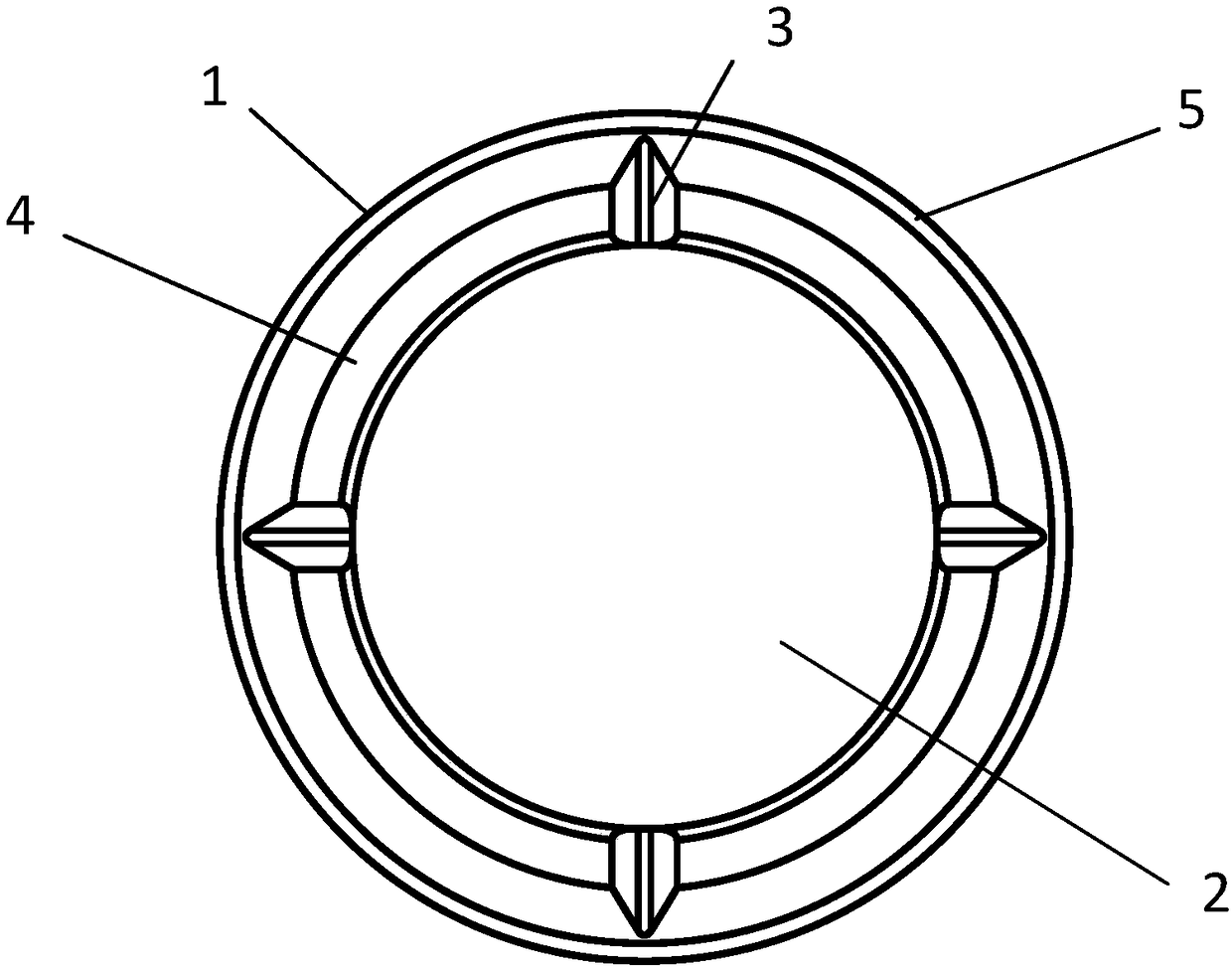

Metal sealing terminal plate

ActiveCN101916927AEasy to operateEasy to install and maintain on siteElectrically conductive connectionsEngineeringMetal

The invention relates to a metal sealing terminal plate comprising a terminal plate body (1). The metal sealing terminal plate is characterized in that the middle of the terminal plate body (1) is fixedly provided with a plurality of electric connectors (2); each electric connector (2) is internally provided with two-phase conducting electrodes (3); and the two-phase conducting electrodes (3) are fused with the terminal plate body (1) together in a glass sintering way and are isolated by an insulating medium (4). The invention has the advantages of high strength, good shielding effect, easy and convenient electric wiring operation and convenient field installation and maintenance.

Owner:CHANGZHOU BORI ELECTRIC POWER AUTOMATION EQUIP

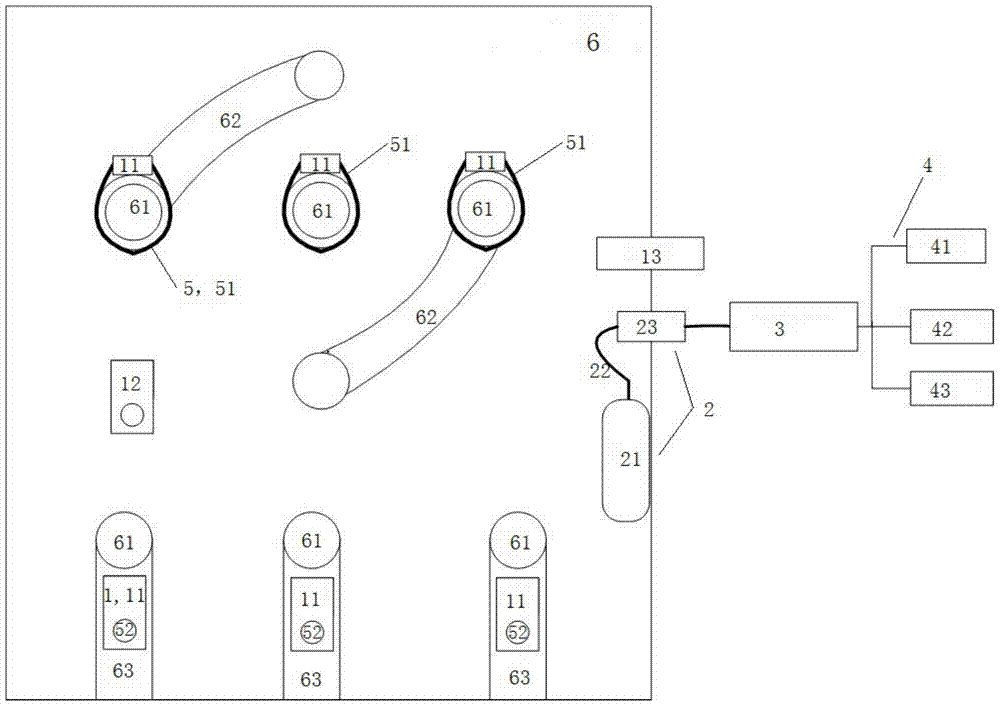

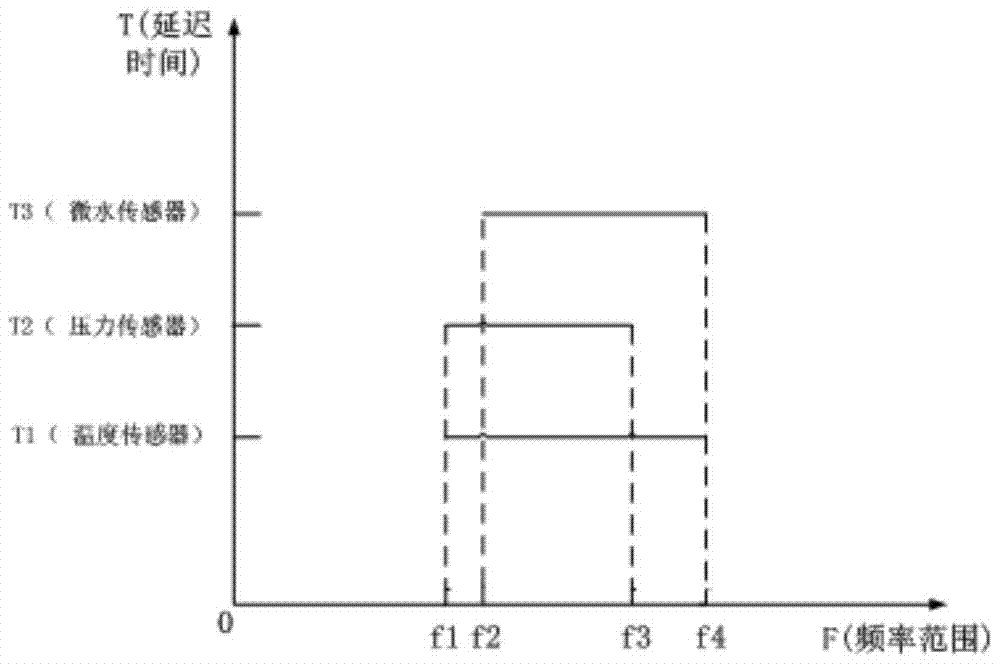

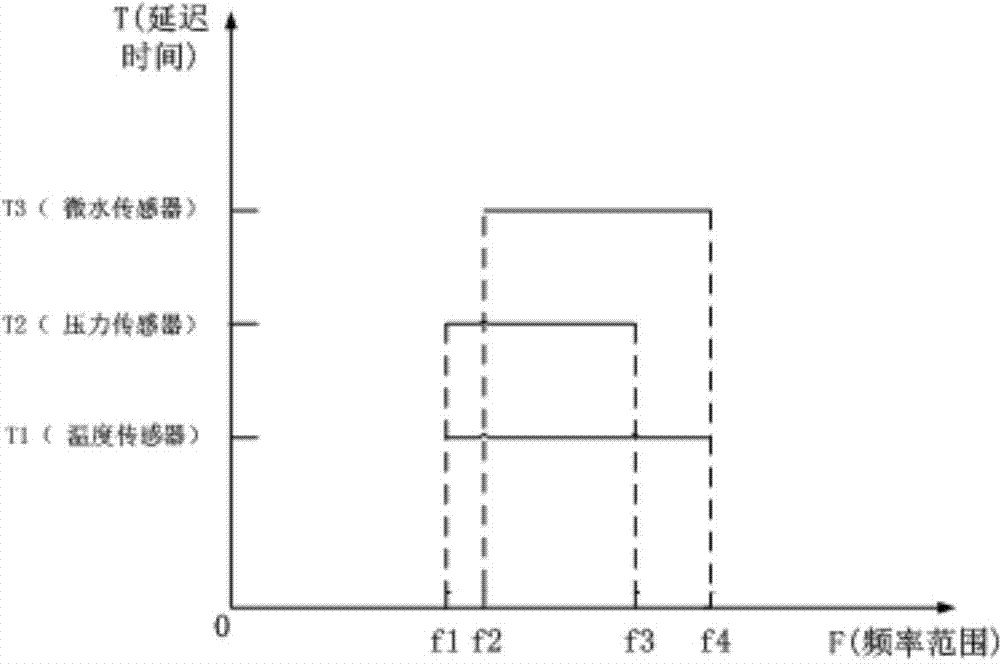

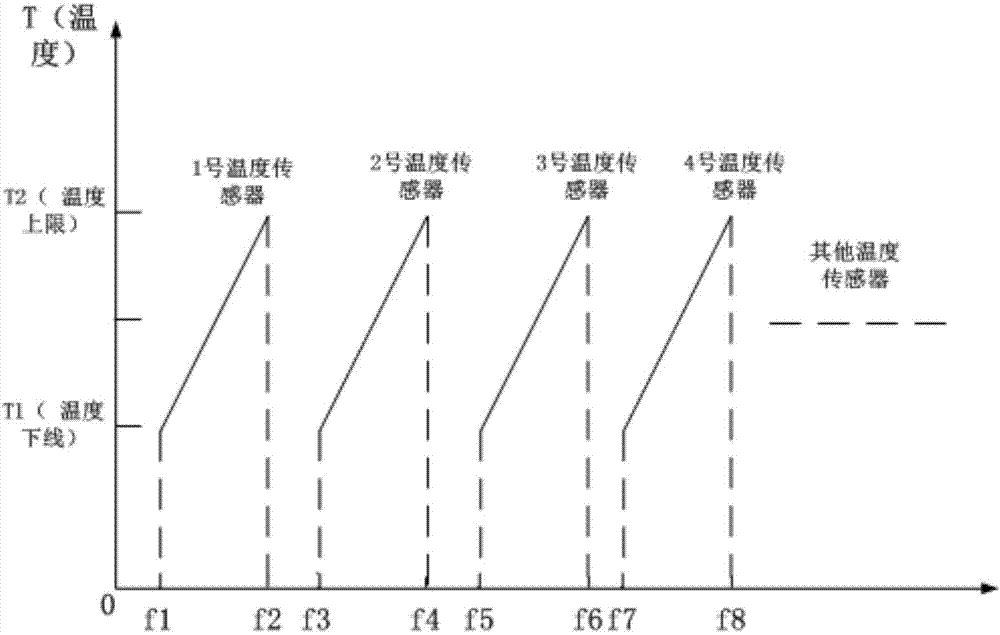

On-line detection system of gis switchgear based on surface acoustic wave

ActiveCN104729584BRealize online monitoringFlexible and comprehensive monitoringMeasurement devicesCommunications systemRadio frequency signal

Owner:CHANGZHOU SMARTSAW SENSING TECH

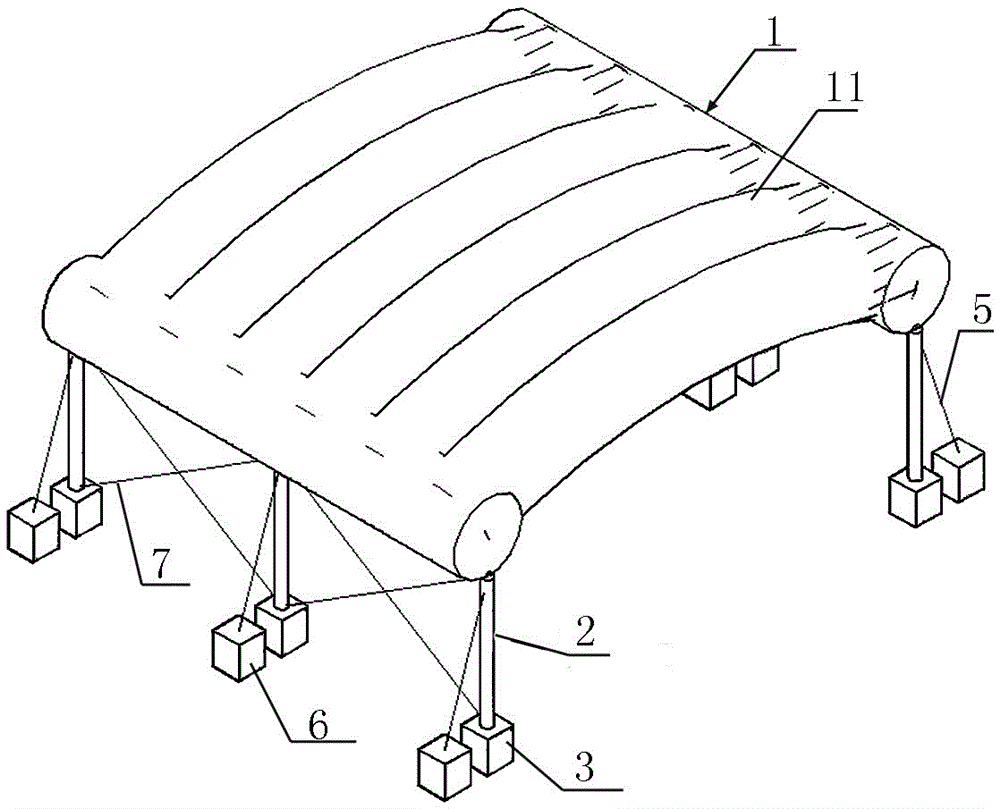

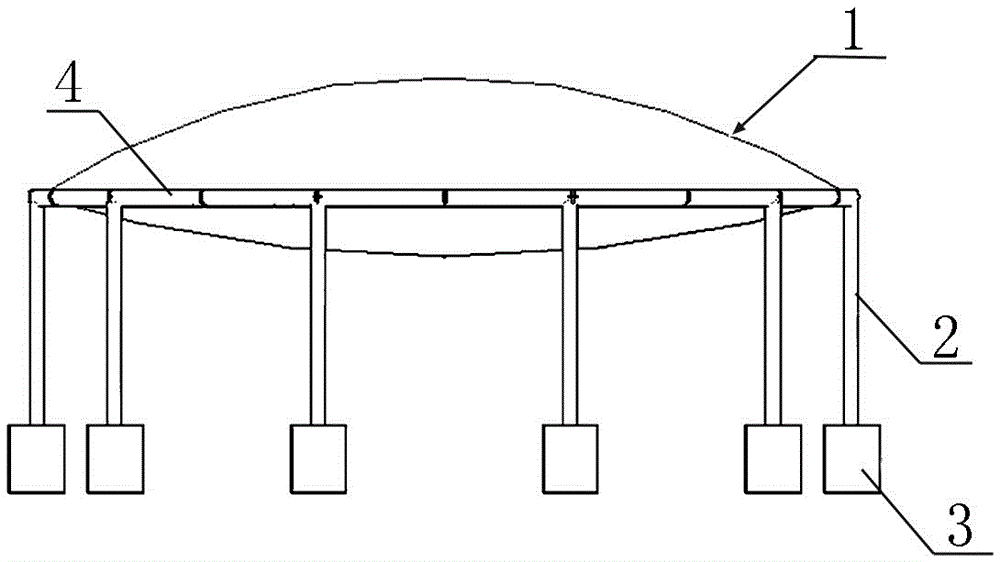

Mooring space structure system and method for designing same

The invention discloses a mooring space structure system and a method for designing the same. The mooring space structure system comprises an inflatable air bag, a support structure and anchor structures. Roofs can be formed by the inflatable air bag, the support structure is used for supporting the inflatable air bag, and the anchor structures are arranged between the bottom of the support structure and the ground in a connected manner, cavities of the inflatable air bag are filled with helium, the integral inflatable air bag is in the shape of a curved surface, and inflatable air bag units are sequentially spliced with one another to form the inflatable air bag; the inflatable airbag units are of double-layer film structures and comprise force holding layers of outer films and air blocking layers of inner films; every two adjacent inflatable air bag units are connected with each other by the corresponding outer films; annular stiffening straps and lifting straps are arranged outside the inflatable air bag units; the support structure comprises vertical supports and connection beams, the vertical supports are parallelly arranged at intervals along the edges of the inflatable air bag, and the connection beams are arranged between the tops of the adjacent vertical supports in a connected manner; the inflatable air bag is connected with the top of the support structure; the anchor structures are gravity anchors. The mooring space structure system and the method have the advantages of reasonable stress and capability of meeting applicability requirements of super-large span structures and super-large closed space structures.

Owner:BEIJING ACAD OF BUILDING ENG

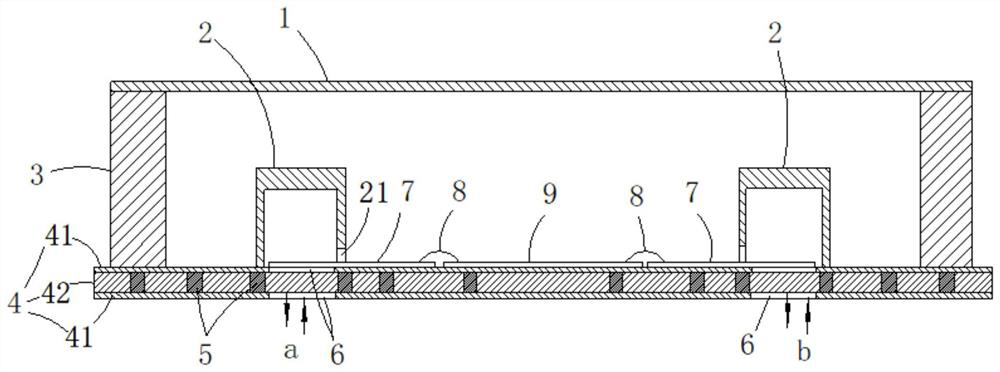

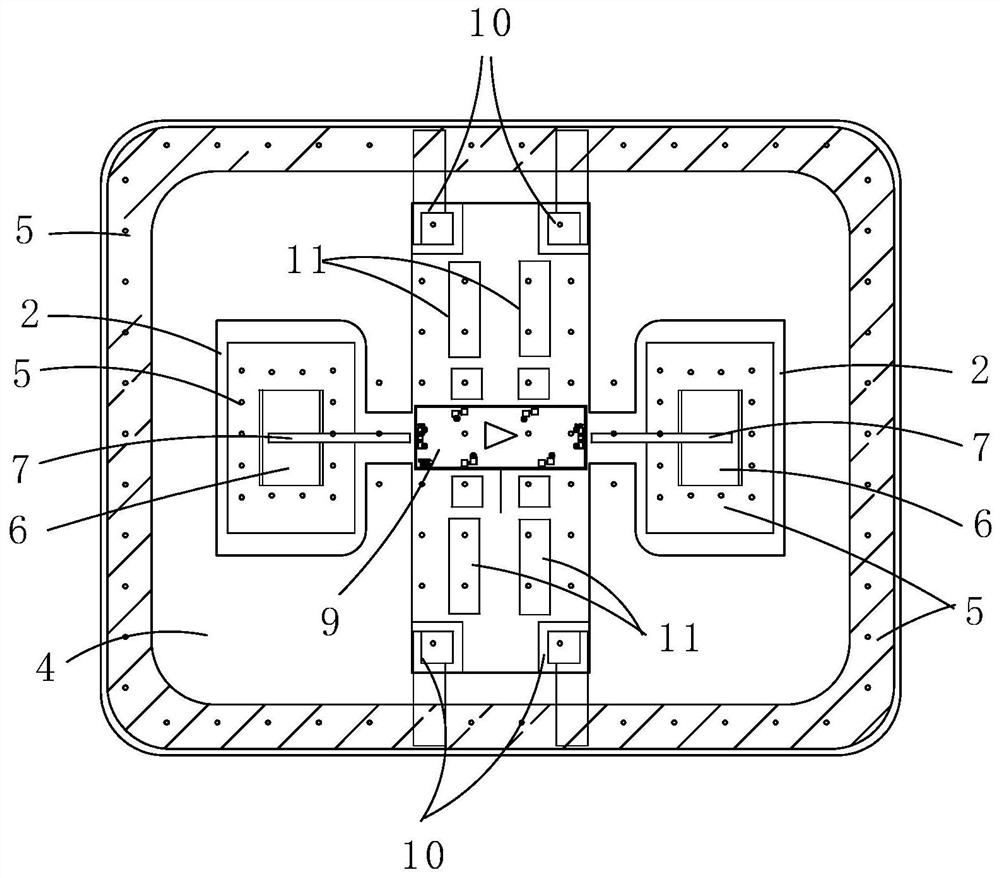

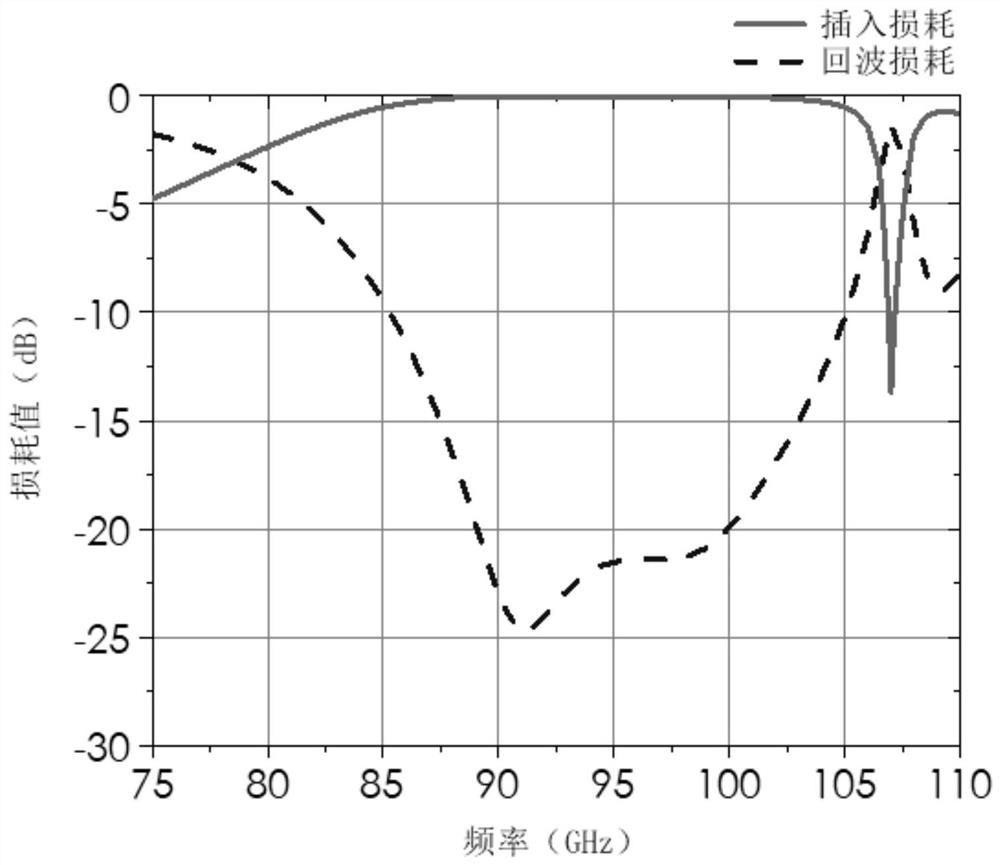

Millimeter wave surface-mounted airtight packaging structure and packaging method

PendingCN113871368AImprove sealingInhibit deteriorationSemiconductor/solid-state device detailsSolid-state devicesMicrowaveDielectric plate

The invention provides a millimeter wave surface-mounted airtight packaging structure and packaging method, and belongs to the technical field of microwave packaging. The millimeter wave surface-mounted airtight packaging structure comprises a packaging shell, a chip and waveguide cavity reflection structures, wherein the packaging shell comprises a bottom plate, a welding frame and a metal cover plate, and the bottom plate comprises a dielectric plate and grounding plates arranged on the upper surface and the lower surface of the dielectric plate respectively; the chip is arranged on the grounding plate on the upper surface; the waveguide cavity reflection structures are arranged on the grounding plate on the upper surface and are respectively arranged on the left side and the right side of the chip, and the waveguide cavity reflection structures are connected with the chip through microstrip line probes and bonding wires; and the part, which directly faces the grounding plate, of the cavity of each waveguide cavity reflection structure is provided with a window, and the two windows respectively form a radio frequency input port and a radio frequency output port. According to the invention, through structure adjustment, chip airtight packaging can be expanded to a millimeter wave frequency band range, the requirements of packaging precision and airtight packaging can be met, batch production is facilitated, the production efficiency is greatly improved, and the production cost is reduced.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

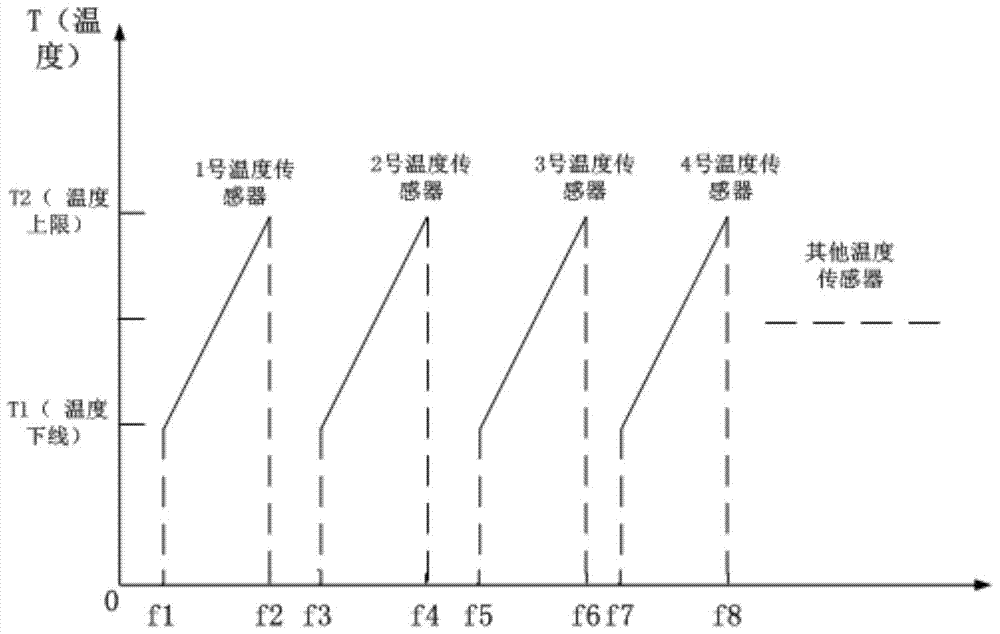

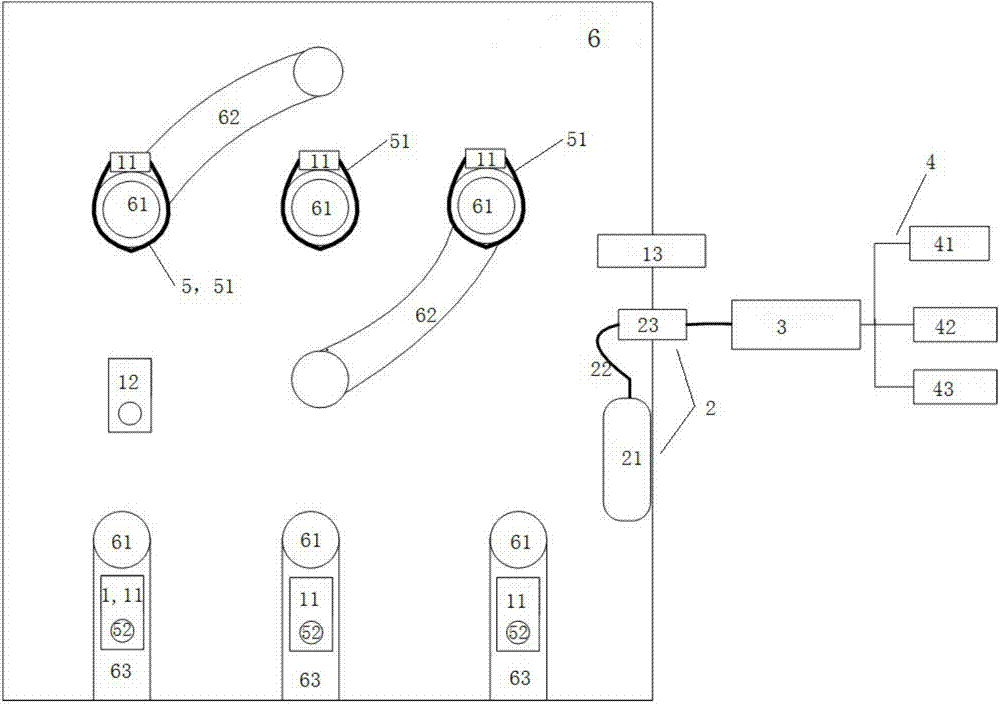

GIS switch cabinet on-line detecting system based on surface acoustic wave

ActiveCN104729584ARealize online monitoringFlexible and comprehensive monitoringMeasurement devicesMonitoring systemRadio frequency signal

The invention discloses a GIS switch cabinet on-line detecting system based on the surface acoustic wave. The GIS switch cabinet on-line detecting system based on the surface acoustic wave comprises a plurality of SAW sensors, a transmitting-receiving device of radio-frequency signal, a collector of the SAW sensors, a background monitoring system and a fixing mechanism of the SAW sensors; the SAW sensors is fixed in a GIS switch cabinet through the fixing mechanism of the SAW sensors; corresponding frequency signals are transmitted to each SAW sensor through the transmitting-receiving device of radio-frequency signal through the collector of the SAW sensors, and signals of SAW sensors retuning frequency are collected; the data are transmitted to the background monitoring system through communication; each SAW sensor comprises a plurality of SAW temperature sensors. According to the GIS switch cabinet on-line detecting system based on the surface acoustic wave, all kinds of physical quantities such as temperature, sensor and moisture in the GIS switch cabinet are measured through the SAW sensors, the operating state of whole equipment can be reflected through the variation of the physical quantities, and the data are collected through the collector of the SAW sensors uniformly and is transmitted to the monitoring system and a background through a communication-extending mode uniformly, so that the on-line detecting is realized.

Owner:CHANGZHOU SMARTSAW SENSING TECH

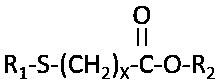

Polyester molding composition and preparation method and application thereof

InactiveCN109749371AMeet air tightness requirementsImprove bindingSemiconductor devices for light sourcesReflectorsMetal stripsAging resistance

Owner:KINGFA SCI & TECH CO LTD +1

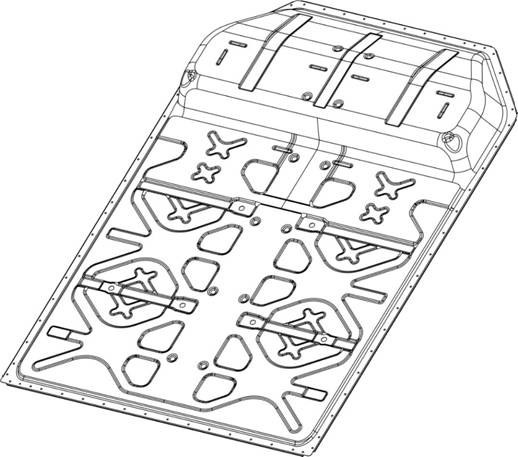

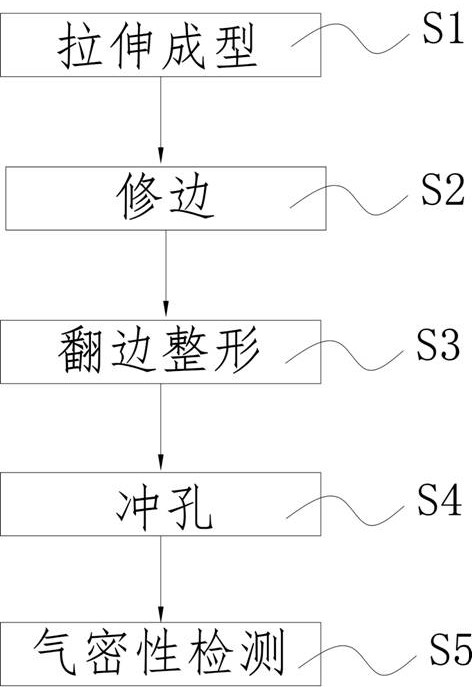

Stamping detection method for new energy automobile battery pack upper cover

ActiveCN113414292AOvercoming airtightnessOvercome efficiencyShaping toolsMetal working apparatusStampingAutomotive battery

The invention provides a stamping detection method for a new energy automobile battery pack upper cover. The stamping detection method comprises the following steps of S1, stretching and forming, specifically, stretching forming is conducted on a plate through a stretching die on a stretching station, in the stretching forming process, first edge pressing rib structures and second edge pressing rib structures which are not equal in height on the stretching die match and control the flowing direction of materials so as to ensure the forming quality. S2, trimming, specifically, the outer edge is punched and trimmed through a trimming die on a trimming station; S3, flanging and shaping, specifically, bending and flanging are carried out on the outer edge through a flanging and shaping die on a flanging and shaping station; s4, stamping, specifically, a stamping die on a stamping station is used for carrying out stamping treatment on a workpiece; and S5, air tightness detection, specifically, the air tightness detection is carried out on the finished product through an air tightness detection device on a detection station. According to the stamping detection method for the new energy automobile battery pack upper cover, the defects that an existing battery pack upper cover is poor in air tightness and low in machining efficiency are overcome.

Owner:宁波明讯实业有限公司

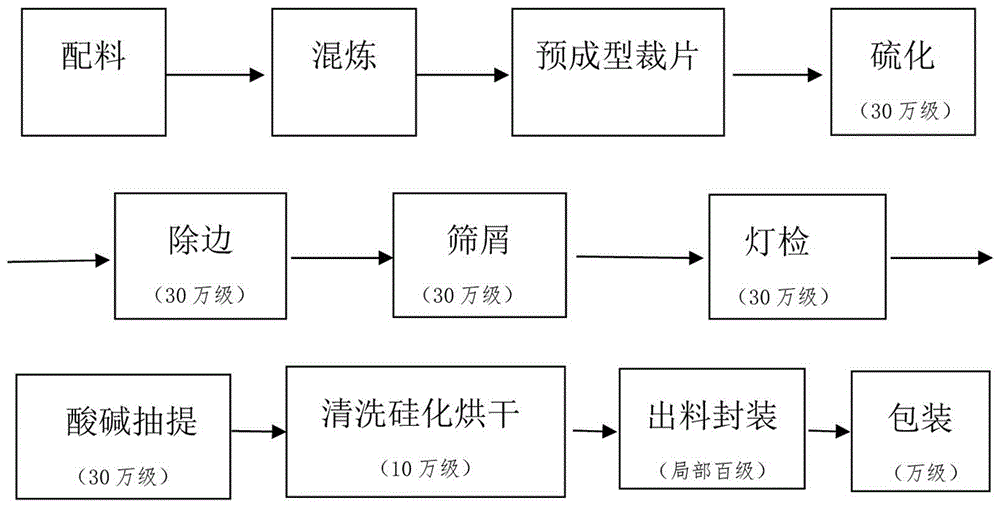

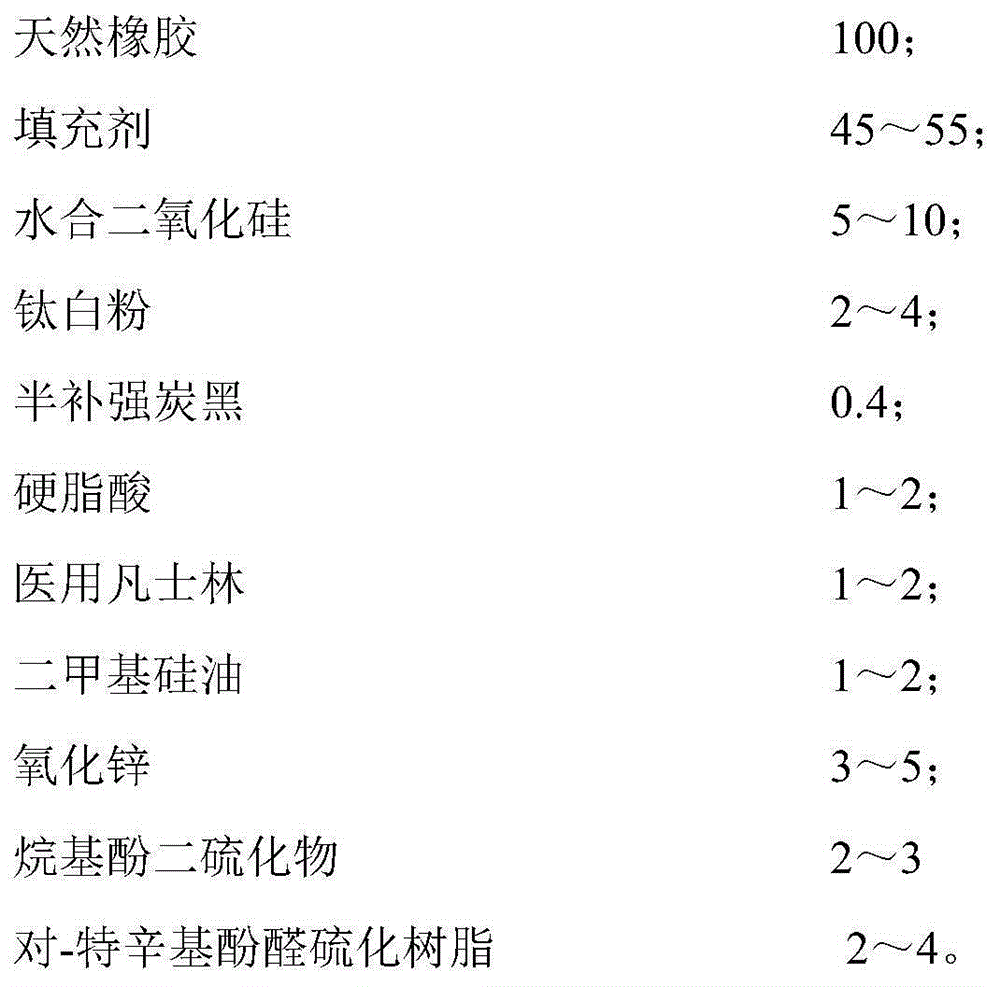

Formula for oil-resistant rubber plug

The invention discloses a formula for an oil-resistant rubber plug. The oil-resistant rubber plug is prepared from, by mass, 100 parts of natural rubber, 45-55 parts of filling agents, 5-10 parts of silicon dioxide hydrate, 2-4 parts of titanium dioxide, 0.4 part of semi-reinforcing furnace black, 1-2 parts of stearic acid, 1-2 parts of petroleum jelly for medical purposes, 1-2 parts of dimethyl silicone oil, 3-5 parts of zinc oxide, 2-3 parts of alkylphenol disulfide and 2-4 parts of p-tert-octylphenolic curing resin. Compared with the prior art, the oil-resistant rubber plug prepared through the formula has good air tightness and oil resistance, can be used for sealing oil preparation medicine and meet the air tightness requirements of medicine sealing and the compatibility with the medicine, and is good in oil resisting property.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

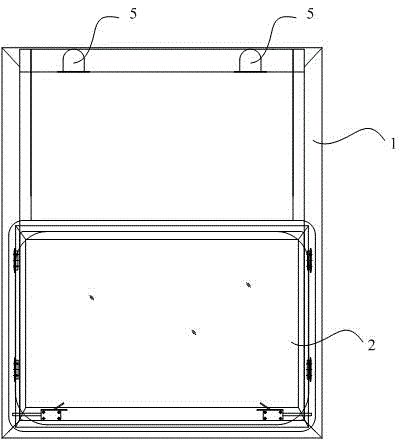

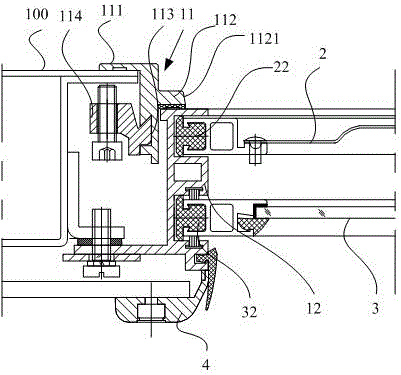

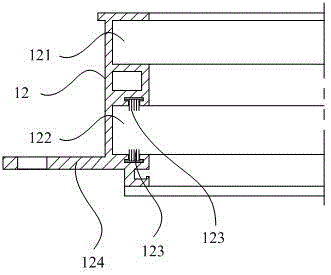

Window for railway vehicle, railway vehicle and window mounting method

InactiveCN106184249AImprove use comfort performanceImprove privacyWindow arrangementsWindow shutterFlanging

The invention provides a window for a railway vehicle, a railway vehicle and a window mounting method. The window for the railway vehicle comprises a window frame, an outer blind window and an inner glass window, wherein the window frame comprises an outer frame body and an inner frame body; a flanging structure is formed at the edge of the outer frame body; a retainer ring is formed on the inner ring of the outer frame body; an inserting groove is formed in the outer side wall of the outer frame body; a detachable inserting plate is arranged in the inserting groove; a plurality of threaded holes are formed in the inserting plate; an outer sliding groove and an inner sliding groove, which are arranged in parallel, are formed in the internal side wall of the inner frame body; the outer blind window is arranged in the outer sliding groove in a sliding way; the inner glass window is arranged in the inner sliding groove in a sliding way; brush strips are oppositely arranged in the inner sliding groove; the inner glass window is clamped between the two brush strips; a mounting plate is arranged on the external side wall of the inner frame body; a plurality of mounting through holes are formed in the mounting plate; and the inner frame body clings to the retainer ring in a sealed way. According to the invention, the comfort performance of the window for the railway vehicle in use is improved and ventilation demands of passengers are satisfied on the premise that sealing property of the window is ensured.

Owner:CRRC SIFANG CO LTD

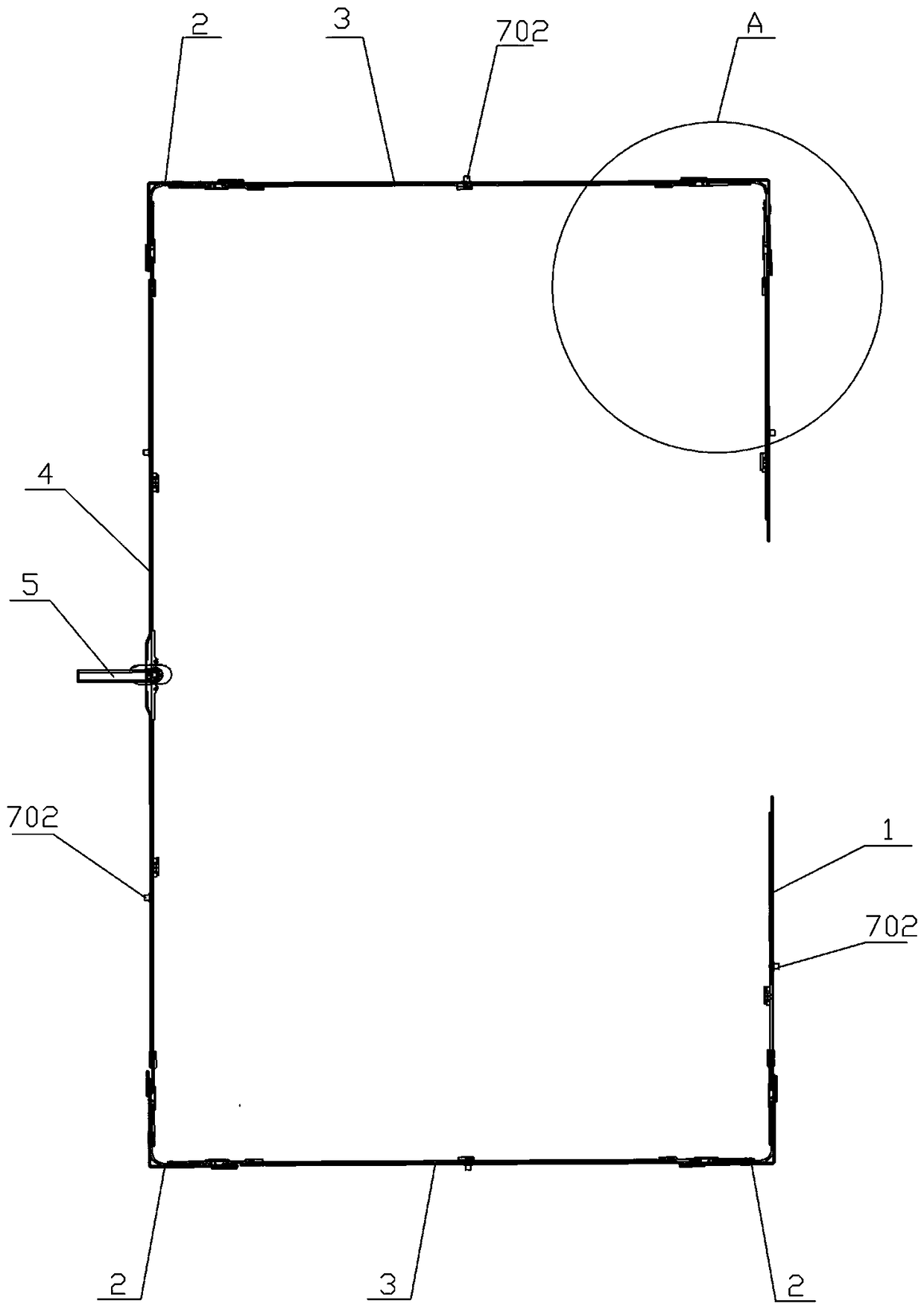

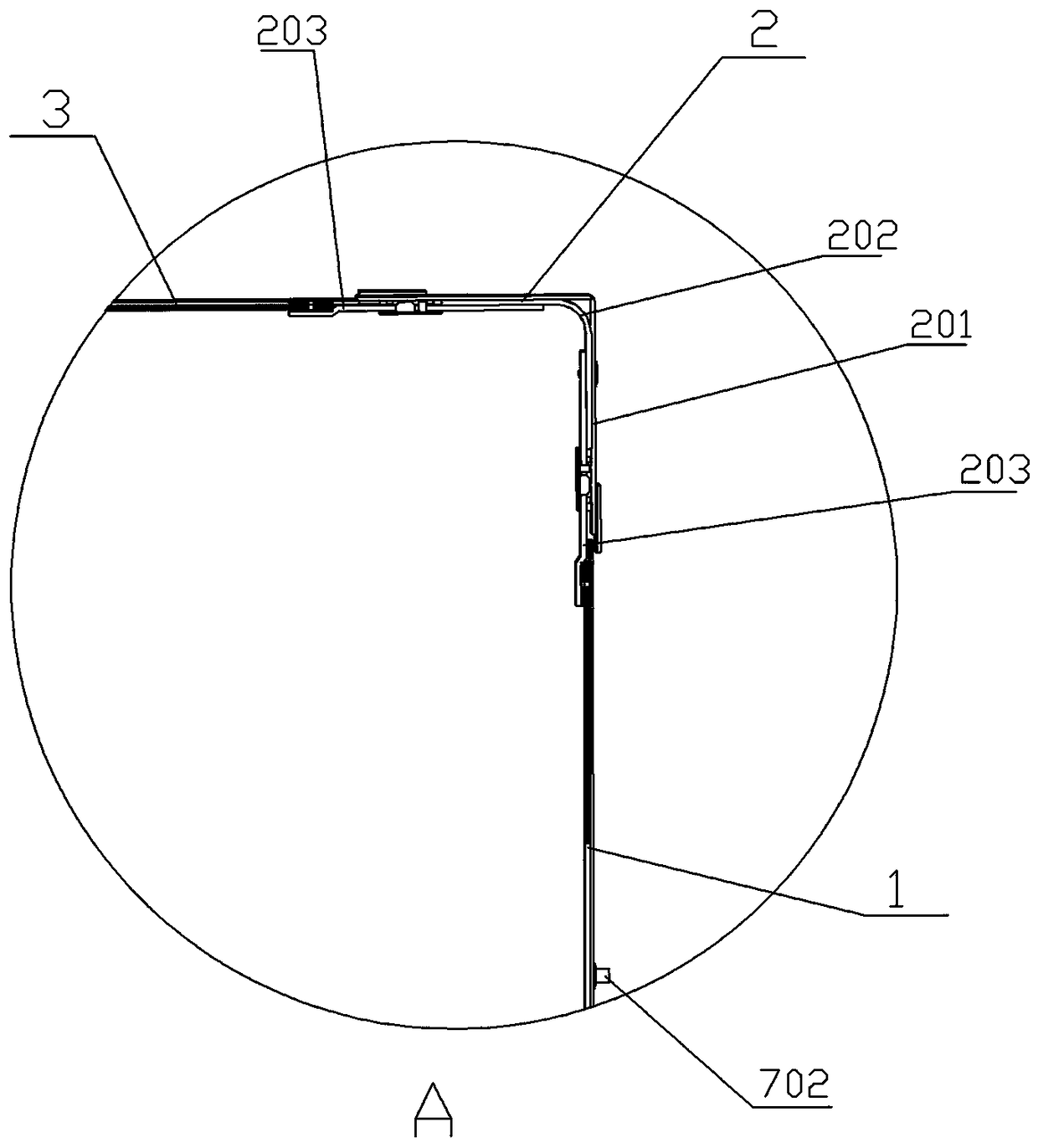

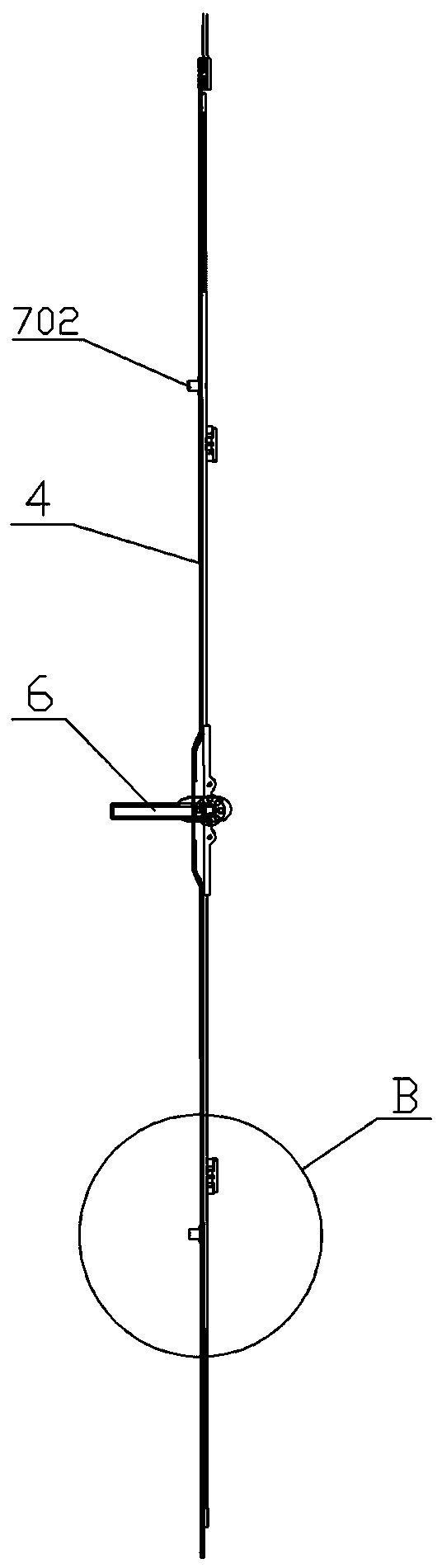

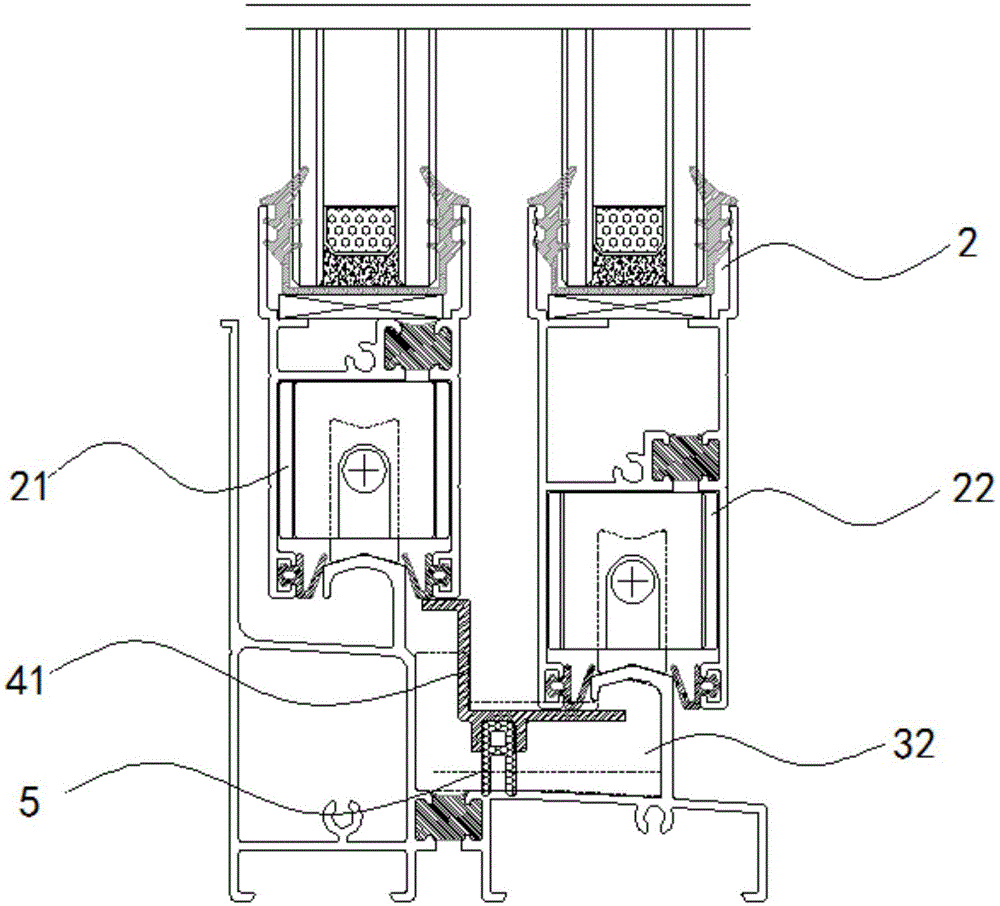

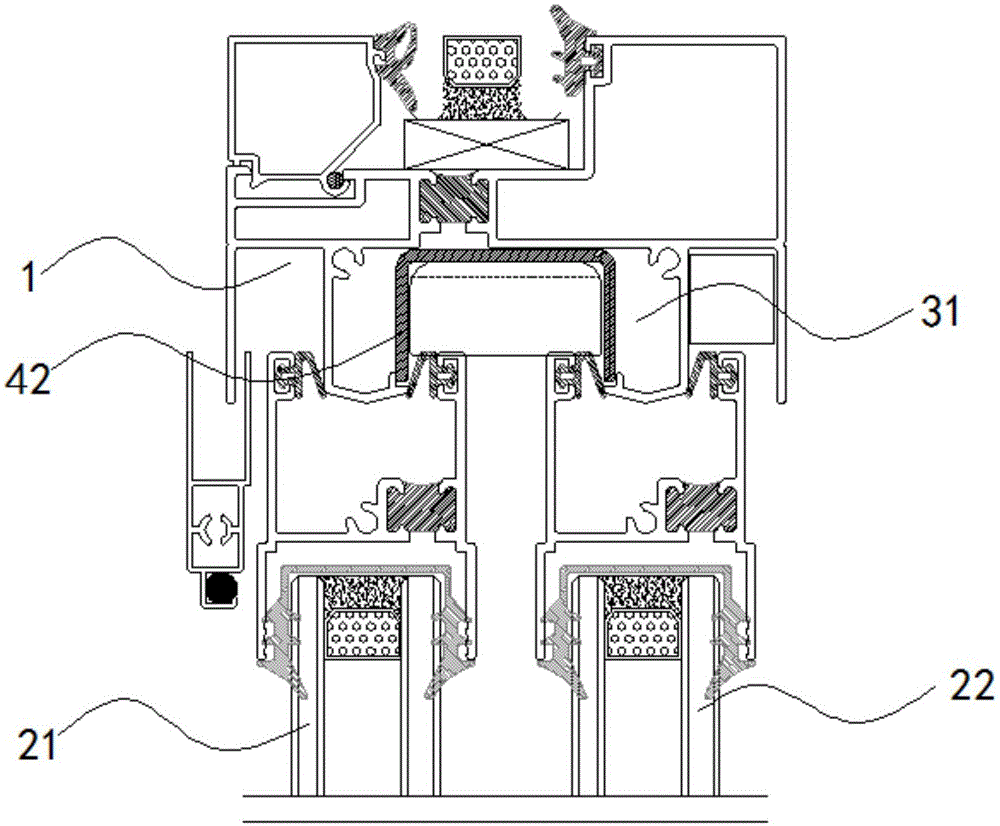

Building door and window self-telescopic locking seal hardware structure

PendingCN108561025AEvenly sealedImprove air tightnessWing accessoriesConstruction fastening devicesHardware structureSash window

The invention relates to the technical field of building door and window hardware systems, in particular to a building door and window self-telescopic locking seal hardware structure which comprises transmission assemblies, corner assemblies, connection transmission lock point assemblies, a middle lock angle driver, a lever handle and a lock base. The corner assemblies are fixedly arranged on thefour corners of the outer side wall of a window sash, the connection transmission lock point assemblies are fixedly arranged on an upper frame and a lower frame of the outer side wall of the window sash, and the two ends of the connection transmission lock point assemblies are fixedly connected with the corner assemblies on the two corners of the upper and lower ends of the window sash. The transmission assemblies are fixedly arranged on a side frame on one side of the window sash in an up-down symmetrical mode. The middle lock angle driver is fixed to a side frame, opposite to the side framewhere the transmission assemblies are arranged, of the window sash. According to the building door and window self-telescopic locking seal hardware structure, the structure is reliable, universality is high, the building whole window air tightness can be remarkably improved, building energy saving standards are improved, and the requirements of passive ultralow-energy-consumption buildings on window system air tightness can be met.

Owner:河南省建筑科学研究院有限公司

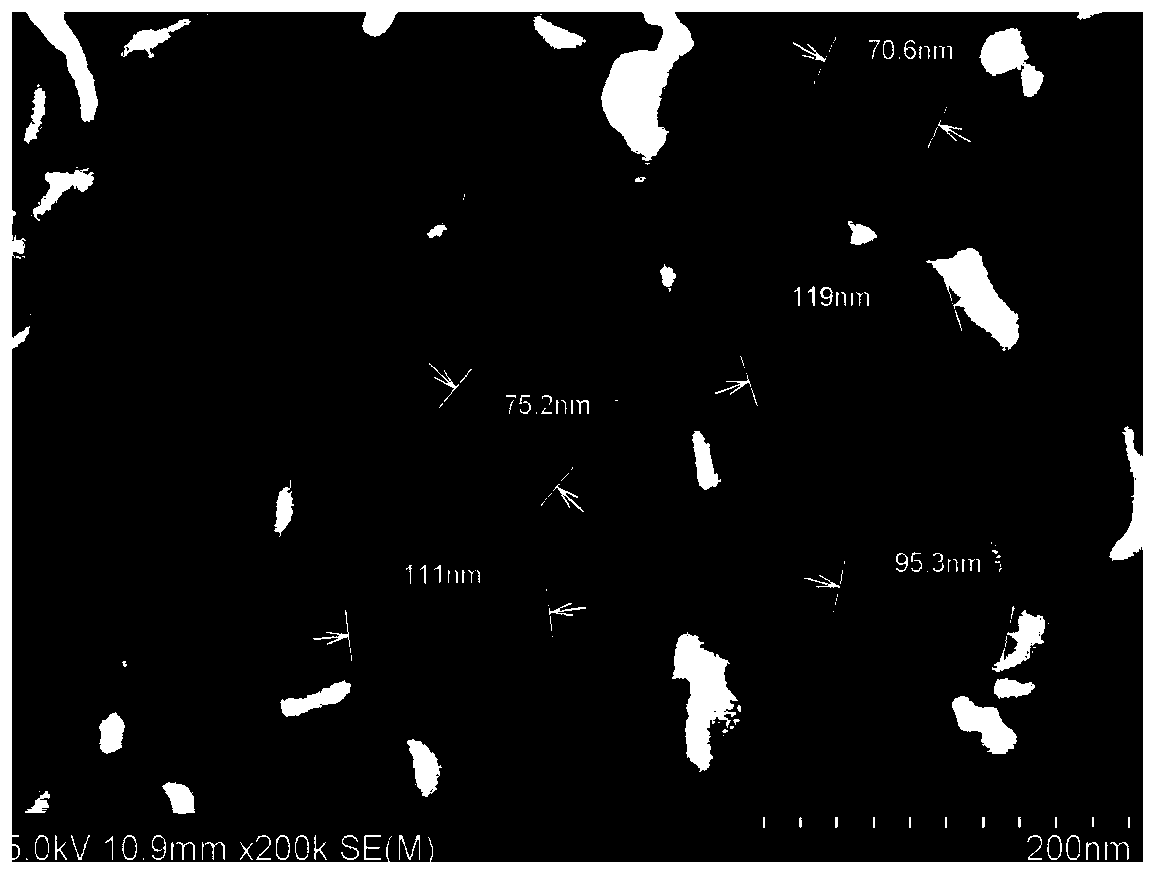

Battery cover plate structure based on nano injection molding and preparation method thereof

The invention discloses a battery cover plate structure based on nano injection molding and a preparation method thereof. The battery cover plate structure comprises a cover plate and a connecting sheet, and the surface of the connecting sheet and the surface, facing the connecting sheet, of the cover plate are provided with a plurality of nano holes. The cover plate and the connecting sheet are fixedly connected through an injection molding part, and the injection molding part penetrates into the nano holes. According to the invention, the injection molding plastic can permeate into the nano holes, so the binding force between the connecting sheet and the cover plate is improved, and the good air tightness of the joint of the connecting sheet and the cover plate is ensured. Compared with the prior art, the lower plastic part and the sealing ring are reduced, the qualification rate of finished products can be improved, and the cost is reduced. Furthermore, in the traditional technology, if the connecting sheet is of a composite structure and needs to be subjected to friction welding machining, the binding force can be improved through injection molding of plastic by use of an existing composite structure, friction welding is not needed any more, cost is reduced, and the fracture risk of the connecting sheet can be completely avoided.

Owner:池州市骏智机电科技有限公司

Novel sealing process of fuel cell membrane electrode

PendingCN114464852APrevent excessive drop distanceImprove reliabilityCollectors/separatorsSealing/support meansComposite materialPolymer chemistry

The invention discloses a novel sealing process of a fuel cell membrane electrode, and relates to the technical field of fuel cell membrane electrodes. The product quality is improved; a fuel cell membrane electrode of the process comprises a catalyst coating membrane, and the catalyst coating membrane is specifically a 3CCM composed of a proton exchange membrane, an anode catalyst layer and a cathode catalyst layer; a first polyester resin frame A and a second polyester resin frame A are arranged at the top and the bottom of the catalyst coating film respectively, a first polyester resin frame B is arranged at the top of the first polyester resin frame A, and a second polyester resin frame B is arranged at the bottom of the second polyester resin frame A; and a first gas diffusion layer is arranged at the top of the first polyester resin frame B. According to the invention, through a sealing process of'first frame and then gas diffusion layer ', accurate positioning of the polyester resin frame is realized by using the positioning holes. And precise positioning of the gas diffusion layer is realized by utilizing the inner edge of the polyester resin frame.

Owner:安徽明天氢能科技股份有限公司

Polyester molded composition and production method and application thereof

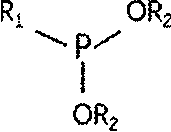

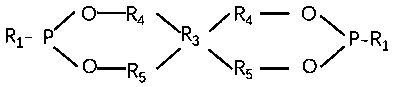

InactiveCN109867923AImprove bindingMeet air tightness requirementsSemiconductor devicesChemistryCarbon atom

The invention discloses a polyester molded composition. The polyester molded composition comprises the following components: 50-80 parts of PCT resin, 10-30 parts of white pigment, 10-30 parts of enhancing material and / or filler and 0.1-2 parts of phosphorous compound; and the phosphorous compound is of a structure as shown in the description, wherein R1 is aryl or OR2, R2 is aryl or alkyl containing 1-30 carbon atoms, R3 is alkyl containing 1-10 carbon atoms, and R4 and R5 are phenyl or alkyl containing 0-10 carbon atoms. A production method comprises the steps of mixing the polyester resin,the white pigment and the phosphorous compound in a high-speed mixer according to proportions, adding a mixture, the enhancing material and / or the filler into a twin-screw extruder, and conducting melt blending, extruding and granulating on a mixture to obtain the polyester molded composition. The polyester molded composition has high adhesion to a metal material strap and good air impermeability,reflectivity and light-resistant and heat-aging-resistant performance.

Owner:KINGFA SCI & TECH CO LTD +1

Waterproof cable core water blocking sealant

The invention provides a waterproof cable core water blocking sealant. 100 parts of methyl vinyl silicone rubber, 10-25 parts of fumed silica, 25-30 parts of calcium hydrogen carbonate, 5-10 parts of rutile type titanium dioxide, 1-5 parts of zinc stearate and 5-10 parts of anilmo-methyl triethoxy silane are mechanically stirred for 20-30min at the temperature of 25 DEG C according to weight ratio, and 0.5-1 part of mixture of dibutyltin dilaurate curing agents and dibutyl phthalate is added to form the finished product sealant. The sealant is free from pollution, convenient to use, safe and reliable.

Owner:CSIC HULUDAO SPECIAL CABLE CO LTD

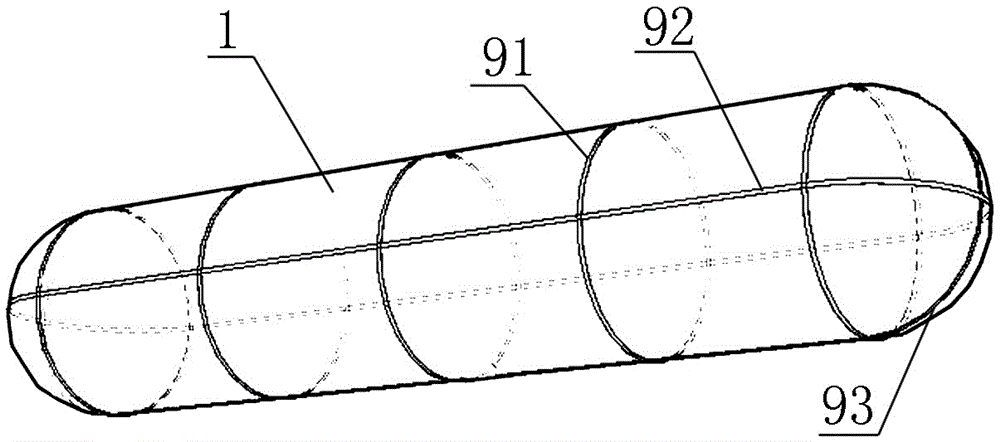

Tubular inflating filling mold for cast-in-situ concrete

The invention discloses a tubular inflating filling mold for cast-in-situ concrete, which comprises a tube bag, wherein the tube bag consists of an outer bag and an inner bag, the outer bag consists of an equal section dimension cylindrical tube body and a variable section dimension tube end after the outer bag inflation and the inner bag consists of an equal section dimension cylindrical tube body and a variable section dimension tube end formed after the inner bag inflation, or the tube bag only consists of an airtight outer bag. The filling mold does not need to be inflated in the production and transportation stage, the size is small, the production and storage occupation space is small, the transportation cost is low, and the defects of requirement of a large production and storage space and high transportation cost of the existing tube and pipe production are overcome.

Owner:赵东昕

Convex-point-free perforated stamping connection method for sheets different in material and large in thickness difference

InactiveCN104959476AMeet air tightness requirementsRealize stamped connectionPlastic propertyAir tightness

Owner:CHONGQING UNIV

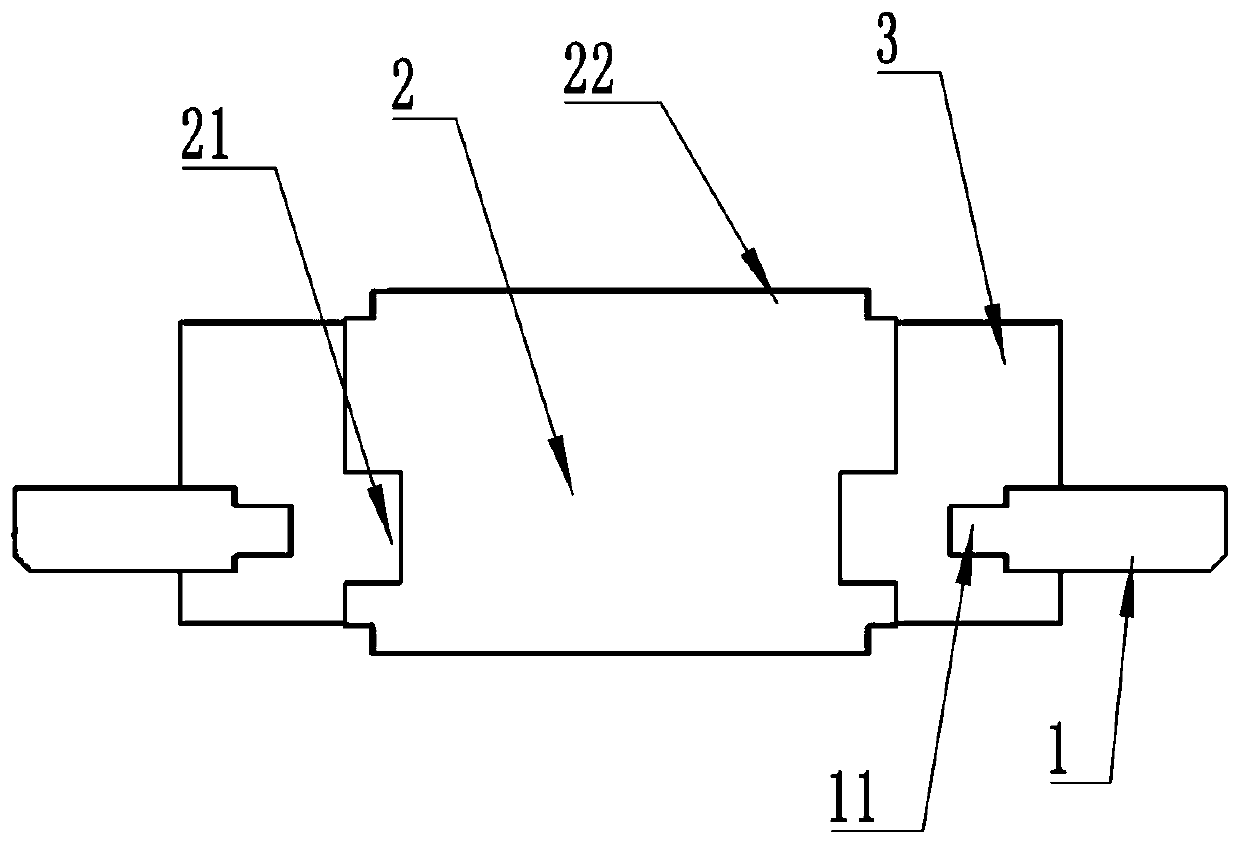

Waterproof rivet nut and production process thereof

The invention discloses a waterproof rivet nut and a production process thereof. The waterproof rivet nut comprises a heat flange and a rod portion integrally connected with the head flange. A chamferis arranged at the joint of the head flange and the rod portion, a plurality of half-rib mechanisms are evenly arranged on the periphery of the chamfer, and the half-rib mechanisms extend towards thebottom surface of the head flange from the surface of the rod portion. Since the half-rib mechanisms are added to the head flange, the waterproof rivet nut can meet the requirement for the rotating torque which is three times or above that of existing products in the same specification. The waterproof rivet nut can be used for edges of shells of new energy batteries, a traditional process of aluminum welding with low efficiency is replaced, the gas leakage preventing rivet nut with a certain air pressure value can be satisfied, and the waterproof rivet nut is matched with waterproof glue to achieve double assurance.

Owner:BINKE AUTOMOBILE FASTENER KUNSHAN

Battery top cover based on block pole and preparation method thereof

PendingCN110212124AEnhance binding strengthTightly boundFinal product manufactureElectric connector introductionAir tightnessChemical corrosion

The invention discloses a battery top cover based on a block pole and a preparation method thereof. The battery top cover comprises a cover plate, a plastic part and a block pole; the block pole and the cover plate are fixedly connected through the plastic part, and a block pole groove is formed in each surface, facing the cover plate, of the block pole; the plastic part is arranged between the cover plate and the block pole; and the plastic part is filled into the block pole grooves, covers a part, facing the block pole, of the cover plate, and is fixedly connected with each surface, facing the cover plate, of the block pole. According to the battery top cover based on a block pole and the preparation method thereof in the invention, the block pole and the cover plate are fixedly connected through the plastic part, a block pole groove is formed in each surface, facing the cover plate, of the block pole, and the plastic part is filled into the block pole groove, so that the block poleand the plastic part are combined more tightly. Through the block pole groove, the air tightness of the battery top cover can be guaranteed, moreover, nano-holes are formed in the block pole and the cover plate through chemical corrosion, the plastic part is permeated into the nano-holes, so that the bonding strength of the plastic part, the block pole and the cover plate can be further improved.

Owner:池州市骏智机电科技有限公司

Airtight sliding window

InactiveCN105019783AEasy to slideEasy to replaceSealing arrangementsWing arrangementsSash windowSlide window

The invention discloses an airtight sliding window. The airtight sliding window comprises a window frame and window sashes, wherein sliding channels are formed in the top and the bottom of the window frame, the window sashes are arranged in the sliding channels, a first sealing PVC (polyvinyl chloride) channel is formed in the bottom sliding channel of the window frame and is matched with the bottom sliding channel in shape, and elastic fabric is further arranged below the first sealing PVC channel. The elastic fabric below the first sealing PVC channel enables the first sealing PVC channel to be elastic in use, on one hand, friction between the bottom sliding channel and the first sealing PVC channel can be reduced, and the window sashes can slide in the bottom sliding channel conveniently, on the other hand, the first sealing PVC channel can be closely contacted with the bottom surfaces of the window sashes in use, and the requirement for wind-proof airtightness is met.

Owner:奋安铝业股份有限公司

Ultrasonic rolling and welding process

The invention discloses an ultrasonic rolling and welding process. The conventional vertical arrangement direction of a vibration cylinder, and an ultrasonic oscillator and a transducer which are arranged in the vibration cylinder is changed into the horizontal arrangement direction; both ends of the vibration cylinder are provided with supporting plates for positioning the vibration cylinder; the two ends of the vibration cylinder are rotatably connected with the supporting plates by bearings; two carbon brushes are symmetrically arranged outside the vibration cylinder in the radial direction; a motor for driving the vibration cylinder to axially rotate around the vibration cylinder is provided; by the carbon brushes, the continuously rotated ultrasonic oscillator can obtain electric energy so as to avoid the situation that the ultrasonic cannot continuously work during vibration and ensure that the ultrasonic continuously works for long time to generate heat; as a welded die head keeps rotating, vibrations are generated by the welded die head in a vertical plane besides the former horizontal linear direction when the welded die head and 20kHz ultrasonic are resonated; therefore, the power energy of the ultrasonic is converted into power energy in the horizontal transverse direction and power energy in various directions in the vertical plane, so the requirement of welding of peripheries of a workpiece in the transverse direction and in the vertical plane is met.

Owner:YUQIU MOLD PLASTICS CO LTD OF KUNSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com