Polyester molding composition and preparation method and application thereof

A technology of molding composition and polyester, which is applied in the field of polyester resin composition, can solve problems such as the influence of the binding force of the bracket material and the metal strip on the service life of the lamp bead airtight LED lamp, and meet the requirements of Effect of airtightness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

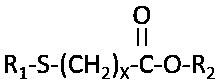

Method used

Image

Examples

Embodiment and

[0069] Embodiment and comparative example:

[0070] According to the parts by weight in Table 1, various PCT resins, white pigments, reinforcing materials, sulfur-containing compounds D1, and sulfur-containing compounds D2 were weighed respectively, and various PCT resins, white pigments, sulfur-containing compounds D1, and sulfur-containing compounds D2 were weighed respectively. Mix in a high mixer, add the mixture to the twin-screw extruder, feed the reinforcing material in the 4th to 9th section of the extruder, and use a weight loss scale to control the feeding, and the temperature in each section of the extruder is 270 °C in the first section. , 280°C in zone 2-4, 290°C in zone 5-7, 280°C in zone 8-9, and 270°C in the machine head, melt blending, extrusion and granulation to obtain a polyester molding composition.

[0071] Table 1. The specific composition and test performance results (parts by weight) of each composition in Examples 1-8 and Comparative Examples 1-5

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com