Battery top cover based on block pole and preparation method thereof

A pole and block technology, which is applied in the field of battery top cover based on block pole and its preparation, can solve the problem of low pass rate of the cover plate, and achieve the effect of cost reduction, tight combination and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

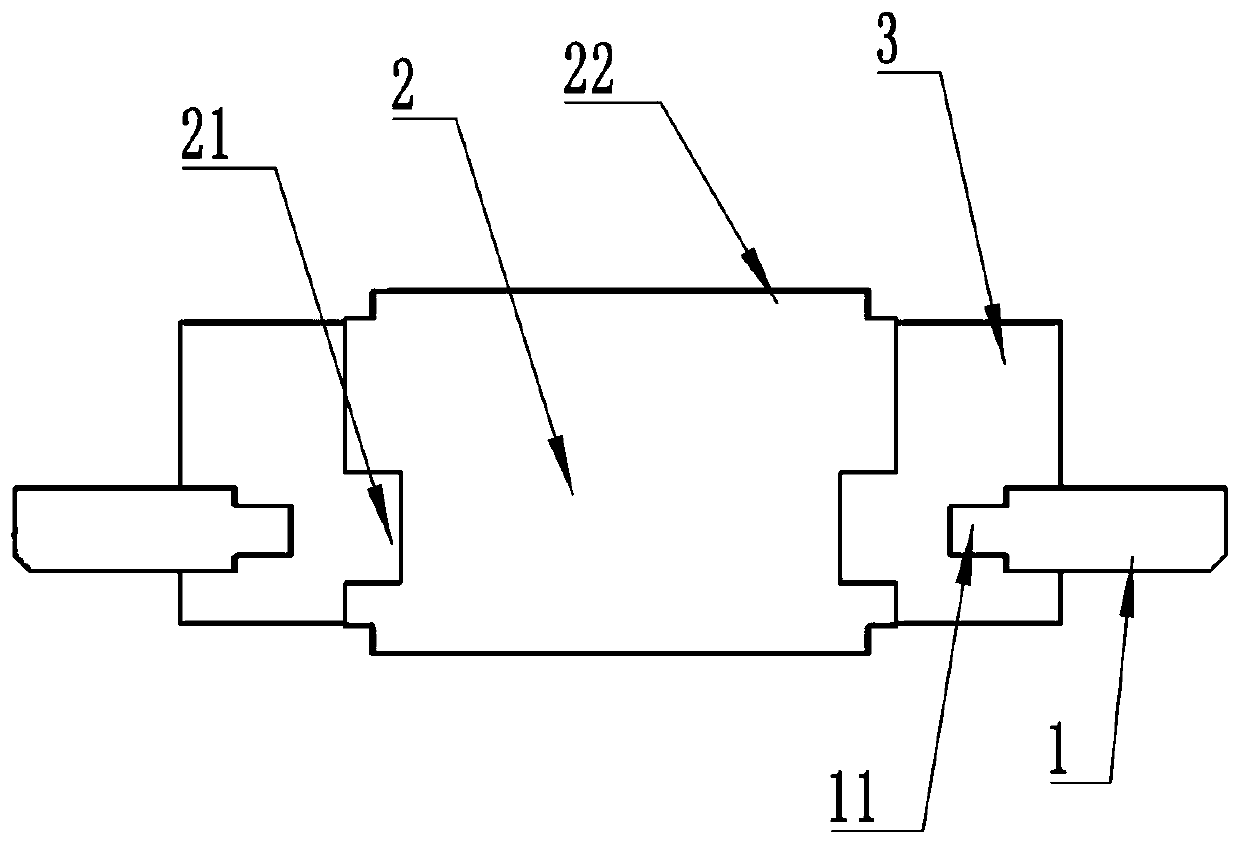

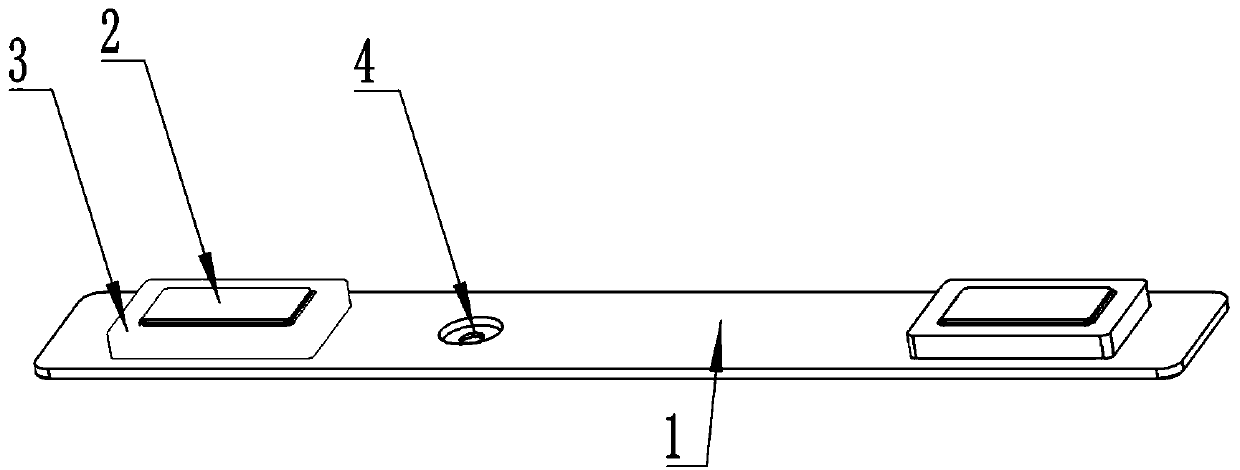

[0035] Please refer to Figure 1 to Figure 2 , this embodiment 1 provides a battery top cover based on block poles.

[0036] The battery top cover includes a cover plate 1, a plastic part 3 and at least one block pole 2; the block pole 2 and the cover plate 1 are fixedly connected through the plastic part 3;

[0037] The cover plate 1 is provided with a cover plate 1 hole for inserting the block pole 2, and the cover plate 1 hole penetrates the two opposite surfaces of the cover plate 1; the block pole 2 is inserted into the cover In the hole of the plate 1, a block-shaped pole groove 21 is opened on each surface of the block-shaped pole 2 facing the cover plate 1;

[0038] The plastic part 3 is arranged between the cover plate 1 and the block pole 2; the plastic part 3 fills the block pole groove 21 and wraps the part of the cover plate 1 facing the block pole 2 , and fixedly connect each surface of the block pole 2 facing the cover plate 1 .

[0039] In this embodiment, t...

Embodiment 2

[0052] This embodiment 2 provides a method for preparing a battery top cover based on block poles, and the battery top cover in embodiment 1 can be obtained.

[0053] The preparation method comprises the following steps:

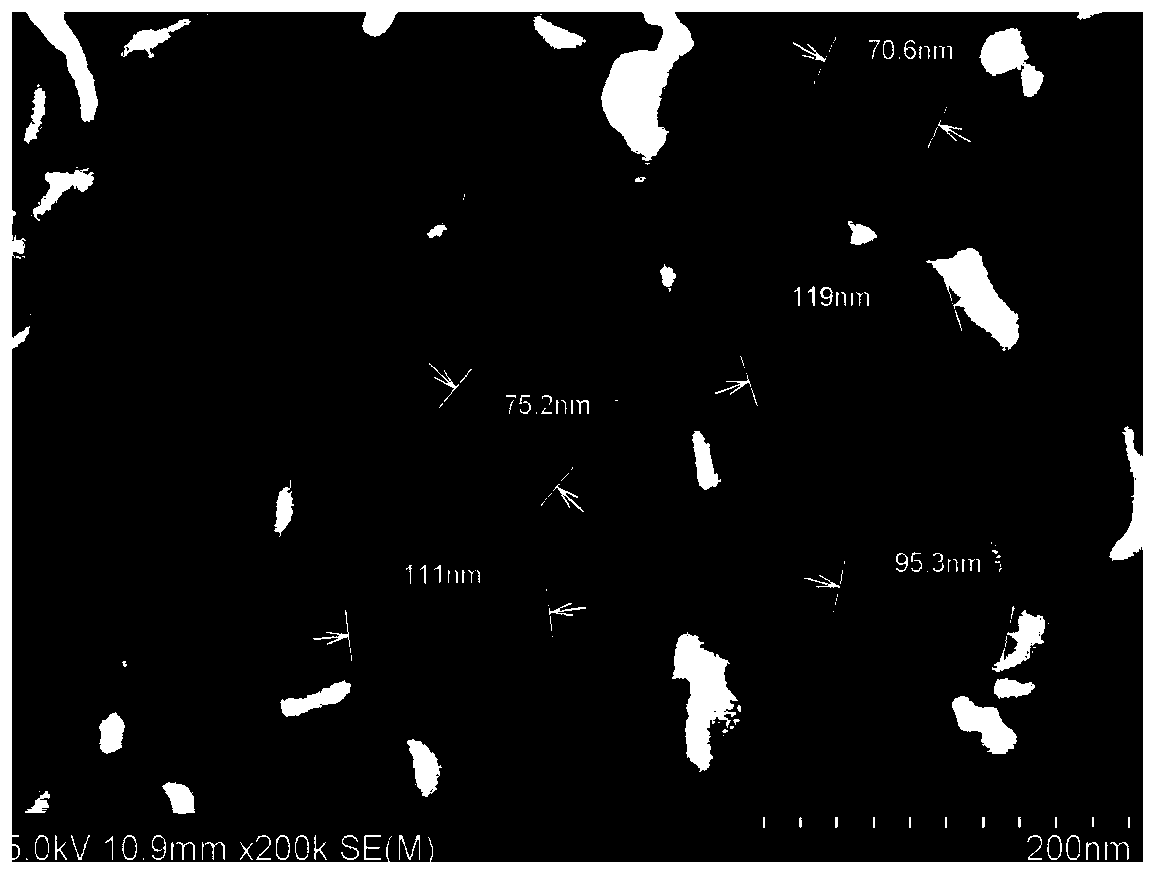

[0054] S1, opening a plurality of nanometer holes on the surface of the block pole 2 and the surface of the cover plate 1 facing the block pole 2 through chemical corrosion;

[0055] S2. Insert the block pole 2 into the hole of the cover plate 1;

[0056] S3. Plastic is injected at the junction of the block pole 2 and the cover plate 1 to form a plastic part 3, so that the block pole 2 and the cover plate 1 are fixedly connected.

[0057] Among them, the size and distribution density of the nanopores, the material of the injection molding plastic, etc. are all introduced in detail in Example 1, and will not be repeated here.

[0058] The opening of the nanopores in step S1 is carried out by chemical etching, and the chemical etching specifically includes t...

Embodiment 3

[0072] Embodiment 3 provides a lithium ion battery, including the battery top cover described in Example 1 and the battery top cover prepared by the preparation method in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com