High-performance ceramic coating and preparing method thereof

A ceramic coating, high-performance technology, applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of raw materials and processes that are not very mature, difficult to meet industrialization, etc., and achieve broad application prospects and economical Benefits, high production efficiency, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

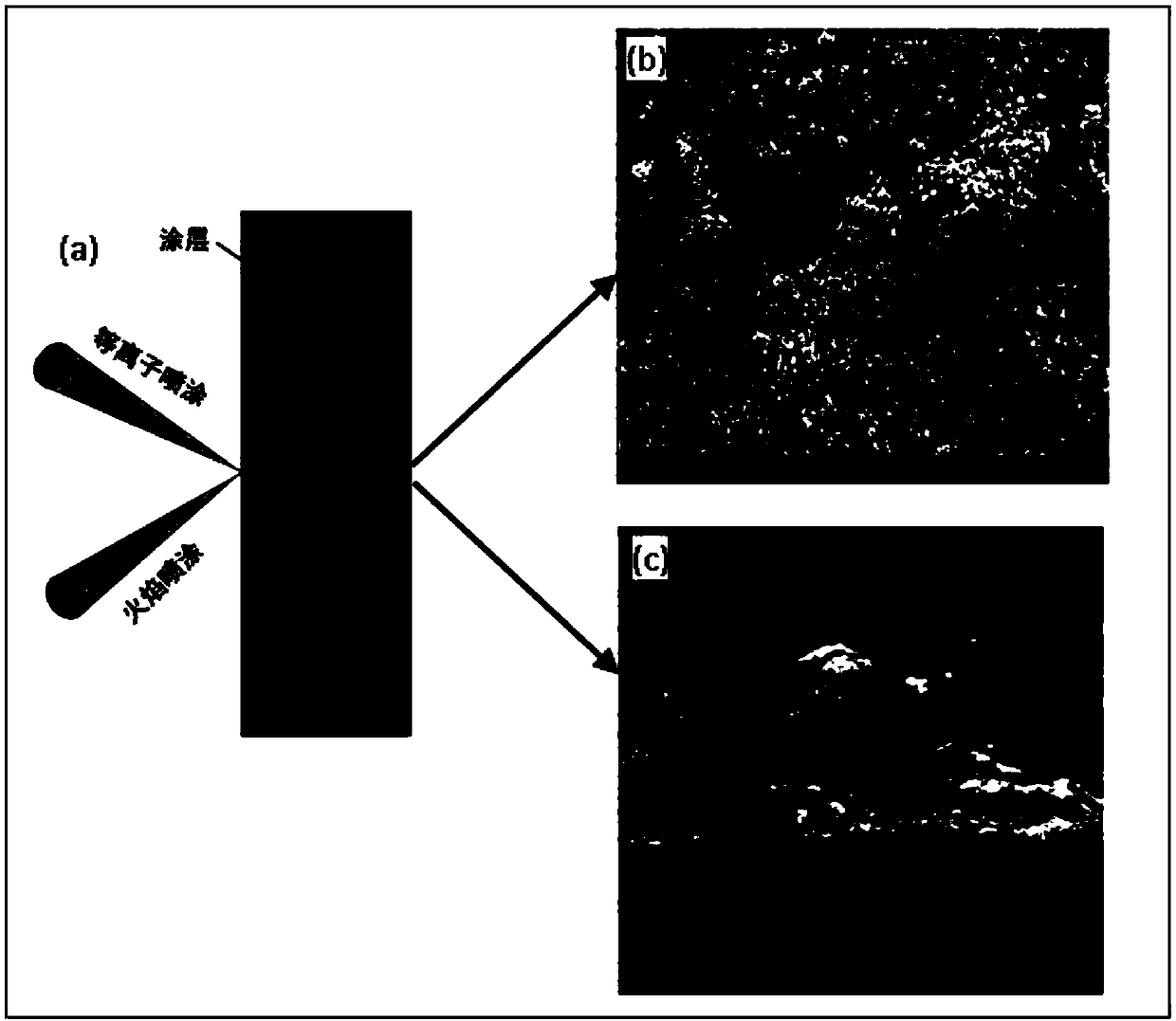

Method used

Image

Examples

Embodiment 1

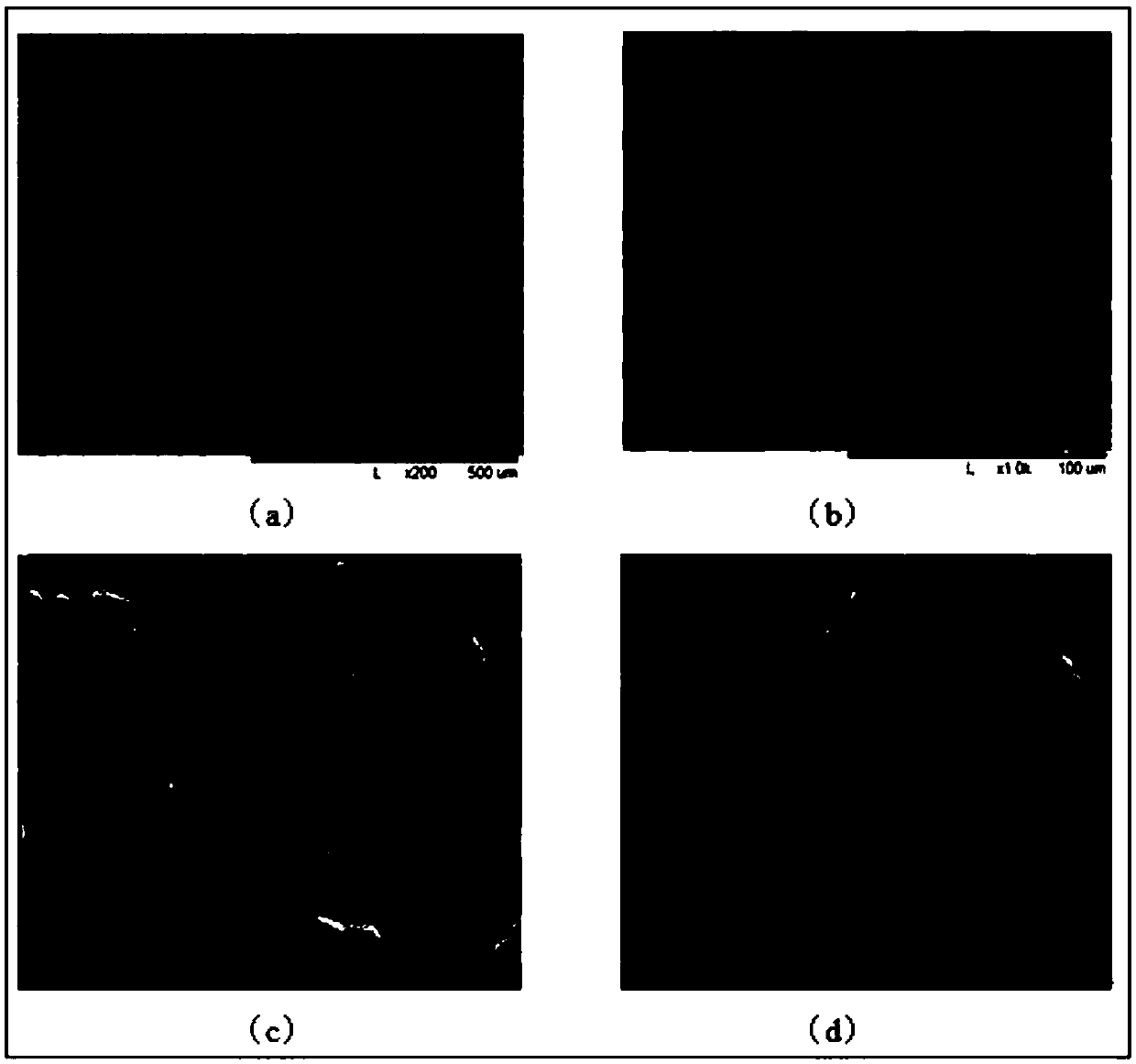

[0051] In this embodiment, micron powder selects TiO 2 Powder (particle size about 15-80μm), nano powder choose TiO 2 Powder (particle size about 10-100nm), nano-TiO in ceramic coating 2 The proportion of powder is 4wt%, and the thickness of the coating is about 50 μm. The specific preparation method of the coating is as follows:

[0052] 1. Use deionized water and alcohol as solvent, add 1wt% sodium carbonate powder as binder, add 4000ml of solvent into a 5000ml capacity beaker, and then weigh 4g of nano-TiO 2 Powder as solute. Put the configured nano-suspension into the ultrasonic cleaner and ultrasonically disperse for 30min, so as to reduce the concentration of nano-TiO 2 The agglomeration of the powder makes a relatively uniform nano-suspension.

[0053] 2. The substrate used is stainless steel. After cleaning, degreasing and derusting the substrate before spraying, put the substrate into the box dry sandblasting machine and use the pressure sandblasting method for su...

Embodiment 2

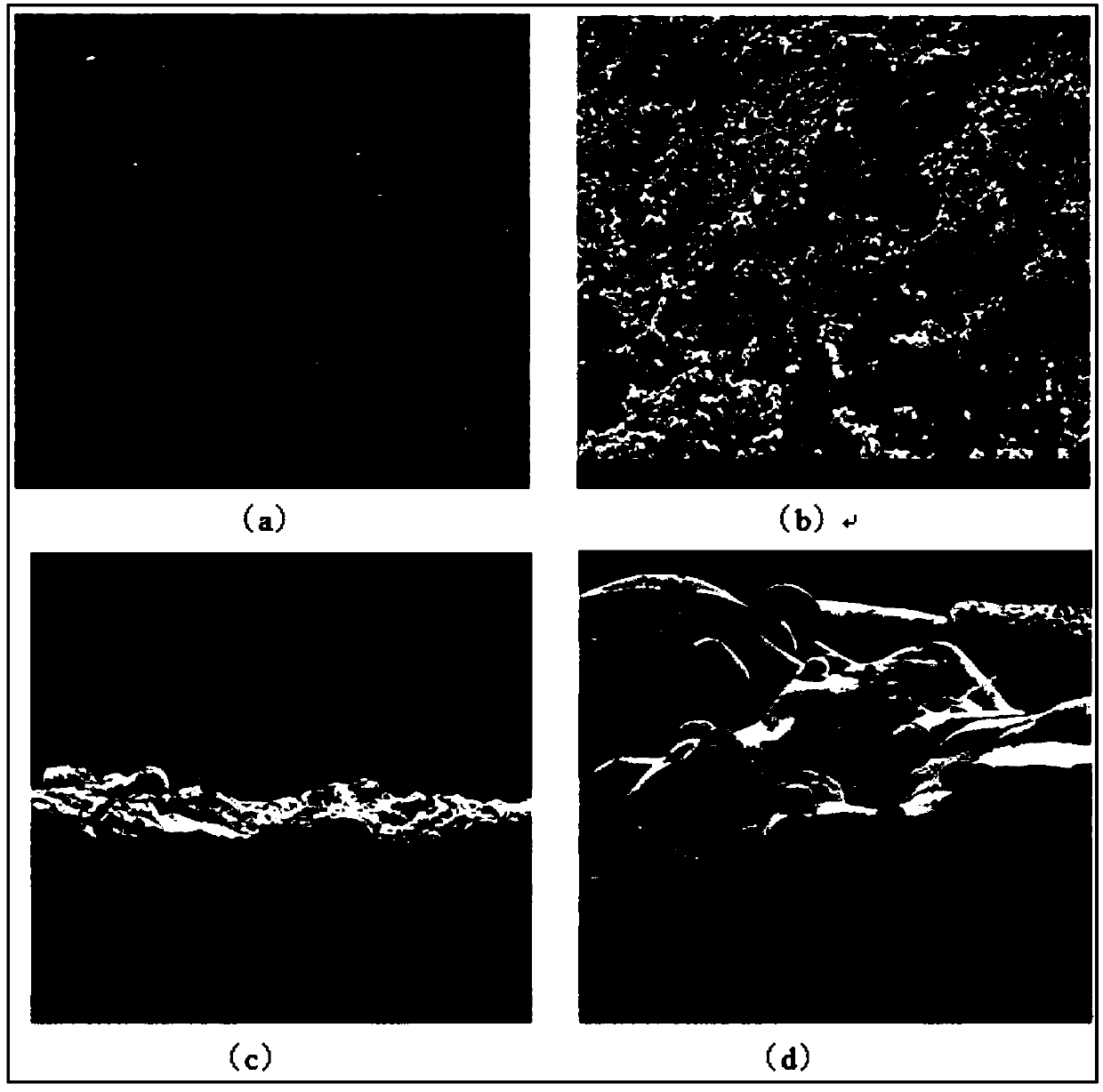

[0074] In this example, the specific preparation method of the ceramic coating is basically the same as that in Example 1, except that the proportion of nano-ceramic powder in the ceramic coating is 7 wt%.

[0075] Carry out following performance test to the ceramic coating that above-mentioned preparation obtains:

[0076] 1. Microhardness of the coating: The average hardness of the coating measured by the coating microhardness test method is 534.1HV.

[0077] 2. Coating adhesion: Through the coating adhesion test, the measured coating adhesion is 25.5N, which is higher than conventional coatings.

[0078] 3. Coating wear rate: using the coating friction and wear test method, the measured coating wear rate is 4.72×10 -7 mm 3 / N·m, the results show that the wear resistance of the coating is better than that of the conventional coating.

Embodiment 3

[0080] In this example, the specific preparation method of the high-performance ceramic coating is basically the same as that in Example 1, except that the powders used are micron Al 2 o 3 (particle size about 50μm) and nano-Al 2 o 3 (Particle size about 30nm) powder.

[0081] Carry out following performance test to the ceramic coating that above-mentioned preparation obtains:

[0082] 1. Microhardness of the coating: The average hardness of the coating measured by the coating microhardness test method is 575.4HV.

[0083] 2. Coating adhesion: Through the coating adhesion test, the measured coating adhesion is 37.5N, which is higher than the conventional coating.

[0084] 3. Coating wear rate: using the coating friction and wear test method, the measured coating wear rate is 5.45×10 -7 mm 3 / N·m, the results show that the wear resistance of the coating is better than that of the conventional coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com