Ultrasonic rolling and welding process

An ultrasonic and welding technology, which is applied in the technical field of connecting two objects, can solve the problems that the welding effect cannot be achieved, cracking and air leakage are easy to occur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

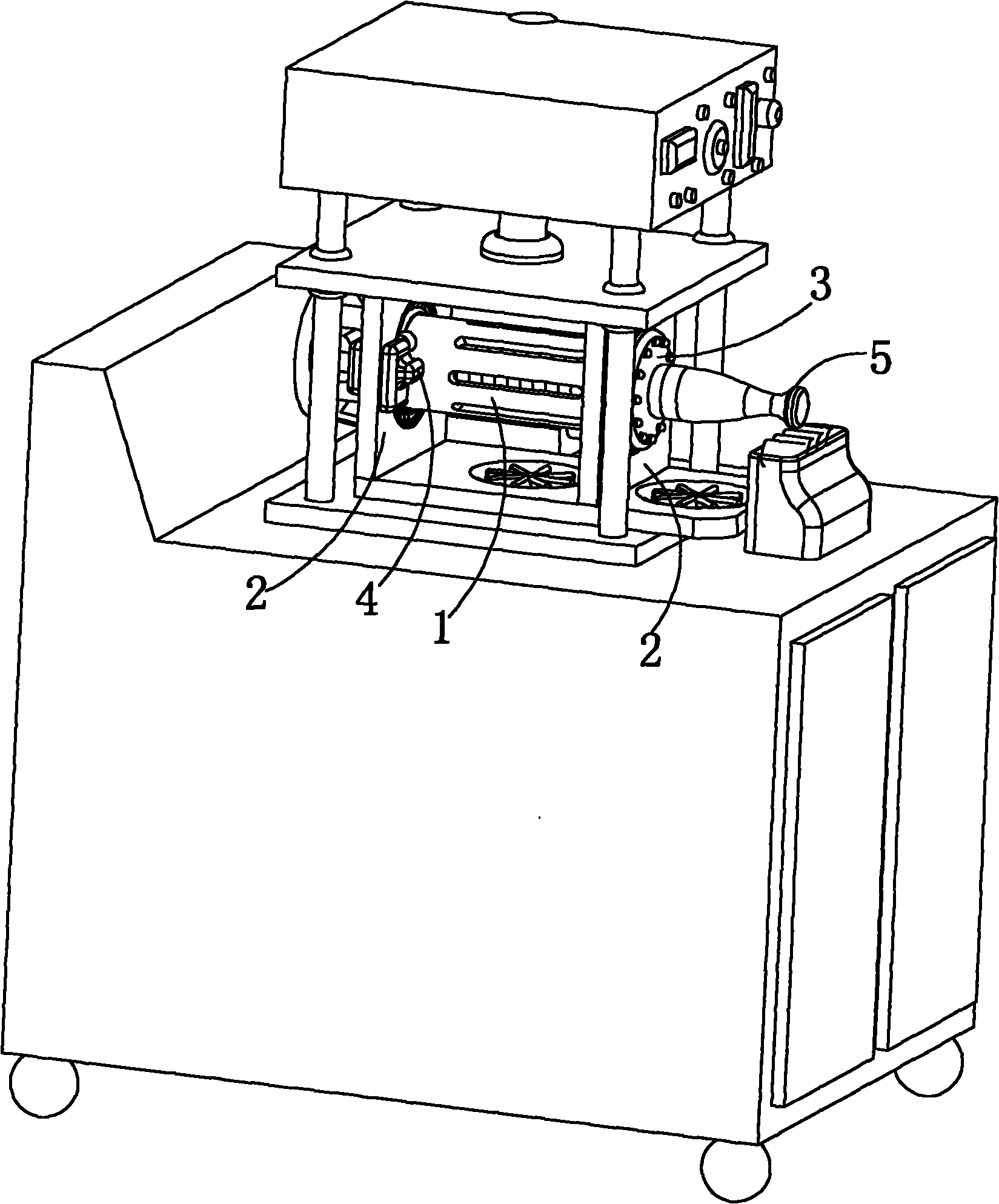

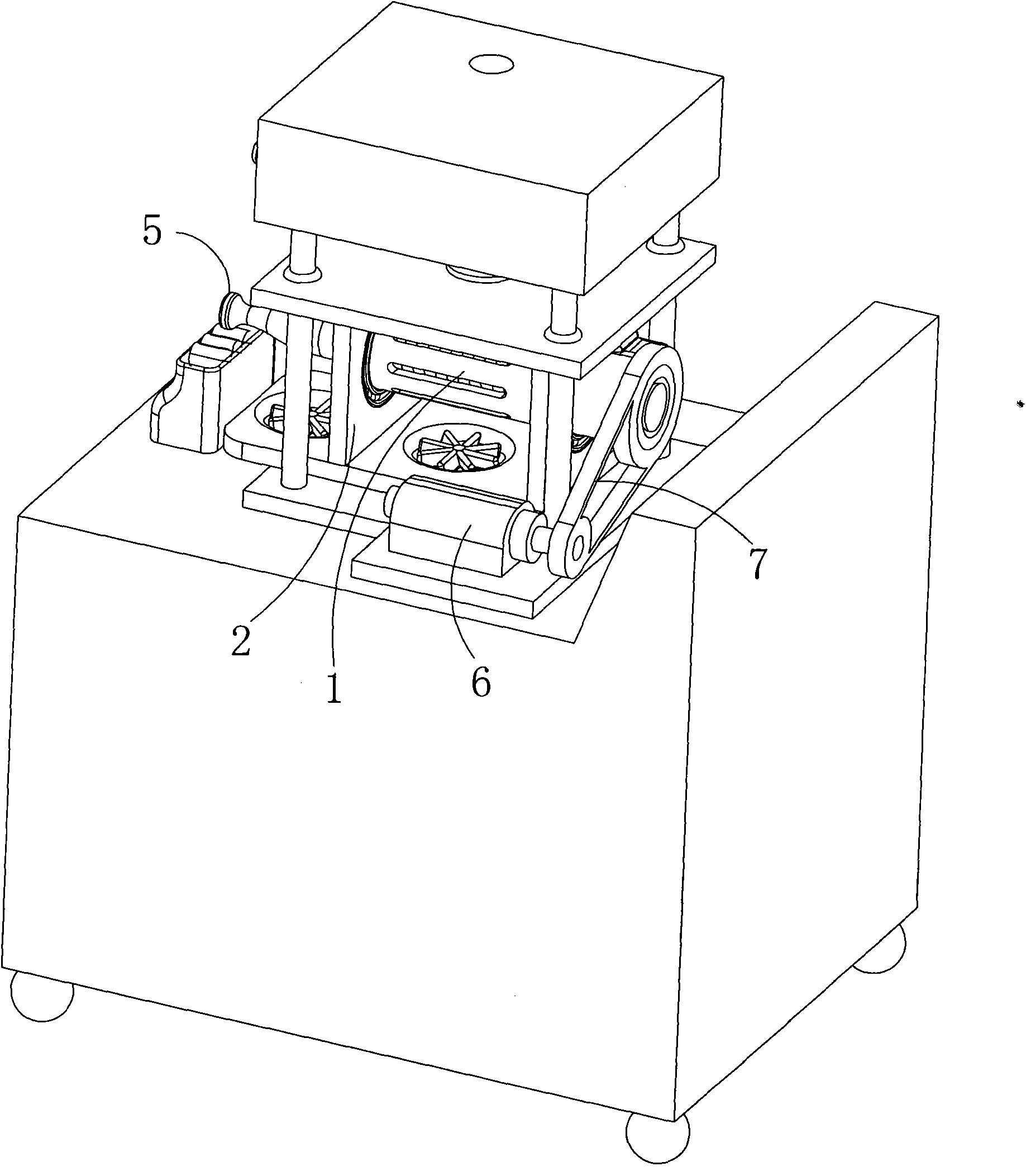

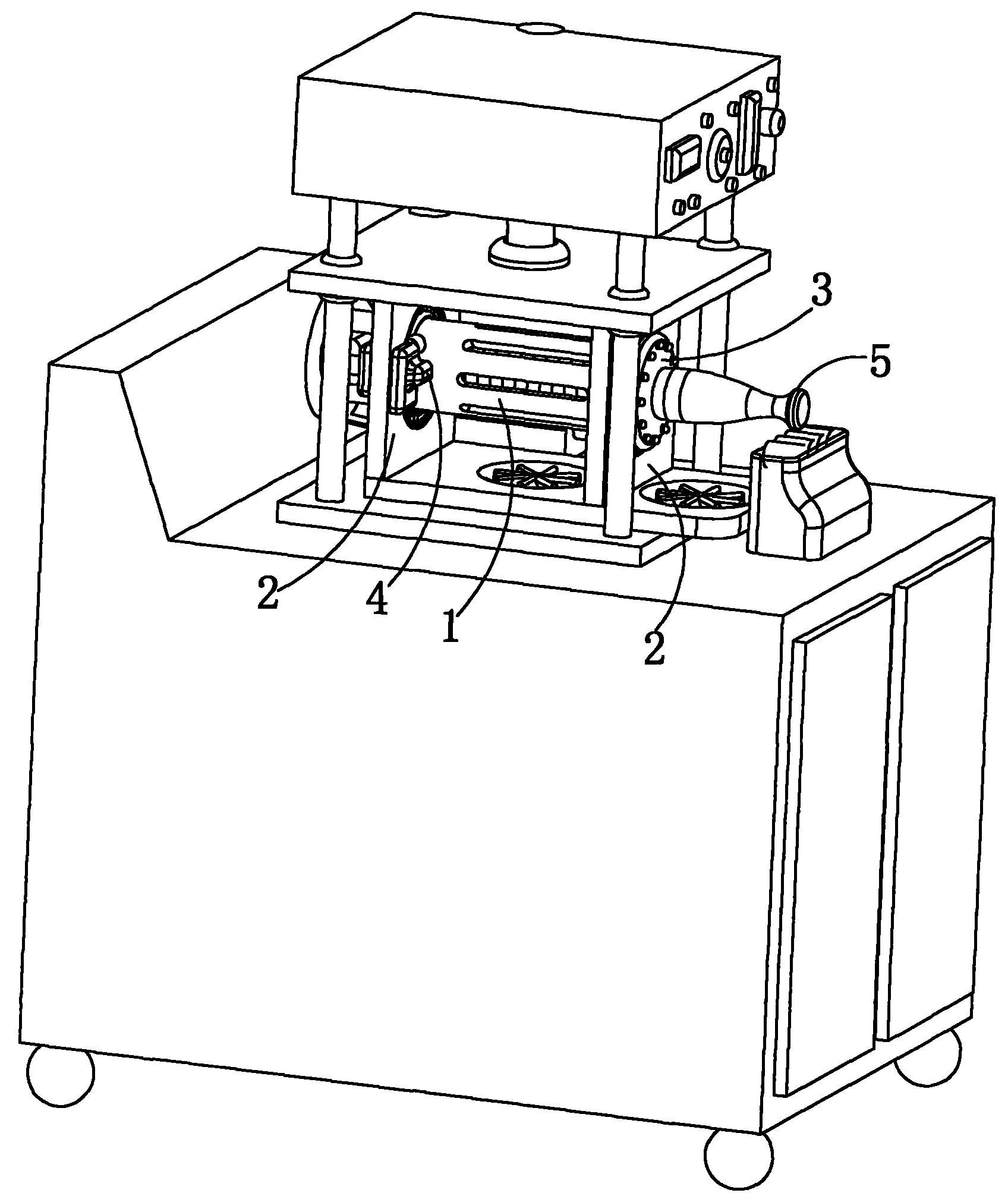

[0022] Embodiment: An ultrasonic rolling welding process, the vibrating cylinder 1 and the ultrasonic vibrators and transducers inside it are placed in the horizontal direction instead of the conventional vertical direction, and there are devices at both ends of the vibrating cylinder for Position the support plate 2 of the vibrating cylinder, and the two ends of the vibrating cylinder are rotatably connected to the supporting plate with bearings 3. There are two carbon brushes 4 arranged radially and symmetrically on the outside of the vibrating cylinder. The carbon brushes are connected with the ultrasonic oscillator, and the transducer will The frequency of the ultrasonic wave is controlled at 20kHz, and the transducer is connected with a welding die head 5 capable of resonating with the 20kHz ultrasonic wave. The welding die head is located outside the vibrating cylinder, and is provided with a motor 6 for driving the vibrating cylinder to rotate around its own axis , when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com