Sintering welding process of high-air-tightness powder metallurgical part

A technology of powder metallurgy and welding technology, which is applied in the direction of welding medium, welding equipment, metal processing equipment, etc. It can solve the problems that it is difficult to meet the requirements and can not completely guarantee the solder sealing pores, and achieve the requirements of improving air tightness and high air tightness , Improve the strength and airtightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

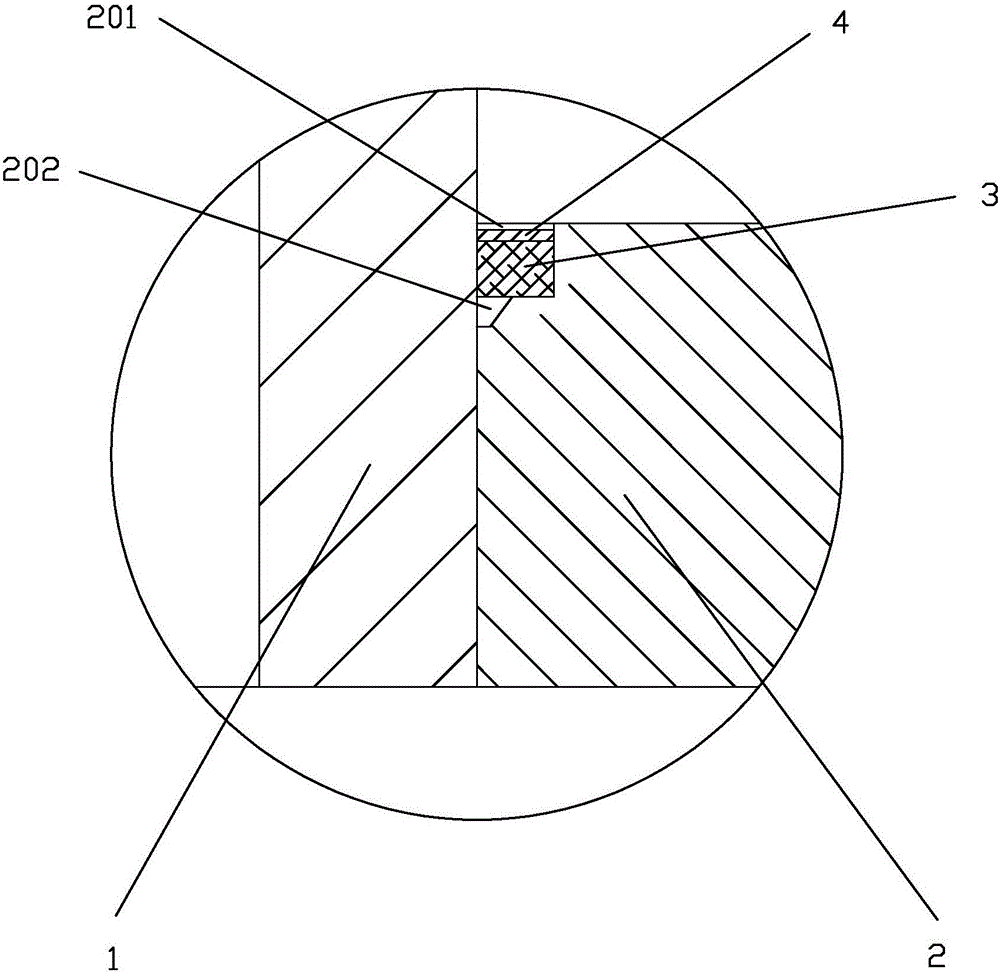

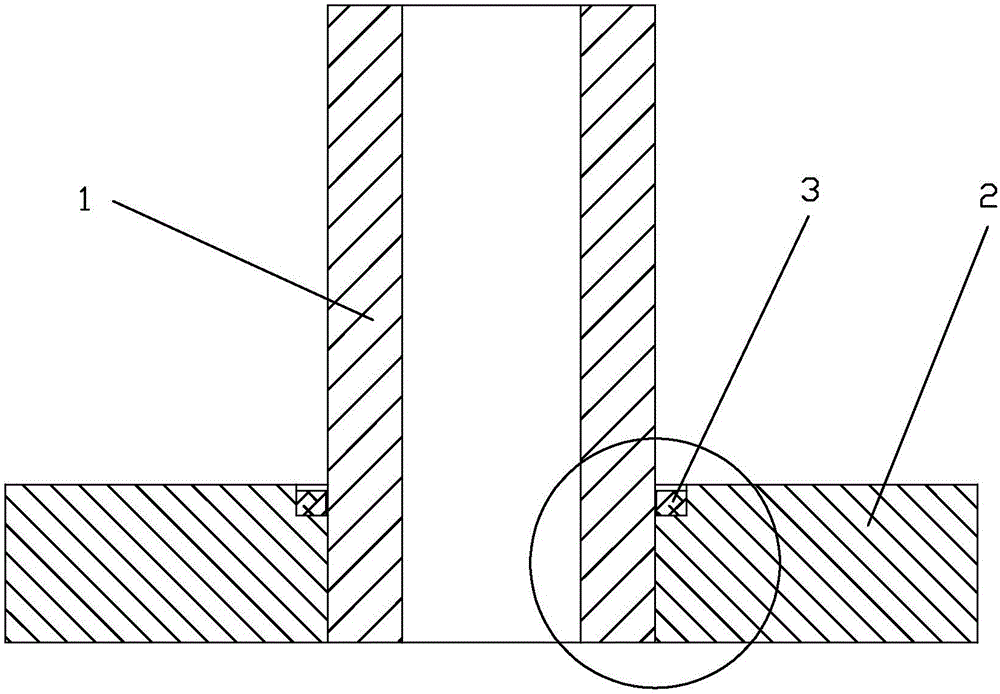

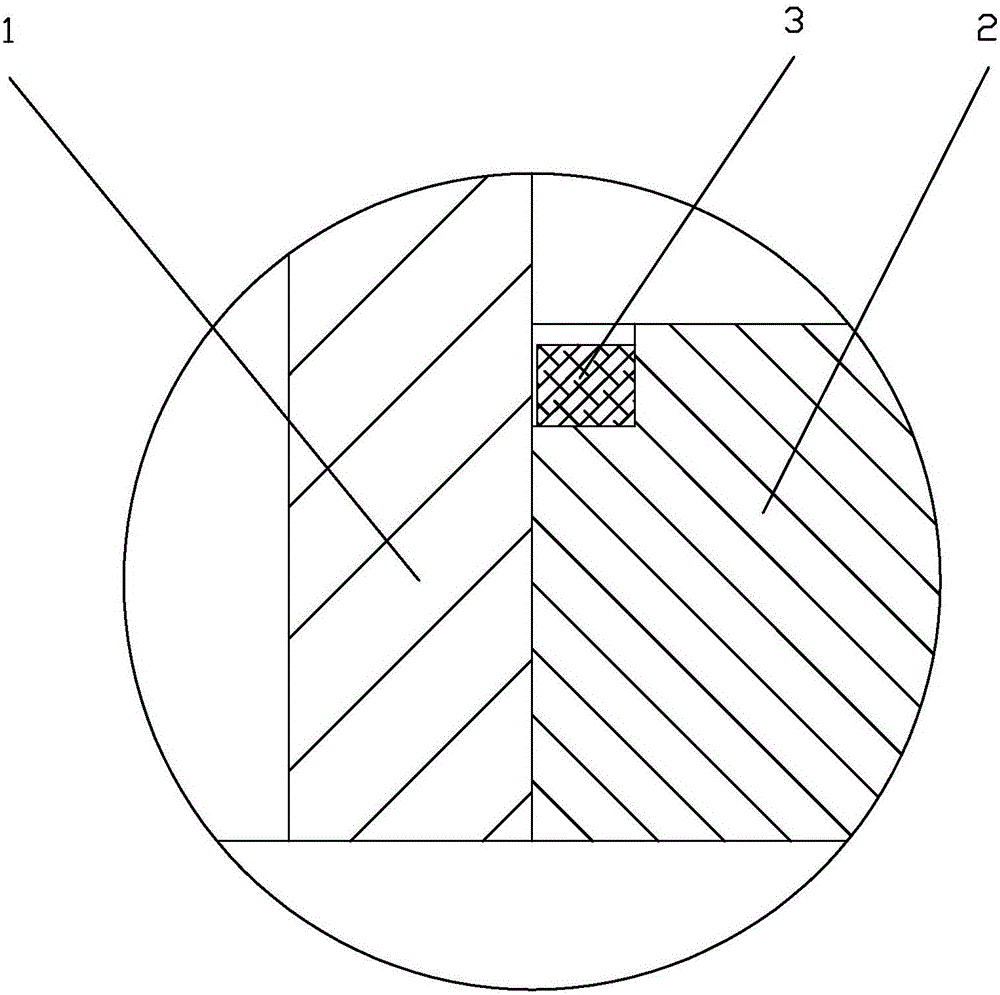

[0014] refer to figure 1 , a sintering and welding process of powder metallurgy parts with high airtightness, comprising the following steps: a. Combining powder metallurgy formed green bodies 1 and 2, assembling and positioning the two green bodies 1 and 2, and the gap requirement is 0.1~0.4mm; b. placing Solder 3; c, place the copper sheet 4 for welding, the copper sheet 4 is placed above the solder 3; d, enter the furnace for sintering, and there are four areas in the furnace, which are pre-fired and dewaxed areas in turn-temperature 580~630 degrees , Primary welding area - temperature 950 ~ 1000 degrees, sintering and secondary welding area - temperature 1100 ~ 1200 degrees, circulating water cooling area; e, furnace cooling. First, position the two green bodies 1 and 2 to ensure that the welding gap is 0.1~0.4mm, place the solder 3 and the copper sheet 4 in the solder placement tank 201, put the copper sheet 4 on the solder 3, and then send them into the sintering furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com