Automobile fuel tank

A technology for fuel tanks and automobiles, which is applied to vehicle components, the arrangement combined with the fuel supply of internal combustion engines, power plants, etc., and can solve the problems of fatigue cracking at the connection between the upper tank and the lower tank, vibration and instability of the fuel pump and dump valve , Stress dispersion at the joint, local stress and other issues, to achieve the effect of compact structure, high toughness, and easy processing and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

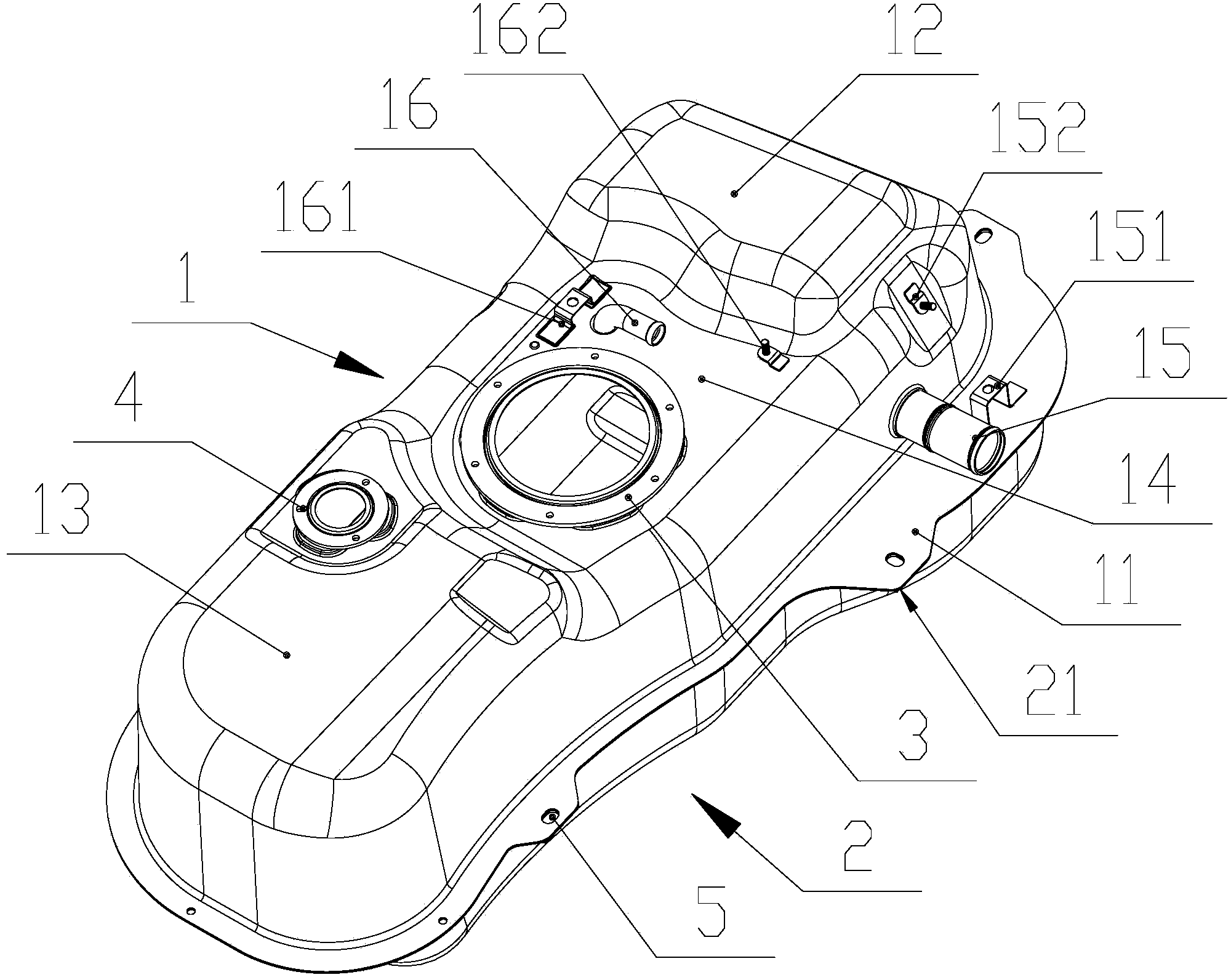

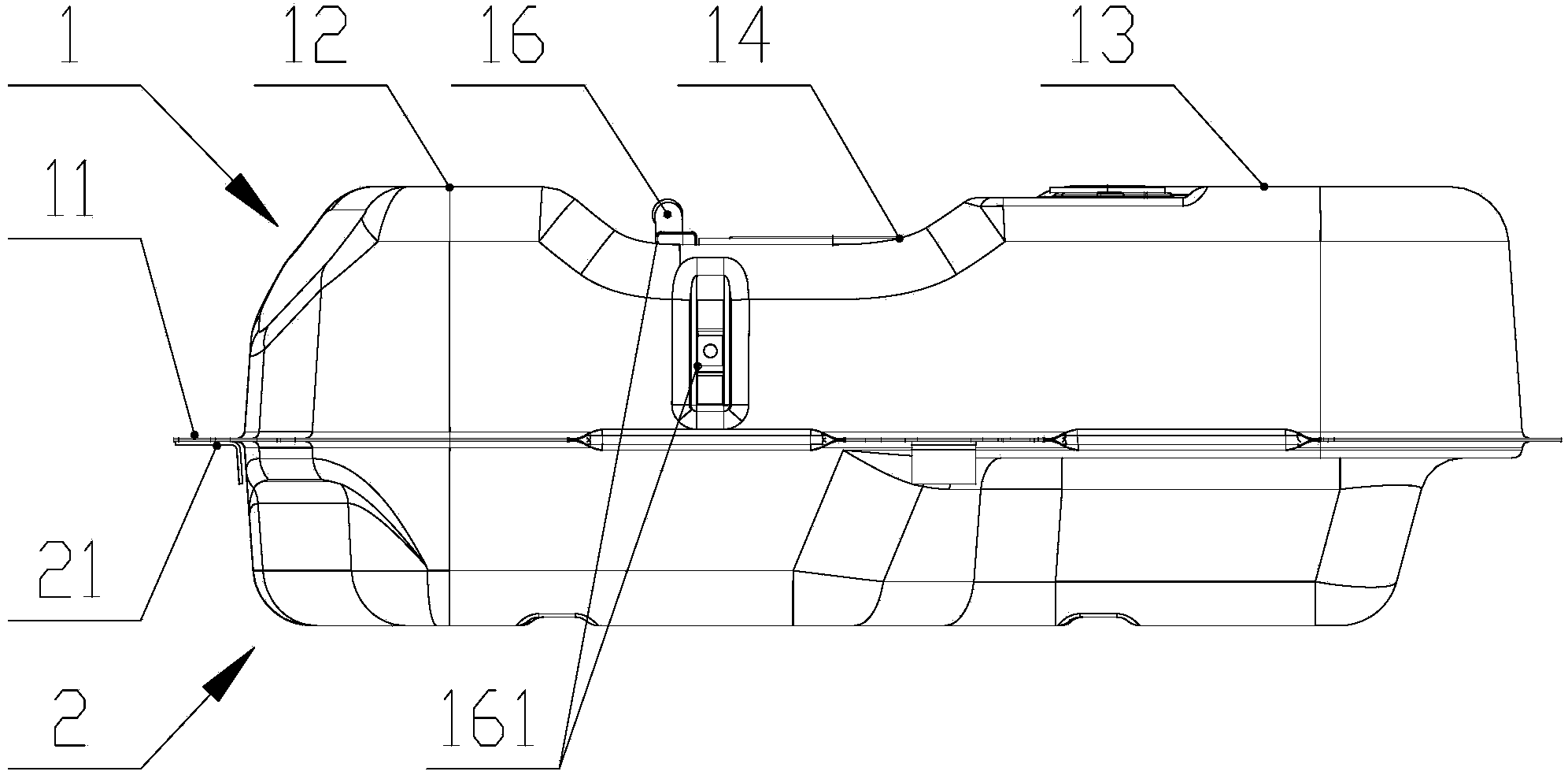

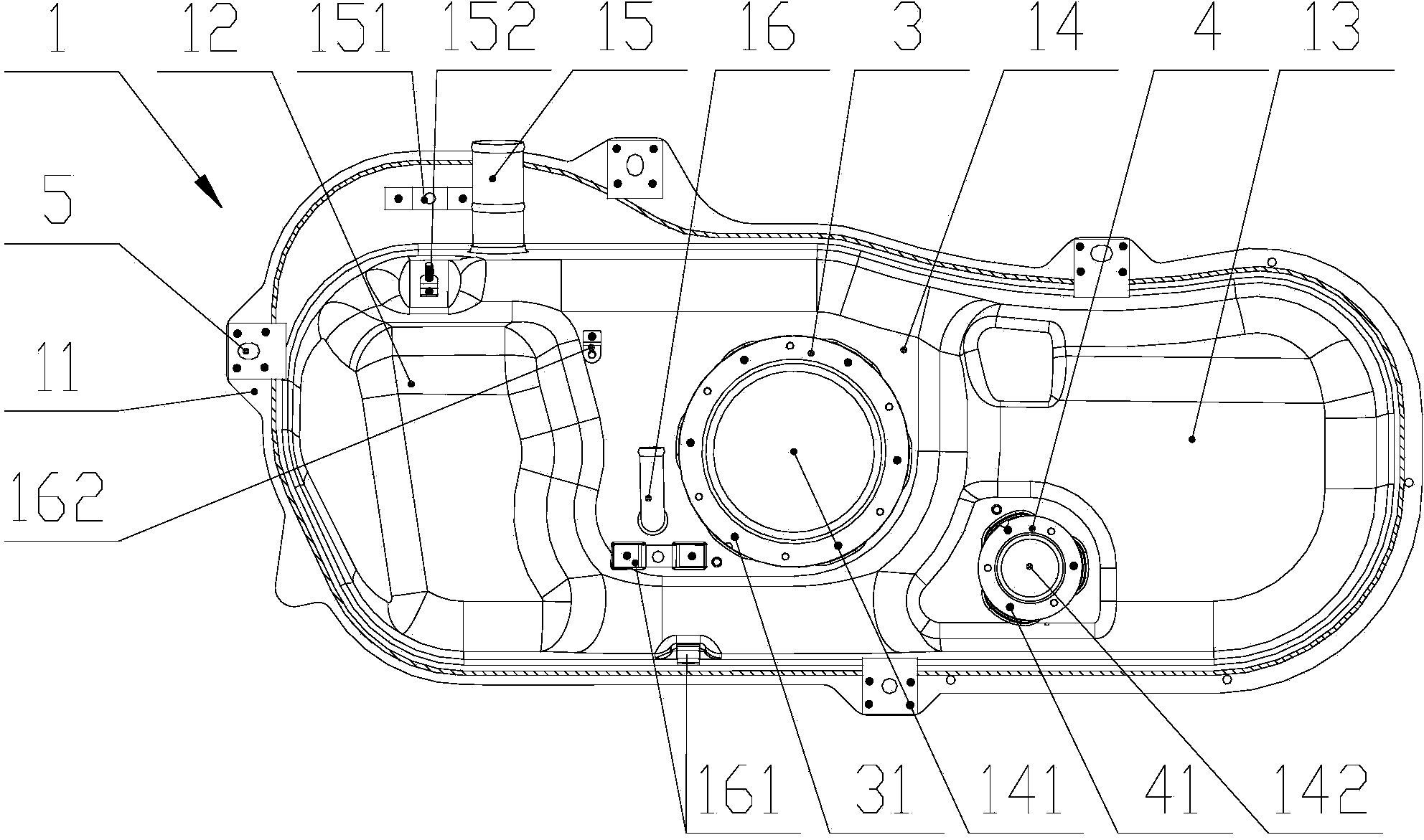

[0035] The upper box 1 is made of cold-rolled steel plate DC04 with a thickness of 0.8mm, and the lower box 2 is made of cold-rolled steel plate DC04 with a thickness of 1.0mm; the height of the upper box 1 is 150mm, and the height of the lower box 2 is 110mm; The transition fillet radius between the sides of the upper box 1 is 85mm, the transition fillet radius between the top surface and the side of the upper box 1 is 25mm; the transition fillet between the sides of the lower box 2 The radius is 85mm, and the transition fillet radius between the bottom surface and the side of the lower box body 2 is 30mm; the transition fillet between the upper box body 1 and the upper box ring edge 11 is 5mm; the lower box body 2 and the lower box ring The transition fillet between the sides 21 is 5 mm; ensure that the upper box body 1 and the lower box body 2 cannot have defects such as cracking and wrinkling during the molding process, and the material thinning rate is greater than or equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com