Battery cover plate structure based on nano injection molding and preparation method thereof

A battery cover, nano-injection technology, applied in battery cover/end cover, battery, nanotechnology and other directions, can solve the problem of low pass rate of battery cover, and achieve the effect of improving pass rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

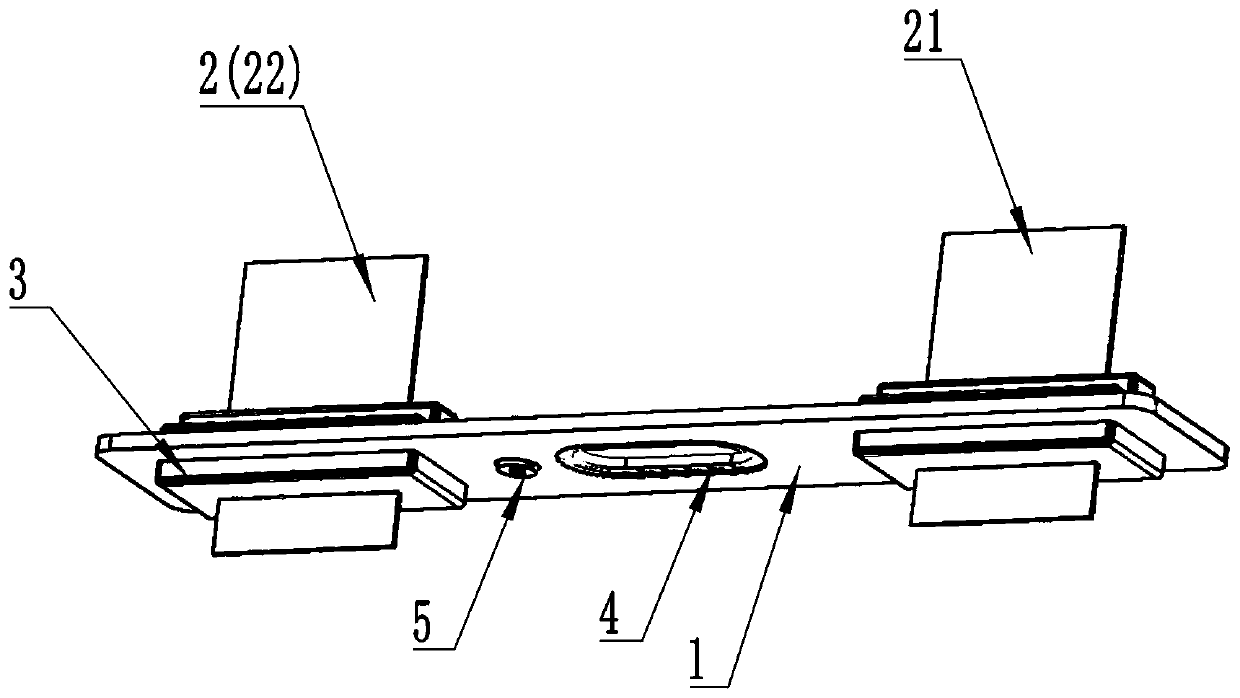

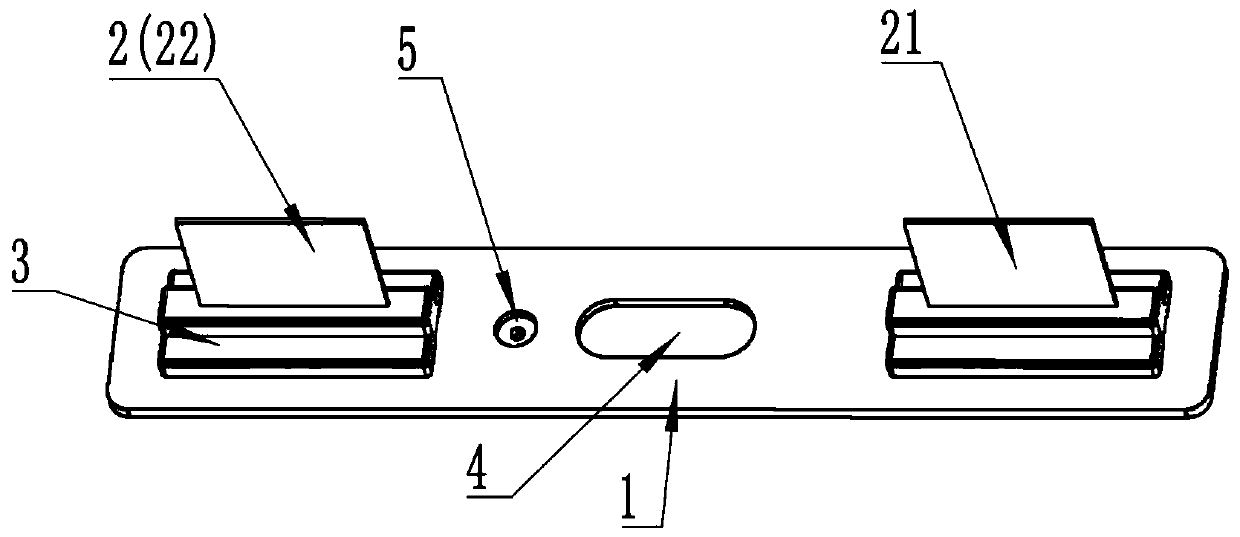

[0033] Please refer to figure 1 , this embodiment 1 provides a battery cover plate structure based on nano-injection molding.

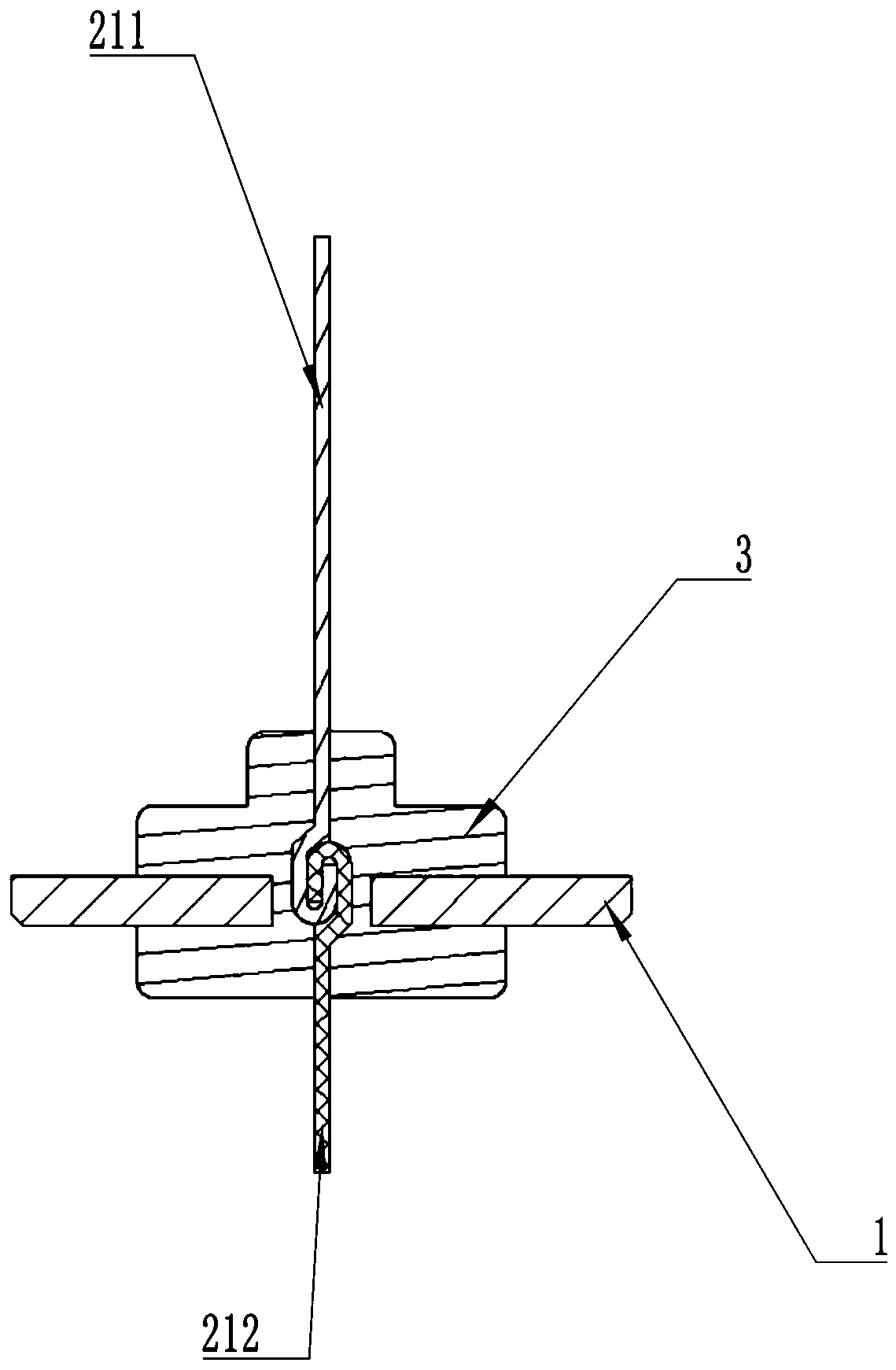

[0034] The battery cover plate structure includes a cover plate 1 and a connecting piece 2, and a plurality of nanopores are opened on the surface of the connecting piece 2 and the surface of the cover plate 1 facing the connecting piece 2; the cover plate 1 and the connecting piece 2 are fixedly connected by an injection molded part 3, and the injection molded part 3 penetrates into the nanopore.

[0035] After the airtightness test, it was found that the airtightness test leakage rate of the battery cover plate structure was less than 10 -7 (Pa·m 3 ) / s. The equipment used in the air tightness test is a helium detector provided by Anhui Wanyi Technology Co., Ltd. The specific process and parameters are as follows:

[0036] Place the battery cover structure in a sealed jig, and draw the internal vacuum through a vacuum pump (set time 15s, end at 3...

Embodiment 2

[0049] This embodiment 2 provides a method for preparing a battery cover structure based on nano-injection molding, and the battery cover structure in embodiment 1 can be obtained.

[0050] The preparation method comprises the following steps:

[0051] S1. Open a plurality of nanopores on the surface of the connecting sheet 2 and the surface of the cover plate 1 facing the connecting sheet 2;

[0052] S2. Insert the connecting sheet 2 with nanopores on the surface into the battery cover plate 1;

[0053] S3. Injecting plastic at the joint between the connecting piece 2 and the battery cover 1 to form an injection molded part 3, so that the connecting piece 2 and the battery cover 1 are fixedly connected.

[0054] Among them, the size and distribution density of the nanopores, the material of the injection molding plastic, etc. are all introduced in detail in Example 1, and will not be repeated here.

[0055] The opening of the nanopores in step S1 is carried out by chemical ...

Embodiment 3

[0069] Example 3 provides a lithium ion battery, including the battery cover structure described in Example 1 and the battery cover structure prepared by the preparation method in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com