Building door and window self-telescopic locking seal hardware structure

A technology for building doors and windows and self-retraction, which is applied in building structures, building fastening devices, buildings, etc., can solve the problems of the window system being difficult to meet the requirements of air tightness, the aging deformation of sealing materials, and the long service cycle of the door and window system. , to achieve the effect of improving building energy-saving standards, improving air tightness and structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

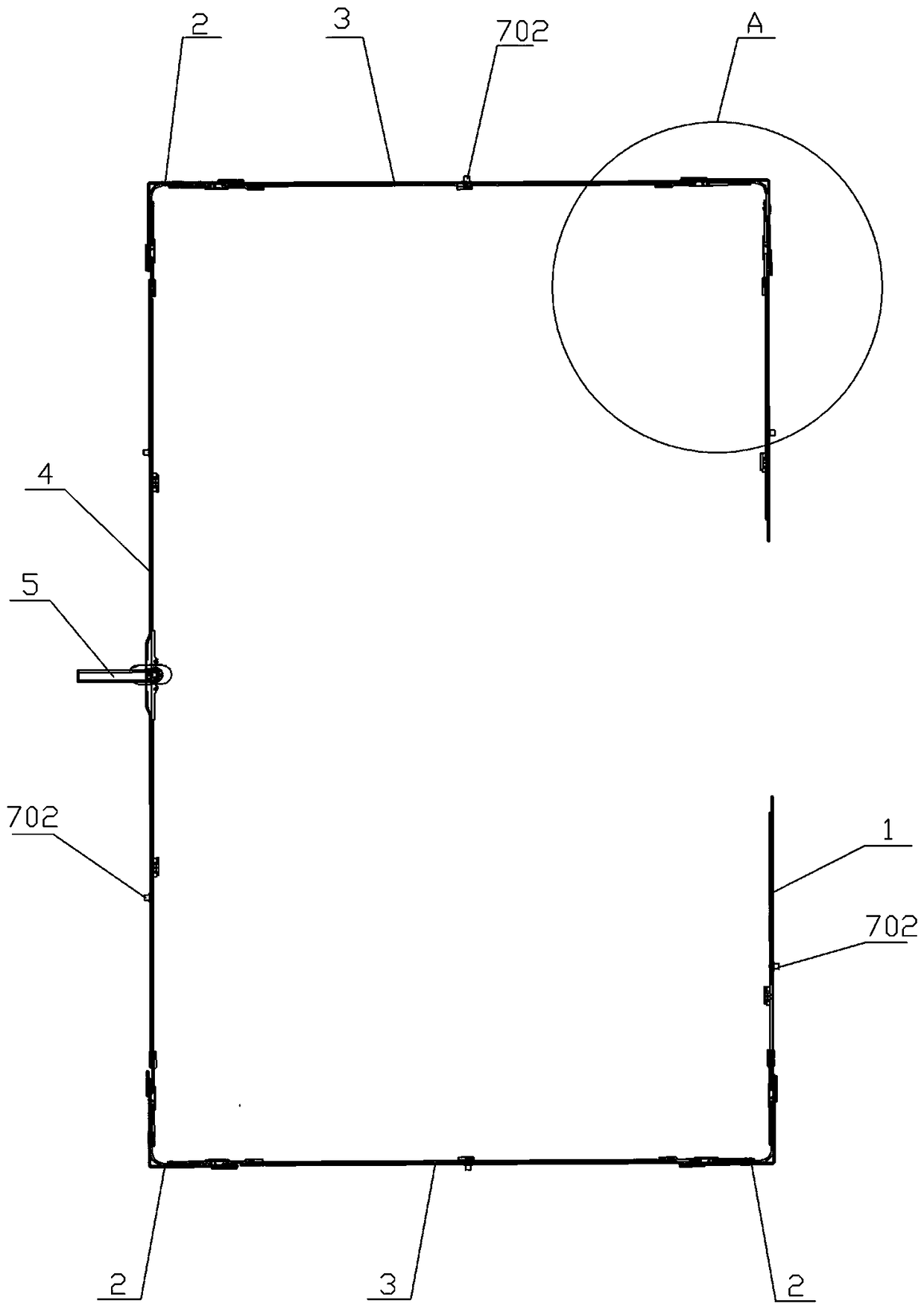

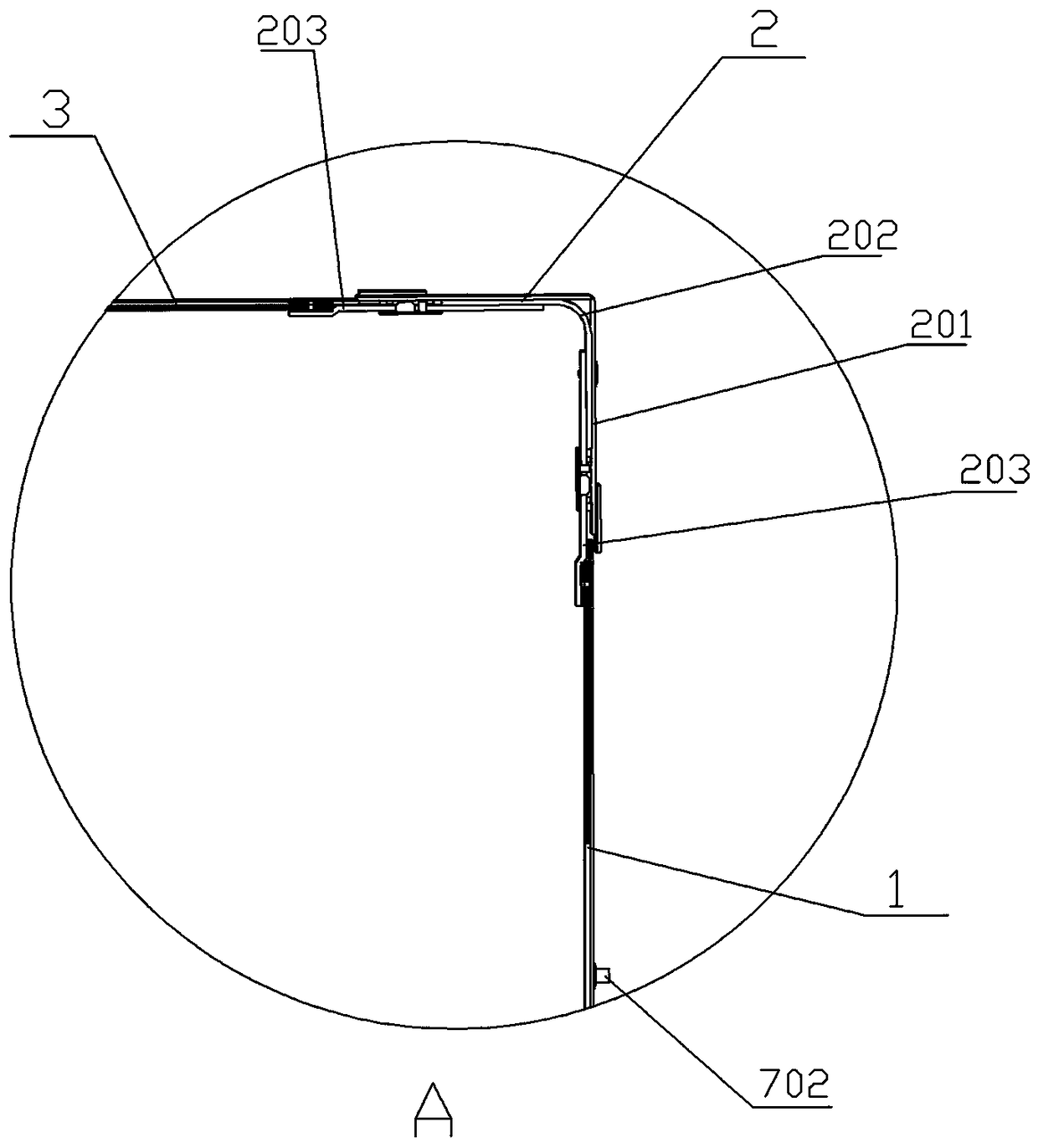

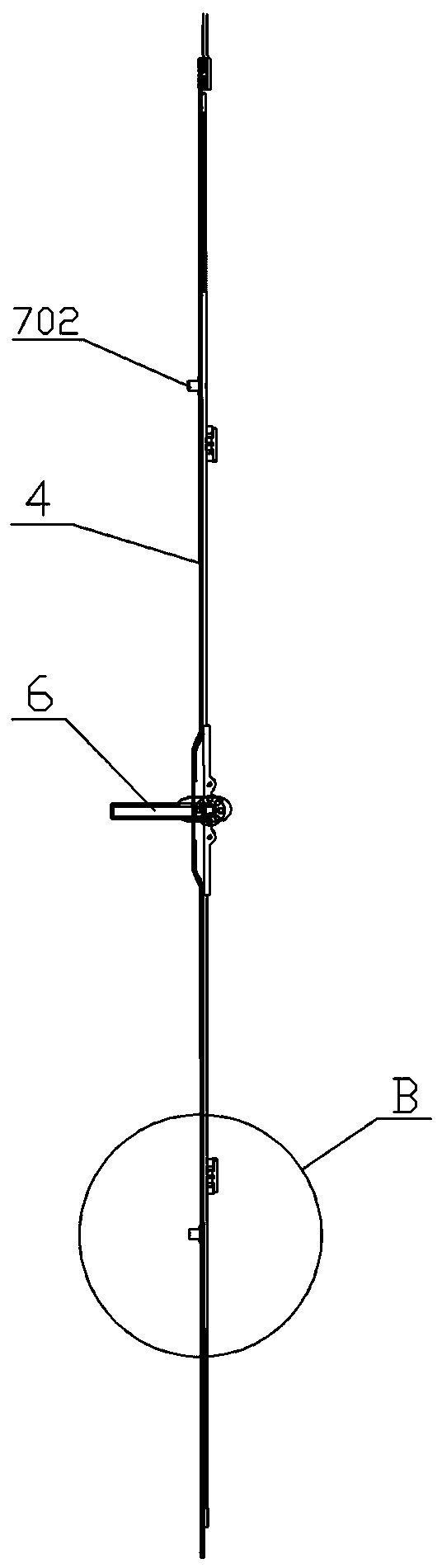

[0027] The building door and window self-telescopic locking and sealing hardware structure of the present invention includes a transmission assembly 1, a corner assembly 2, a connecting transmission lock point assembly 3, an intermediate lock angle transmission 4, a handle 5 and a lock seat 6, and the corner assemblies 2 are respectively Fixedly arranged at the four corners of the outer side wall of the window sash, the connecting transmission locking point assembly 3 is fixedly arranged on the upper and lower frames of the outer side wall of the window sash, and the connecting transmission locking point assembly 3 is arranged parallel to the upper and lower frames of the window sash. The two ends of the locking point assembly 3 are fixedly connected with the corner assembly 2 at the upper and lower corners of the window sash; the transmission assembly 1 is fixed and symmetrically arranged on the side frame on one side of the window sash; The corner assembly 2 with side up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com