Plastic film sealing blade

a sealing blade and plastic film technology, applied in the direction of packaging, metal working equipment, etc., can solve the problems of deteriorating the quality and appearance of packaged goods, affecting the sealing edge, and observing irregular sealing edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

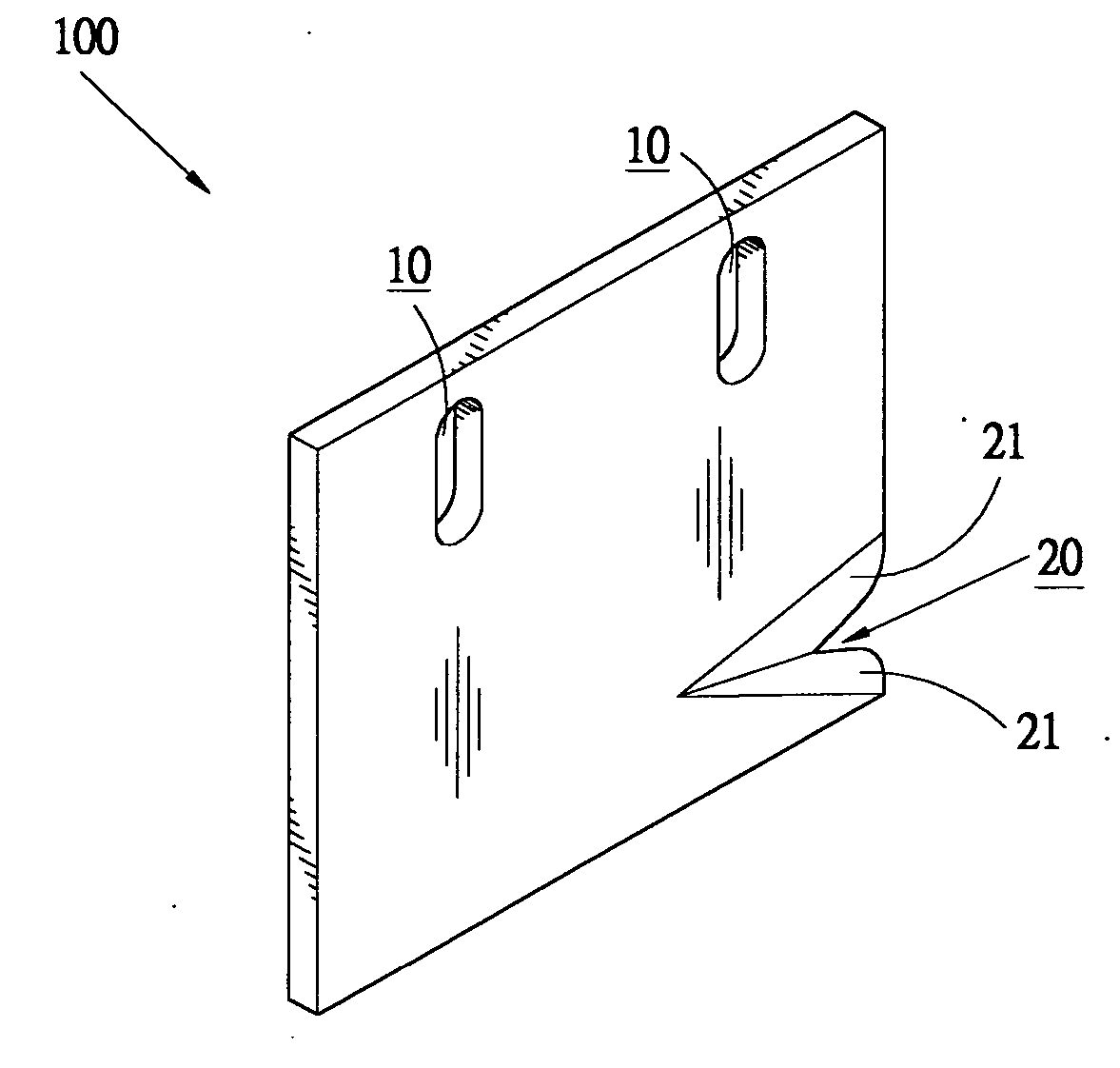

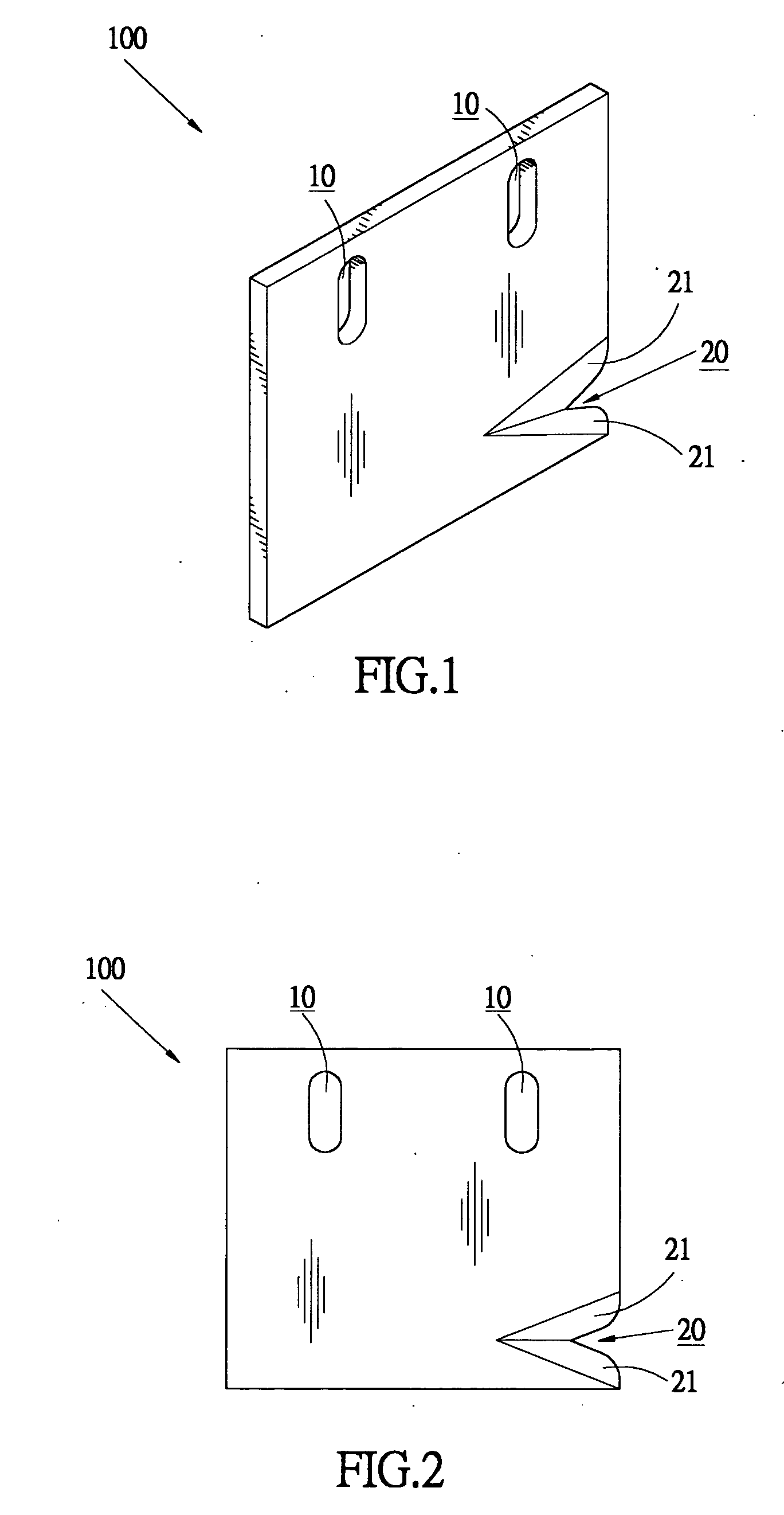

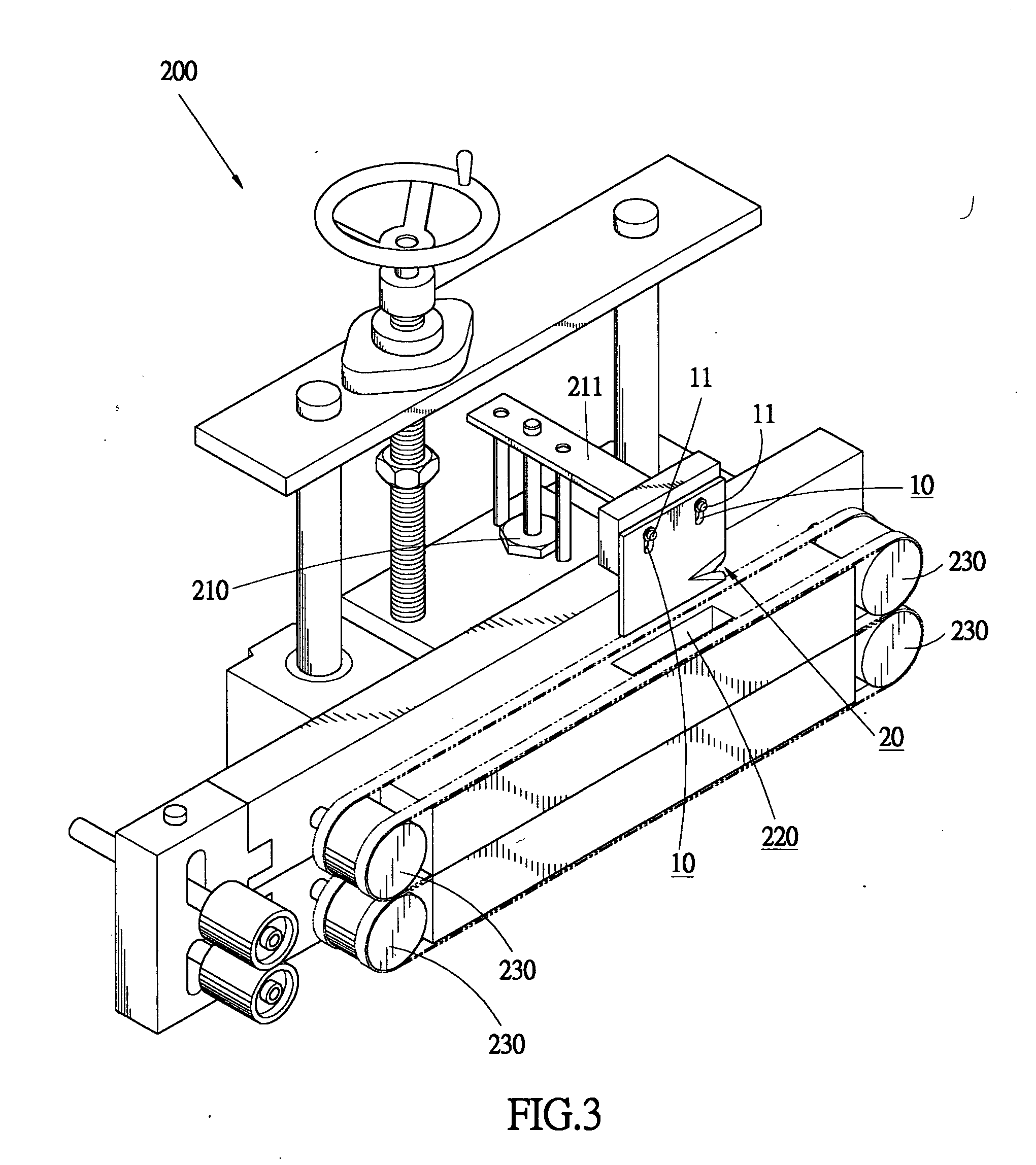

[0018] With reference to the drawings and in particular to FIGS. 1 and 2, a sealing blade constructed in accordance with the present invention, generally designated with reference numeral 100, comprises a flat-board-like body having opposite primary surfaces defining a thickness of the boar. A plurality of connecting slots 10 is defined in the blade 100. The slots 10 can be of any desired shaped and are preferably elongated. A cutoff or notch 20 is defined in a front edge of the board. The notch 20 can be of any desired shaped, but is preferably a V-shape as illustrated in the drawings. The V-shaped notch 20 is delimited by two sharp edge sections 21, each edge section having an edge line and opposite inclined faces extending from the edge line to the primary faces of the board respectively. Alternatively, the edge line may be coincident with one of the primary face and the sharp edge section 21 has only one inclined face extending from the edge line to the opposite primary face of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com