Skin of morphing wing and drive method thereof

A technology of variant wings and driving methods, applied in the directions of wings, aircraft parts, transportation and packaging, etc., can solve the problems that cannot meet the requirements of smooth surface, continuous and overall air tightness of the wing, internal structure of the wing, and driving methods. It can solve the problems of complex deformation control and low overall bearing capacity of the wing, so as to achieve the effect of light weight, large deformation and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

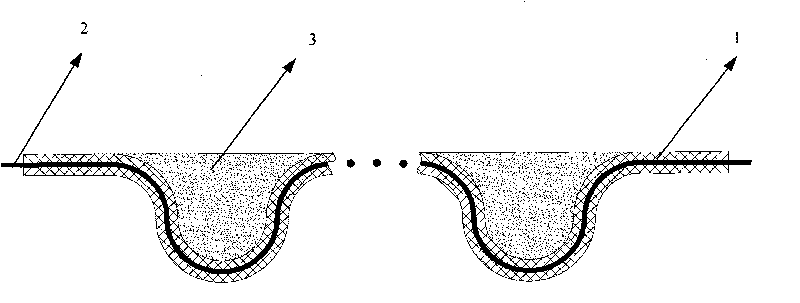

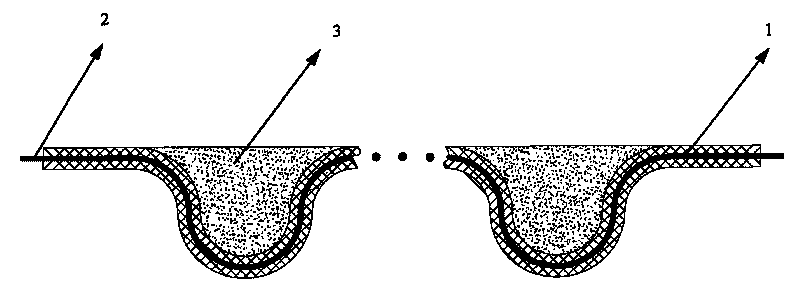

[0029] like figure 1 , figure 2 As shown, a variant wing skin is made of fiber-reinforced composite material 1, which is made of glass fiber, carbon fiber or aramid fiber prepreg, in two layers of fiber-reinforced A shape memory alloy actuator 2 is arranged between the composite materials 1, and the fiber reinforced composite material 1 and the shape memory alloy actuator 2 are pressed together into a corrugated configuration at 10°C; the troughs of the upper fiber reinforced composite material are filled with Silicon-based rubber 3; the shape memory alloy actuator 2 has a high-temperature memory linear shape; the shape memory alloy actuator 2 adopts a one-way shape memory alloy.

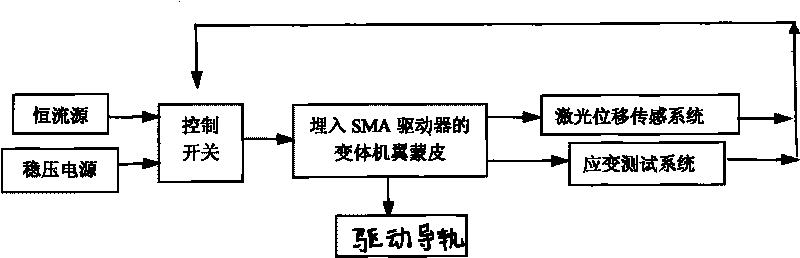

[0030] The driving method of the variant wing skin in this embodiment is:

[0031] The modified wing skin is installed on the driving guide rail, and a spring-type shape memory alloy driver is respectively installed on both sides of the modified wing skin through a reinforcement sheet, which is u...

Embodiment 2

[0036] like figure 1 , figure 2 As shown, a variant wing skin is made of fiber-reinforced composite material 1, and the fiber-reinforced composite material is made of fiber, made of glass fiber, carbon fiber or aramid fiber and resin matrix by conventional methods, A shape memory alloy actuator 2 is arranged between two layers of fiber-reinforced composite materials 1, and the fiber-reinforced composite material 1 and the shape memory alloy actuator 2 are pressed into a corrugated configuration at 40°C; the upper layer of fiber-reinforced Silicon-based rubber 3 is filled in the trough of the composite material; the shape memory alloy actuator 2 memorizes a linear shape at high temperature; the shape memory alloy actuator 2 adopts a two-way shape memory alloy, which memorizes a linear shape at high temperature and a corrugated shape at low temperature.

[0037] The driving method of the variant wing skin in this embodiment is:

[0038]Install the variant wing skin on the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com