Stamping detection method for new energy automobile battery pack upper cover

A new energy vehicle and detection method technology, which is applied in the stamping detection field of the battery pack cover of the new energy vehicle, can solve the problems of low processing efficiency and poor airtightness of the battery pack cover, and achieve high processing efficiency and stretch forming quality Good, overcome the effect of low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

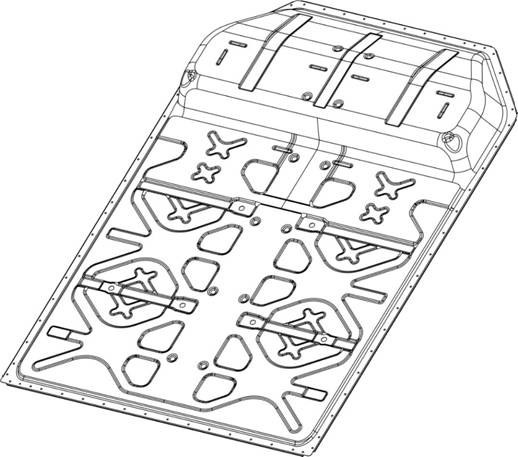

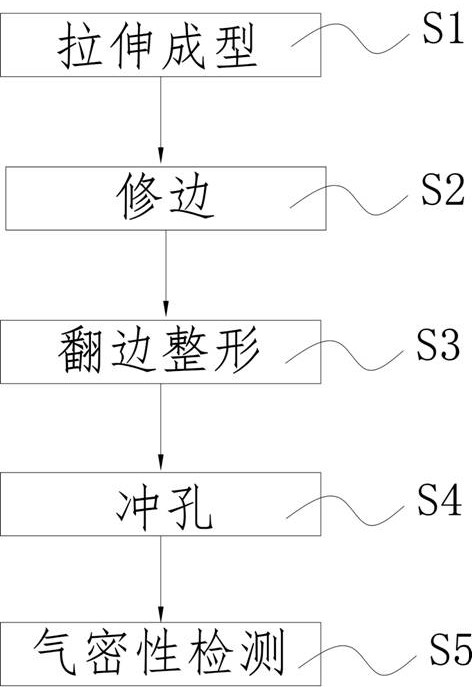

[0045] refer to Figure 2 to Figure 19 , the invention provides a stamping detection method for the upper cover of a battery pack of a new energy vehicle, comprising the following steps.

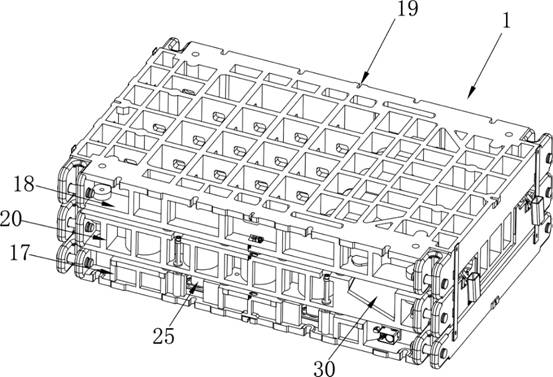

[0046] Step S1: Stretch forming; feed the plate to be processed to the stretching station, and stretch and form the plate through the stretching die 1 on the stretching station; The high first bead structure and the second bead structure cooperate to control the flow direction of materials to ensure the molding quality.

[0047] Step S2: trimming; moving the material to the trimming station, and punching and trimming the outer edge of the stretched semi-finished product through the tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com