Palladium/palladium alloy membrane purifier and use method thereof

A palladium alloy membrane and purifier technology, which is applied in chemical instruments and methods, separation methods, hydrogen/synthesis gas production, etc., can solve the problems of hydrogen purification device failure, inconsistent film thickness, pinholes, etc., and achieve hydrogen permeation efficiency and The effect of high energy utilization rate, wide application field and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

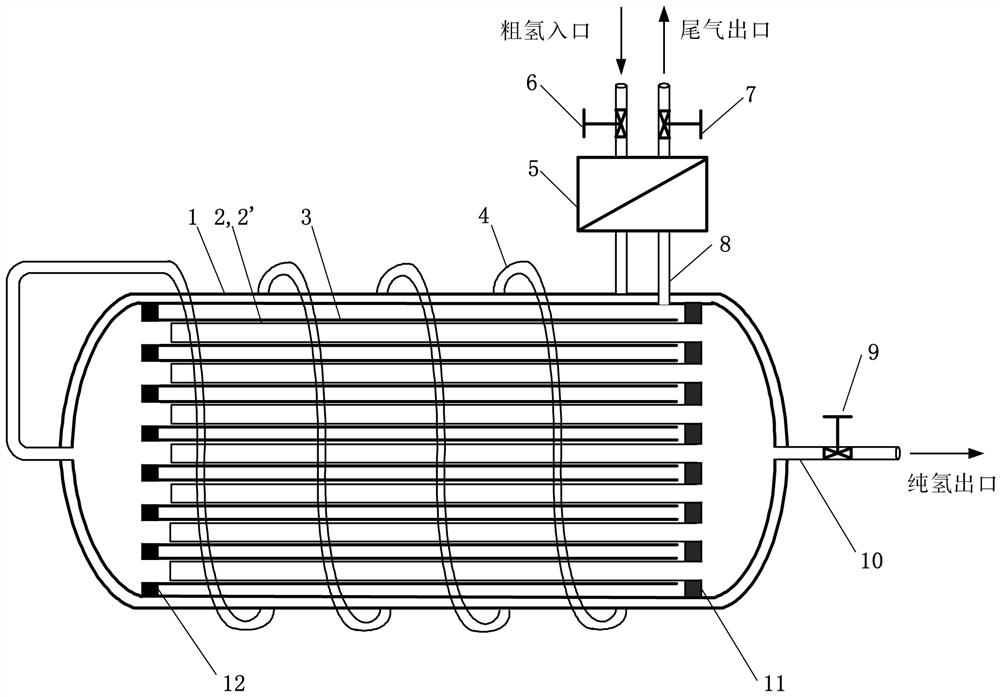

[0029] A basic embodiment of palladium / palladium alloy membrane purifier of the present invention, as figure 1 As shown, it includes a cylindrical outer casing 1 with elliptical heads at both ends, a heat exchanger 5 and a membrane tube bundle 2' composed of several palladium / palladium alloy membrane tubes 2 in the outer casing 1, and palladium / palladium alloy membrane tubes 2'. The sleeve tube 3 outside the membrane tube 2, the sleeve tube integration plate 12, and the membrane tube bundle integration plate 11; one end of each palladium / palladium alloy membrane tube 2 is closed, and the other end is fixedly connected to the membrane tube bundle integration plate 11; each One end of the casing 3 is fixedly connected to the casing bundle integration plate 12, and the other end is inserted in parallel outside the palladium / palladium alloy membrane tube 2; one end of the outer casing 1 communicates with the crude hydrogen input pipe 4 equipped with the crude hydrogen inlet valve 6...

Embodiment 2

[0031] Further embodiment on the basis of embodiment 1: described palladium / palladium alloy membrane purifier, the material of its outer casing 1, sleeve pipe 3, membrane tube bundle integration disc 11 and sleeve tube integration disc 12 all have the same thermal expansion Coefficient of 316 or 316L stainless steel. The distance between the centers of the palladium / palladium alloy membrane tubes 2 is 1.2-2.5 times the outer diameter, and the distance between the outer wall of the palladium / palladium alloy membrane tube 2 and the inner wall of the casing 3 is 60-600um. The distance between the open end of the casing 3 and the proximal surface of the membrane tube bundle integration tray 11 is 1-8 mm. The fixed connection between one end of the palladium / palladium alloy membrane tube 2 and the membrane tube bundle integration tray 11 and the connection between the sleeve tube 3 and the sleeve integration tray 12 are all welded by laser welding.

Embodiment 3

[0033]It is a further embodiment on the basis of embodiment 2. The difference from Example 2 is that the center distance between the palladium / palladium alloy membrane tubes 2 is 1.5 times the outer diameter, and the distance between the outer wall of the palladium / palladium alloy membrane tube 2 and the inner wall of the casing 3 is 60um. The distance between the open end of the casing 3 and the proximal surface of the membrane tube bundle integration tray 11 is 1 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com