Novel sealing process of fuel cell membrane electrode

A fuel cell membrane and electrode technology, which is applied to fuel cell components, fuel cells, sealing/supporting devices, etc., can solve problems such as technical difficulties, and achieve the effect of preventing the falling distance from being too large and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

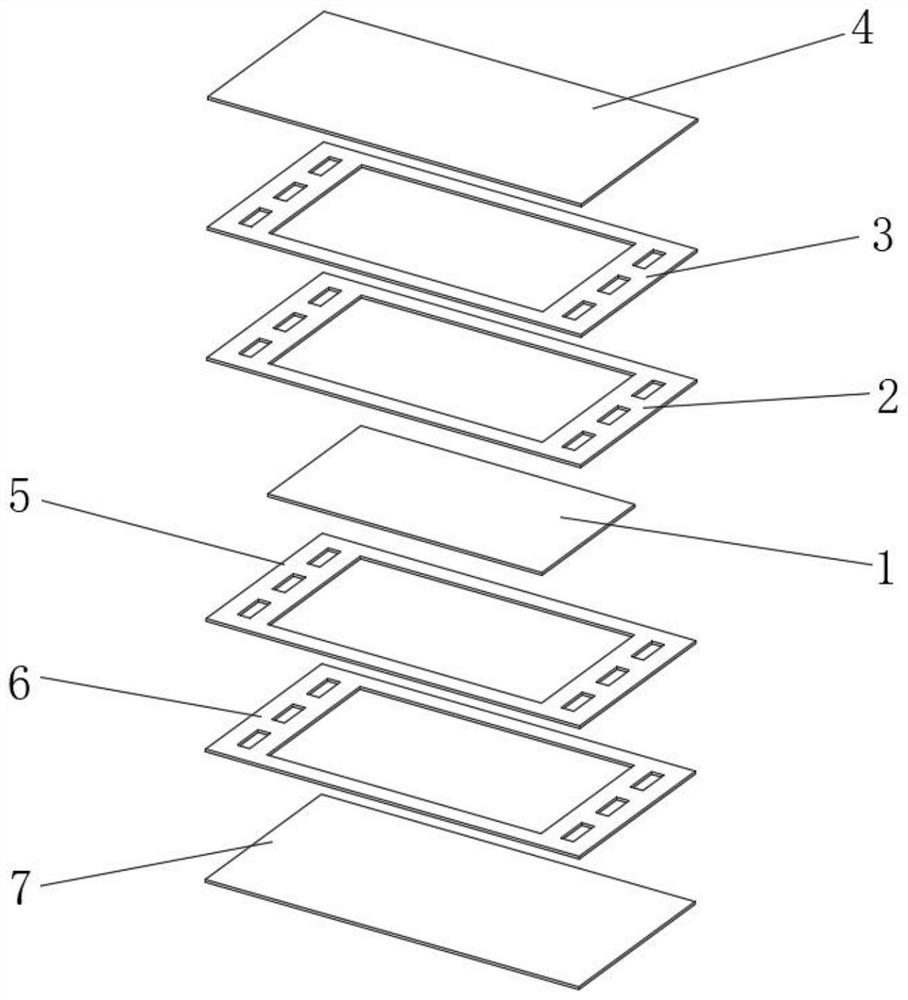

[0038] A new sealing process for fuel cell membrane electrodes, such as Figure 1-5 As shown, the fuel cell membrane electrode of the process includes a catalyst coating membrane 1, and the catalyst coating membrane 1 is specifically a 3CCM composed of a proton exchange membrane, an anode catalyst layer and a cathode catalyst layer; the catalyst coating membrane 1 top and The bottom is respectively provided with a first polyester resin frame A2 and a second polyester resin frame A5, the top of the first polyester resin frame A2 is provided with a first polyester resin frame B3, and the bottom of the second polyester resin frame A5 is provided with a second polyester resin frame B6, the top of the first polyester resin frame B3 is provided with a first gas diffusion layer 4, and the bottom of the second polyester resin frame B6 is provided with a second gas diffusion layer 7; the first polyester resin frame A2, the second polyester resin frame A5, the first polyester resin fram...

Embodiment 2

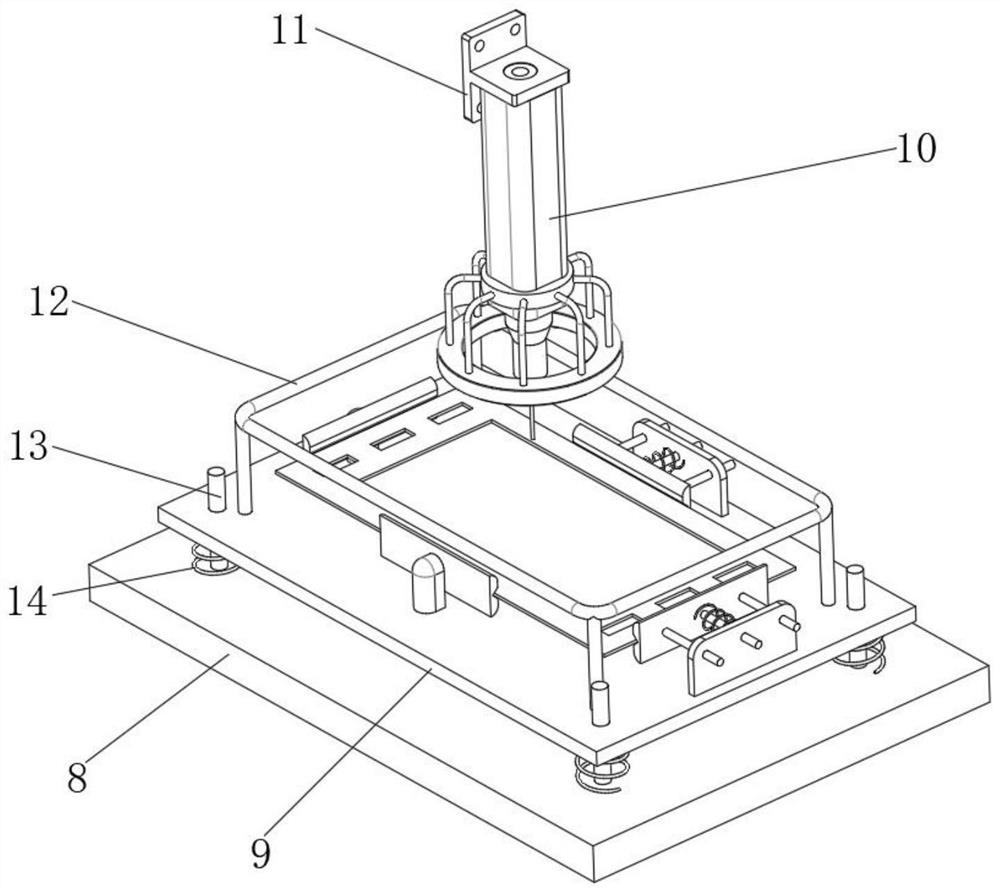

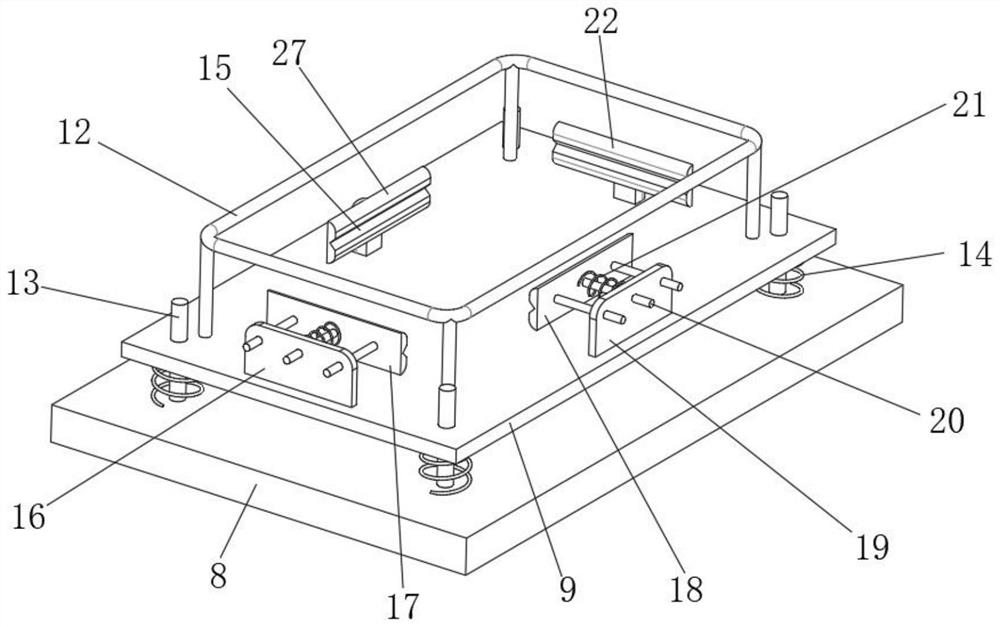

[0053] A new sealing process for fuel cell membrane electrodes, such as Figure 2-5 As shown, in order to better carry out the dispensing process; this embodiment makes the following improvements on the basis of Embodiment 1: the dispensing machine in the S1 step includes a dispensing mechanism, a driving mechanism for driving the dispensing mechanism to dispense glue, and The fixture used in cooperation with the dispensing mechanism; the fixture includes a base 8 and a movable seat 9, the movable seat 9 is installed on the top of the base 8, and the outer wall of the movable seat 9 top is fixed with a longitudinal splint 27 and a transverse splint 22 by screws, The top of the movable seat 9 is also fixed with a first fixed plate 19 and a second fixed plate 16 by screws, and one side of the first fixed plate 19 is equipped with a longitudinal moving splint 18 suitable for the longitudinal fixed splint 27, and the second fixed plate One side of 16 is equipped with a horizontal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com