Oil production method of nitrogen and carbon dioxide composite huff and puff

A technology of carbon dioxide and nitrogen, applied in the direction of mining fluid, earthwork drilling, drilling equipment, etc., can solve the problems of inefficient production, difficult control of safety risk control, complex flow rules, etc., and meet the requirements of tensile strength and air tightness , avoid gas injection and production conversion operations, and broaden the effect of popularization and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the purpose, structure and function of the present invention, a nitrogen and carbon dioxide compound huff and puff oil recovery method of the present invention will be further described in detail.

[0018] A nitrogen and carbon dioxide compound huff and puff oil recovery method of the present invention is carried out in the following steps:

[0019] The first step is to lower the integrated injection-production string to the target oil layer in the oil well;

[0020] In the second step, the top of the integrated injection-production string is connected to the gas injection device and thin oil injection device on the ground. The gas injection device on the ground includes a nitrogen injection device and a carbon dioxide injection device, and the nitrogen injection device and the carbon dioxide injection device are connected in parallel connect;

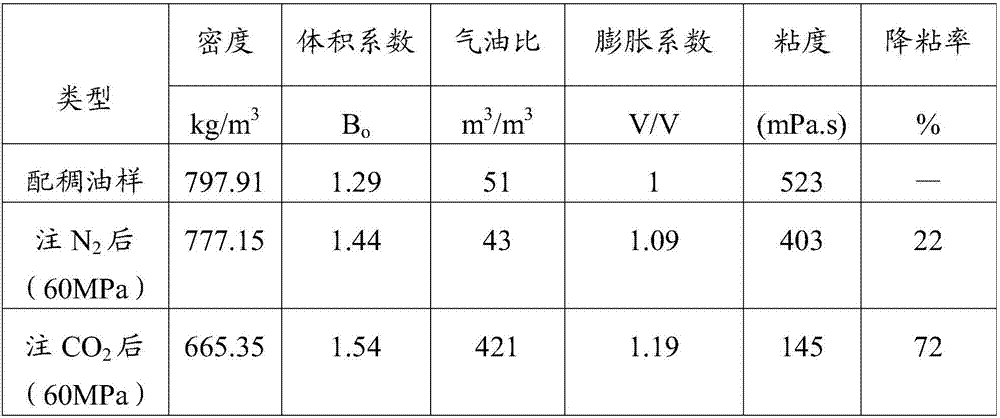

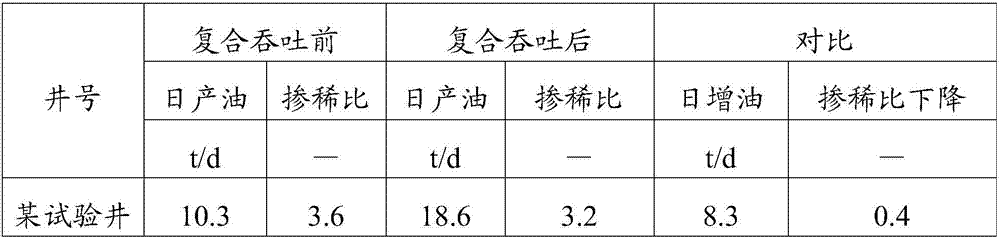

[0021] In the third step, the gas injection device injects gas into the oil well through the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com