Die-casting die for pump bodies

A technology for die-casting molds and pump bodies, which is applied in the field of die-casting molds for diesel pump bodies, can solve the problems of large energy consumption, large machining allowances for pump bodies, and high injection speeds of liquid metal hydraulics, and achieve high production efficiency, low porosity, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

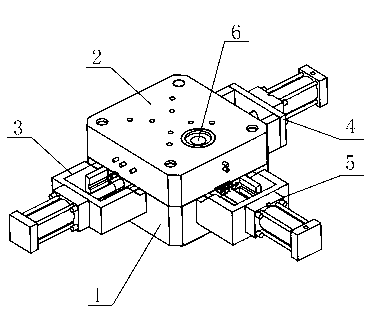

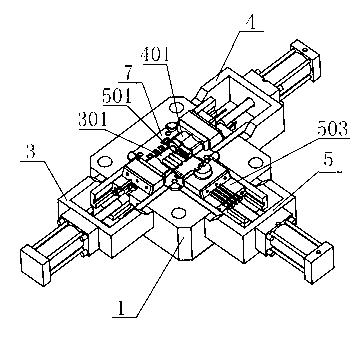

[0025] Such as figure 1 , figure 2 , Image 6 with Figure 7 Shown, the present invention comprises fixed mold frame 1, fixed mold 7, movable mold 8 and movable mold frame 2; Fixed mold 7 is fixed in the fixed mold groove 101 of fixed mold frame 1; Inside the movable die groove; between the three side walls of the fixed die frame 1 and the three side walls of the corresponding fixed die groove 101, there are respectively square slideways 102, and the two side walls and the bottom surface of the slideway 102 are respectively fixedly connected with slide rails 103 and block 104;

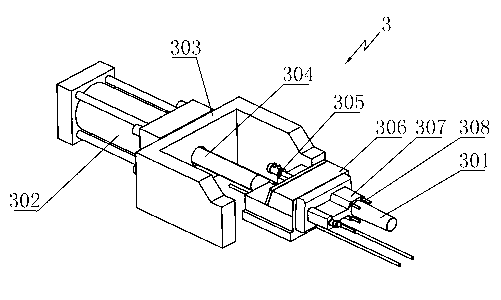

[0026] Such as figure 2 As shown, the left core-pulling device 3 and the right core-pulling device 4 are respectively installed on the two opposite slideways 102, and the lower core-pulling device 5 is installed on the other slideway 102. The core device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com