Silicon-based suspended microstrip line structure for terahertz waves, and manufacturing method therefor

A microstrip line and terahertz technology, applied in the field of microelectronics, can solve the problems of large volume, high cost, and high loss of microstrip line, and achieve the effects of high surface flatness, high structural strength, and good microwave performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

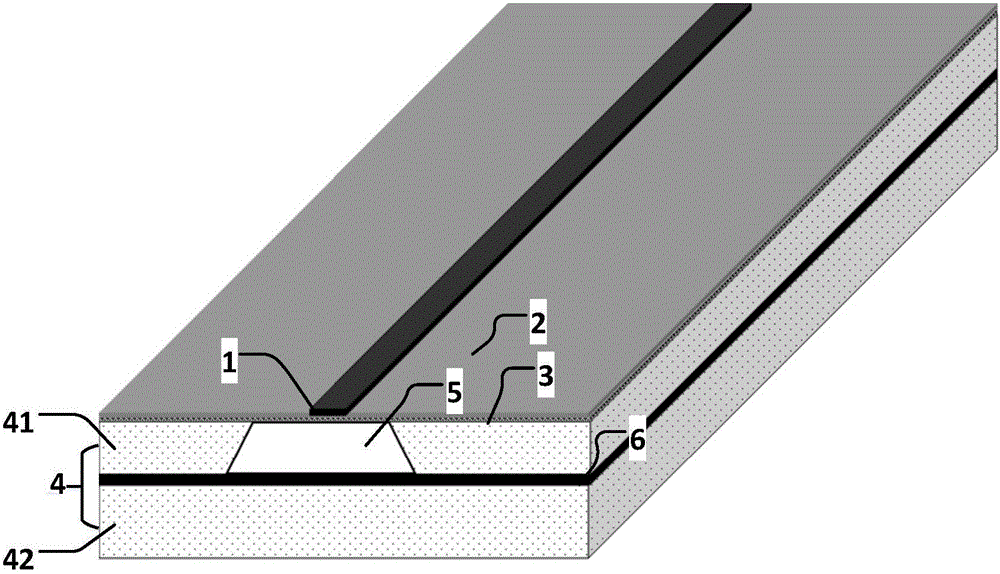

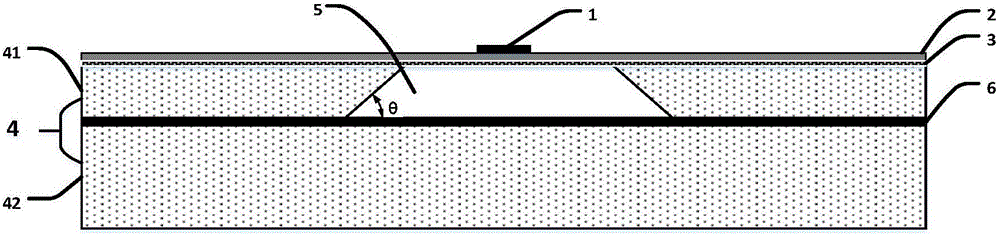

[0057] Example 1: Making a 50-ohm terahertz silicon-based suspended microstrip line

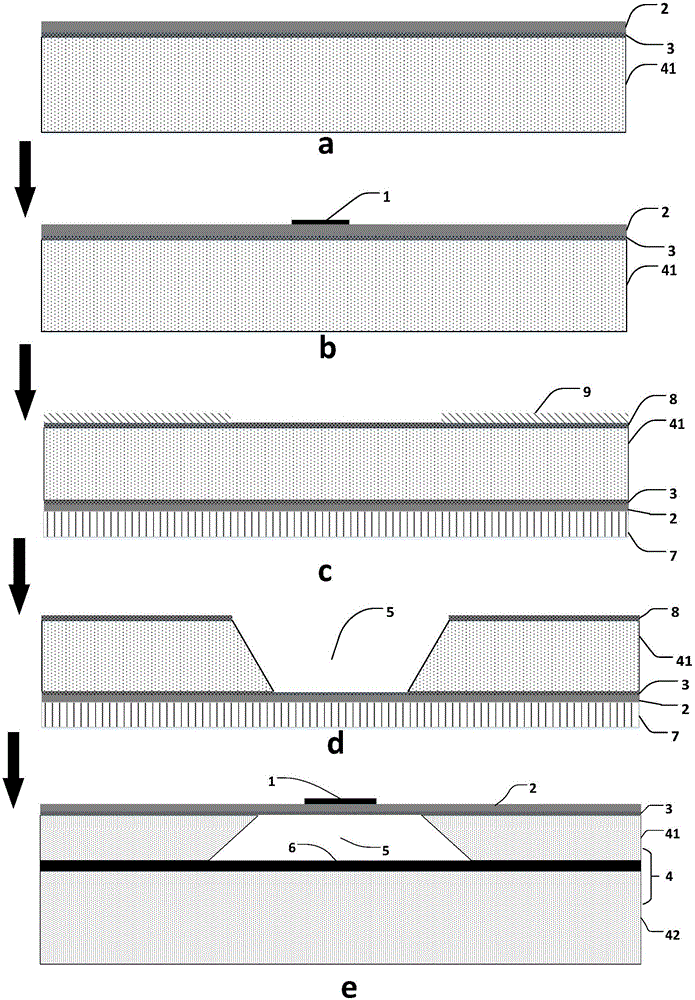

[0058] Step A, making a suspension layer of the microstrip line.

[0059] Get two silicon wafers of the same size as the upper silicon substrate 41 and the lower silicon substrate 42 respectively, and grow a 0.1 micron thick silicon nitride layer 3 on the upper surface of the upper silicon substrate 41; 3. Smear the adhesion promoter and BCB photoresist in sequence, and after exposure, it will be cured by self-heating to form a smooth and flat suspension layer with a thickness of 5 microns, such as image 3 as shown in a.

[0060] Step B, making microstrip lines.

[0061] B1) Deposit a layer of titanium Ti with a thickness of 8 nanometers on the suspension layer by evaporation or sputtering, and then deposit a layer of gold Au with a thickness of 92 nanometers on the titanium metal layer to form a plating layer for the microstrip line;

[0062] B2) smear a layer of 4 micron thick positive ...

Embodiment 2

[0077] Embodiment 2: Fabricate a 100-ohm terahertz silicon-based suspended microstrip line.

[0078] Step 1, making the suspension layer of the microstrip line.

[0079] Get two silicon wafers of the same size as the upper silicon substrate 41 and the lower silicon substrate 42 respectively, and grow a 0.2 micron thick silicon nitride layer 3 on the upper surface of the upper silicon substrate 41; 3. Smear the adhesion promoter and BCB photoresist in sequence, and after exposure, it will be cured by self-heating to form a smooth and flat suspension layer with a thickness of 4 microns, such as image 3 as shown in a.

[0080] Step 2, make the microstrip line.

[0081] 2.1) Deposit a layer of titanium Ti with a thickness of 6 nanometers on the suspension layer by evaporation or sputtering, and then deposit a layer of gold Au with a thickness of 94 nanometers on the titanium metal layer to form a plating layer for the microstrip line;

[0082] 2.2) Apply a layer of positive ph...

Embodiment 3

[0095] Embodiment 3: Fabricate a 150-ohm terahertz silicon-based suspended microstrip line.

[0096] Step 1, making the suspension layer of the microstrip line.

[0097] Get two silicon wafers of the same size as the upper silicon substrate 41 and the lower silicon substrate 42 respectively, and grow a 0.3 micron thick silicon nitride layer 3 on the upper surface of the upper silicon substrate 41; 3. Smear the adhesion promoter and BCB photoresist in turn, after exposure, it will be cured by self-heating to form a smooth and flat suspension layer with a thickness of 3 microns, such as image 3 as shown in a.

[0098] Step 2, making the microstrip line.

[0099] First deposit a layer of titanium Ti with a thickness of 10 nanometers on the suspension layer by evaporation or sputtering, and then deposit a layer of gold Au with a thickness of 90 nanometers on the titanium metal layer to form a plating layer for the microstrip line;

[0100] Then, smear a layer of 2 micron thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com