Low-temperature co-fired microwave dielectric ceramic materials and preparation method thereof

A technology of microwave dielectric ceramics and low-temperature co-firing, which is applied in the field of low-temperature co-fired microwave dielectric ceramic materials and its preparation, can solve the problems of loss of microwave dielectric properties, poor microwave and dielectric properties, etc., and achieve the improvement of inherent microwave properties , chemical composition and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

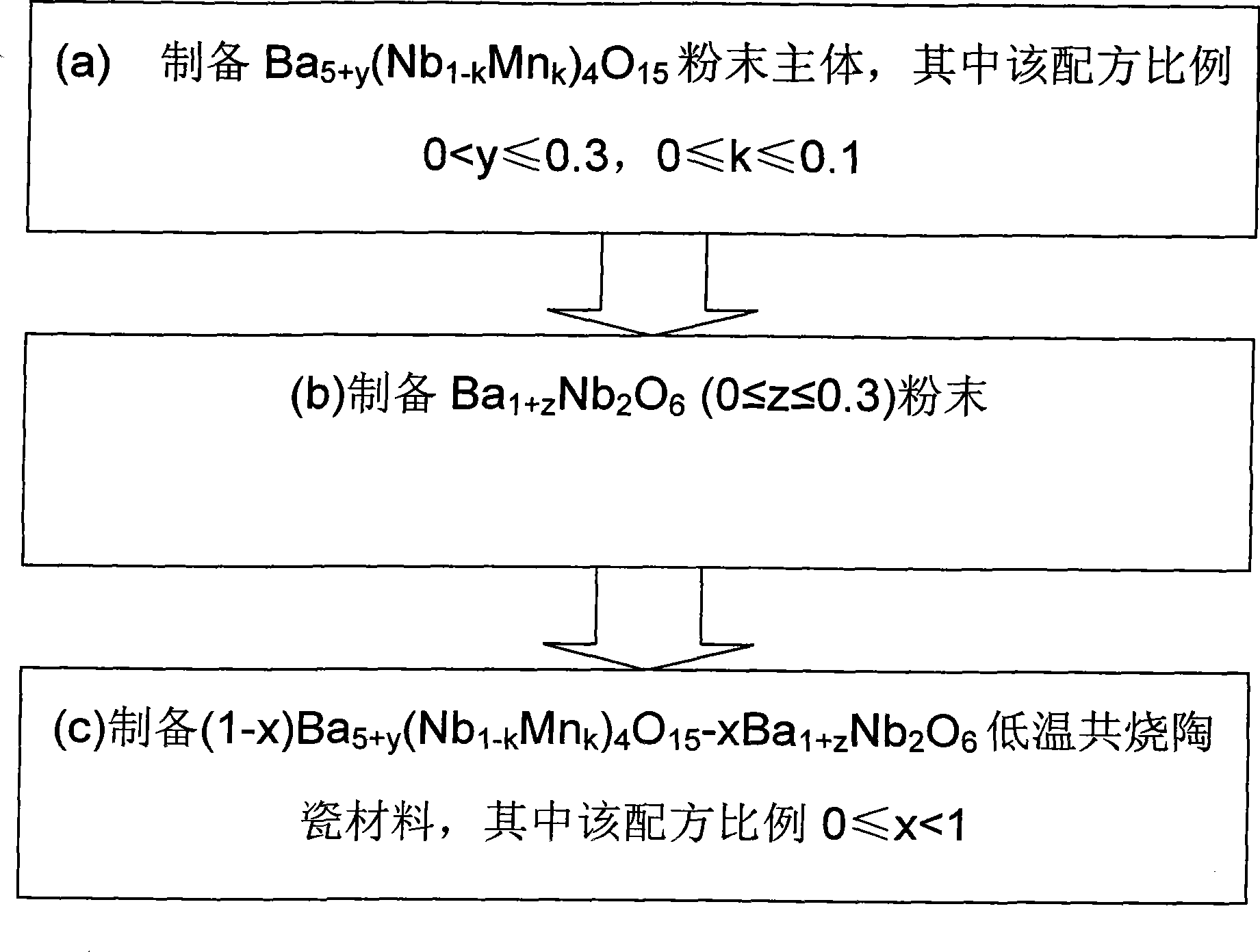

[0030] The invention provides a method for preparing a low-temperature co-fired microwave dielectric ceramic material, the specific steps of which are as follows:

[0031] (a) Pure phase Ba 5+y (Nb 1-k mn k ) 4 o 15 powder production

[0032] industrial grade powder BaCO 3 (99.9%), Nb 2 o 5 (99.7%), MnO 2 (99.5%) according to the molecular formula Ba in a non-stoichiometric dosage ratio 5+y (Nb 1-k mn k )4 o 15 Preparation, where 05 Nb 4 o 15 After the crystalline powder is formed, deionized water and YTZ balls are added in proportion to the second ball milling for 24 hours. After drying at 120°C, it is ground, sieved, granulated, and pressed into tablets with a uniaxial pressure of 1 ton. A green body with a height of 5 mm and a diameter of 10 mm was sintered at 1350°C to 1450°C (holding temperature for 2 to 4 hours), and the material properties were analyzed.

[0033] (b) Pure phase Ba 1+z Nb 2 o 6 (0≤z≤0.3) powder production

[0034] According to the abov...

Embodiment 1

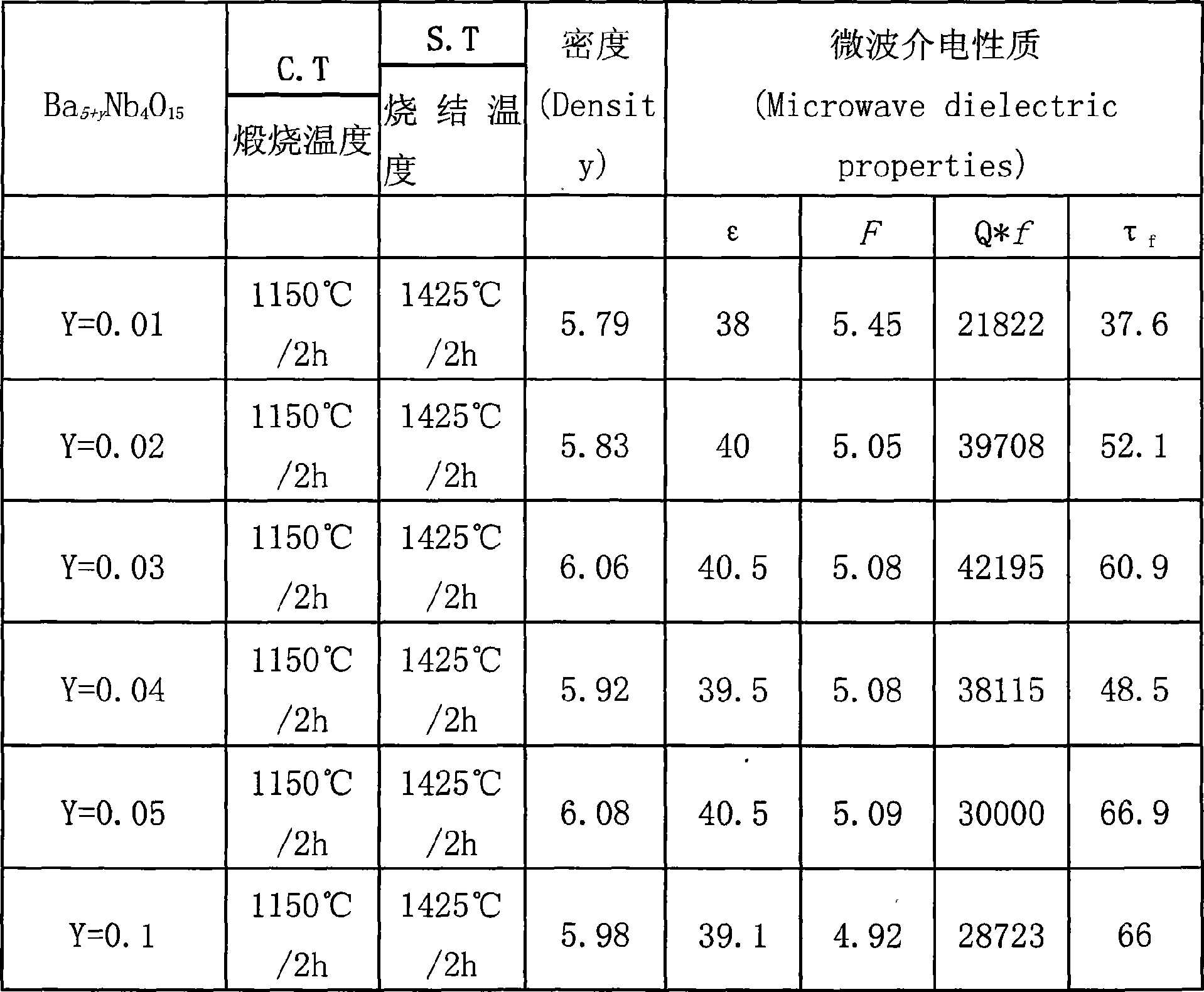

[0055] First, the microwave dielectric ceramic Ba 5+y (Nb 1-k mn k ) 4 o 15 The main powder is sintered at 1350°C to 1450°C according to different raw material ratios (holding temperature for 2 to 4 hours), and the material properties are analyzed. The characteristics are shown in Table 1 and Table 2 below:

[0056] Table 1: Ba 5+y Nb 4 o 15 Microwave Dielectric Properties of Ceramics

[0057]

[0058] Table 2: Ba 5 (Nb 1-k mn k ) 4 o 15 Microwave Dielectric Properties of Ceramics

[0059]

[0060] The above results show that the density and electrical properties of the ceramics increase with the increase of Ba content. When y=0.03, the sintering temperature is 1425 ° C, and the temperature is kept for 2 hours, the density and electrical properties of the ceramic body reach the highest value; the density of the ceramic body is It can reach more than 95% of theoretical density (T.D.%), K=40~41, Q*f>40000, τ f =60ppm / ℃; and the addition of Mn has no obvious imp...

Embodiment 2

[0061] Ba 5.03 Nb 4 o 15 low temperature sintering

[0062] Generally, there are two types of sintering aids used to reduce the sintering temperature, one is glass with low melting point, and the other is metal oxide with low melting point. Although adding glass can reduce the sintering temperature, it will also reduce the dielectric properties of the material, so It is necessary to add some oxides with low melting point to reduce the sintering temperature while maintaining excellent dielectric properties.

[0063] The metal oxides commonly used to reduce the sintering temperature are B 2 o 3 , CuO, ZnO, V 2 o 5 etc., due to BaO, B 2 o 3 There is a eutectic phase reaction with CuO, so the secondary phase BaCu(B 2 o 5 ), and the addition of BaO can improve the relationship with Ba 5.03 Nb 4 o 15 Wetting behavior between, so the liquid phase BaCu (B 2 o 5 ) sintered on Ba 5.03 Nb 4 o 15 material, and add B 2 o 3 -CuO, ZnO-B 2 o 3 and other powders to reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com