Five hundred and ninety Mpa-grade dual-phase steel and production method thereof

A dual-phase steel, mass percentage technology, applied in the field of steel manufacturing, can solve the problem of rising cost of precious metals, achieve excellent strength-plastic toughness matching, reduce the amount of alloy used, and meet the effects of weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

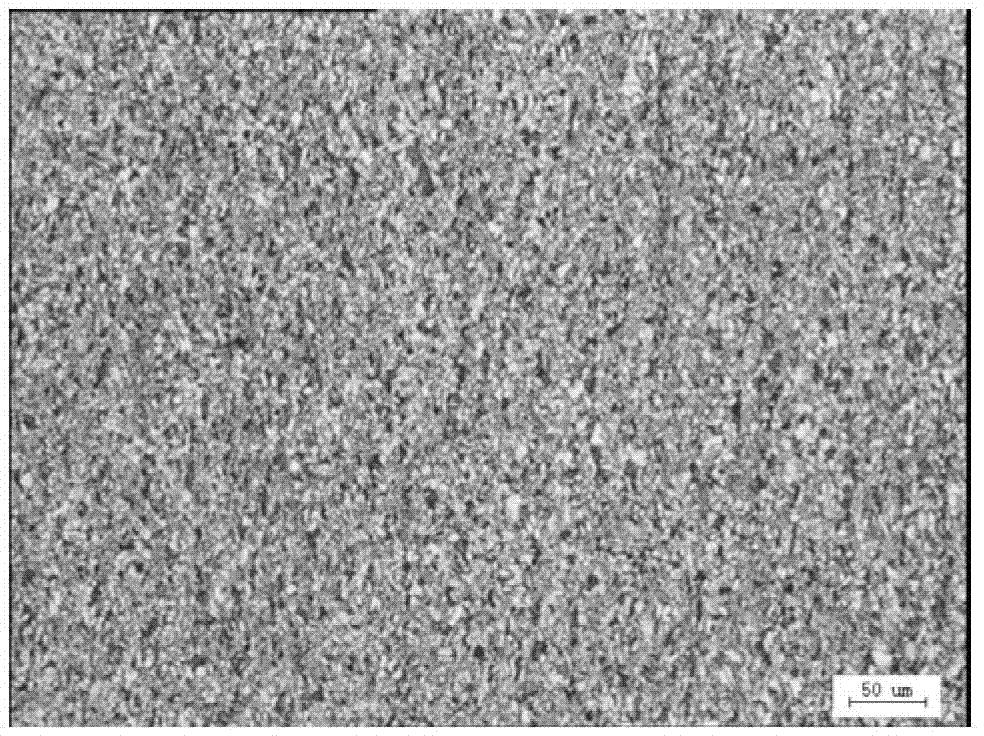

Embodiment 1

[0017] A 590MPa-grade dual-phase steel, the mass percentage of its composition is shown in Table 1, and the balance is iron and unavoidable impurities.

[0018] A method for producing 590MPa dual-phase steel, including molten iron pretreatment-converter smelting-alloy fine-tuning station-LF-continuous casting-hot continuous rolling, the hot continuous rolling process is: the heating temperature is 1180°C, and the final rolling temperature is 870°C, rapid cooling to 671°C after rolling, air cooling for 8.4 seconds, and rapid cooling to the target coiling temperature, the coiling temperature is 416°C; the thickness of the rolled steel plate is 2.3mm.

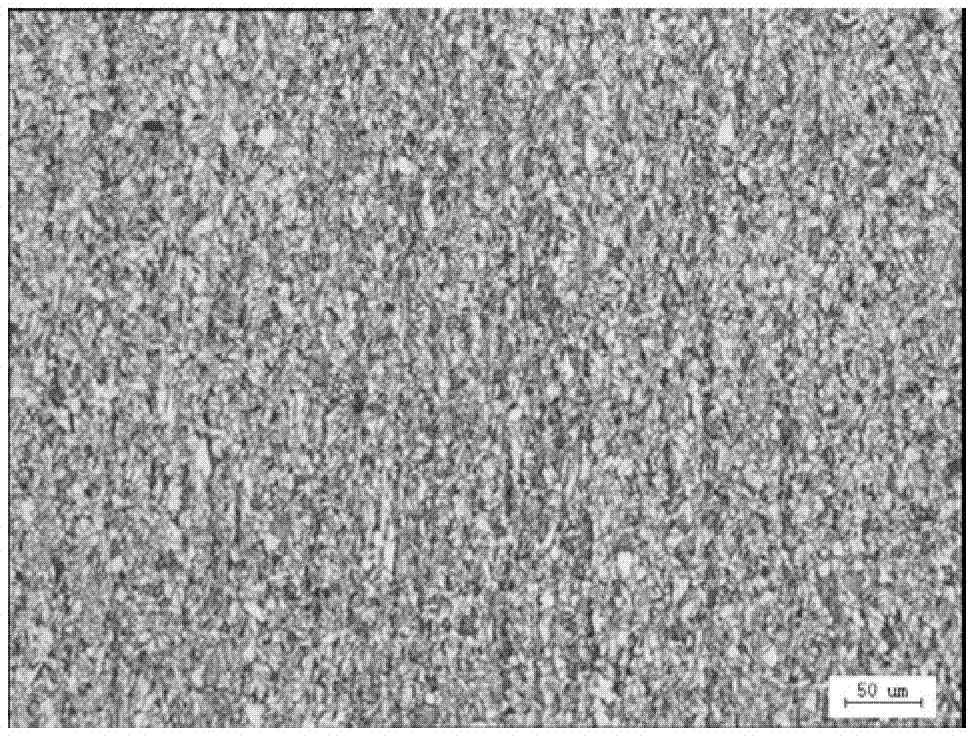

Embodiment 2

[0020] A 590MPa-grade dual-phase steel, the mass percentage of its composition is shown in Table 1.

[0021] A method for producing 590MPa dual-phase steel, including molten iron pretreatment-converter smelting-alloy fine-tuning station-LF-continuous casting-hot continuous rolling, the hot continuous rolling process is: the heating temperature is 1250°C, and the final rolling temperature is 883°C, rapid cooling to 685°C after rolling, air cooling for 10.2 seconds, and rapid cooling to the target coiling temperature, the coiling temperature is 431°C; the thickness of the rolled steel plate is 3.2mm.

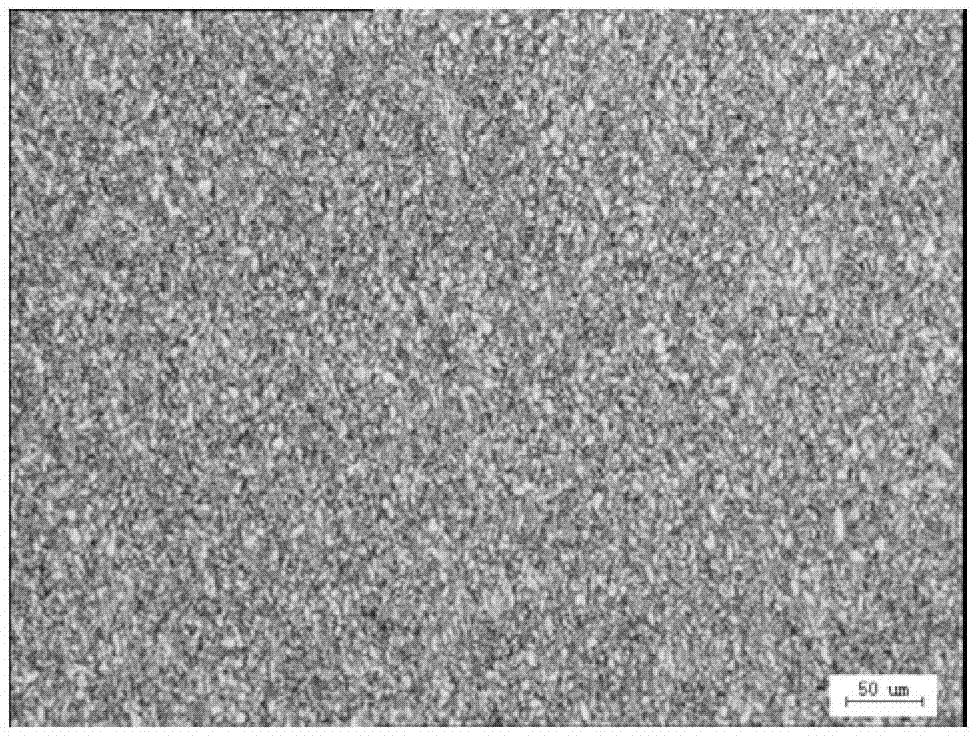

Embodiment 3

[0023] A 590MPa-grade dual-phase steel, the mass percentage of its composition is shown in Table 1.

[0024] A method for producing 590MPa dual-phase steel, including molten iron pretreatment-converter smelting-alloy fine-tuning station-LF-continuous casting-hot continuous rolling, the hot continuous rolling process is: the heating temperature is 1200°C, and the final rolling temperature is 869°C, rapid cooling to 668°C after rolling, air cooling for 7.8 seconds, and rapid cooling to the target coiling temperature, the coiling temperature is 402°C; the thickness of the rolled steel plate is 3.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com